Ultra-high temperature elasticity and toughness agent for oil and gas well cementing and composition and application thereof

A well cementing and ultra-high temperature technology is used in the field of oil and gas well cementing and cement toughening agent for oil and gas well cementing. Insufficient thermal performance and other problems, to achieve the effect of improving brittleness, convenient preparation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Taking G-grade oil well cement with 40% sand as an example, optimizing the formula of high-temperature elastic-toughening agent

Embodiment 2

[0062] An ultra-high temperature elastic-ductile well cementing cement slurry, comprising the following components by mass:

[0063] Oil well G-grade cement 100 parts, silica sand 40 parts, polytetrafluoroethylene rubber powder 3 parts, basalt fiber 0.4 part, nano-alumina fiber 0.3 part, water 56 parts;

[0064] The preparation method comprises the following steps:

[0065] Mix oil well G-grade cement, silica sand, polytetrafluoroethylene rubber powder, basalt fiber, and nano-alumina fiber evenly, then add water and stir evenly to obtain ultra-high temperature elastic and tough cementing cement slurry.

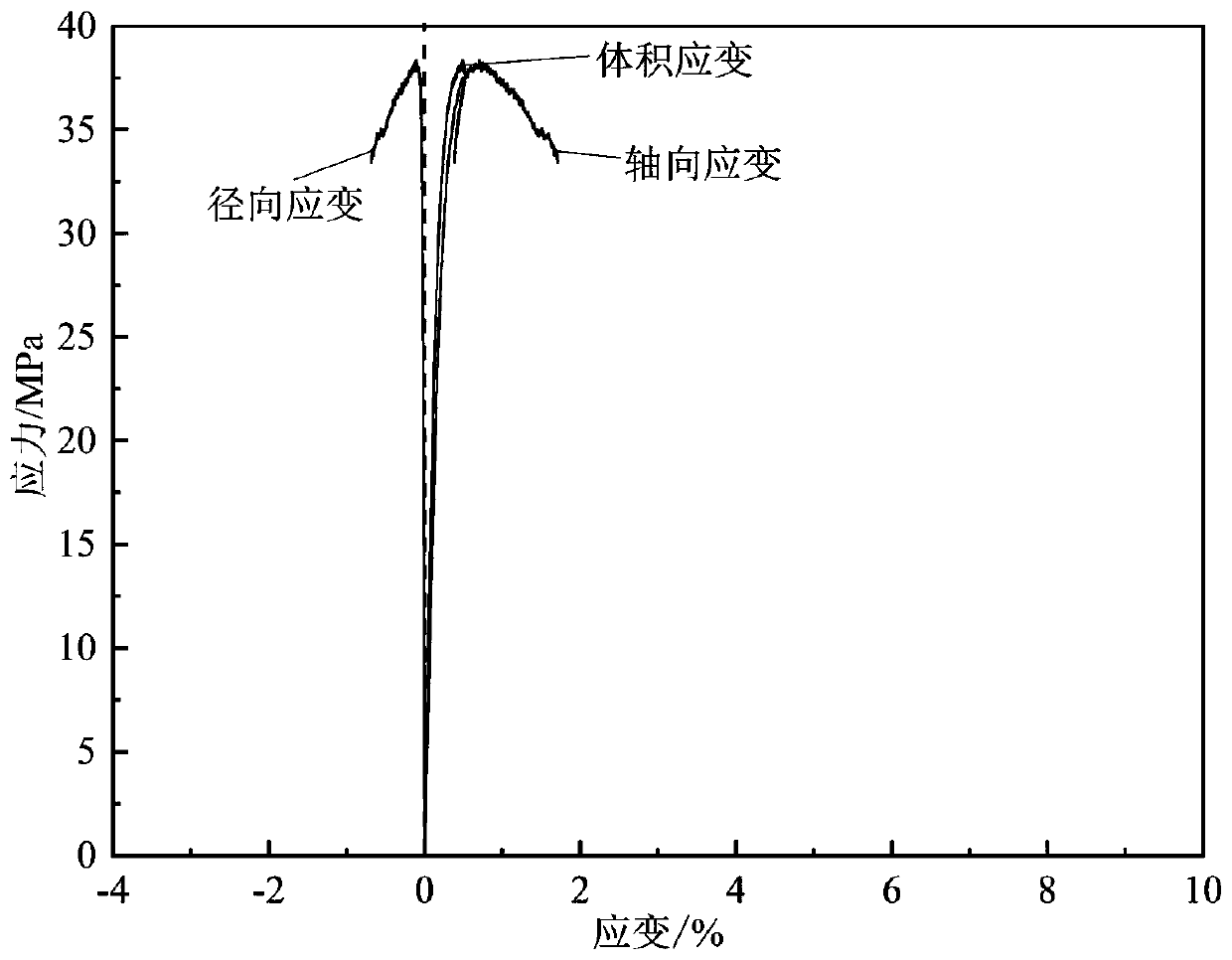

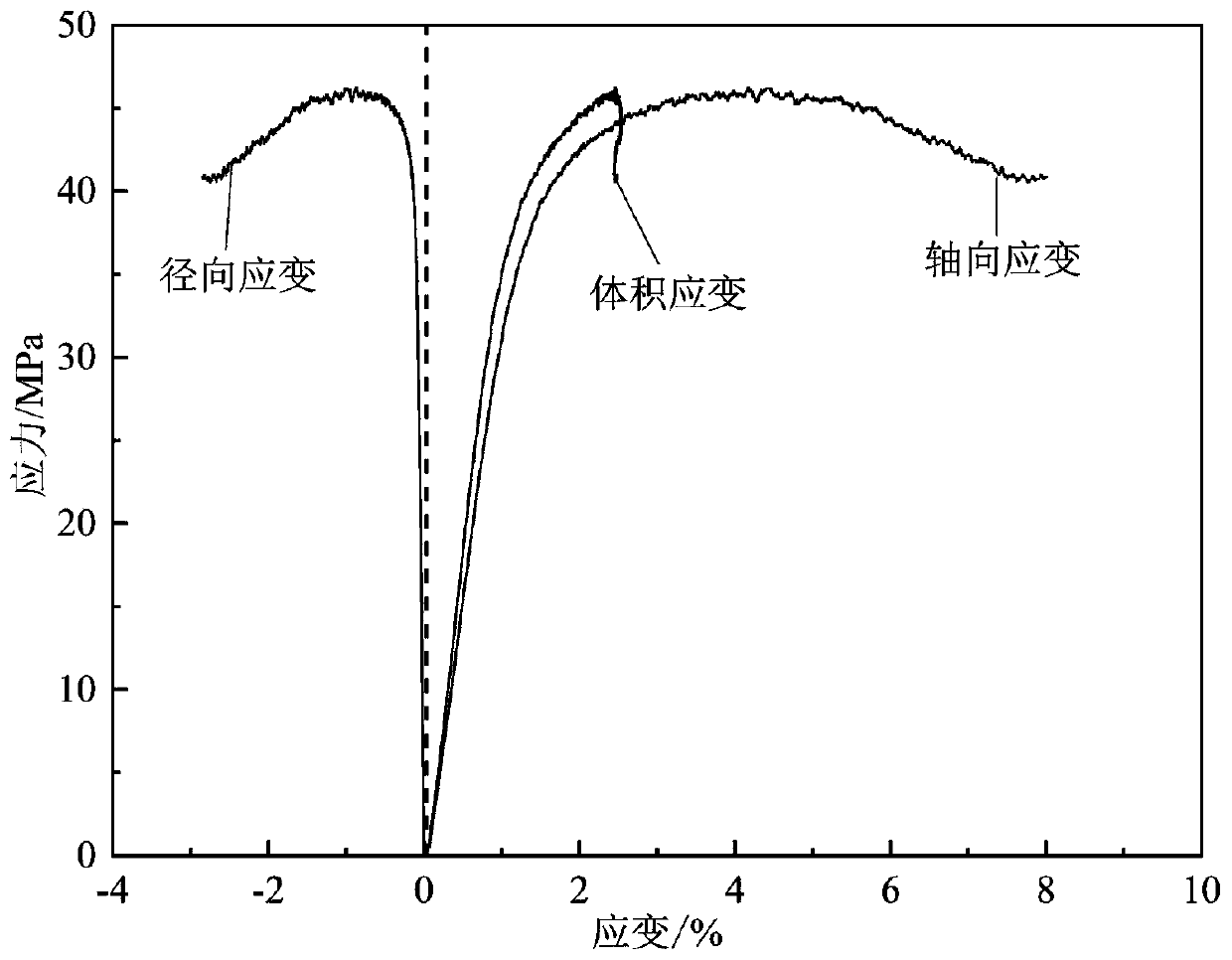

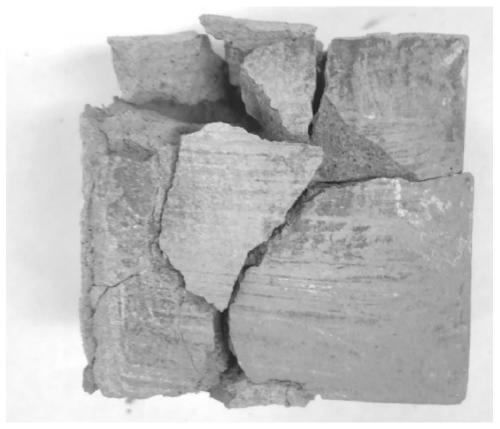

[0066] The ultra-high temperature elastic-ductile cementing cement slurry prepared in this example is cured for 5 days under the condition of 265°C / 35MPa, and the test results of triaxial mechanical properties are shown in the figure figure 2 . After the compressive strength test, the cement stone looks like Figure 4 . Compared with the cement stone added with silica san...

Embodiment 3

[0068] An ultra-high temperature elastic-ductile well cementing cement slurry, comprising the following components by mass:

[0069] Oil well G grade cement 100 parts, silica sand 35 parts, polytetrafluoroethylene rubber powder 5 parts, basalt fiber 0.3 part, nano alumina fiber 0.5 part, water 54 parts;

[0070] The preparation method is the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com