High-strength gypsum-based self-leveling mortar and preparation method thereof

A self-leveling mortar and gypsum-based technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of high cost and high strength, and achieve enhanced mechanical strength, high strength, and reduced hydration The effect of exothermic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

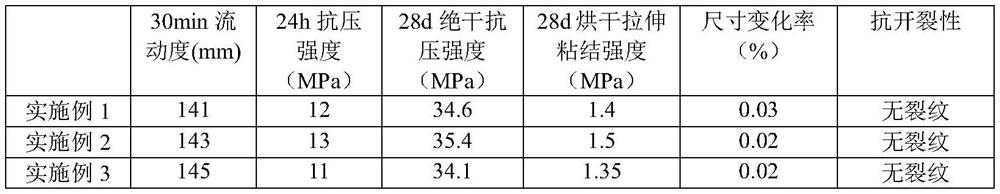

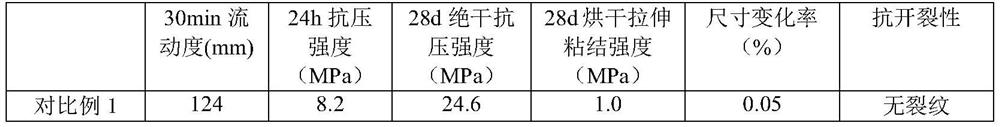

Examples

Embodiment 1

[0025] A high-strength gypsum-based self-leveling mortar and a preparation method thereof, comprising the following raw materials:

[0026] Including plaster of Paris 100kg, water 45kg, cement 10kg, silica fume 7kg, fly ash 3kg, sand aggregate 30kg, water retention agent 0.1kg, retarder 0.15kg, water reducing agent 0.35kg, defoamer 0.1kg, rubber powder 0.2kg.

[0027] Among them, the building gypsum is desulfurized building gypsum with a specific surface area of 350m 2 / kg, the particle size is 100μm, the cement is 42.5 grade fast-hardening ordinary Portland cement (P O 42.5R), the water is ordinary tap water, and the specific surface area of silica fume is 25000m 2 / kg, in which the fly ash is grade I ash, and the ore sand is a mixture of large particle size ore with a fineness of 120 meshes and small particle size ore sand with a fineness of 35 meshes in a mass ratio of 2:1, wherein the water-retaining agent is hydroxypropyl methyl cellulose ether, the viscosity is 400...

Embodiment 2

[0032] A high-strength gypsum-based self-leveling mortar and a preparation method thereof, comprising the following raw materials:

[0033] Including plaster of Paris 100kg, water 38kg, cement 6kg, silica fume 5kg, fly ash 6kg, sand aggregate 15kg, water retention agent 0.07kg, retarder 0.1kg, water reducing agent 0.25kg, defoamer 0.05kg, rubber powder 0.3kg.

[0034] Among them, the building gypsum is desulfurized building gypsum with a specific surface area of 400m 2 / kg, the particle size is 75μm, the cement is 42.5 grade fast-hardening ordinary Portland cement (P O 42.5R), the water is ordinary tap water, and the specific surface area of silica fume is 20000m 2 / kg, in which the fly ash is grade I ash, and the ore sand is a mixture of large particle size ore with a fineness of 140 mesh and a small particle size ore with a fineness of 45 mesh in a mass ratio of 2:1, wherein the water-retaining agent is hydroxypropyl methyl cellulose ether, the viscosity is 500mpa s, t...

Embodiment 3

[0039] A high-strength gypsum-based self-leveling mortar and a preparation method thereof, comprising the following raw materials:

[0040] Including plaster of Paris 100kg, water 30kg, cement 3kg, silica fume 3kg, fly ash 10kg, sand aggregate 5kg, water retention agent 0.05kg, retarder 0.05kg, water reducing agent 0.2kg, defoamer 0.05kg, rubber powder 0.2kg.

[0041] Among them, the building gypsum is desulfurized building gypsum with a specific surface area of 300m 2 / kg, the particle size is 150μm; the cement is 42.5 grade fast-hardening ordinary Portland cement (P O 42.5R), the water is ordinary tap water, and the specific surface area of silica fume is 15000m 2 / kg, in which the fly ash is grade I ash, and the ore sand is a mixture of large particle size ore with a fineness of 100 meshes and a small particle size ore with a fineness of 30 meshes in a mass ratio of 2:1, wherein the water-retaining agent is hydroxypropyl methyl cellulose ether, the viscosity is 450mpa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com