High-strength high-temperature-resistant flame-retardant concrete viscosity modifier as well as preparation method and application thereof

A viscosity modifier and concrete technology, applied in the field of concrete admixtures, can solve the problems of concrete workability, poor bleeding and wrapping properties, poor thermal stability and flame retardant properties, affecting the overall strength of buildings, etc. , to achieve the effect of good inhibition of combustion and flame retardant properties, improved strength and thermal properties, and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

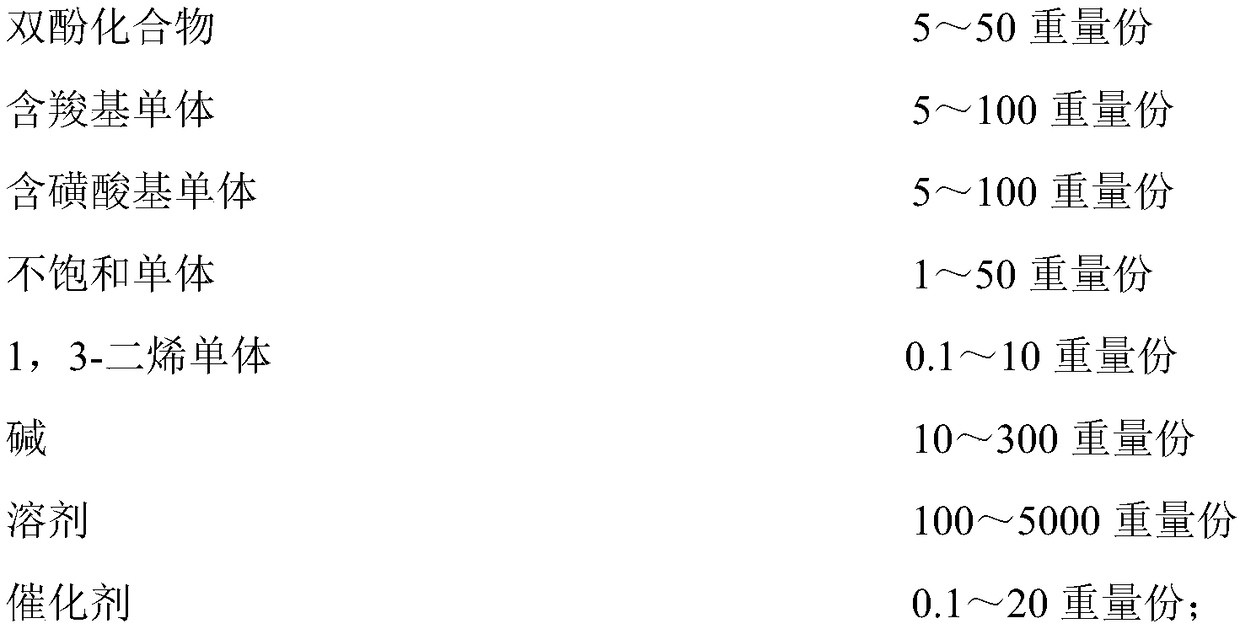

Method used

Image

Examples

Embodiment 1

[0044] Add 50g of acrylic acid, 50g of propylenesulfonic acid, 20g of sodium hydroxide, and 2000g of water into the reaction kettle, react at a temperature of 20°C for 10 minutes, then add 28g of bisphenol S, 20g of acrylamide, azobisisobutyronitrile + FeCl 3 (1+1)g was reacted at 50°C for 120min to obtain a light yellow viscous solution; add 1g of 1,3-butadiene monomer and stir at 60°C for 60min, filter a very small amount of insoluble residue, and collect the filtrate ; Then add double bond photocatalyst (PI-184+PI-127: 0.1g+0.05g) to the filtrate, and disperse it evenly to obtain the finished high-strength, high-temperature-resistant, flame-retardant concrete viscosity modifier.

[0045] Using a rotational viscometer at a temperature of 30.0±0.1°C, the apparent viscosity is measured to be 750 Pas, the limiting oxygen index (LOI) of pure resin is 39, and the flame retardancy is excellent. The raw materials of each component are shown in Table 1. The obtained viscosity modif...

Embodiment 2

[0047] Add 70g of methacrylic acid, 50g of methacrylic acid, 25g of lithium hydroxide, water+ethanol (4000+10)g into the reaction kettle, and react at a temperature of 25°C for 20min; then add BP+DTBT(5+20) g, methacrylamide 20g, ammonium persulfate+potassium thiosulfate (0.2+0.1)g react at a temperature of 50°C for 120min to obtain a light yellow viscous solution; then add 1,3-octadiene monomer 5g Stir and react at 50°C for 80 minutes; filter a very small amount of insoluble residue, collect the filtrate, then add double bond photocatalyst (PI-BDK: 0.01g) to the filtrate, and disperse it evenly to prepare the finished high-strength, high-temperature-resistant, flame-retardant concrete Viscosity modifier.

[0048] Using a rotational viscometer at a temperature of 30.0±0.1°C, the apparent viscosity was measured to be 780 Pas, and the limiting oxygen index (LOI) of the pure resin was 39, showing excellent flame retardancy. The raw materials of each component are shown in Table ...

Embodiment 3

[0050] Add acrylic acid + itaconic acid (40+20) g, methacrylic acid + styrene sulfonic acid (40 + 5) g, potassium hydroxide 30 g, and water 5000 g into the reaction kettle, and react at a temperature of 10 ° C for 15 min; Then add BHPPE+DOPO-HQ(10+15)g, acrylamide 50g, potassium persulfate+vitamin C(1+0.7)g and react at 35°C for 100min to obtain a light yellow viscous solution; then add 1, React 3g of 3-pentadiene monomer at a temperature of 45°C for 100min; filter a very small amount of insoluble residue, collect the filtrate, and then add a double-bond photocatalyst (PI-TPO: 0.05g) to the filtrate to disperse it evenly. The finished high-strength, high-temperature-resistant, flame-retardant concrete viscosity modifier was obtained.

[0051] Using a rotational viscometer at a temperature of 30.0±0.1°C, the apparent viscosity is measured to be 820 Pas, the limiting oxygen index (LOI) of pure resin is 40, and the flame retardancy is excellent. The raw materials of each compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com