Polymer wide-temperature-zone retarder for oil-gas well cement and preparation method thereof

A technology for polymers and oil and gas wells, which is applied in the polymer field, can solve the problems of bulging of the thickening curve of cement slurry, abnormal gelation of cement slurry, poor high temperature resistance, etc., and achieves easy availability and low price of raw materials, simple preparation method, Environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation of embodiment 1 polymer:

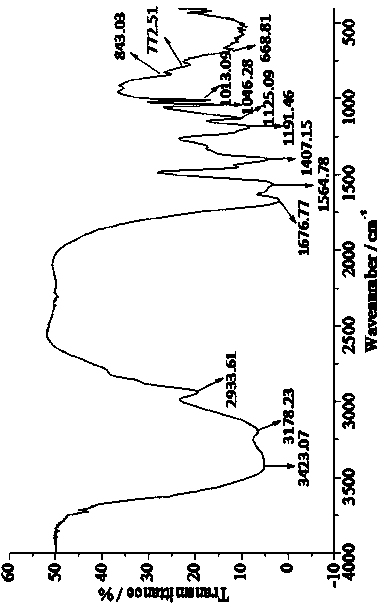

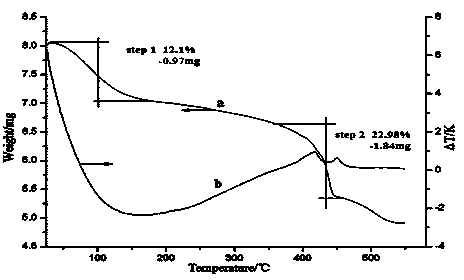

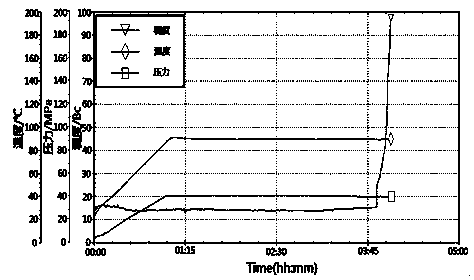

[0031] Add 255ml of deionized water to the three-necked flask, fully dissolve itaconic acid, acrylamide, and sodium p-styrenesulfonate in deionized water at a mass ratio of 1:4:3, to ensure that itaconic acid, acrylamide, and p-styrene The mass sum of sodium ethylene sulfonate is 45 g, and the pH value of the solution in the three-necked flask is adjusted to 6-7 with 4 mol / L sodium hydroxide solution. Accurately weigh 0.68 g of sodium hypophosphite and dissolve into the solution. Accurately weigh 0.68g of potassium persulfate, fully dissolve it with deionized water and transfer the solution to a constant pressure separatory funnel. Nitrogen was introduced into the reaction flask to remove air, and the temperature of the system was raised to 55°C. The potassium persulfate solution was added dropwise through a constant-pressure separating funnel for reaction. After 5 hours, the reacted mixed solution was immersed in a sufficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com