A kind of chrome leather shavings toughened cement slurry and its preparation method

A technology of cementing slurry and chrome leather chips, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., to achieve the effects of reducing pollution, small damage, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

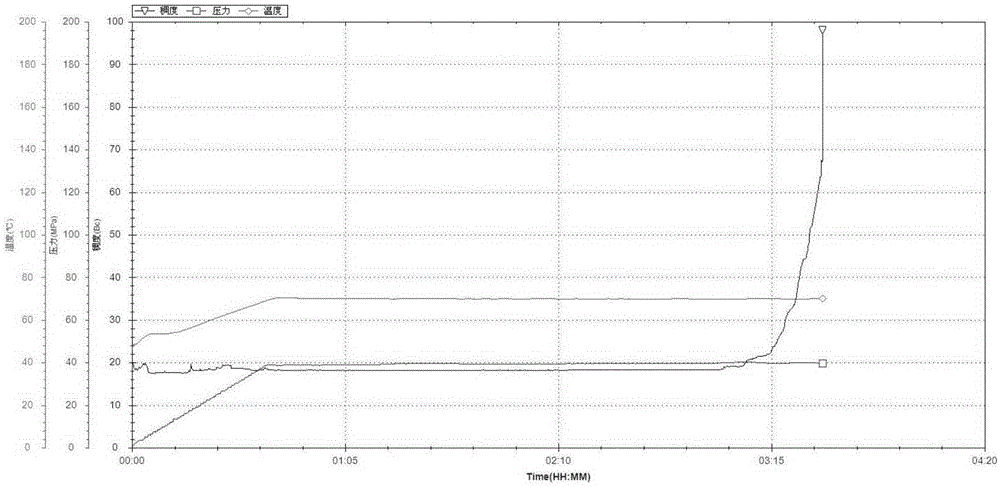

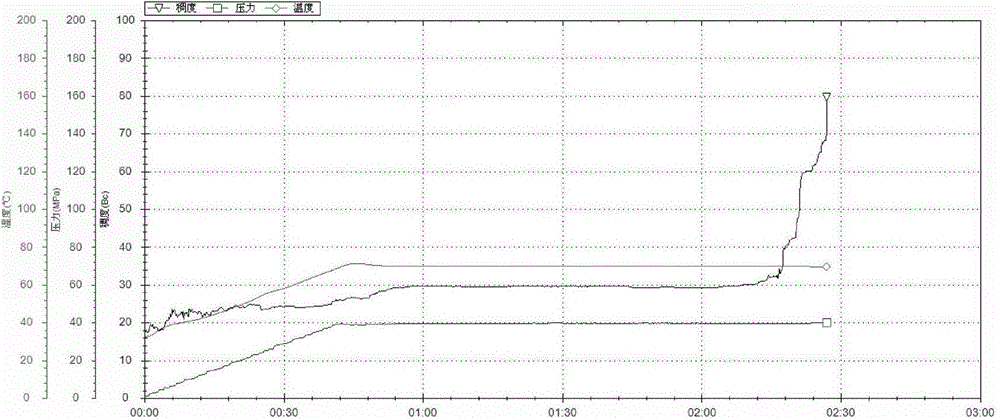

Image

Examples

Embodiment 1

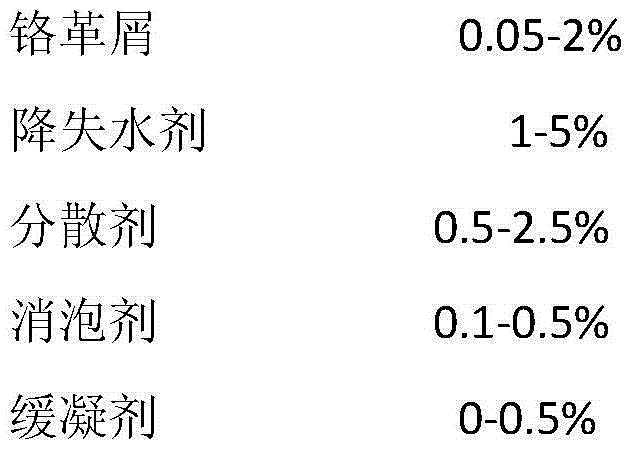

[0030] A kind of chrome leather shavings toughening cement slurry, each component and weight are respectively:

[0031] Chrome leather shavings (diameter 0.02mm): 4g

[0032] Acrylamide / 2-acrylamide-2-methylpropanesulfonate sodium (AM / AMPS) copolymer: 32g

[0033]

[0034] Preparation method: in accordance with API standards: fully mix water, additive components, and G-grade oil well cement.

Embodiment 2

[0036] A kind of chrome leather shavings toughening cement slurry, each component and weight are respectively:

[0037] Chrome leather shavings (diameter 0.05mm): 1.6g

[0038] Acrylamide / 2-acrylamide-2-methylpropanesulfonate sodium (AM / AMPS) copolymer: 16g

[0039]

[0040] Preparation method: in accordance with API standards: fully mix water, additive components, and G-grade oil well cement.

Embodiment 3

[0042] A kind of chrome leather shavings toughening cement slurry, each component and weight are respectively:

[0043]

[0044] Preparation method: According to API standards: fully mix water, additive components, and G-grade oil well cement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com