Toughening agent for well cementing slurry

A technology for cementing cement slurry and toughening agent, which is applied in the field of cement toughening agent to achieve the effects of improving toughness and crack resistance, good compatibility and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

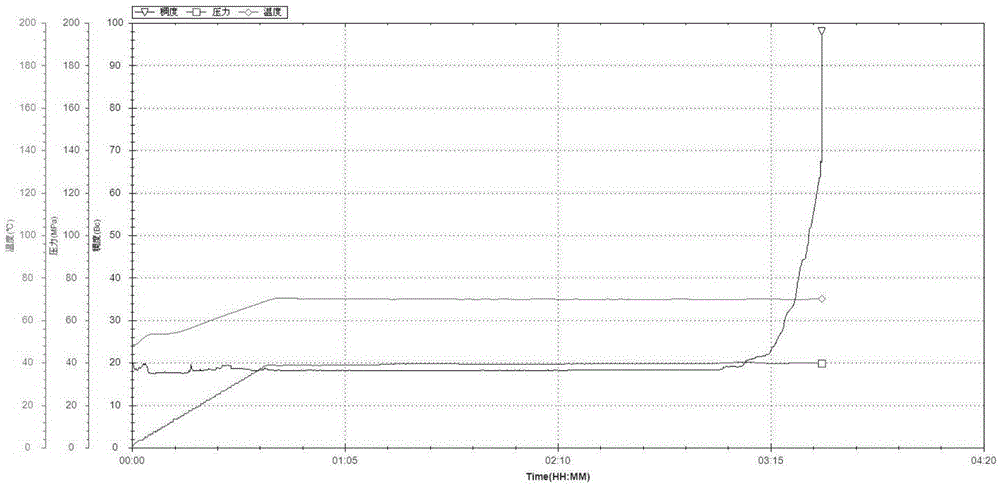

Image

Examples

Embodiment 1

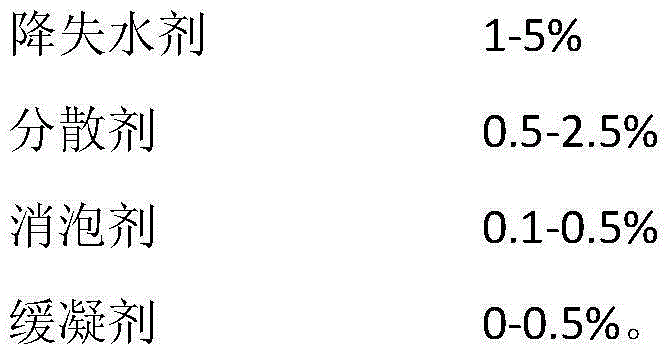

[0032] A kind of toughening agent for well cementing slurry, each component and weight are respectively:

[0033]

[0034] According to the API standard, the additives, 800g of grade G oil well cement, and 299g of tap water were thoroughly mixed evenly to obtain the toughening agent cement slurry.

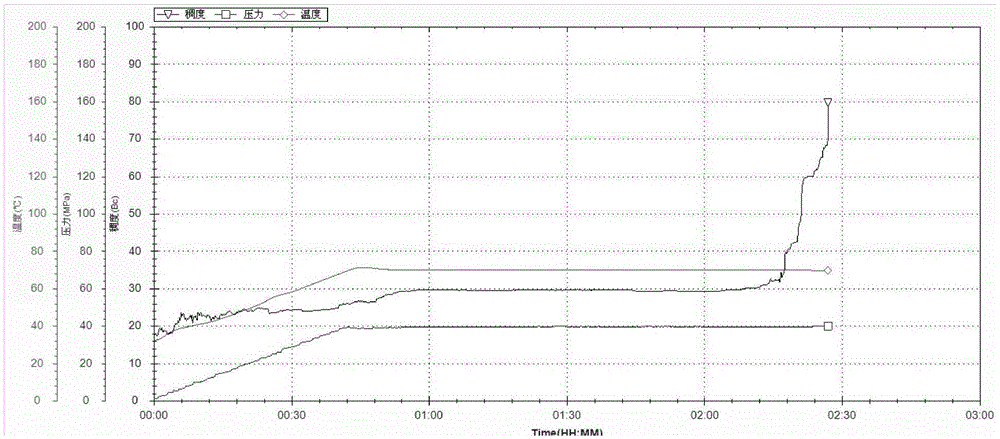

Embodiment 2

[0036] A kind of toughening agent for well cementing slurry, each component and weight are respectively:

[0037]

[0038] According to the API standard, the additives, 800g of grade F oil well cement, and 318.4g of tap water were fully mixed evenly to obtain the toughening agent cement slurry.

Embodiment 3

[0040] A kind of toughening agent for well cementing slurry, each component and weight are respectively:

[0041]

[0042] According to the API standard, the various additives, 800g of grade D oil well cement, and 307.8g of tap water were thoroughly mixed evenly to obtain the toughening agent cement slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com