Waterborne polyurethane dispersion, preparation method thereof and self-crosslinking waterborne polyurethane waterproof coating

A water-based polyurethane and dispersion technology, which is applied in the field of coatings and architectural waterproof coatings, can solve the problems that cannot truly reflect the waterproof state of water-based polyurethane waterproof coatings, and achieve excellent mechanical properties, ensure durability, and improve adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

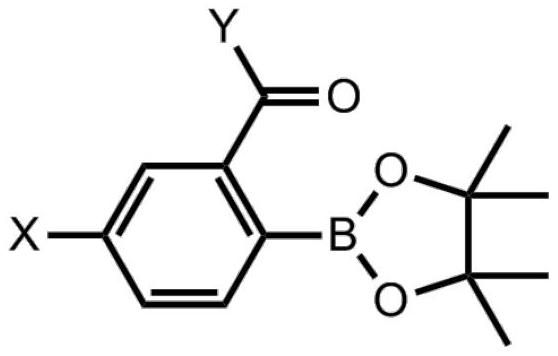

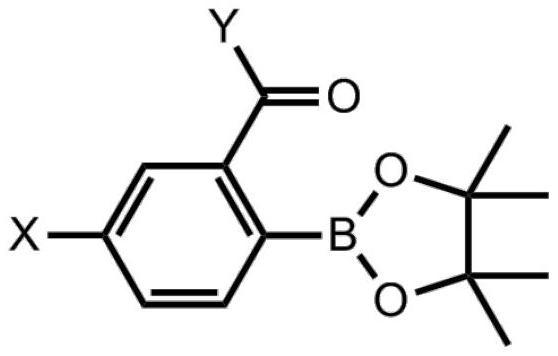

Method used

Image

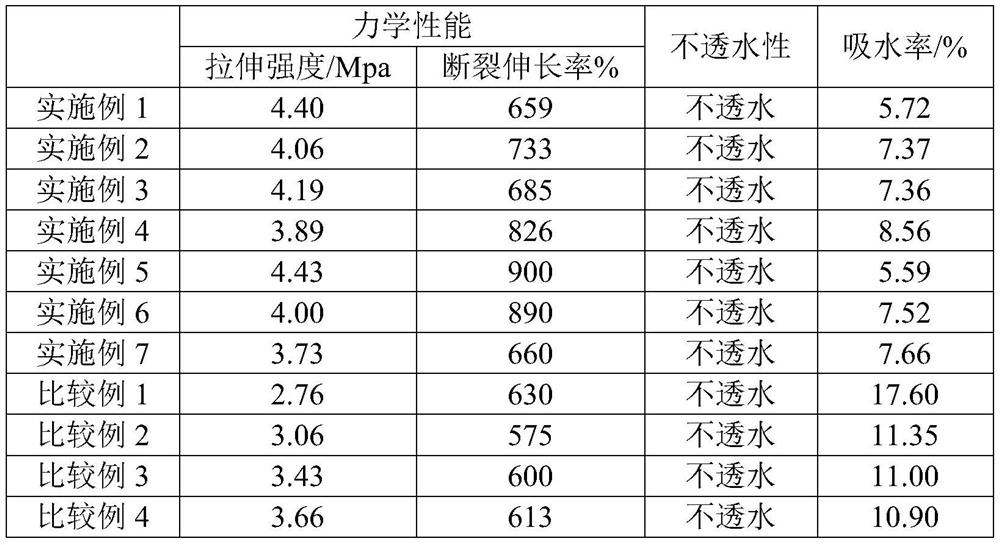

Examples

Embodiment 1

[0098] Heat 325.00g DL-2000D, 4.08g MPEG-1200, 6.39g DMPA and 6.57g 1,2-PG to 55°C and stir to mix well, then add 107.60g HMDI, finally add 67.60g acetone and 0.18g 8108, heated up to 75°C and reacted for 2 hours, then added 0.90 g of HBA and continued the reaction at 80°C for 3 hours to form a prepolymer.

[0099] Reduce the temperature to below 50 °C, add 2.70 g of acetone solution of 1010 and 2.70 g of 292 to the prepolymer (total 527.46 g) and mix well, add 5.30 g of TEA below 40 °C and neutralize for 5 minutes, then meter in 3.35 g Gram EDA and 1.35 g KH-792 (18.80 g acetone diluted) were reacted at 35-40° C. for 15 minutes to generate a polyurethane polymer precursor solution.

[0100] Add 556.63 g of deionized water under the condition of shearing and dispersing at 1200-1500 r / min of the dispersing machine, add 0.32 g of ADH (diluted with 3.20 g of water) and continue stirring for 10 minutes. Finally, the acetone was distilled off under reduced pressure to obtain an...

Embodiment 2

[0102] Heat 283.00g DL-2000D, 47.00g PTMEG-2000, 4.62g MPEG-1200, 8.22g DMPA and 9.89g NPG to 55°C and stir to mix well, then add 25.00g HMDI and 65.00g TDI-80 with 48.86 g of acetone and 0.13 g of acetone added at the end 8108, heated up to 75°C and reacted for 1 hour, then added 1.33 g of HBA and continued the reaction at 75°C for 2 hours to form a prepolymer.

[0103] Lower the temperature to below 50°C, add 2.22g of acetone solution of 1010 and 2.22g of 292 to the prepolymer (total 363.40g) and mix well, add 5.58g of TEA below 40°C and neutralize for 5 minutes, then meter in 8.43g g NHEEA and 1.78 g KH-792 (40.83 g acetone diluted) were reacted at 30-35° C. for 15 minutes to generate a polyurethane polymer precursor solution.

[0104] Add 556.63 g of deionized water under the condition of shearing and dispersing at 1200-1500 r / min of the dispersing machine speed, add 0.47 g of ADH (diluted with 4.70 g of water) and continue stirring for 10 minutes. Finally, the aceto...

Embodiment 3

[0106] Heat 251.00g DL-2000D, 84.00g PTMEG-2000, 5.30g MPEG-1200, 9.35g DMPA and 7.60g 1,2-PG to 50°C and stir and mix well, then add 92.00g TDI-80, finally added 54.10 g of acetone and 0.07 g of 8108 catalyst, heated to 70 °C and reacted for 1 hour, then added 1.80 g of HBA and continued the reaction at 70 °C for 2 hours to form a prepolymer.

[0107] Reduce the temperature to below 50 °C, add 1.80 g of acetone solution of 1010 and 1.80 g of 292 to the prepolymer (total 313.70 g), mix well, add 5.64 g of TEA below 40 °C and neutralize for 5 minutes, then meter in 3.30 g Gram EDA, 6.69 g NHEEA and 2.70 g KH-792 (50.79 g acetone diluted) were reacted at 30-35° C. for 10 minutes to form a polyurethane polymer precursor solution.

[0108] Add 556.63 g of deionized water under the condition of shearing and dispersing at 1200-1500 r / min of the dispersing machine, add 0.63 g of ADH (diluted with 6.30 g of water) and continue stirring for 10 minutes. Finally, the acetone was distil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com