Patents

Literature

59results about How to "Reduce hydrolysis reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

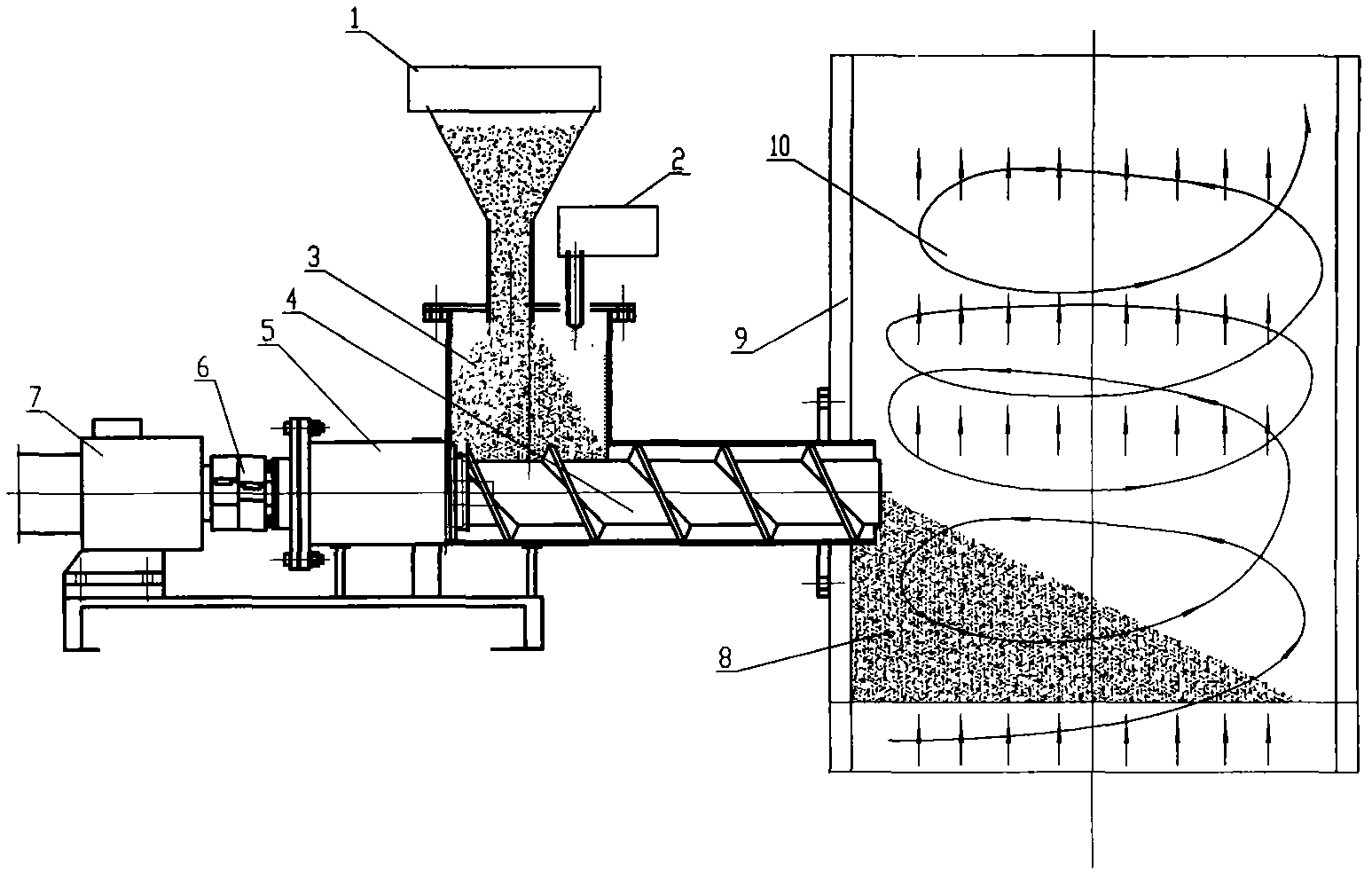

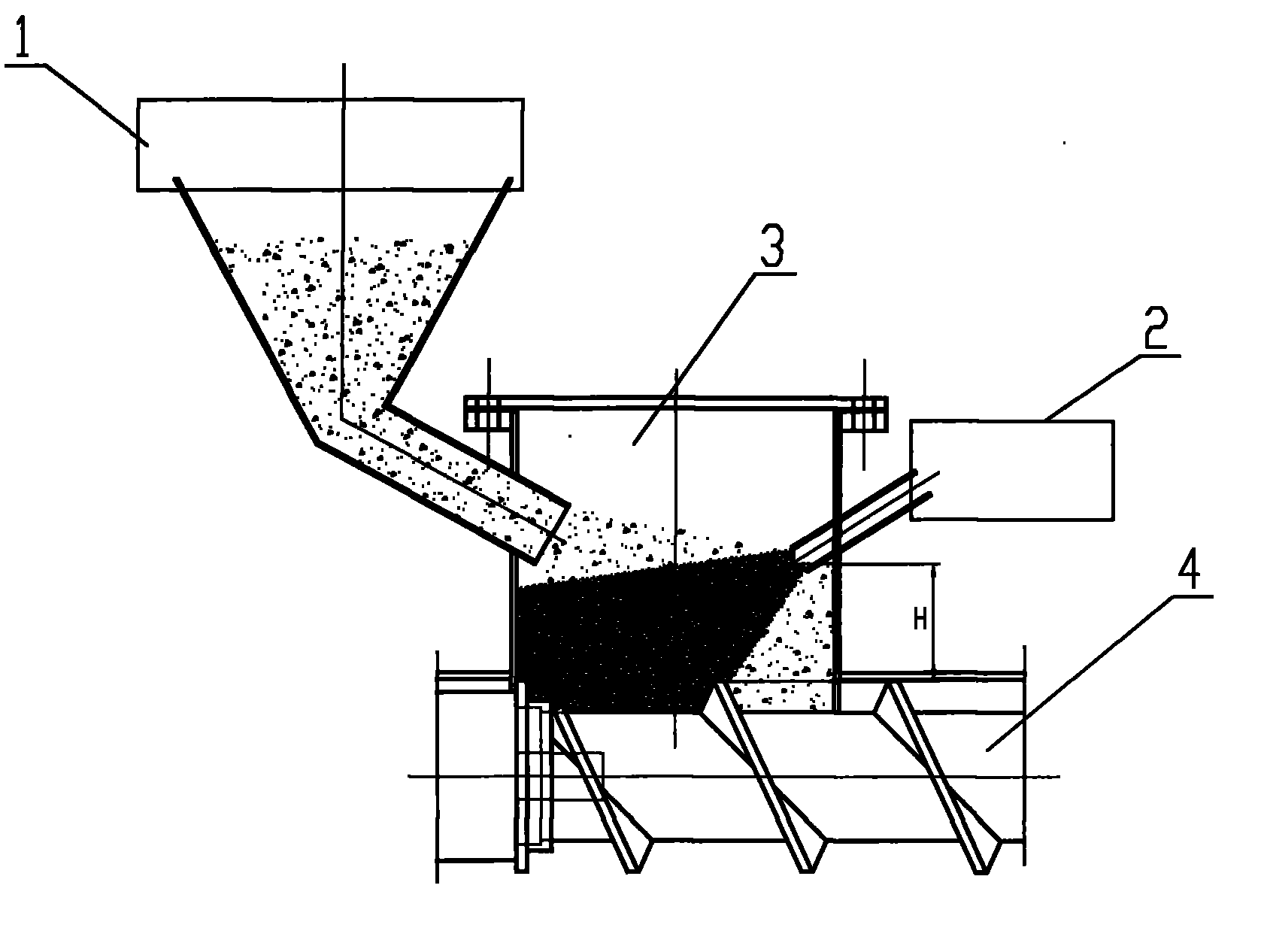

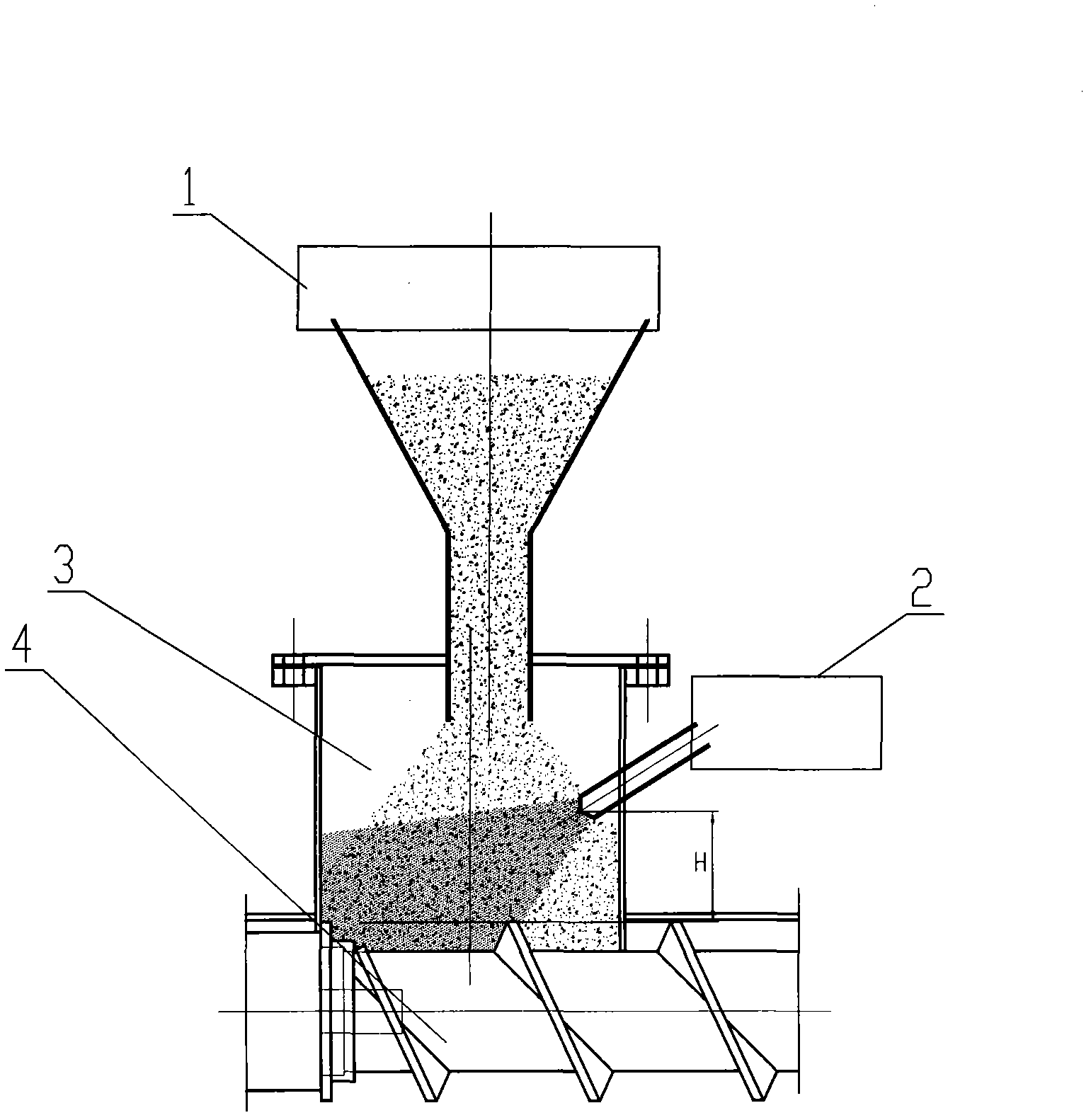

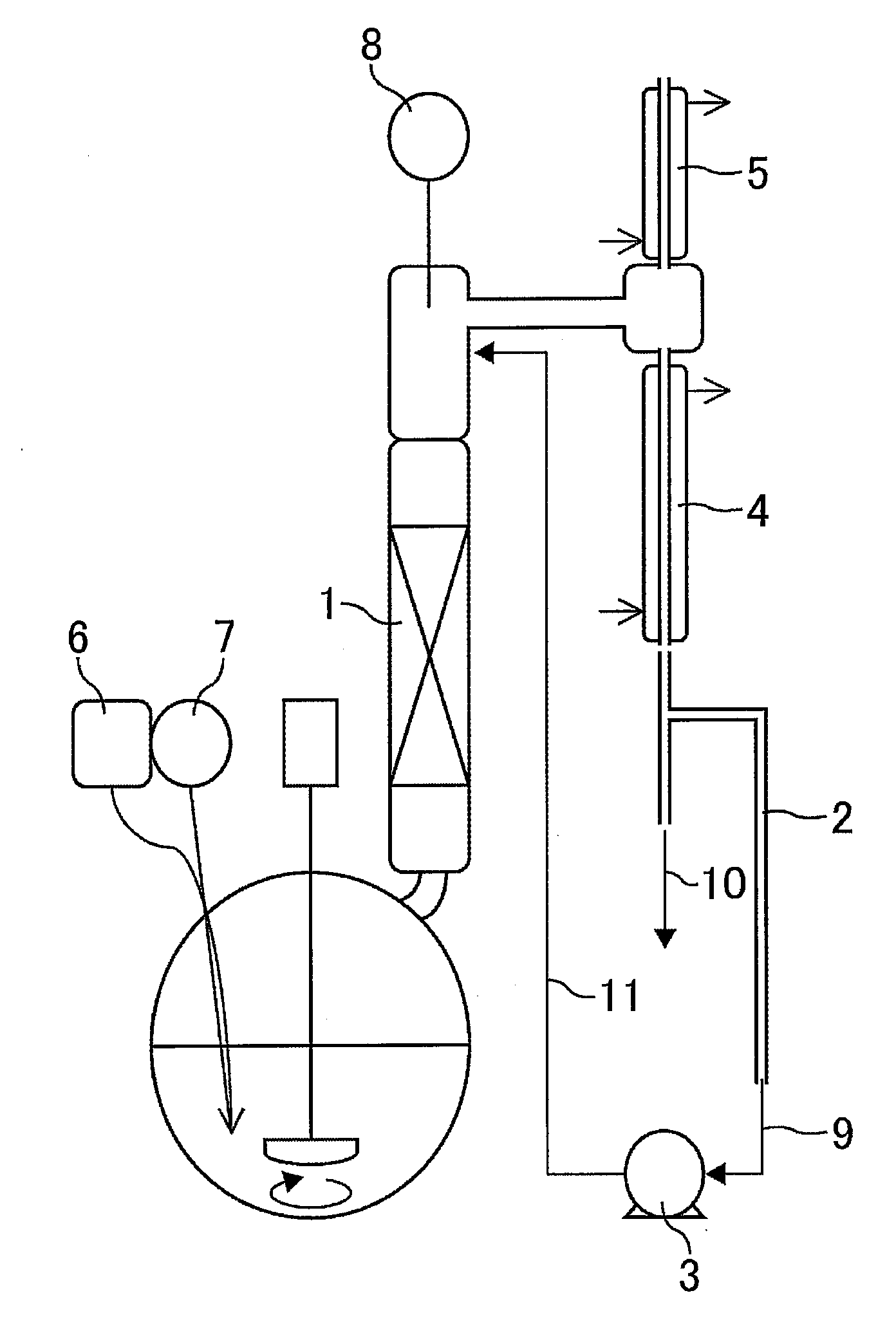

Catalyst successive impregnation equipment and method

ActiveCN102806109AImprove impregnation efficiencyImprove impregnation uniformityCatalyst activation/preparationEngineeringCatalyst support

The invention relates to catalyst successive impregnation equipment and a method. The catalyst successive impregnation equipment comprises a carrier continuous feeding system (1), an impregnation liquid conveying system (2), an impregnation chamber (3), a conveying part (4), a dryer (9) and a power system; the carrier continuous feeding system (1) and the impregnation liquid conveying system (2) are open in the impregnation chamber (3); the bottom of the impregnation chamber (3) is open at the initial end of the conveying part (4); the conveying part (4) is positioned between the impregnation chamber (3) and the dryer (9); an outlet at the tail end of the conveying part (4) is communicated with the dryer (9); and power is provided for the operation of the conveying part (4) by the power system. The invention also discloses the method applying the equipment. The catalyst successive impregnation equipment and the method which are provided by the invention can be used for carrying out catalyst carrier impregnation to prepare a catalyst; a catalyst carrier is continuously impregnated; the impregnation efficiency is high; the impregnation uniformity is good; and the catalyst carrier is crushed a little.

Owner:CHINA PETROLEUM & CHEM CORP +1

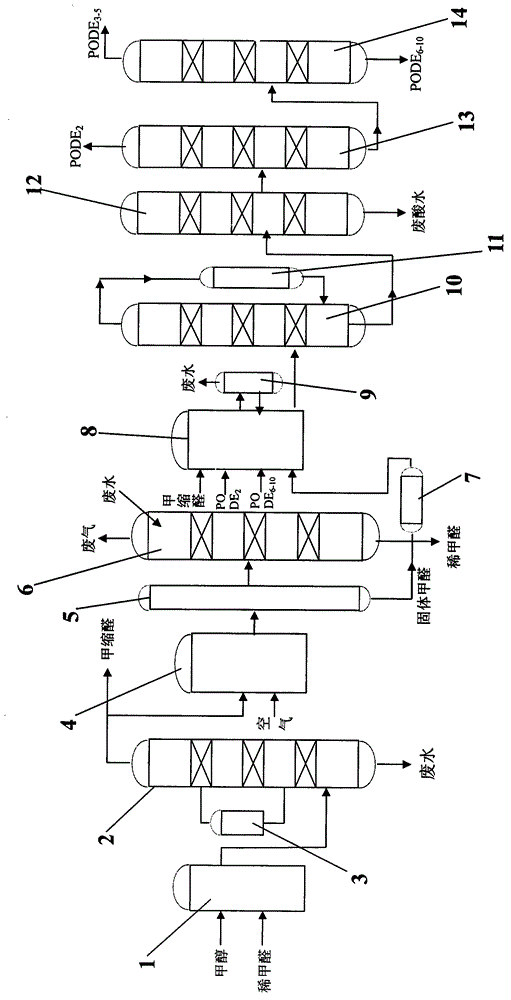

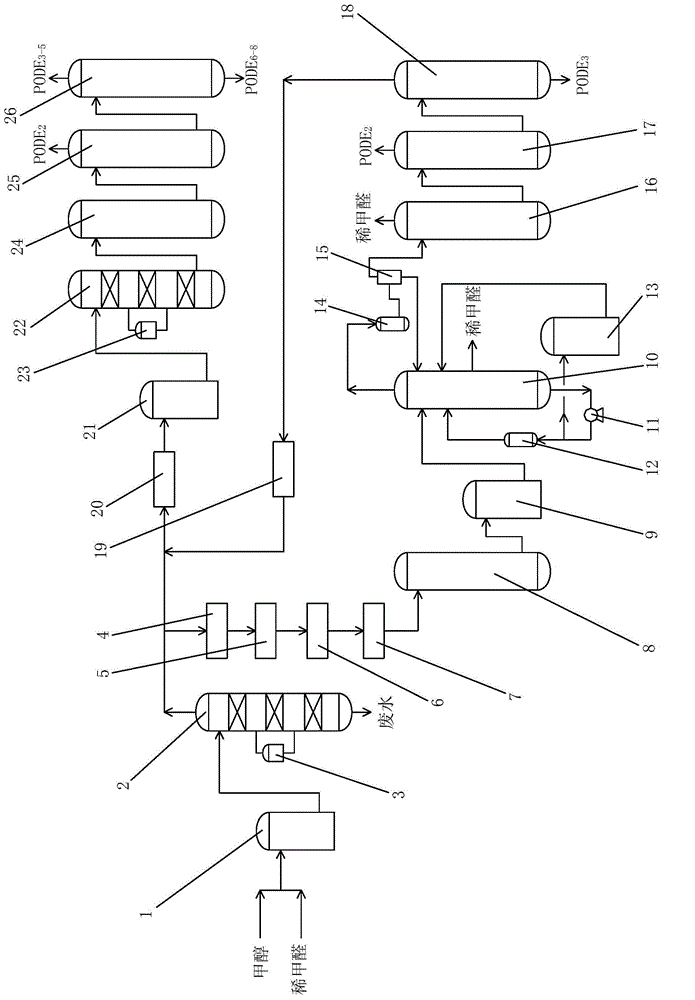

Method for continuously producing polymethoxy dimethyl ether by using methanol as original reaction material

InactiveCN104447239AHigh catalytic activityEasy to separateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsStrong acidsDimethoxymethane

The invention discloses a method for continuously producing polymethoxy dimethyl ether by using methanol as an original reaction material. The method comprises: 1, performing condensation reaction on methanol serving as the original reaction material and dilute formaldehyde (return material) to produce methylal of which the mass purity is more than 95%; 2, catalytically oxidizing methylal with air in the presence of an iron-molybdenum catalyst in a separator to obtain solid formaldehyde of which the mass purity is not less than 95%; 3, melting solid formaldehyde by steam heating, then performing polymerizing etherification reaction on the solid formaldehyde and the methylal under the catalytic action of self-developed modified strong acid cation exchange resin to generate polymethoxy dimethyl ether, and dehydrating and refining the polymethoxy dimethyl ether to obtain PODE3-5 of which the mass purity is more than 99.5%. By adopting the method, the single pass yield of the polymethoxy dimethyl ether can be improved from general 40-50% to 97%, wherein the PODE3-5 yield is improved from 25% to 92%; and the method is low in equipment investment, low in energy consumption, low in production cost, simple and easy to operate, and can realize large-scale continuous industrial production.

Owner:白教法

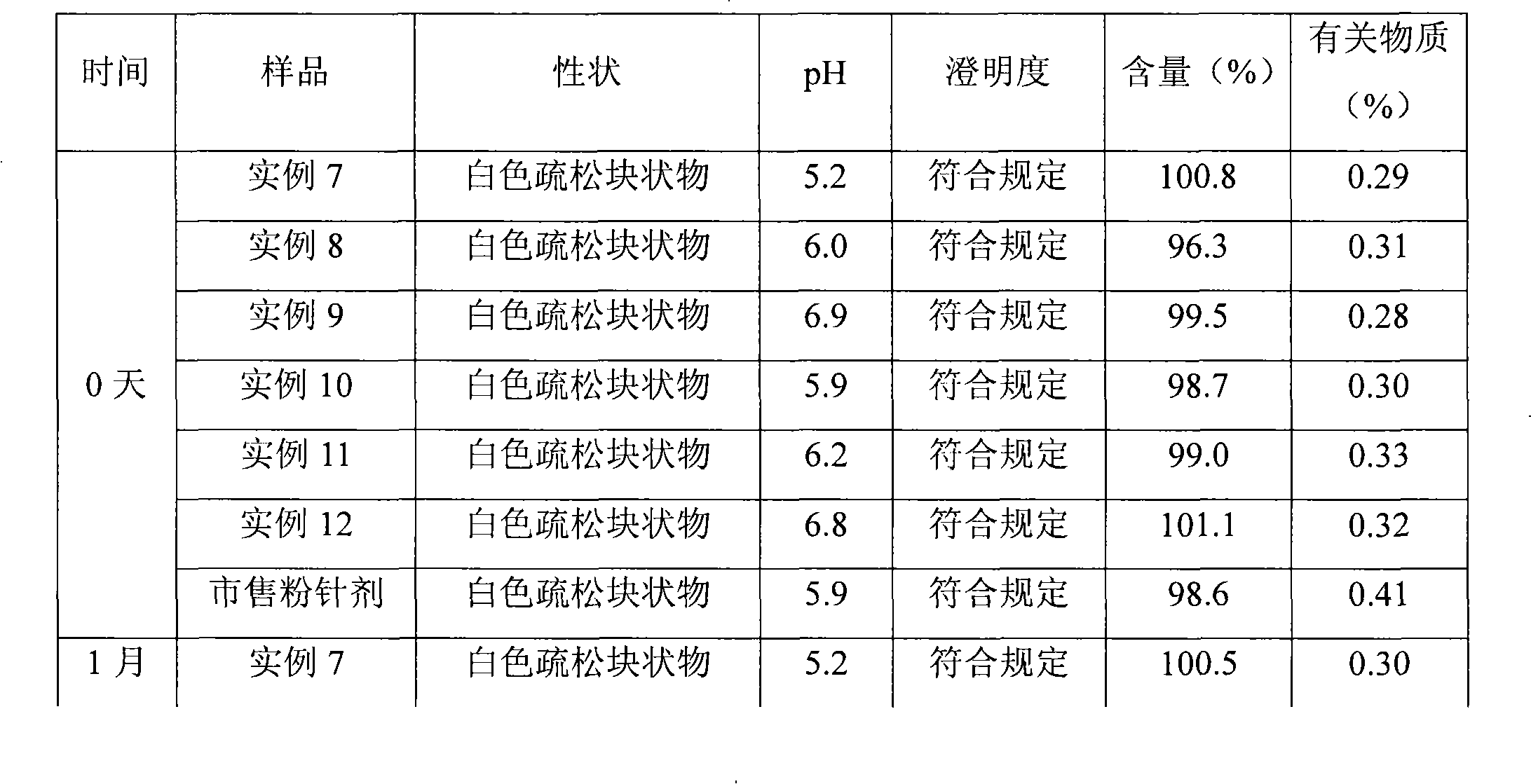

Preparation method of anhydrous cerium chloride

InactiveCN108455650AAdequate responseReduce hydrolysis reactionRare earth metal chloridesCeriumCombined use

The invention provides a preparation method of anhydrous cesium chloride. The preparation method is characterized in that cerium oxide is taken as a raw material, reaction is conducted by using ammonium chloride solid, then dried hydrogen chloride gas enters, heating is conducted until the reaction is completed, and products are dried to obtain anhydrous cesium chloride. By the combined use of theammonium chloride and the hydrogen chloride gas, and by the combination and the proportioning of the using amount of reactants, the synergistic effect of the ammonium chloride and the hydrogen chloride is achieved to adjust the position relationship of each reactant, to make the reaction more complete, the yield of the reaction product is high, drying is conducted under an inert atmosphere by reducing pressure to prevent the occurrence of redox side reaction, improve the product purity, and the preparation method is safe and effective, and the products are pure.

Owner:上海泰坦科技股份有限公司

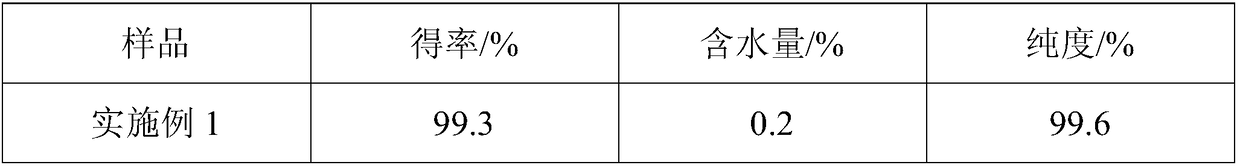

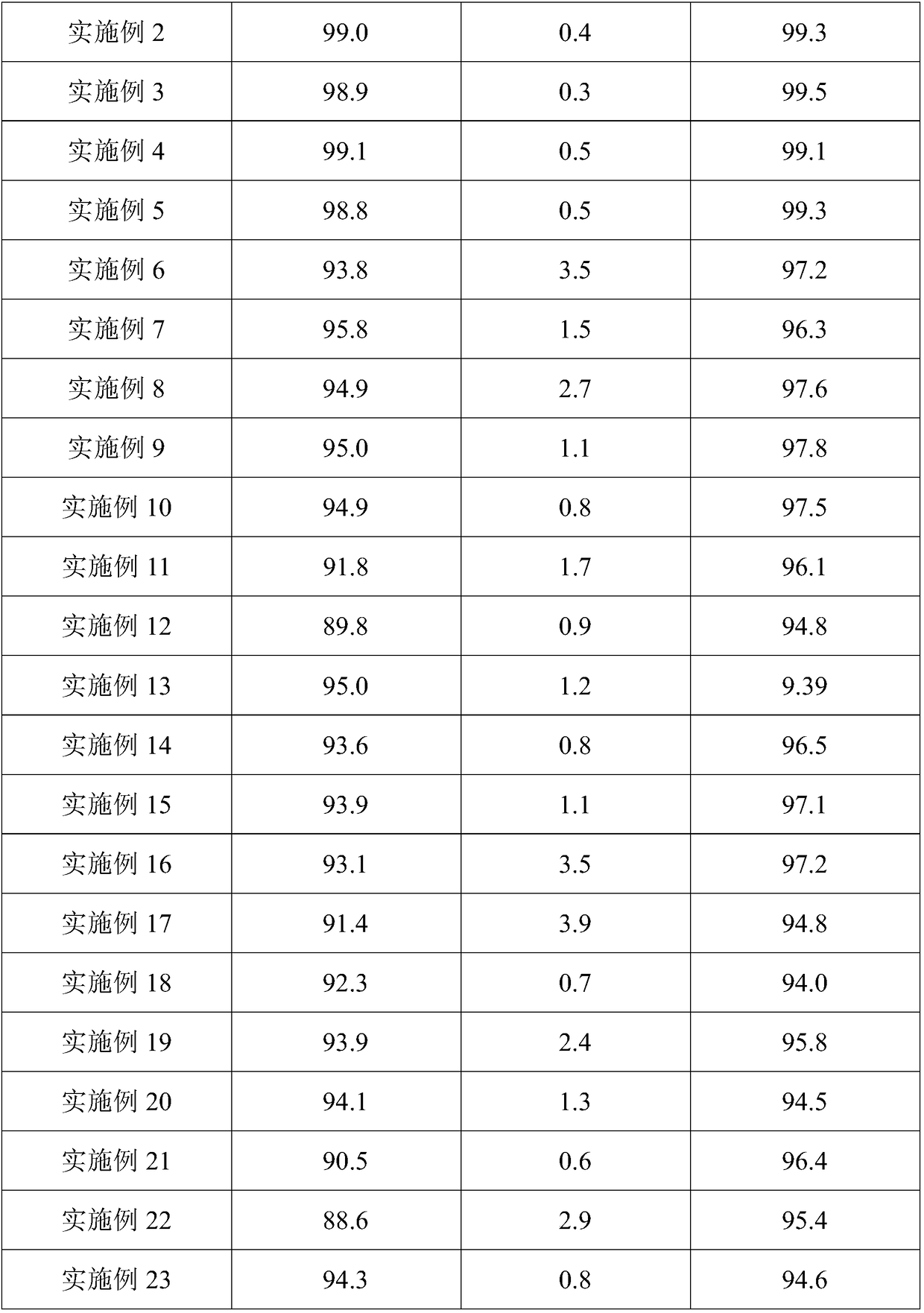

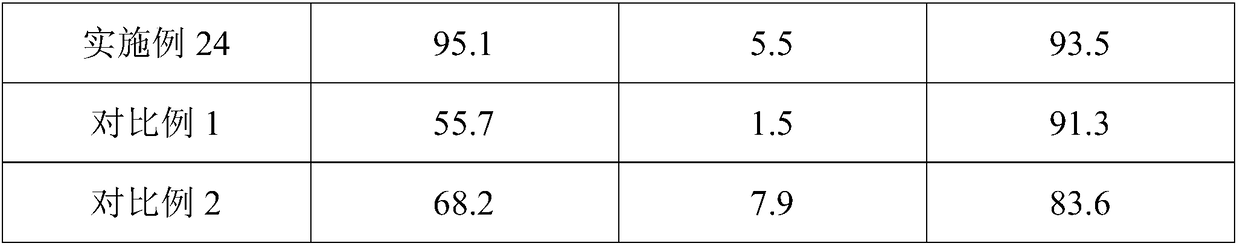

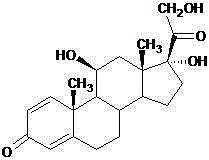

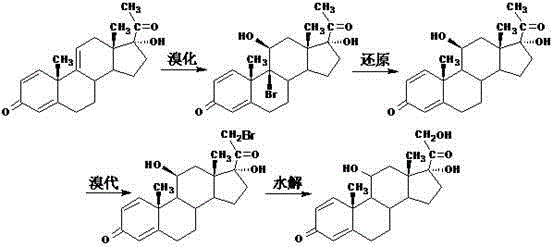

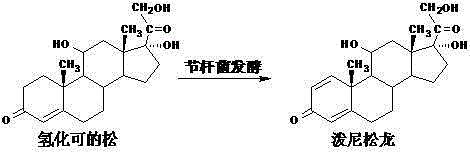

Preparation method of prednisolone

The invention relates to a preparation method of prednisolone. The preparation method comprises the steps of sequentially carrying out 3, 20-keto protective reaction, 11-keto reduction reaction, 21-hydroxyl esterification reaction, 3, 20-keto deprotection reaction and 21-acetic ester hydrolysis reaction by taking prednisone acetate as a raw material to obtain prednisolone. The invention provides a novel synthesis route sequentially comprising the steps of esterifying and deprotecting; nitrosification quenching reaction and resin hydrolysis reaction are omitted in the deprotection process; and ester hydrolysis reaction is finished under the protection of a mixed solvent and inert gases, so that the condition that byproducts are produced by hydrolysis reaction is avoided. The preparation method is novel in process route, simple and rapid in operation process, low in production cost and suitable for large-scale industrial production.

Owner:HUAZHONG PHARMA

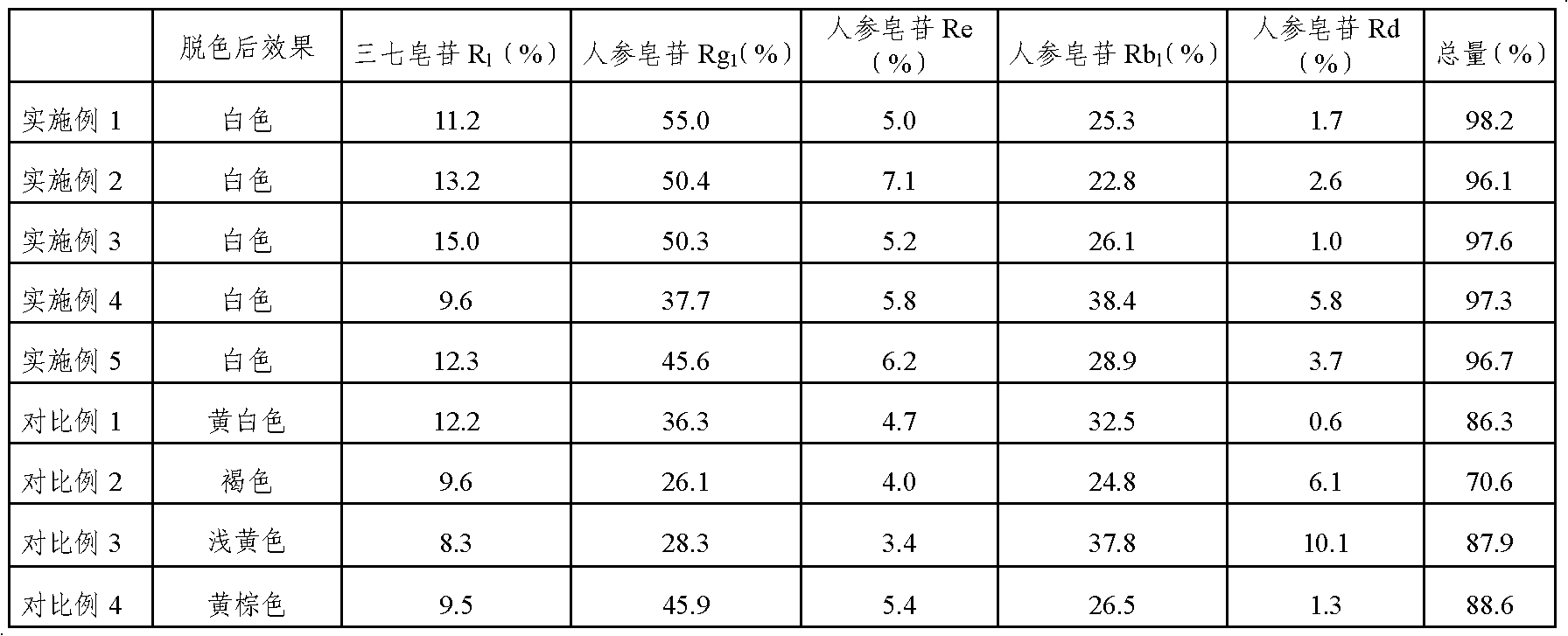

Decolorization method of panax notoginsenoside extract

ActiveCN102423329AGood decolorization effectHigh selectivityNervous disorderMetabolism disorderPolystyrenePanax notoginseng

The invention relates to a decolorization method of a panax notoginsenoside extract. In the decolorization method, panax notoginsenoside is decolorized mainly by combining strongly polar polystyrene copolymer macroporous resin ADS-7 with neutral aluminium oxide. According to the method, the strongly polar polystyrene copolymer macroporous resin ADS-7 is used for decolorizing, the decolorization effect is good, the amount of residues of the panax notoginsenoside in the resin is reduced, and hydrolysis of the panax notoginsenoside is reduced.

Owner:GUANGXI WUZHOU PHARMA GRP

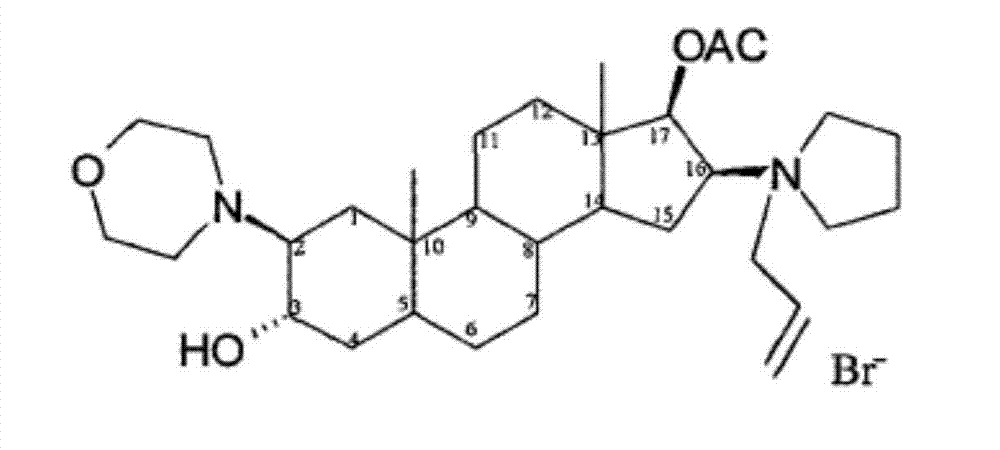

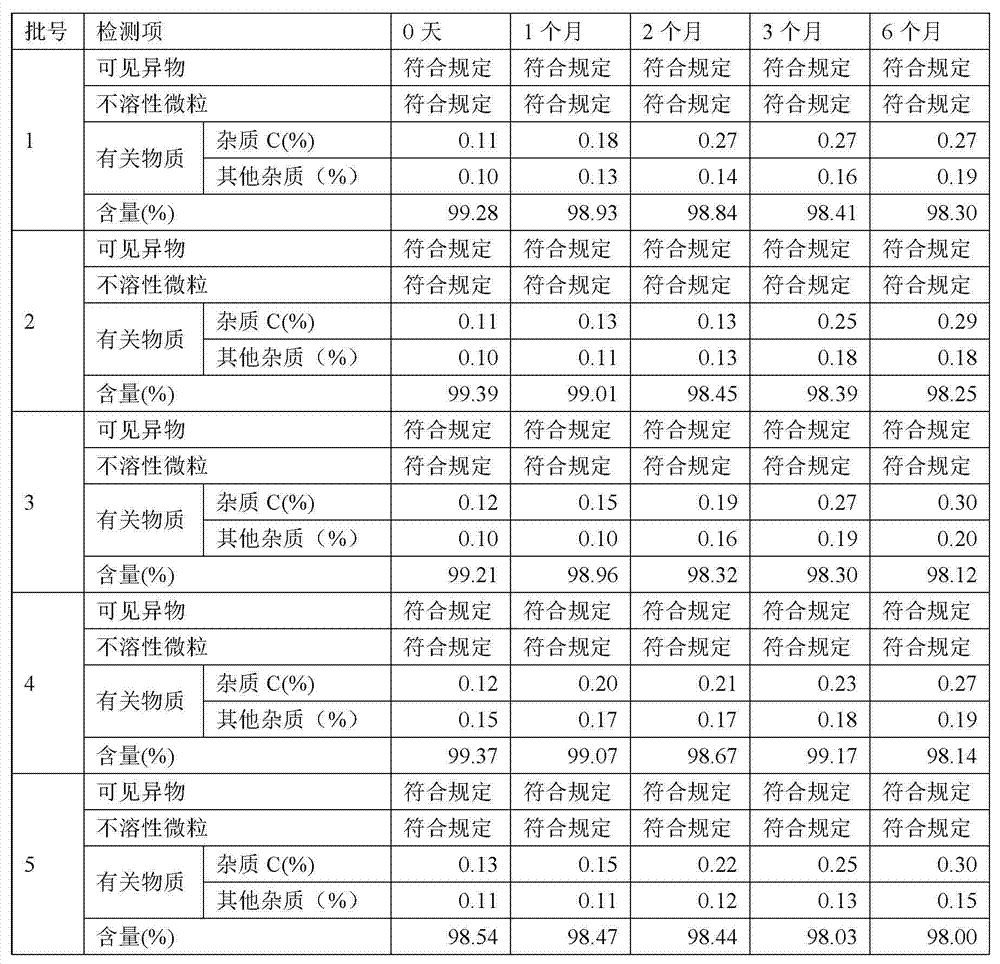

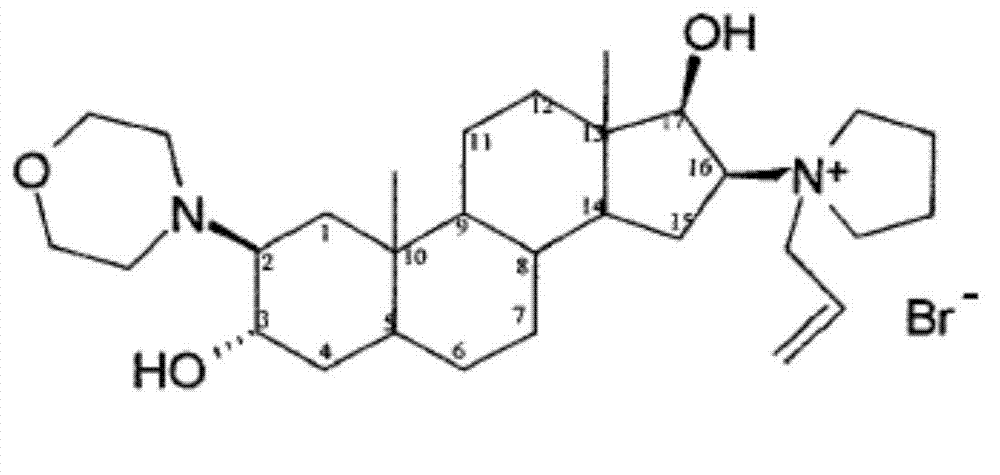

Rocuronium bromide-containing injection

ActiveCN102949339AReduce hydrolysisReduce hydrolysis reactionOrganic active ingredientsMuscular disorderBULK ACTIVE INGREDIENTActive ingredient

The invention relates to a rocuronium bromide-containing injection. The injection is prepared from rocuronium bromide serving as an active ingredient and a pharmaceutically-acceptable carrier as accessories. The pH value of a system is maintained by adding a 1-5 percent acetate buffer solution, so that the stability of the solution is enhanced, the pH value of a system is maintained at the same time, degradation of main medicaments in a preparation process is suppressed, the stability of the main medicaments is enhanced, and the quantity of rocuronium bromide impurities C in an autoclave sterilizing process is reduced. Finally, a rocuronium bromide injection which has high stability and stable quality and is suitable for storing for a long time is obtained.

Owner:TIANJIN CHASE SUN PHARM CO LTD

Alternate pulse formation charging process

ActiveCN109616702AReduced responseReduce the temperatureFinal product manufactureLead-acid accumulators constructionEnvironmental resistanceElectrical battery

Disclosed is an alternate pulse formation charging process. The alternate pulse formation charging process comprises the steps of primary acid addition, battery connection, power supplying, and charging and forming, wherein in the procedure of charging and forming, the forming and charging process of a storage battery is divided into multi-mode and multi-stage alternate charging, such as trickle preprocessing, constant current charging, standing, positive and negative pulse charging, intermittent pulse charging and the like according to certain chemical and physical characteristics of a lead-acid storage battery. By virtue of the process of the invention, the polarization reaction and the electrolyte temperature in the middle and later periods of the traditional constant-current charging mode formation are reduced, the charging efficiency is improved, the formation time is shortened, the formation period is shortened by 30%, the charge electric quantity is reduced by 20%, energy conservation and consumption reduction are achieved, and the production efficiency is improved; meanwhile, the polar plate conversion efficiency is improved, the initial capacity of the battery is increased; and formation of acid mist in the middle and later periods of formation is reduced, electrochemical polarization in the middle and later periods of formation is eliminated, the hydrolysis reaction is reduced, the groove temperature and voltage are lowered, the gas evolution is reduced, and the environmental protection is facilitated.

Owner:CAMEL GRP XIANGYANG BATTERY

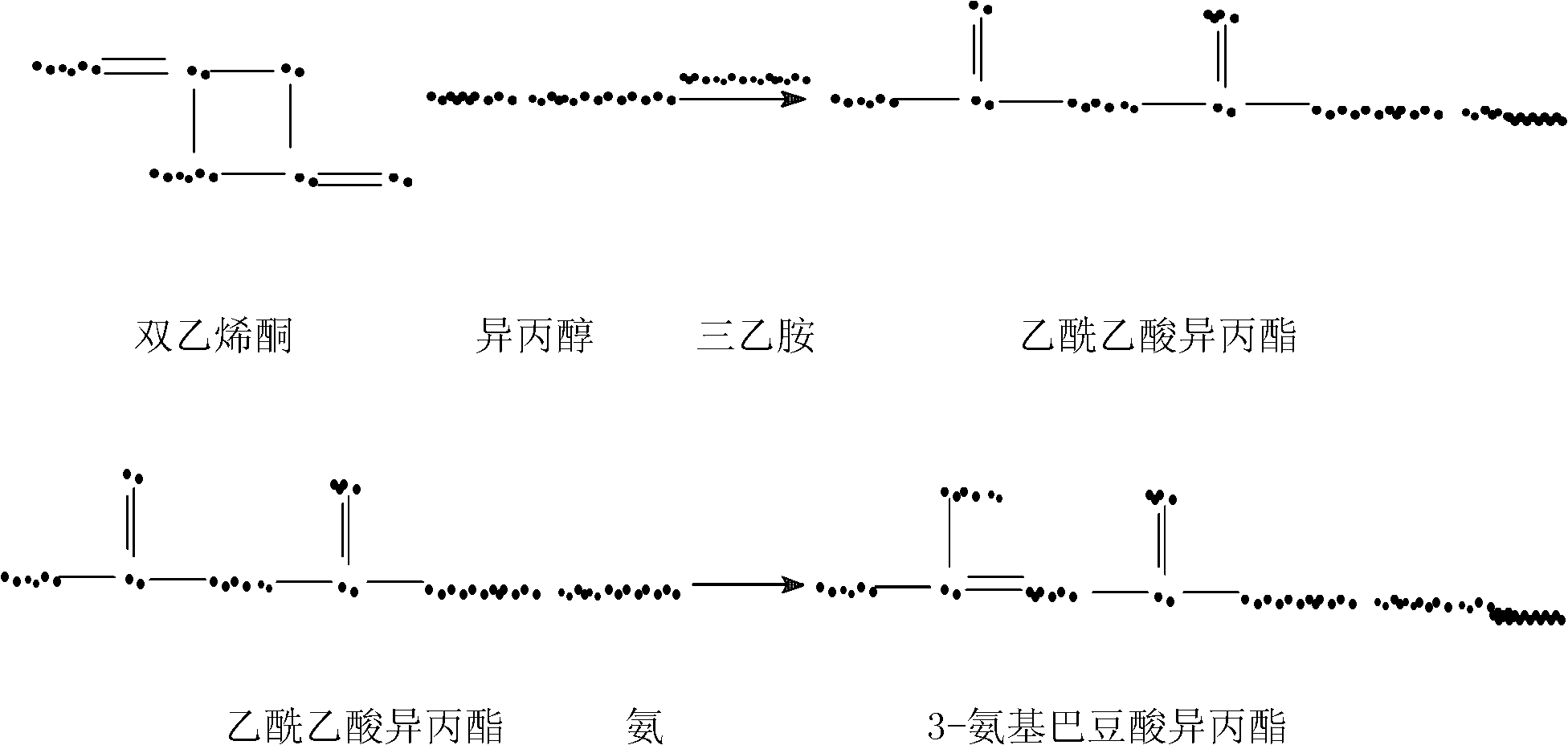

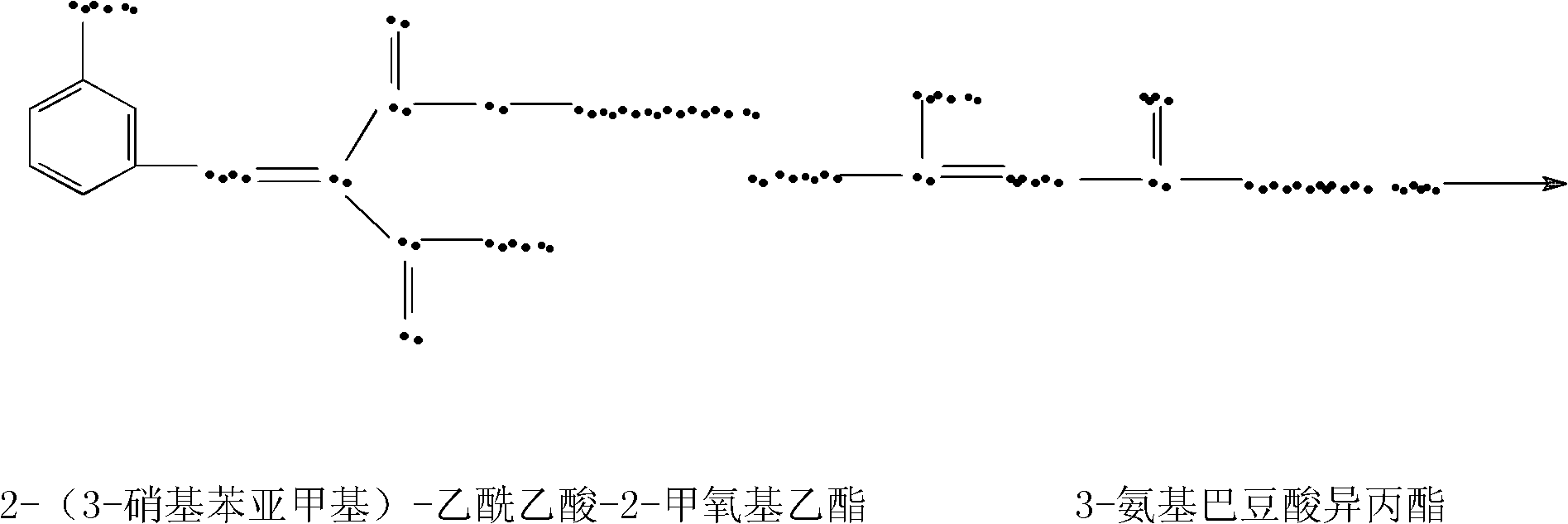

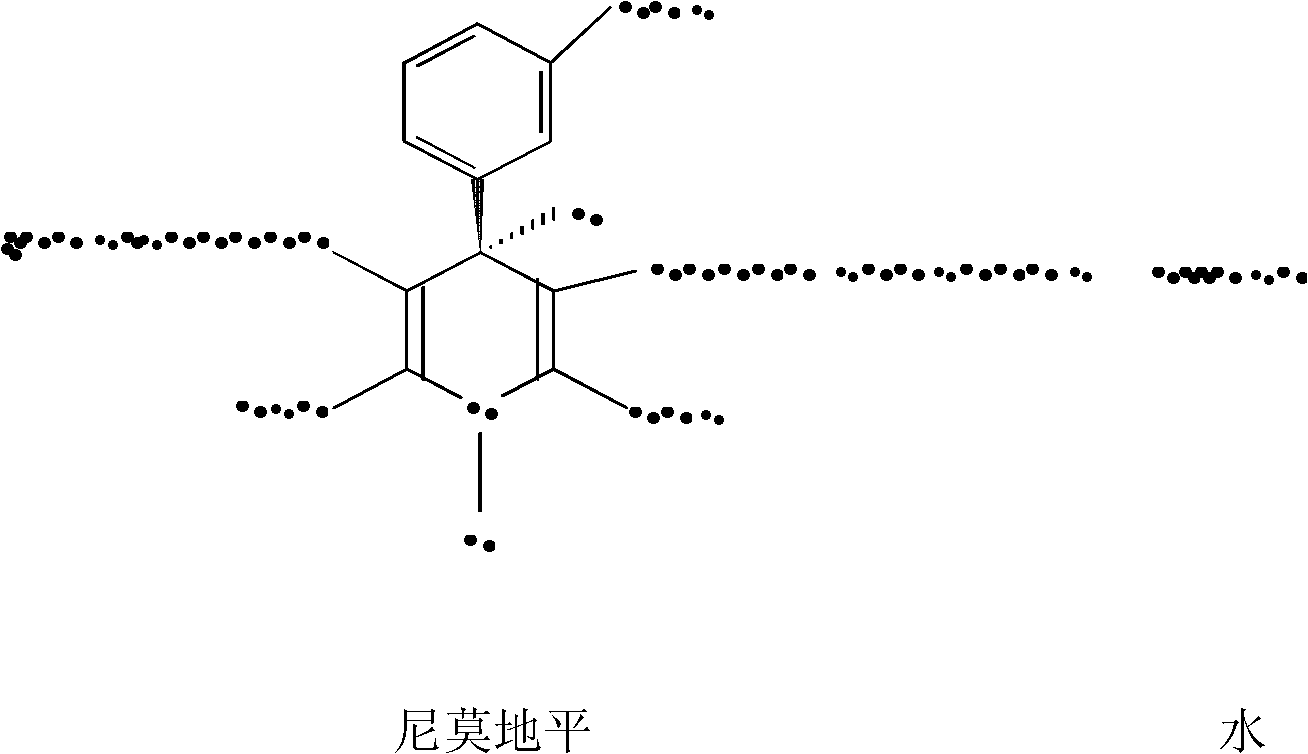

Preparation method of nimodipine

ActiveCN102174012AReduce hydrolysis reactionIncrease contentOrganic chemistryAcetic acidInorganic salts

The invention belongs to the technical field of pharmacy, and in particular relates to a preparation method of nimodipine, comprising urethane reaction and cyclization reaction, wherein in the urethane reaction, after ammonia introducing reaction, adding an inorganic salt for dewatering the urethane reaction liquid, then rectifying to obtain isopropyl-3-aminocrotonate; and performing cyclization reaction with 2-(3-nitrobenzylidene)-acetoacetic acid-2-methoxyethyl ester by taking fatty alcohol as a reaction solvent. The invention has the advantages of high product yield and good quality, the primary yield can reach 85-89%, the solvent can be recovered for use, the raw material cost can be greatly reduced, and the content of total impurities is decreased from 0.4-1.0% of the original process to 0.1-0.3% by HPLC (High Performance Liquid Chromatography) detection.

Owner:SHANDONG XINHUA PHARMA CO LTD

Graphene modified silicone grease with high thermal conductivity and preparation method thereof

The invention discloses an insulating silicone grease with high heat conductivity coefficient special for electron industry. The insulating silicone grease is prepared from raw materials including long-chain alkyl silicone oil (viscosity of 600-900mm2 / s), polyether silicone oil (viscosity of 200-400mm2 / s, viscosity of 400-600mm2 / s), zinc oxide (1mum), spherical aluminum oxide (20mum), aluminum nitride (10mum), boron nitride (3mum), silicon carbide (5mum) and sulfonated graphene. The invention also discloses a preparation method for the insulating silicone grease with high heat conductivity coefficient special for electron industry.

Owner:江苏中恒电子新材料有限公司

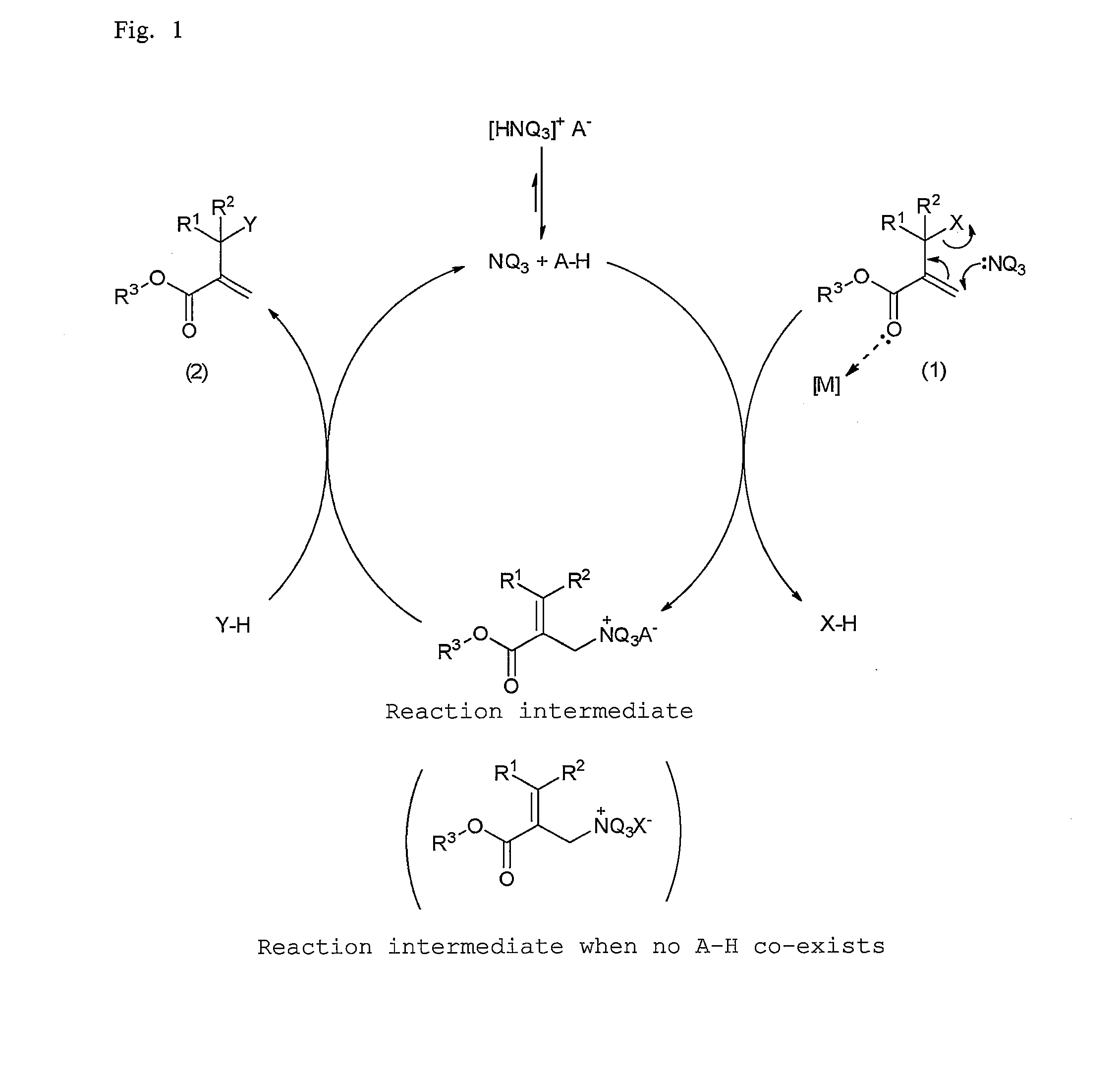

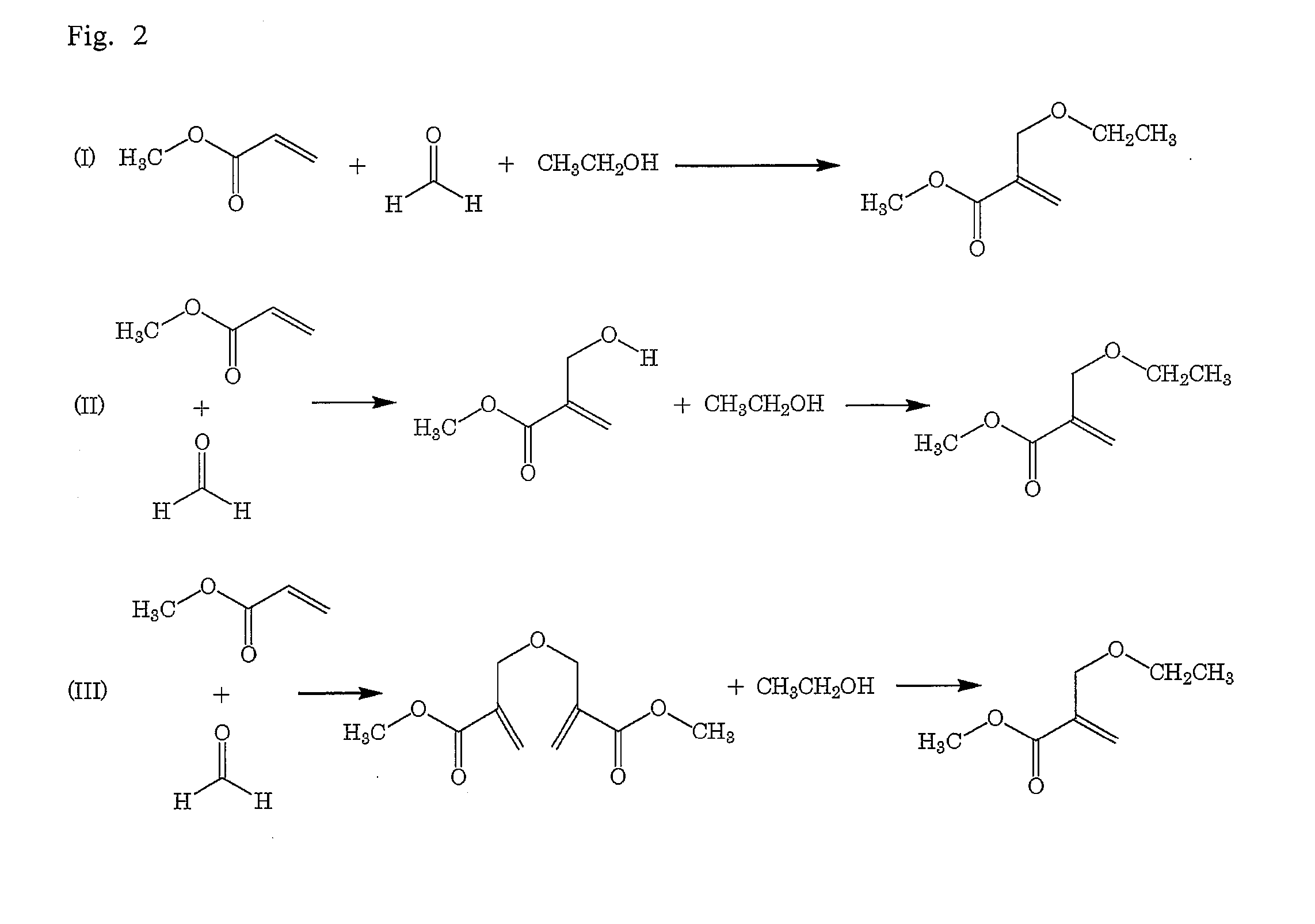

Alpha-substituted acrylate esters, composition containing thereof, and method for producing those

InactiveUS20130072712A1Short timeHigh yieldOrganic compound preparationCarboxylic acid esters preparationHydrogenCorrosion

A method for producing α-substituted acrylate esters is provided which can be suitably used as an industrial method for producing α-substituted acrylate esters because the method does not have problems of apparatus corrosion or does not require waste detoxification and allows reaction in a short time with high yield. The method for producing an α-substituted acrylate ester includes a step of carrying out a reaction of a compound having a specific structure and an active hydrogen-containing compound under a condition where a tertiary amine and an acid and / or a salt thereof coexist.

Owner:NIPPON SHOKUBAI CO LTD

Lyophilized injection of lentinan and preparation process thereof

InactiveCN1969876AReduce lossesSafe choicePowder deliveryOrganic active ingredientsNeutral Amino AcidsFreeze-drying

The invention discloses a freeze dried of mushroom polysaccharide, which comprises the following steps: adopting neutral amino acid as rack agent; blending evenly; reducing the density of sodium hydroxide; filtering; adjusting pH value.

Owner:成都普瑞法科技开发有限公司

Method for synthesizing polyoxymethylene dimethyl ether through condensation, oxidation, polycondensation and etherification of methanol

ActiveCN104058940BHigh catalytic activityEasy to separateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholReactive distillation

Owner:XIAN SHANGHUA TECH DEV CO LTD

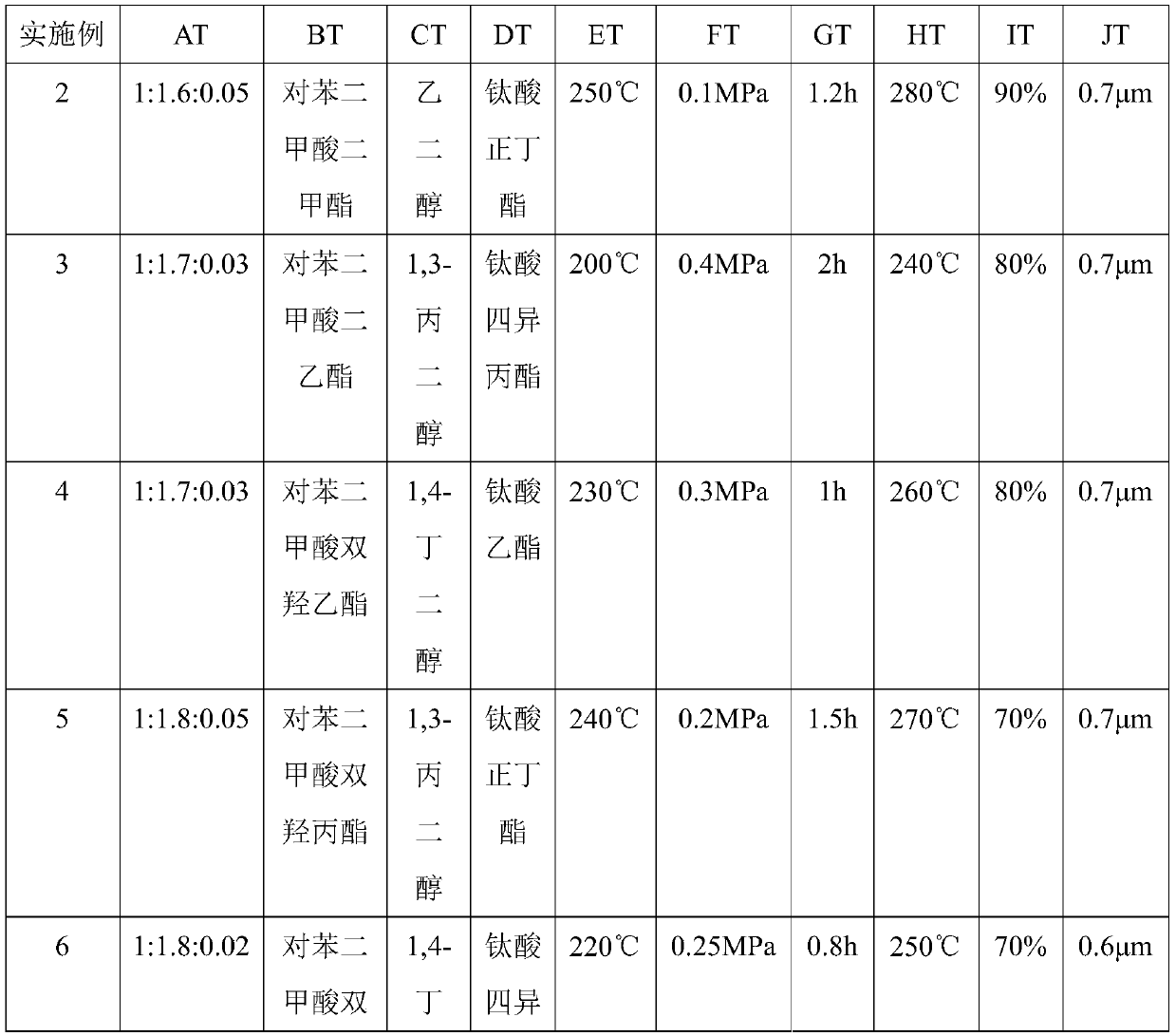

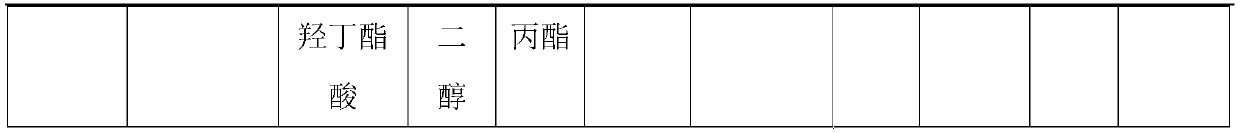

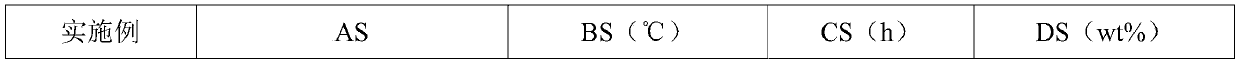

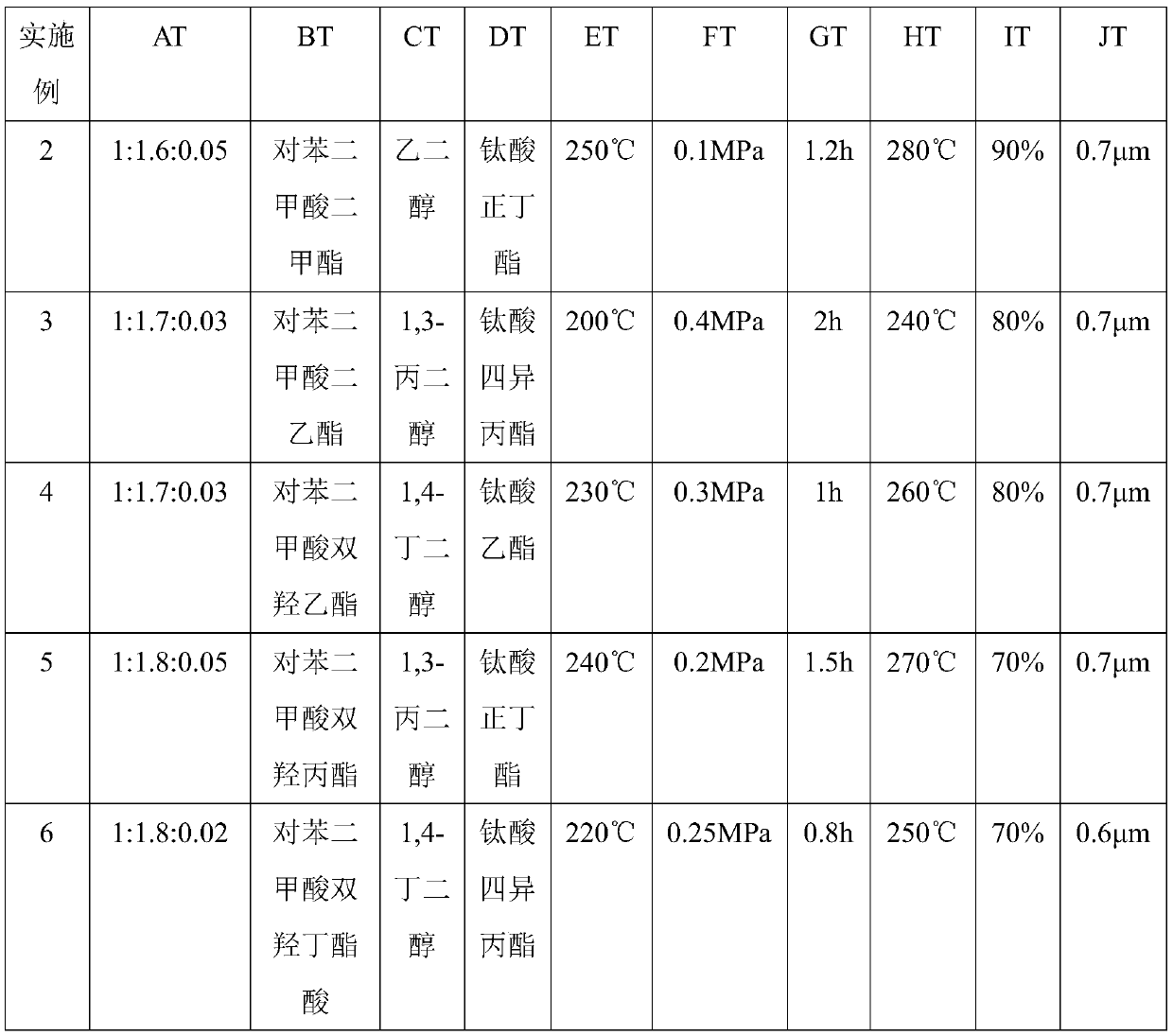

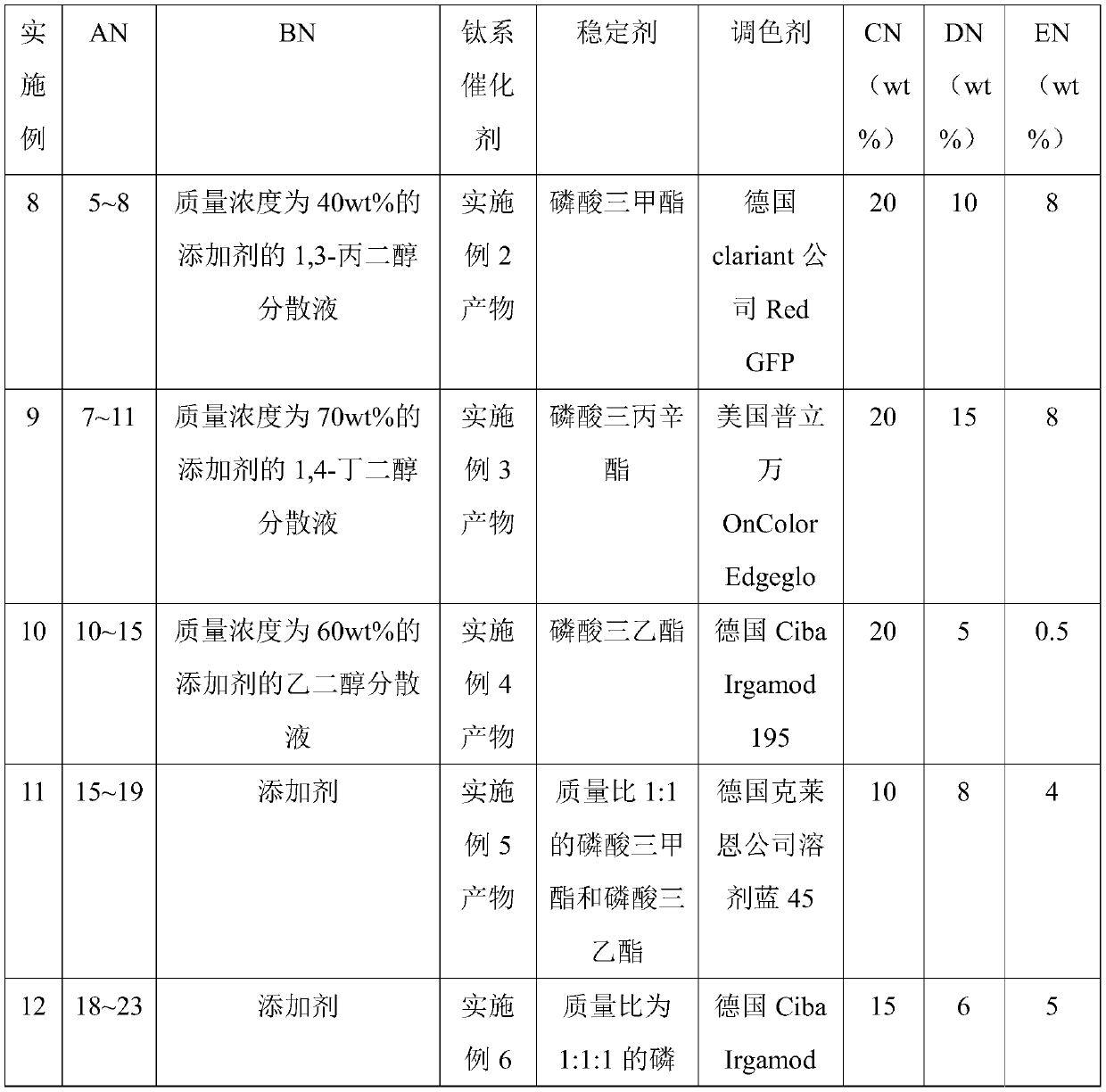

Method for preparing titanium-based matte polyester fiber through direct melt spinning and product

ActiveCN111286805AReduce adverse effectsReduce usageMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterPolymer science

The invention relates to a method for preparing a titanium-based matte polyester fiber through direct melt spinning and a product. The preparation method comprises the steps of firstly synthesizing atitanium-based matte polyester melt by taking PTA, EG, a polyester titanium catalyst composite material system and a nanocomposite material for in-situ polymerization of polyester as main raw materials, and then carrying out direct melt spinning to obtain a titanium-based matte polyester fiber, wherein the polyester titanium catalyst composite material system is mainly composed of a polyester prepolymer I with the polymerization degree of 3-50 and a titanium catalyst dispersed into the polyester prepolymer I, and the nanocomposite material for in-situ polymerization of the polyester is mainlycomposed of a polyester prepolymer II with the polymerization degree of 3-30 and TiO2 particles dispersed into the polyester prepolymer II; and the finally prepared titanium-based matte polyester fiber is mainly composed of a polyester fiber matrix, and a titanium catalyst and TiO2 particles dispersed into the polyester fiber matrix. According to the method, the stability and the dispersity of thecatalyst can be improved, the activity of the catalyst is ensured and the usage of the catalyst is reduced.

Owner:浙江东太新材料有限公司 +1

Metal-free sulfur-doped carbon material hydrogen peroxide reduction catalyst and preparation method

ActiveCN104051748AWide variety of sourcesLow priceMaterial nanotechnologyPhysical/chemical process catalystsElectrochemistryNitrogen gas

The invention provides a metal-free sulfur-doped carbon material hydrogen peroxide reduction catalyst and a preparation method. The preparation method is characterized by comprising the following steps: putting benzyl disulfide and a carbon material into sufficient ethanol according to a mass ratio of (5-6): (95-94), ultrasonically treating the mixture for 0.5 to 1 hour, centrifuging the mixture to remove the upper substances, vacuum drying the mixture for 5 to 6 hours at the temperature of 50 to 60 DEG C to form solid powder, putting the solid powder into a high-temperature furnace to be reacted for 7 to 8 hours at the temperature of 800 to 900 DEG C under the protection of nitrogen, cooling the solid powder to room temperature under the protection of nitrogen to obtain the sulfur-doped carbon material hydrogen peroxide reduction catalyst. The sulfur is used for substituting carbon to form S-C bonds to form an activity center of the electroreduction of H2O2. The source of the raw material is wide, and the price is low. Not only is the electrochemical activity high, but also the stability is high, and the toxicity resistance is high. The hydrolysis reaction of the H2O2 can be prevented, and the oxygen can be reduced. The electric oxidation performance and utilization rate of the H2O2 can be greatly improved.

Owner:HARBIN ENG UNIV

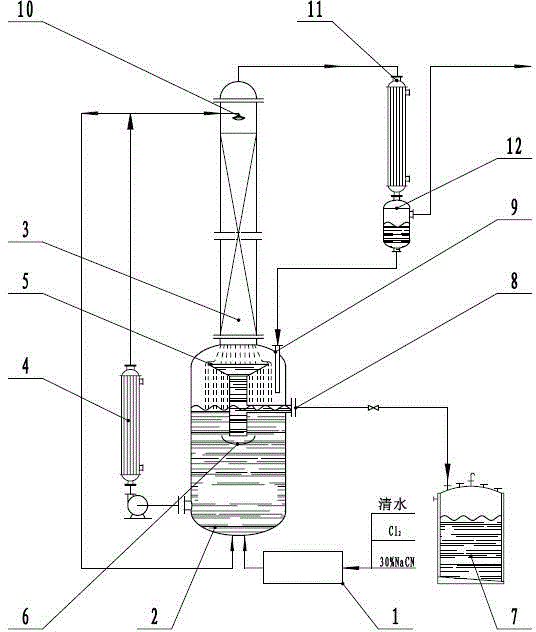

Chlorination reaction device and chlorination reaction technology for preparing cyanogen chloride

The invention provides a chlorination reaction device and a chlorination reaction technology for preparing cyanogen chloride. Chlorination reaction is carried out at a relatively low temperature in the divided three steps of pre-reaction, intermediate reaction and post-reaction. Cyanide is almost completely consumed, and the product residence time is shortened by the technology, so that unnecessary side reactions can be removed, and the raw material yield is maximized.

Owner:营创三征(营口)精细化工有限公司

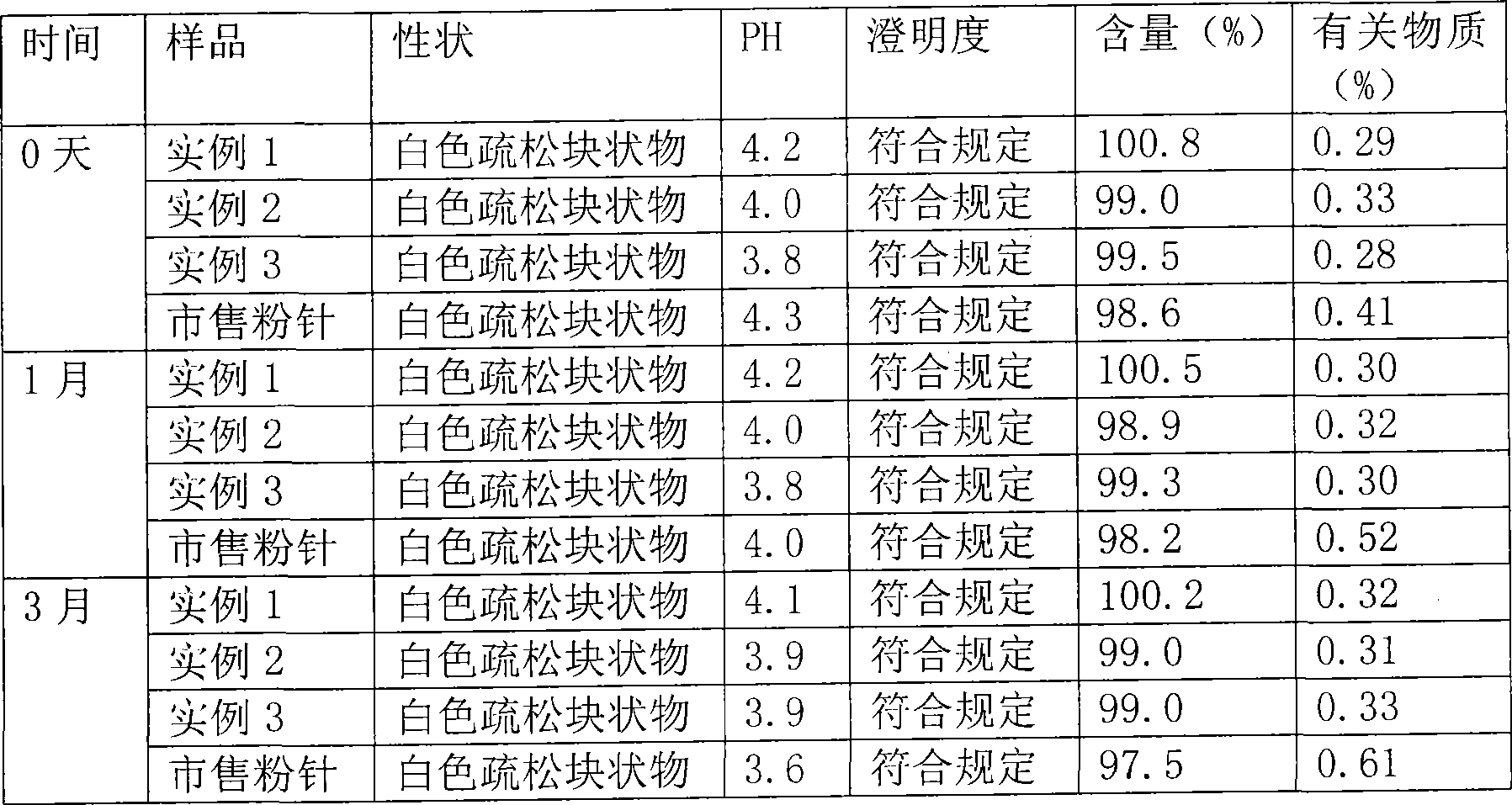

Meclofenoxate hydrochloride preparation freeze-drying technique and preparation method thereof

InactiveCN101455646AReduce hydrolysis reactionImprove bioavailabilityPowder deliveryOrganic active ingredientsMANNITOL/SORBITOLFreeze-drying

The present invention relates to a technique of lyophilized preparation of meclofenxate hydrochloride and a preparing method thereof. According to the invention, mannitol with effective dose of medicament is added with injection water and is dissolved. The meclofenxate hydrochloride with effective dose of medicament is added and mixed to uniform. The pH value is adjusted to 3-5. The obtained preparing is adsorbed with 0.01% of active carbon and is filtered. Then free drying is executed for preparing the lyophilized preparation. The meclofenxate hydrochloride in the invention is enveloped by macromolecule material and greatly reduces the hydrolytic reaction of meclofenxate hydrochloride. Therefore the lyophilized preparation of meclofenxate hydrochloride prepared by the invention has enough stability in water and can totally satisfy the requirement of clinical medicine taking. Furthermore the lyophilized preparation of meclofenxate hydrochloride prepared by the invention can be stably and slowly released. The bioavailability of meclofenxate hydrochloride is increased and transparency after re-dissolving is excellent.

Owner:朗美药业(武汉)有限公司

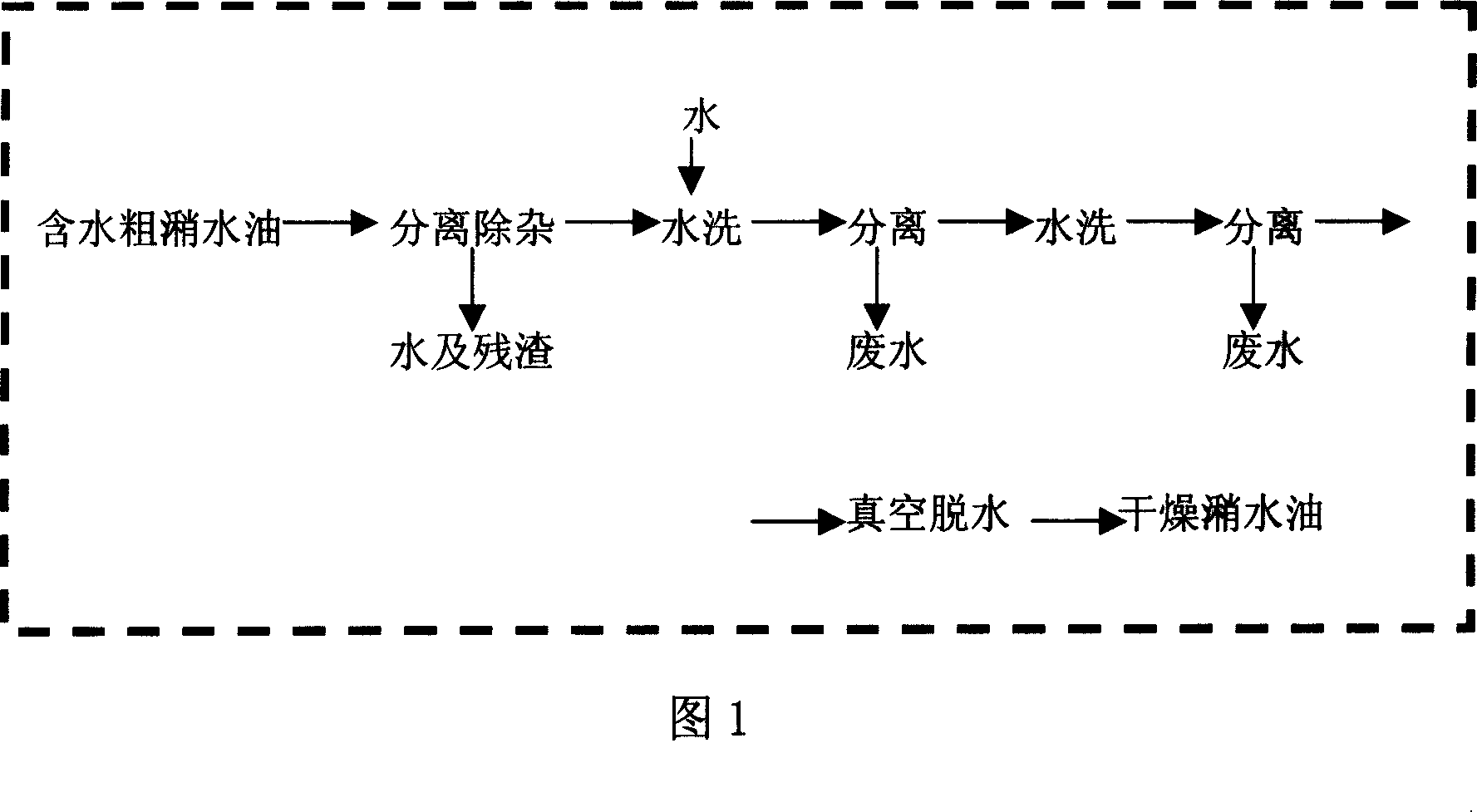

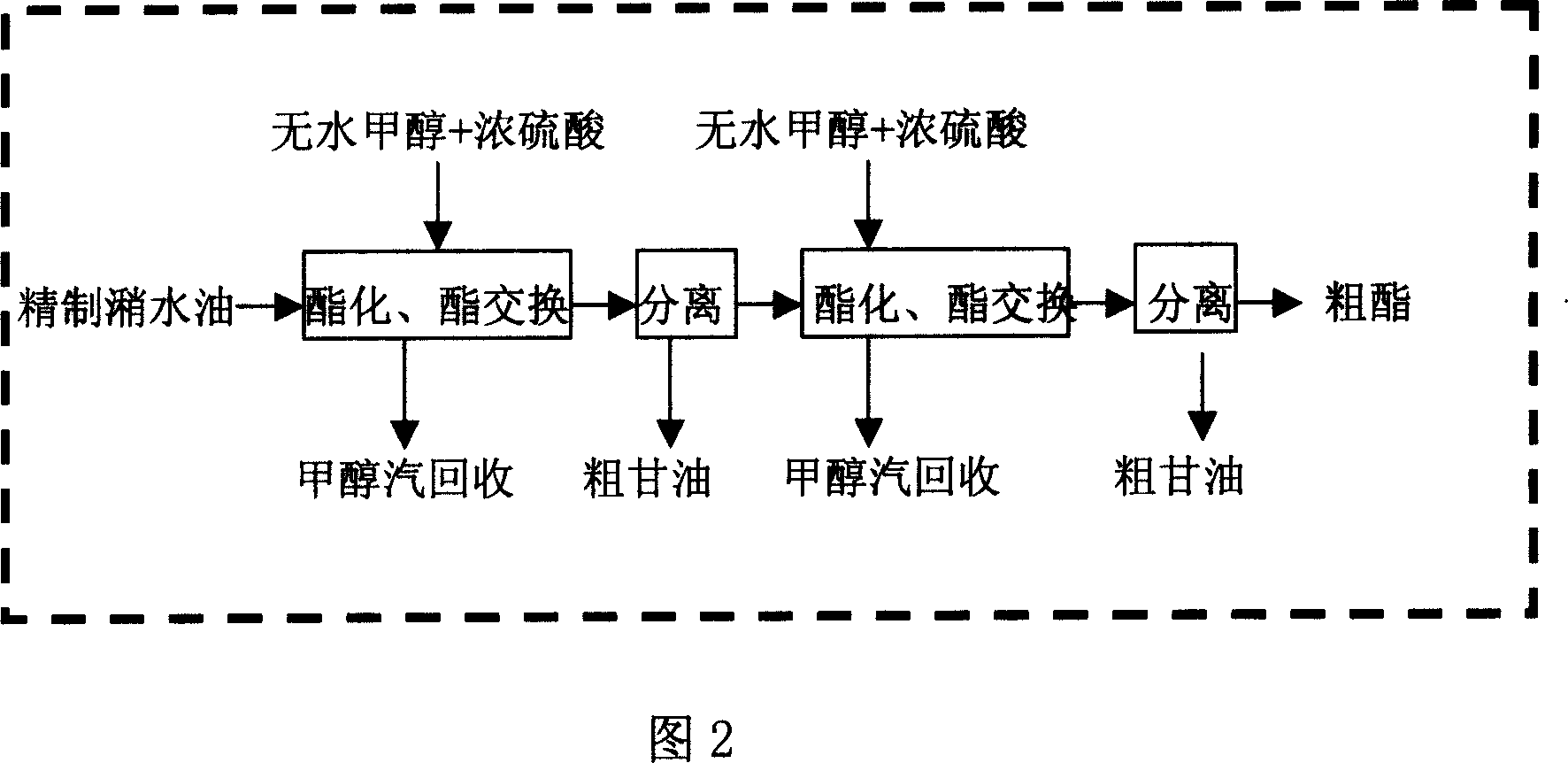

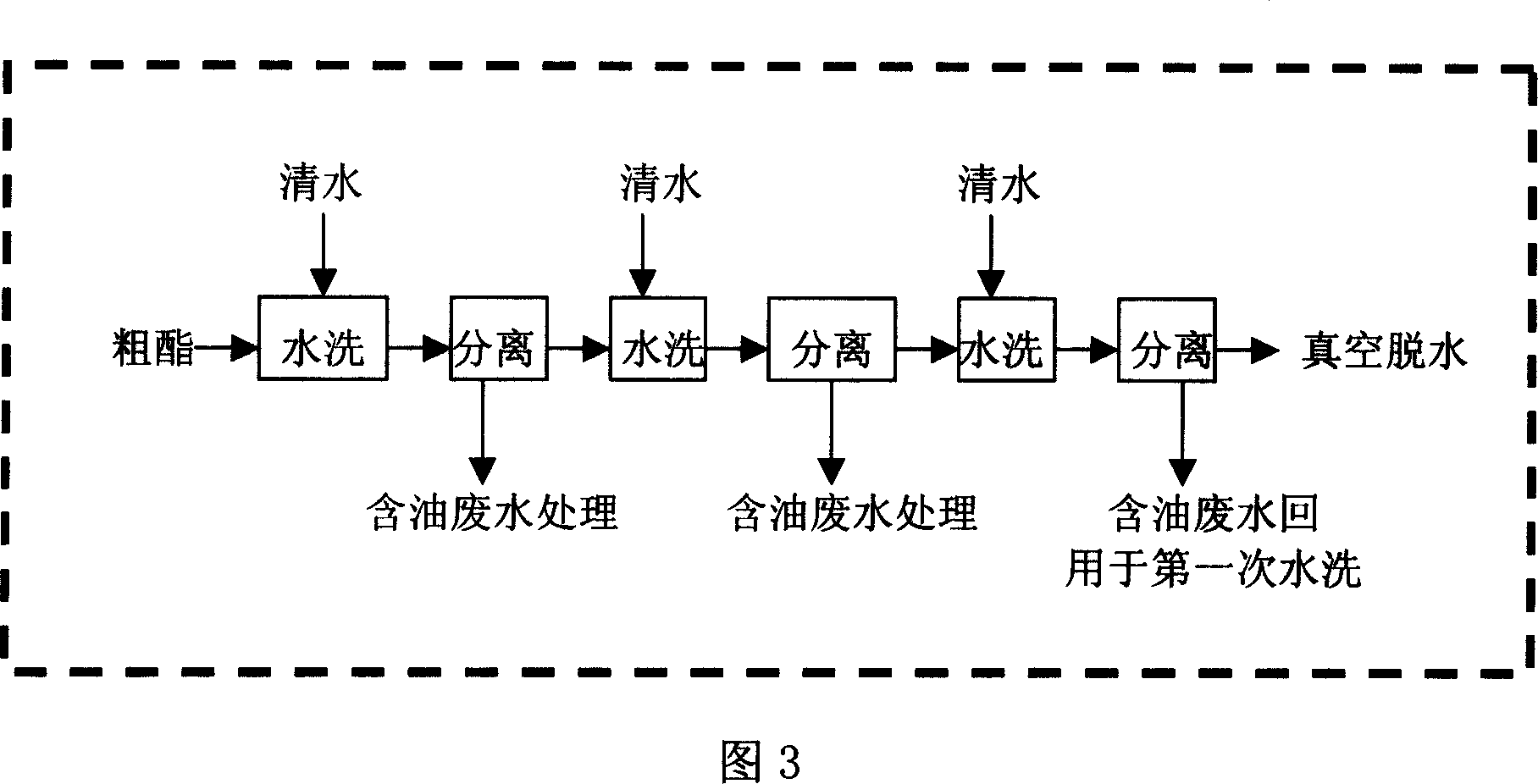

Method for preparing biological diesel by hogwash oil

InactiveCN101063040ASimple cleaning processReduce pretreatment costsBiofuelsLiquid hydrocarbon mixture productionFatty acid methyl esterChemistry

The invention discloses a processing method with water oil to prepare biological diesel, which comprises the following steps: 1 pretreating rough water oil with water; getting refined water oil; 2 esterifying the refined water oil; proceeding ester exchange; getting rough eater; 3 washing the rough eater; getting neutral rough ester; 4 distilling the neutral rough ester; getting the product. The each technical index of this biological diesel can reach request, which possesses very high practical value.

Owner:广东茵绿环境科技有限公司

Method for preparing D-glucosamine hydrochloride

InactiveCN102492000AThe concentration of hydrochloric acid is stableRapid hydrolysisSugar derivativesSugar derivatives preparationHydrolysateDecomposition

A method for preparing D-glucosamine hydrochloride includes the steps: placing chitin into a reaction tank, adding hydrochloric acid with stirring and heating the reaction tank for hydrolysis; uninterruptedly leading hydrochloric acid gas into hydrolysate in backflow hydrolysis; obtaining a solid crude product after cooling, precipitating and leaching the hydrolysate; adding deionized water and activated carbon into the crude product for decolorization prior to filtering so that faint yellow liquor is obtained; and the hydrochloric acid is recovered by means of vacuum concentration, obtaining a wet refined product by centrifugally dewatering concentrated materials and washing the wet refined product in alcohol prior to vacuum drying so that finished product crystals are obtained. Since the hydrochloric acid gas is led into the hydrolysate, the concentration of the hydrochloric acid of the hydrolysate is kept stable, a hydrolysis process is accelerated, and time for hydrolysis reaction is shortened. Besides, by the aid of increase of the hydrochloric acid concentration, the hydrolysis temperature can be decreased, and decomposition of the D-glucosamine hydrochloride is reduced. By the aid of the method, yield is increased, quality of the D-glucosamine hydrochloride is improved, and energy consumption and production cost are reduced.

Owner:石狮市华宝海洋生物化工有限公司

Special silica gel with high coefficient of thermal conductivity for electronic industries and preparation method thereof

InactiveCN109593366AGood dispersionGood viscosity effectPlastic/resin/waxes insulatorsHeat-exchange elementsBoron nitrideSilica gel

The invention discloses special silica gel with high coefficient of thermal conductivity for electronic industries. The special silica gel with the high coefficient of thermal conductivity is preparedfrom long-chain alkyl silicone oil (viscosity 600-900mm<2> / s), polyether silicone oil (viscosity 200-400mm<2> / s), trifluoropropyl silicone oil (viscosity 400-600mm<2> / s), 6-11 parts of zinc oxide (1micrometers), spherical aluminum oxide (20 micrometers), aluminum nitride (10 micrometers), boron nitride (3 micrometers), silicon carbide (5 micrometers), sodium hydrochloride, polydimethylsiloxane,sulfonated grapheme, 1-hydroxybenzotriazole, dicyclohexylcarbodiimide, and N-methylpyrrolidone. The invention also discloses a preparation method of the special silica gel with the high coefficient ofthermal conductivity for electronic industries.

Owner:江苏中恒电子新材料有限公司

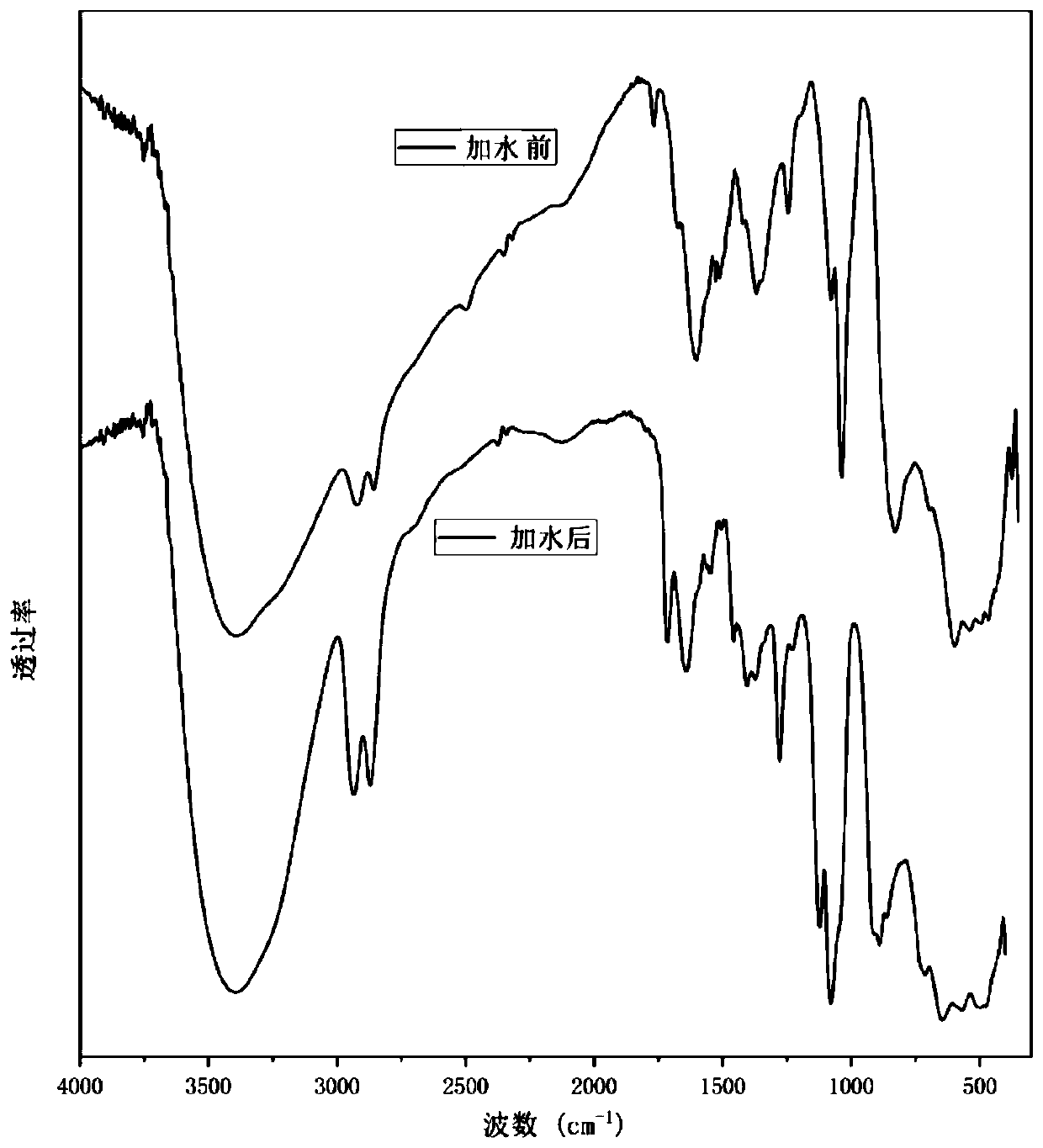

Method for preparing titanium-based polyester through DMT process

ActiveCN111019102AHigh melting pointAvoid reunionMonocomponent polyesters artificial filamentPolyesterTrans esterification

The invention relates to a method for preparing titanium-based polyester through a DMT process. The preparation method comprises the following steps: mixing DMT, EG, a polyester titanium-series catalyst composite material system and an ester exchange catalyst, and then carrying out an esterification reaction and a condensation polymerization reaction to obtain the titanium-based polyester, whereinthe polyester titanium-series catalyst composite material system is mainly composed of a polyester prepolymer with a polymerization degree of 5-30, and a flaky titanium-series polyester catalyst anda phosphorus-series stabilizer which are dispersed in the polyester prepolymer. According to the method for preparing the titanium-based polyester through the DMT process in the invention, the polyester prepolymer with a polymerization degree of 5-30 is used to wrap the flaky titanium-series polyester catalyst with excellent hydrolysis resistance, and the polyester titanium-series catalyst composite material only melts at a high temperature to release the titanium polyester-series catalyst, so the hydrolysis reaction of the titanium-series polyester catalyst caused by water contained in the storage and transportation process can be reduced or even avoided, the high dispersity and high activity of the titanium-series polyester catalyst are ensured, and the yellowing of the titanium-based polyester is reduced.

Owner:上海慧翌新材料科技有限公司 +1

Method for preparing copper-iron alloy based on electro-deposition method

ActiveCN114250489ALow costUniform thicknessPhotography auxillary processesProcess efficiency improvementElectrolytic agentElectromechanics

The invention discloses a method for preparing a copper-iron alloy based on an electro-deposition method, which belongs to the field of electrochemical deposited alloys, and comprises the following steps: by taking a sulfate aqueous solution system as an electrolyte, electroplating copper on a copper plate or a stainless steel plate as a negative electrode and an oxygen evolution positive electrode as a positive electrode, depositing by adopting a pulsed power supply, and applying pulse voltage; and the circulation speed, the pH value, the current density, the pulse width, the deposition temperature, the deposition time and the distance between the positive electrode and the negative electrode of the electrolyte are controlled, and the copper-iron alloy is obtained. The copper-iron alloy prepared by the method is controllable in component and thickness, excellent in mechanical property and corrosion resistance, has electromagnetic shielding performance, compact microstructure and fine crystal, has excellent mechanical property, electrical property, magnetic property and corrosion resistance, and can be widely applied to the industrial fields of electronics, medical treatment, electromechanics, communication and the like.

Owner:SANMENXIA HONGXIN NONFERROUS METALS

Meclofenoxate hydrochloride microcapsule and method for preparing injection thereof

InactiveCN101278924AReduce hydrolysis reactionSlow releaseOrganic active ingredientsNervous disorderChemistryMeclofenoxate Hydrochloride

The invention provides a meclofenoxate hydrochloride microcapsule for injection and a production method thereof. The meclofenoxate hydrochloride microcapsule for the injection is composed of the meclofenoxate hydrochloride and adjuvant, which is characterized in that the adjuvant contains gelatin, dextran and emulsifier. The invention also provides the production method of a meclofenoxate hydrochloride freeze-dry powder and injection. As the meclofenoxate hydrochloride microcapsule with high stability in water is used, the meclofenoxate hydrochloride is not hydrolyzed when redissolving; the clarity is good after redissolving; thereby a product in the invention has the advantages of good stability and good quality, which is good for storing the product for a long time.

Owner:HAINAN LINGKANG PHARMA CO LTD

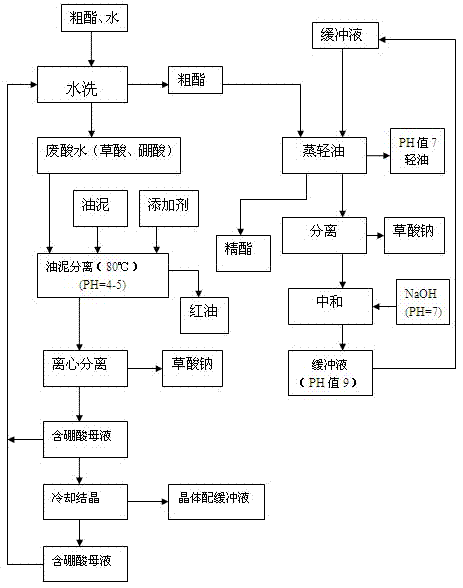

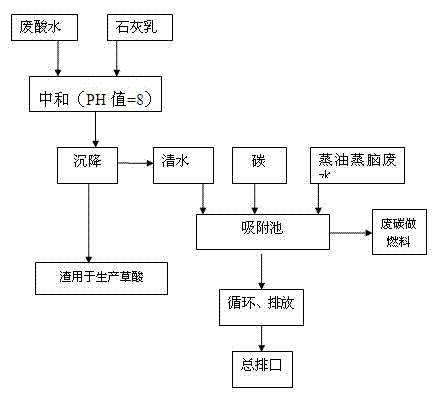

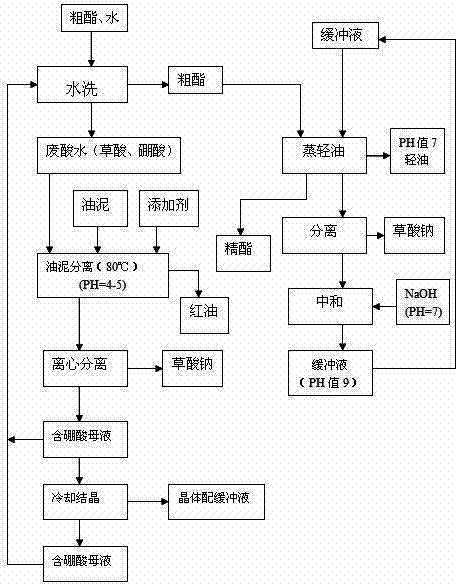

Postprocessing method for synthetic borneol

ActiveCN102584577AIncrease concentrationAdjust affinityPreparation from carboxylic acid saltsSolid fuelsSurface-active agentsNonionic surfactant

A postprocessing method for synthetic borneol comprises the steps of preparing the raw materials of synthetic borneol to obtain raw ester according to a conventional production method, then washing the ester by water, postprocessing the washed ester through a light oil steaming method, mixing the waste water (including oxalic acid and boric acid) obtained by washing the raw ester and oil mud generated by postprocessing refined ester obtained by steaming the light oil, adding non-ionic surface active agent to be taken as a demulsifying agent, conducting oil-mud separation to obtain red oil, and postprocessing the waste water after the oil-mud separation so as to achieve the purposes of recycling and discharging after reaching the standard. If the boric acid content is too high, part of boric acid crystals can be separated out by cooling and crystallizing, so that mother liquor containing boric acid achieves the demanded index and then returns to be taken as a water source for washing the raw ester; and the boric acid crystals can return to be taken as the water source for washing the raw ester through a prepared buffer solution.

Owner:WUZHOU HUANGPU CHEM PHARM CO LTD

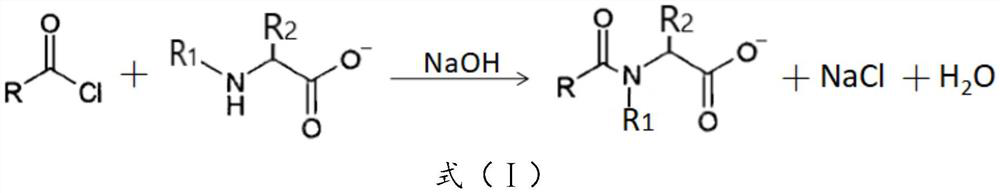

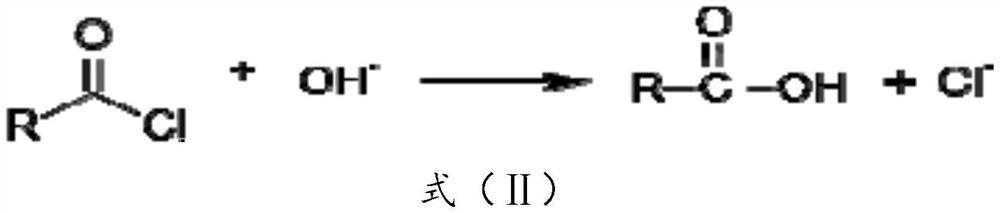

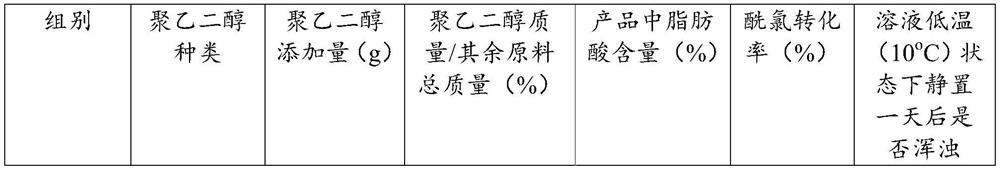

Preparation method of amino acid surfactant

PendingCN114380711AIncrease contact surfaceImprove conversion rateOrganic compound preparationTransportation and packagingActive agentPolyethylene glycol

The invention provides a preparation method of an amino acid surfactant, and relates to the field of fine chemical engineering. The preparation method of the amino acid surfactant provided by the invention comprises the following steps: mixing water, amino acid and polyethylene glycol, adding alkali liquor to adjust the pH value of a mixed system to 8-13, adjusting the temperature of the mixed system to 10-60 DEG C, adding acyl chloride and alkali liquor into the mixed system, maintaining the pH value of the mixed system in a range of 8-13, and reacting for 2-4 hours to obtain the amino acid surfactant. And reacting to obtain the N-acylamino acid surfactant. According to the invention, polyethylene glycol is introduced into a reaction system on the basis of preparing the N-acylamino acid surfactant through a Shore-Baumann condensation reaction at present, so that the contact surface between acyl chloride and amino acid can be increased, the conversion rate of acyl chloride can be increased, the reaction time can be shortened, and the hydrolysis reaction of materials can be reduced; generation of fatty acid and fatty acid salt is effectively reduced, and the problems of unstable product indexes, turbidity and the like are solved.

Owner:广州花语精细化工有限公司

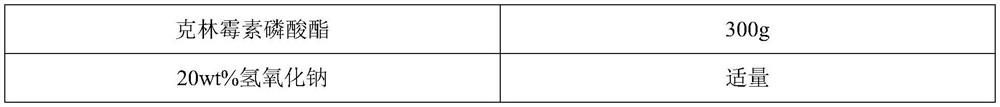

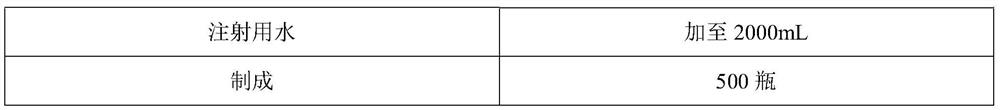

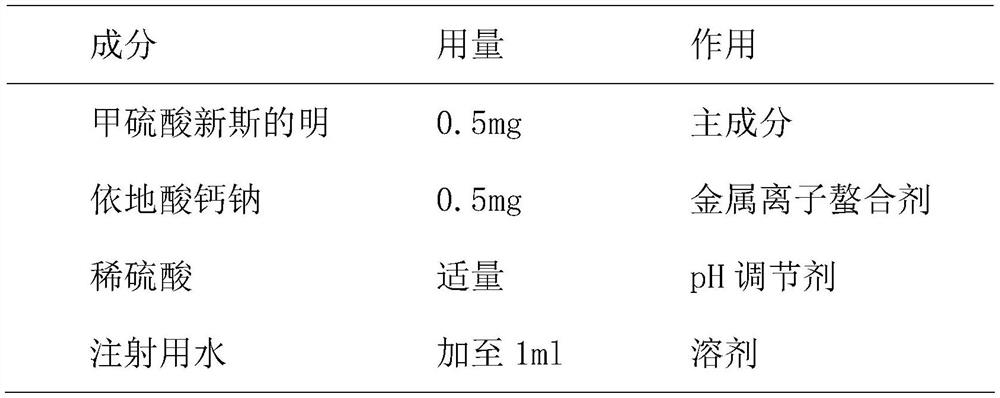

Preparation method of clindamycin phosphate freeze-dried powder injection for injection

ActiveCN113081975AReduce hydrolysisImprove stabilityAntibacterial agentsOrganic active ingredientsClindamycin PhosphateFreeze-drying

The invention provides a preparation method of clindamycin phosphate freeze-dried powder injection for injection, and belongs to the technical field of medicine preparation. The preparation method comprises the steps that water for injection with the temperature smaller than or equal to 25 DEG C is taken, clindamycin phosphate is added in batches, meanwhile, an alkali solution is slowly dropwise added, the system temperature is maintained to be smaller than or equal to 25 DEG C, and the aqueous alkali is dropwise added until the clindamycin phosphate is dissolved and the pH value of the system is 6.0-6.4, and decoloration, degerming filtration and freeze drying is carried out to obtain the clindamycin phosphate freeze-dried powder injection for injection. By adjusting the feeding mode and the dissolving temperature of the clindamycin phosphate and finally adjusting the pH value, the hydrolysis reaction of the clindamycin phosphate is effectively reduced, the stability of the clindamycin phosphate is improved, the impurity content of the finished product is reduced, and the problem that the impurity content of the finished product is relatively high is solved.

Owner:HAINAN JINRUI PHARMA CO LTD

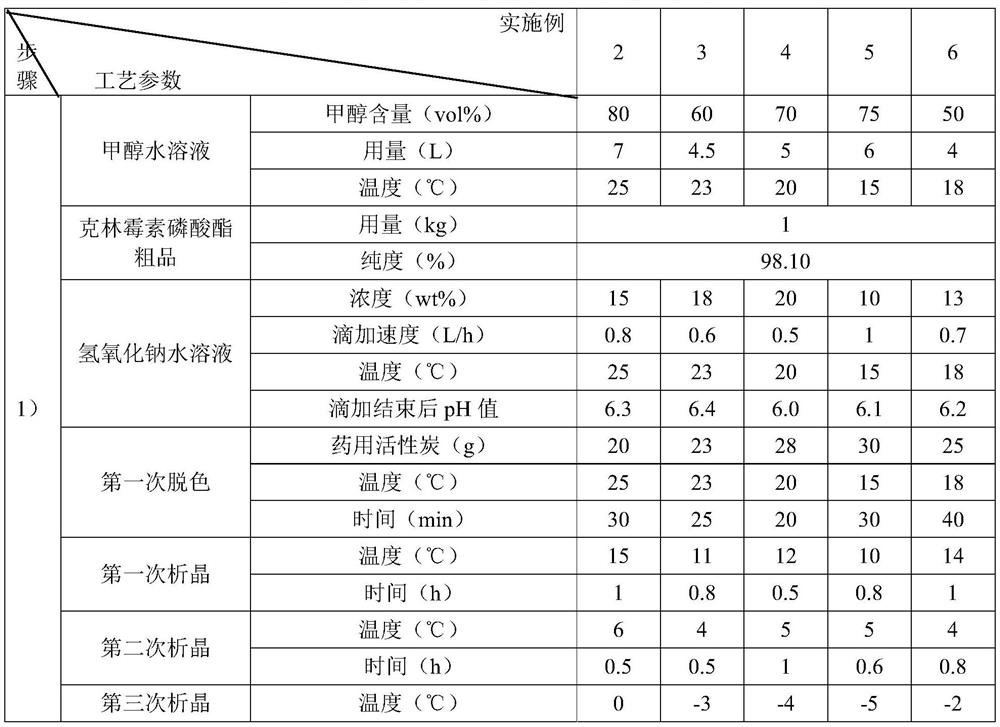

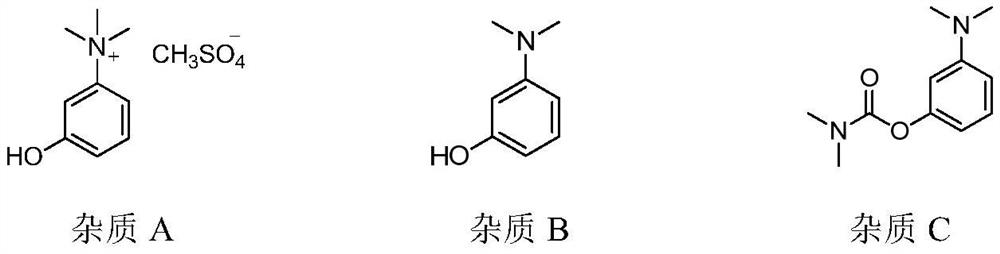

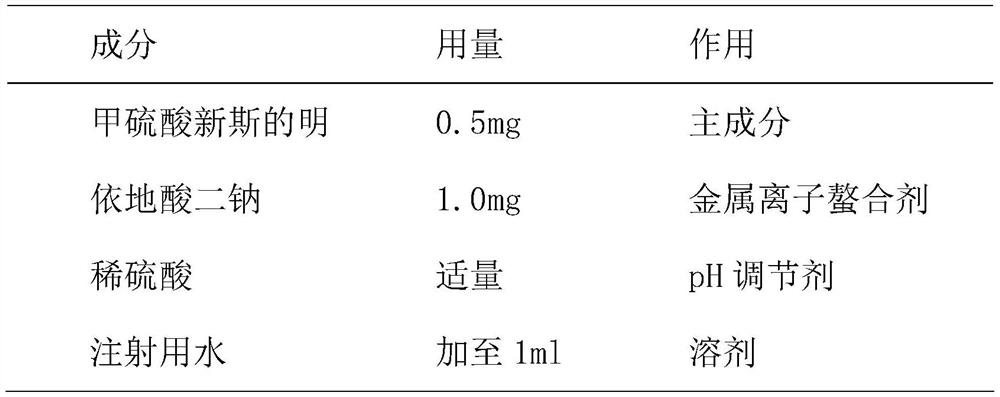

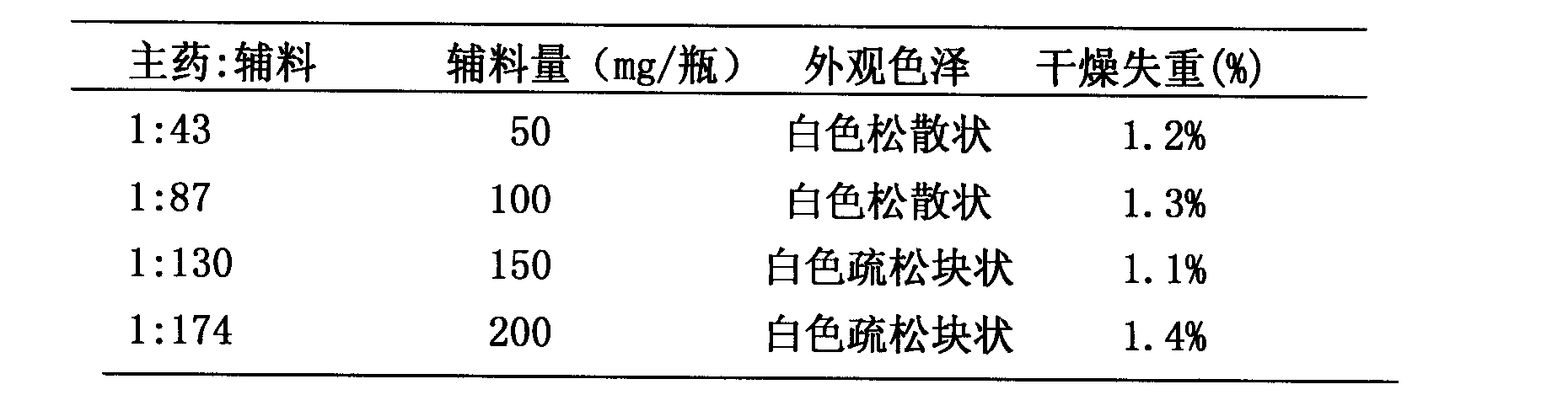

Neostigmine methylsulfate composition and preparation method thereof

PendingCN113230206AReduce dosageReduce pyrogensNervous disorderInorganic non-active ingredientsBiotechnologyMicroorganism

The invention discloses a neostigmine methylsulfate composition and a preparation method thereof. The neostigmine methylsulfate composition comprises an effective amount of neostigmine methylsulfate; a chelating agent; a pH adjusting agent; and water. The composition is simple and small in dosage, the production cost is reduced, the production risk of microorganism and bacterial endotoxin pollution is reduced, the high-temperature resistance of the neostigmine methylsulfate composition is remarkably improved, and the amount of impurity A can be reduced by half after the composition is subjected to high-temperature sterilization.

Owner:CHENGDU XINJIE HIGH TECH DEV CO LTD

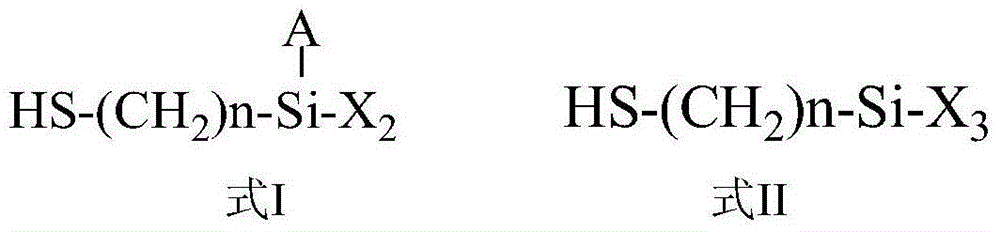

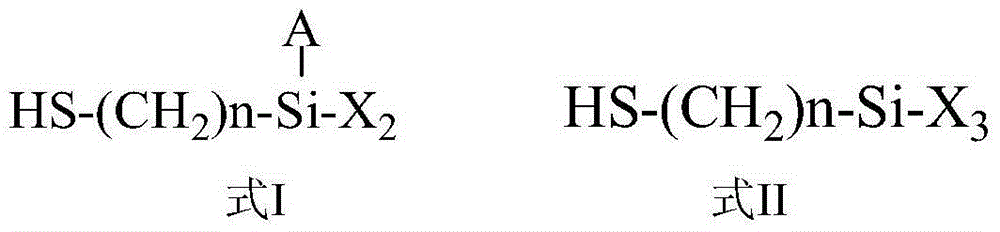

Friction modifier for drilling fluids, and drilling fluid

The invention provides a friction modifier for drilling fluids. The friction modifier includes a mercaptoalkyl silane coupling agent represented by formula I or formula II, and a composition of a lubricant for drilling fluids; and in the formula I and the formula II, n is an integer between 1 and 3, A is a methyl group or an ethyl group, and X is selected from chlorine, methoxy groups, ethoxy groups, methoxyethoxy groups and acetoxy groups. The mercaptoalkyl silane coupling agent can be used in the friction modifier for drilling fluids as an additive, so the friction resistance reduction effect of traditional lubricants is enhanced, and the drilling rate is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Metal-free sulfur-doped carbon material hydrogen peroxide electroreduction catalyst and preparation method

ActiveCN104051748BWide variety of sourcesLow priceMaterial nanotechnologyPhysical/chemical process catalystsOxygenNitrogen gas

Owner:HARBIN ENG UNIV

A drying method for hyaluronic acid

The invention provides a method for drying hyaluronic acid, which includes the following steps: adding organic solvent I containing volatile silicone oil to a solution containing hyaluronic acid, and after precipitating, discarding the supernatant; Wash with organic solvent II containing volatile silicone oil to obtain a precipitate, and obtain the product after drying. The volume fraction of the volatile silicone oil in organic solvent I is 1%-10%; the volume fraction in organic solvent II is 20%-60%. The hyaluronic acid drying method provided by the present invention is suitable for hyaluronic acid samples of different molecular weights and different concentrations. After drying using the method of the present invention, the weight loss on drying does not exceed 5%, and the organic solvent residues comply with regulations.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD +1

Lyophilized injection of lentinan and preparation process thereof

InactiveCN1969876BReduce lossesSafe choiceOrganic active ingredientsPowder deliveryNeutral Amino AcidsFreeze-drying

The invention discloses a freeze dried of mushroom polysaccharide, which comprises the following steps: adopting neutral amino acid as rack agent; blending evenly; reducing the density of sodium hydroxide; filtering; adjusting pH value.

Owner:成都普瑞法科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com