Preparation method of clindamycin phosphate freeze-dried powder injection for injection

A technology of clindamycin phosphate and freeze-dried powder injection, which is applied in the field of preparation of clindamycin phosphate freeze-dried powder injection to achieve the effect of avoiding the precipitation of impurities, avoiding decomposition and reducing hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

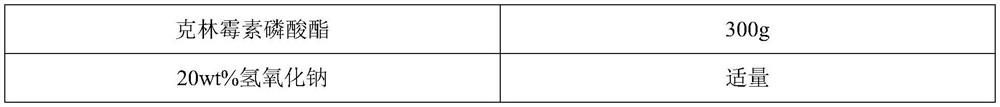

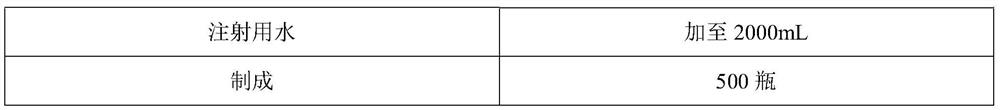

[0037] Embodiment 1 A kind of preparation method of clindamycin phosphate freeze-dried powder for injection

[0038] This embodiment is a preparation method of clindamycin phosphate freeze-dried powder for injection. The specific preparation process includes the following steps carried out in sequence:

[0039] 1) refining of clindamycin phosphate

[0040] Take 5L of methanol aqueous solution with a temperature of 20°C and a methanol content of 71.5vol%, add 1 kg of crude clindamycin phosphate [purity 98.10%, according to "Chinese Pharmacopoeia" (2015 edition of four general rules 0512), using high performance liquid chromatography Determination], stir and fully disperse in methanol aqueous solution, slowly add 20wt% sodium hydroxide aqueous solution dropwise at a rate of 0.5L / h, keep the system temperature at 20°C during the dropping process, and stir to fully dissolve clindamycin phosphate After the crude ester, add aqueous sodium hydroxide solution dropwise until the crude...

Embodiment 2~6

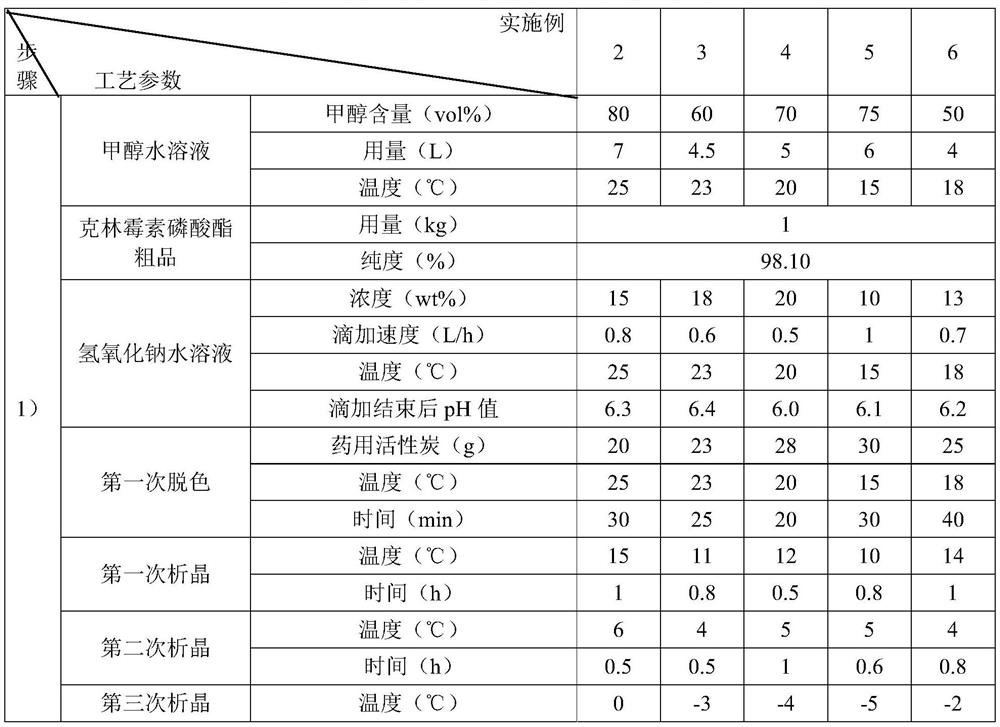

[0060] Example 2-6 The preparation method of clindamycin phosphate freeze-dried powder for injection

[0061] Examples 2 to 6 are respectively a preparation method of clindamycin phosphate freeze-dried powder for injection, and their steps are basically the same as those in Example 1, except that the amount of raw materials and process parameters are different. See Table 3:

[0062] List of various technological parameters in table 3 embodiment 2~6

[0063]

[0064]

[0065]

[0066] The content of the other parts of Examples 2-6 is the same as that of Example 1.

[0067] The clindamycin phosphate freeze-dried powder for injection prepared in Examples 1-6 has good stability and clarity, high main drug content, less impurities, smooth surface, good appearance and excellent resolubility.

experiment example 1

[0068] Influencing factors in experimental example 1 clindamycin phosphate refining method

[0069] Using the same batch of clindamycin phosphate crude product (purity 98.10%), comparative examples 1~10 and the comparative test of clindamycin phosphate refining process in embodiment 1, the difference is only in:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com