Chlorination reaction device and chlorination reaction technology for preparing cyanogen chloride

A chlorination reaction and cyanogen chloride technology, applied in the direction of cyanogen halide, cyanide, inorganic chemistry, etc., can solve the problem of no increase in the yield of raw materials, and achieve the effects of reducing residence time, reducing the probability of occurrence, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

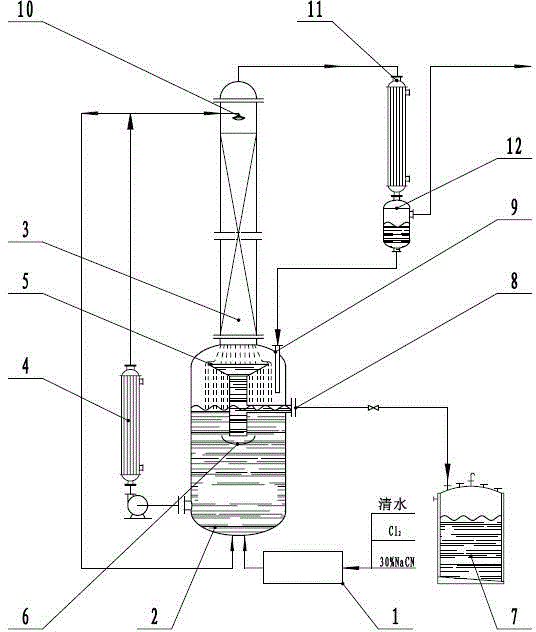

[0019] Such as figure 1 Shown a kind of chlorination reaction device that is used to prepare cyanogen chloride, comprises prereactor 1, intermediate reaction tank 2 and rear reaction tower 3, and prereactor 1 is connected with the tank bottom of intermediate reaction tank 2, and intermediate reaction tank 2 and post-reaction tower 3 are vertically connected, and pre-reactor 1 is provided with raw material inlet, and post-reaction tower 3 is provided with packing layer, and is provided with the outlet of gas phase product at its top; In addition, The intermediate reaction tank 2 is connected to the liquid phase inlet on the top of the rear reaction tower 3 through the external circulation system provided outside it. The external circulation system is provided with a cooler 4, and a distributor 10 is provided at the liquid phase entrance. An overflow pipe 8 is also provided on the tank wall of the reaction tank 2, and the overflow pipe 8 is connected with the collection tank 7. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com