Method for preparing biological diesel by hogwash oil

A technology of biodiesel and process method, which is applied in the field of biodiesel preparation, can solve the problems of increased energy consumption, biodiesel cost and application restrictions, and high raw material cost, so as to reduce energy consumption, save chemical dosage, improve reaction temperature and reaction speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

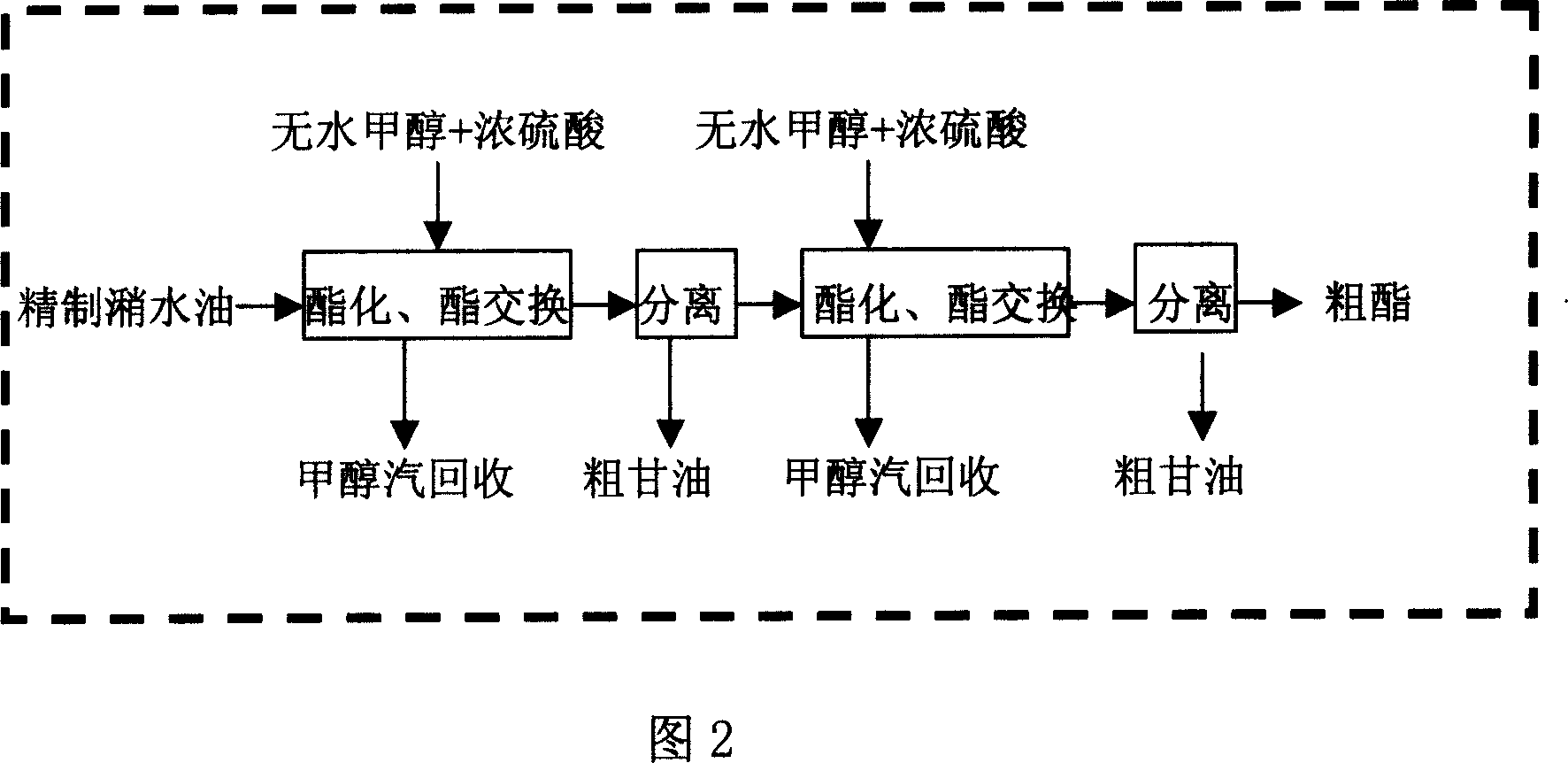

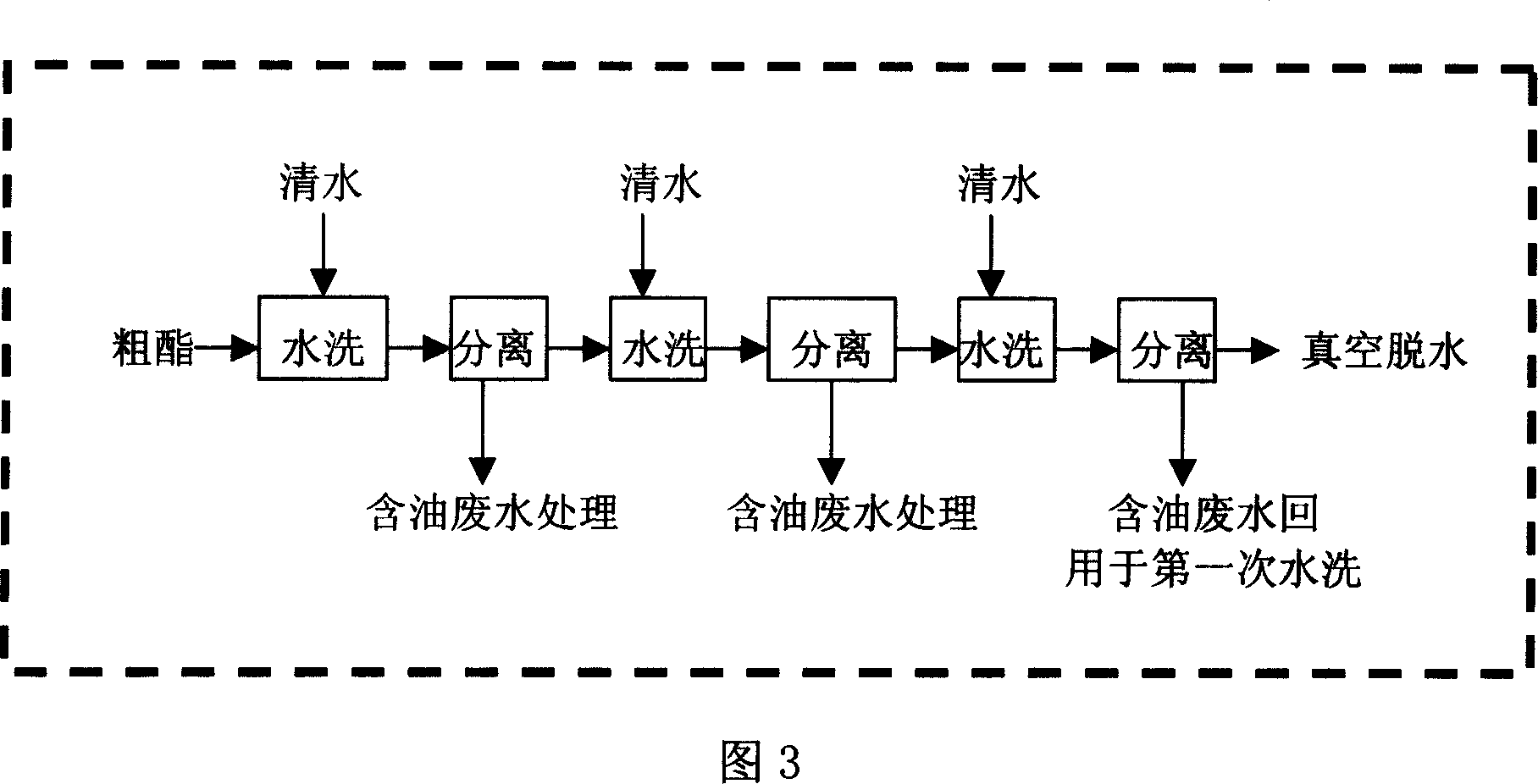

[0024] A process method for preparing biodiesel from hogwash oil, comprising the following steps: ① pretreating the crude hogwash oil containing water to obtain refined hogwash oil; ② performing esterification and transesterification on the refined hogwash oil to obtain crude ester; Wash the esters with water to obtain neutral crude esters; ④ Distill the neutral crude esters to obtain refined fatty acid methyl esters, namely biodiesel. Each step will be described in detail below in conjunction with the accompanying drawings.

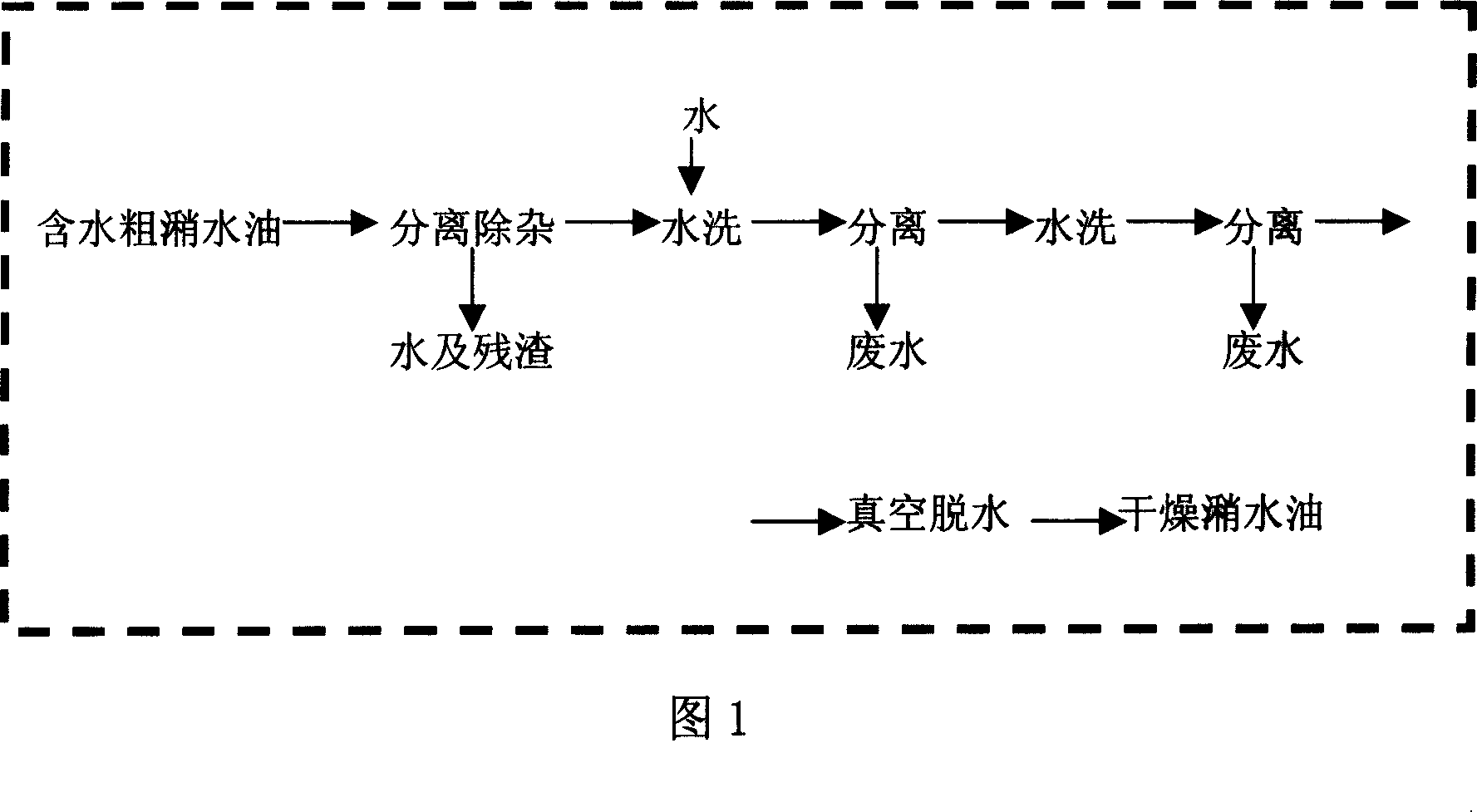

[0025] As shown in Figure 1, the pretreatment method in step ① is: a. Separating and removing impurities from the water-containing crude hog oil to remove water and residues; b. Adding water to wash, and then separating and removing waste water; c. Step b can be repeated Multiple times; d. Carry out vacuum dehydration again to obtain refined hogwash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com