Friction modifier for drilling fluids, and drilling fluid

A friction modifier and drilling fluid technology, which is applied in the field of friction modifier for drilling fluid and water-based drilling fluid, can solve the problems that the friction coefficient of drilling fluid cannot be further reduced, and achieve corrosion protection, reduce flow resistance, The effect of reducing drill tool wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

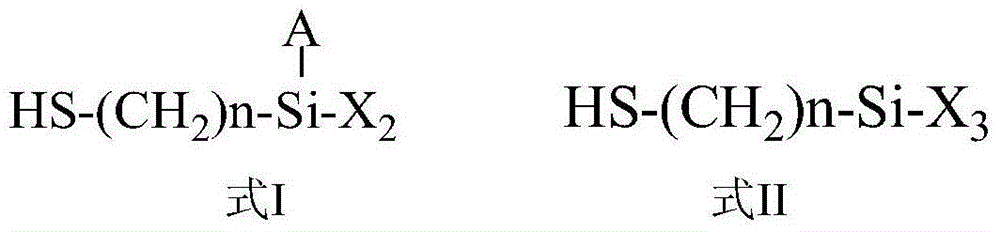

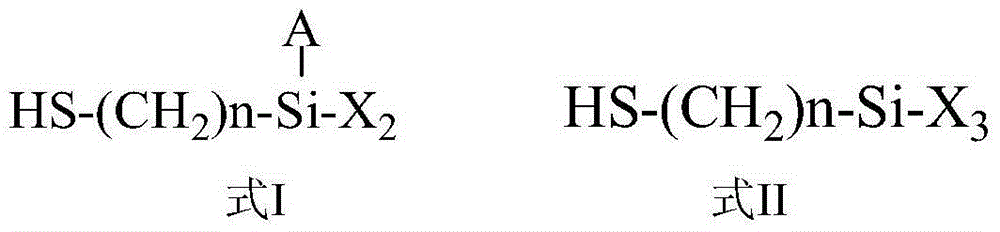

Method used

Image

Examples

Embodiment 1 and comparative example 1

[0022] The purpose of this example is to illustrate the synergistic effect of mercaptoalkylsilane coupling agent and conventional drilling fluid lubricants. The experiment was carried out in a 5% by weight bentonite base slurry. In the specific oil and gas development process, other necessary additives can be added to the base slurry to prepare water-based drilling fluid.

[0023] Table 1 lists the lubricating effect of the mercaptoalkylsilane coupling agent in this example when it is used in conjunction with a variety of different lubricants. Among them, the weight ratio of the lubricant used in Example 1-b to Example 1-f (respectively Lube167, Mill lube, SMJH-1, LUB-N and GM-I) to the mercaptoalkylsilane coupling agent Both are 95:5. Specifically, add 5g of mercaptoalkylsilane coupling agent and 3g of emulsifier to 95g of liquid lubricant, stir and mix evenly at room temperature, and prepare the friction modifier for drilling fluid of the present invention.

[0024] The sp...

Embodiment 2 and comparative example 2

[0029] The purpose of this example is to illustrate the application effect of the friction modifier for drilling fluid in potassium silicate drilling fluid in the present invention. Alkaline silicate drilling fluid is environmentally friendly and widely used in drilling sites, but its friction coefficient is relatively high due to the adsorption of silicate on metal drilling tools. Among them, the potassium silicate drilling fluid is prepared from 460ml of water, 40ml of potassium silicate, 2g of xanthan gum, 2g of starch, 2g of polyanionic cellulose and 30g of bentonite, and it is placed at room temperature for 24 hours before use.

[0030]Table 2 lists the lubricating effect of the mercaptoalkylsilane coupling agent in this example on the potassium silicate drilling fluid when it is used in conjunction with a variety of different lubricants. Wherein, the weight ratios of lubricants (diesel, Lube167, Mill lube, SMJH-1 and LUB-N) to mercaptoalkylsilane coupling agent used in E...

Embodiment 3 and comparative example 3

[0036] The purpose of this example is to illustrate the application effect of different concentrations of drilling fluid friction modifiers in potassium silicate drilling fluid in the present invention. Wherein, the configuration of the potassium silicate drilling fluid is the same as in Example 2.

[0037] Table 3 lists the lubricating effect of the obtained friction modifier in different concentrations in the drilling fluid when the mercaptoalkylsilane coupling agent is used in conjunction with the lubricant Lube167 in this example. Wherein, the weight ratio of lubricant Lube167 and mercaptoalkylsilane coupling agent used in embodiment 2-a to embodiment 2-d is 95:5. Specifically, add 5g of mercaptoalkylsilane coupling agent and 3g of emulsifier to 95g of liquid lubricant, stir and mix evenly at room temperature, and prepare the friction modifier for drilling fluid of the present invention.

[0038] The specific steps of each comparative example and example experiment in Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com