Catalyst successive impregnation equipment and method

A technology for impregnating equipment and catalysts, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of reduced catalyst yield, increased filtration difficulty, increased fine powder content, etc., to achieve shortening Soaking time, good impregnation uniformity, less broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 illustrates the effect of catalyst continuous impregnation equipment and method provided by the present invention for impregnating catalyst.

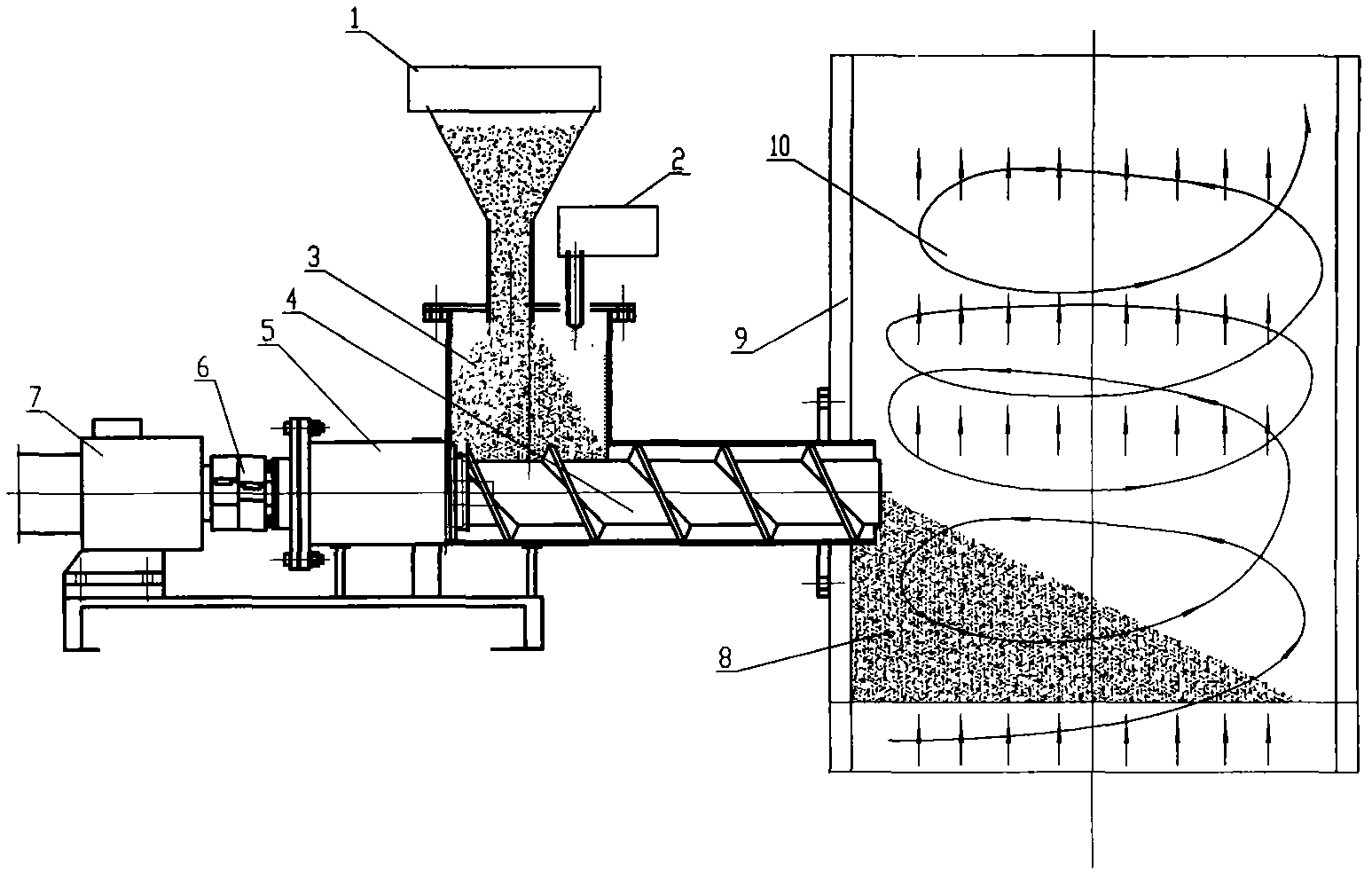

[0035] Such as figure 1 For the catalyst continuous impregnation equipment shown, the length of the catalyst continuous impregnation equipment is 1350 mm, the diameter of the conveying pipe of the conveying part is 100 mm, the length of the conveying part is 400 mm, the volume of the impregnating chamber is 3 L, and the inner diameter of the dryer is 600 mm. In the impregnation chamber, the distance between the outlet of the carrier continuous feeding system and the outlet of the impregnating liquid conveying system is 50 mm from the conveying part 4, the length of the conveying part extending into the side wall of the dryer is 20 mm, the conveying capacity of the catalyst carrier is 70 kg / h, and the impregnating liquid The conveying capacity is 105kg / h, and the design value of the conveying capacity of the conveying pa...

Embodiment 2

[0050] Example 2 illustrates the effect of the catalyst continuous impregnation equipment and method provided by the present invention.

[0051] Catalyst continuous impregnation equipment such as figure 1 As shown, the total length of the catalyst continuous impregnation equipment is 1750mm, the diameter of the conveying pipe of the conveying part is 150mm, the length of the conveying part is 600mm, the inner diameter of the dryer is 800mm, and the volume of the impregnation chamber is 8L. In the impregnation chamber, the outlet of the carrier continuous feeding system . The height of the outlet of the impregnation liquid delivery system from the delivery part 4 at the bottom of the impregnation chamber is 70mm, the length of the outlet of the delivery part extending into the side wall of the dryer is 20mm, and the designed handling capacity of the delivery part is 900Kg / h. The flash drying method is adopted in the dryer, and the internal temperature of the dryer is 180°C.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com