Method for synthesizing polyoxymethylene dimethyl ether through condensation, oxidation, polycondensation and etherification of methanol

A polyoxymethylene dimethyl ether, chemical synthesis technology, applied in polycondensation and etherification synthesis of polyoxymethylene dimethyl ether, methanol condensation, oxidation field, can solve the problem of reducing product yield, product separation difficulties, etc. Achieve the effect of improving purity and yield, reducing hydrolysis reaction, and strong selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

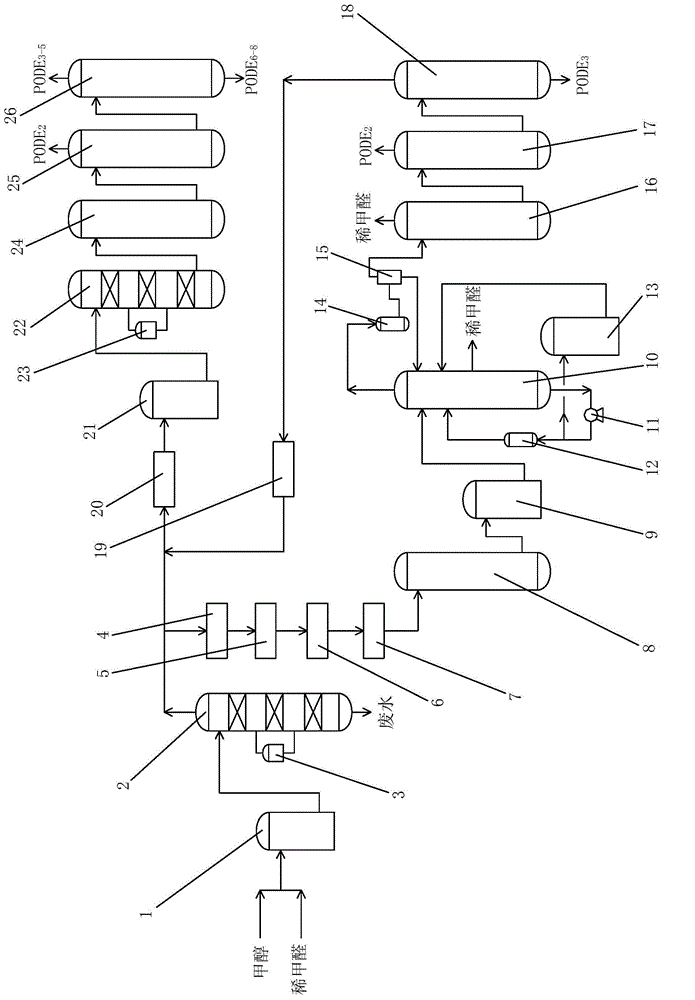

[0042] Such as figure 1 Shown, the synthesis method of the present embodiment is:

[0043] Step 1, methanol condensation to prepare methylal: according to the ratio of the molar ratio of methanol to formaldehyde of 2.0:1, methanol and dilute formaldehyde with a mass concentration of 5% are mixed and then sent to the reactor 1 filled with a catalyst for condensation reaction. The reaction temperature of the condensation reaction is 90°C, the reaction pressure is 8.0MPa, and then the material after the condensation reaction is sent to the first reactive distillation tower 2, and the number of sieve trays on the top of the first reactive distillation tower 2 is 30 , the number of sieve trays at the bottom of the tower is 30, the number of layers of the packed bed is 8 layers, the pressure at the top of the first reactive distillation tower 2 is controlled to be 50kPa, the temperature at the top of the tower is 47°C, and the temperature at the bottom of the tower is 115°C. The ra...

Embodiment 2

[0052] Such as figure 1 Shown, the synthesis method of the present embodiment is:

[0053] Step 1, methanol condensation to prepare methylal: according to the ratio of the molar ratio of methanol to formaldehyde of 3.0:1, methanol and dilute formaldehyde with a mass concentration of 20% are mixed and then sent to the reactor 1 filled with a catalyst for condensation reaction. The reaction temperature of the condensation reaction is 70°C, the reaction pressure is 5.0MPa, and then the material after the condensation reaction is sent to the first reactive distillation tower 2, and the number of sieve plates at the top of the first reactive distillation tower 2 is 20 , the number of sieve trays at the bottom of the tower is 20, the number of layers of the packed bed is 5 layers, the pressure at the top of the first reactive distillation tower 2 is controlled to be 30kPa, the temperature at the top of the tower is 45°C, and the temperature at the bottom of the tower is 108°C. The ...

Embodiment 3

[0062] Such as figure 1 Shown, the synthesis method of the present embodiment is:

[0063]Step 1, methanol condensation to prepare methylal: according to the ratio of the molar ratio of methanol to formaldehyde of 3.5:1, methanol and dilute formaldehyde with a mass concentration of 45% are mixed and then sent to the reactor 1 filled with a catalyst for condensation reaction. The reaction temperature of the condensation reaction is 60°C, the reaction pressure is 2.0MPa, and then the material after the condensation reaction is sent to the first reactive distillation tower 2, and the number of sieve trays on the top of the first reactive distillation tower 2 is 5 , the number of sieve trays at the bottom of the tower is 5, the number of layers of the packed bed is 2, the top pressure of the first reactive distillation tower 2 is controlled to be 5kPa, the top temperature is 42.3°C, the bottom temperature is 100°C, and the reflux ratio is 1.0, the material after the condensation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com