Method for preparing titanium-based matte polyester fiber through direct melt spinning and product

A polyester fiber, melt direct spinning technology, applied in the field of polyester fiber, can solve the problems of large amount of catalyst, easy structure damage, poor particle dispersion, etc., to ensure high dispersion and high activity, avoid agglomeration, The effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for preparing a sheet-like titanium-based polyester catalyst. After mixing terephthalic acid, ethylene glycol, and n-butyl titanate at a molar ratio of 1:1.5:0.01, the temperature is 150°C and the pressure is 0.01MPa. After reacting for 0.5h under the same conditions, the temperature was raised to 200°C and the reaction was continued until the degree of esterification reached 70%. The reaction was terminated, filtered while hot, and then pulverized and ground to obtain a sheet-shaped titanium-based polyester catalyst with an average particle size of 0.5 μm.

Embodiment 2~6

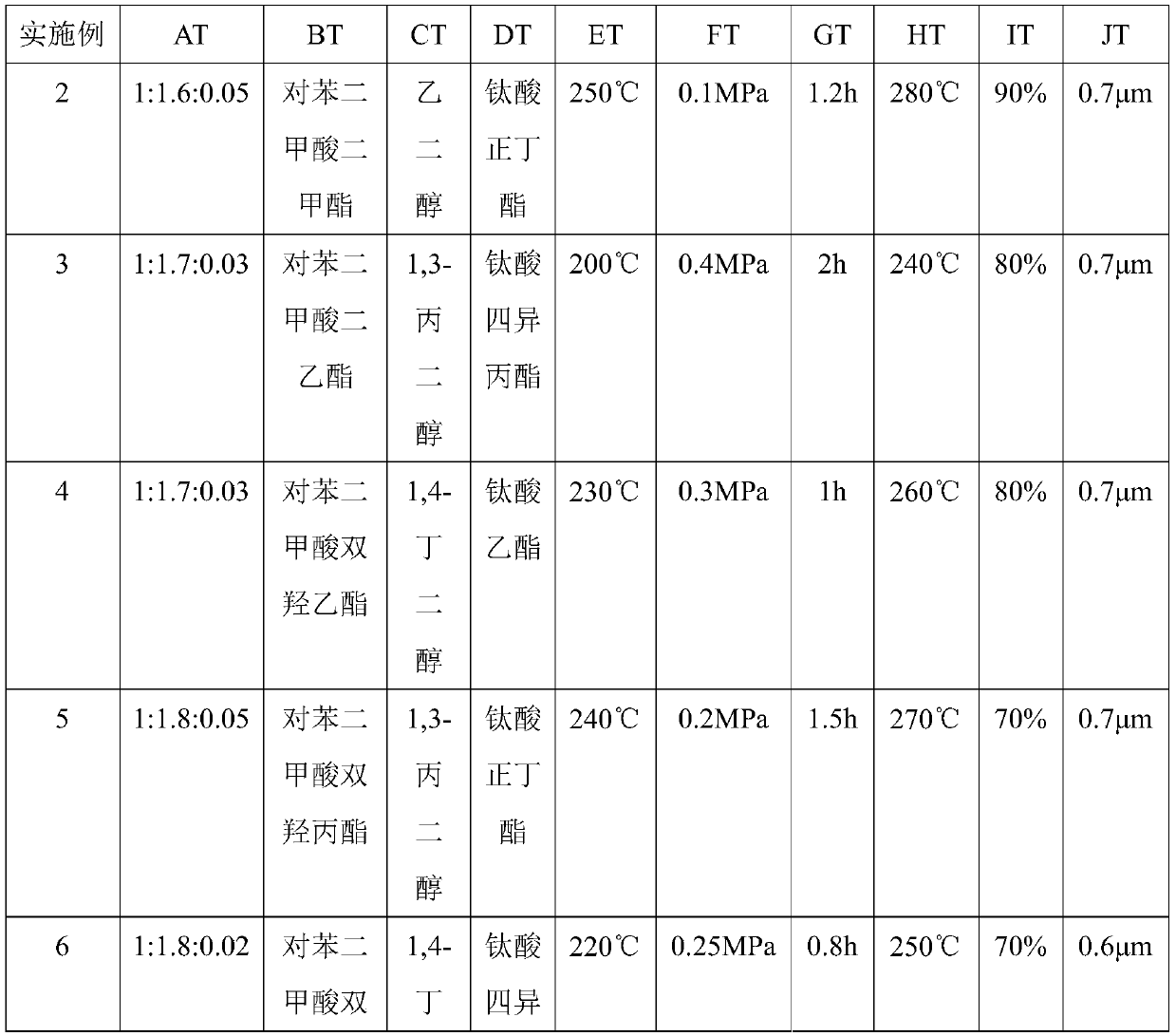

[0047] A preparation method of a sheet-shaped titanium-based polyester catalyst, after mixing BT, CT and DT with a molar ratio of AT, reacting GT at a temperature of ET and a pressure of FT, then raising the temperature to HT to continue the reaction until esterification When the degree reaches IT, the reaction is terminated, filtered while hot, and then pulverized and ground to obtain a sheet-shaped titanium-based polyester catalyst with an average particle size of JT.

[0048]

[0049]

Embodiment 7

[0051] A method for preparing a nanocomposite material for polyester in-situ polymerization modification, firstly adding a mass concentration of 30wt% TiO 2 The ethylene glycol dispersion of the particles, and then uniformly stirred and cooled to obtain a nanocomposite material for in-situ polymerization modification of polyester, TiO 2 The particles are spherical, with an average diameter of 600nm, and TiO in nanocomposites for in-situ polymerization modification of polyester 2 The mass content of the particles is 20% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com