Composition for preparing organic silicon elastomer, organic silicon elastomer and preparation method and application thereof

A composition and elastomer technology, applied in chemical instruments and methods, other chemical processes, coatings, etc., which can solve problems such as difficulty in complete curing and easy release of volatile organic compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

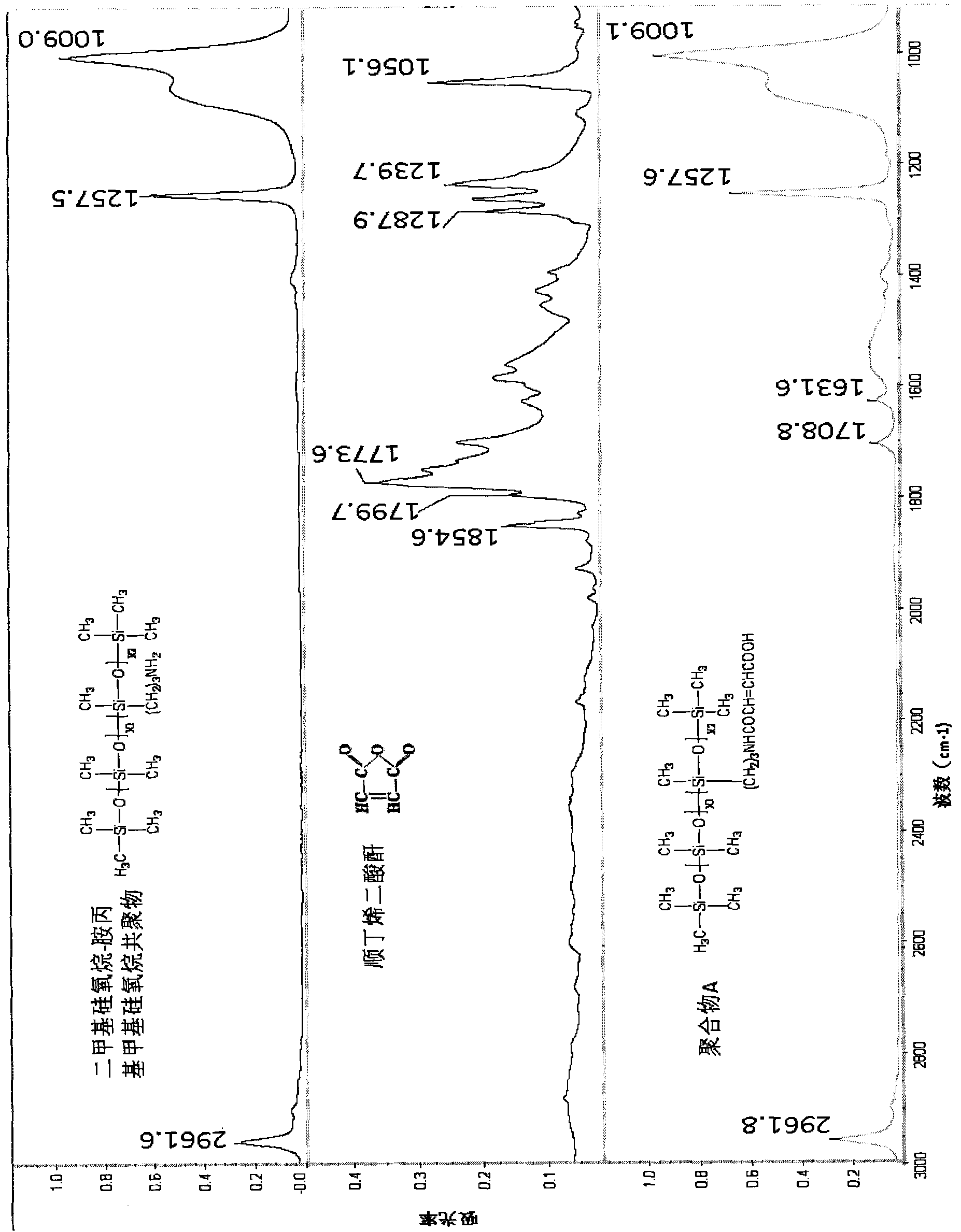

Method used

Image

Examples

Embodiment 1

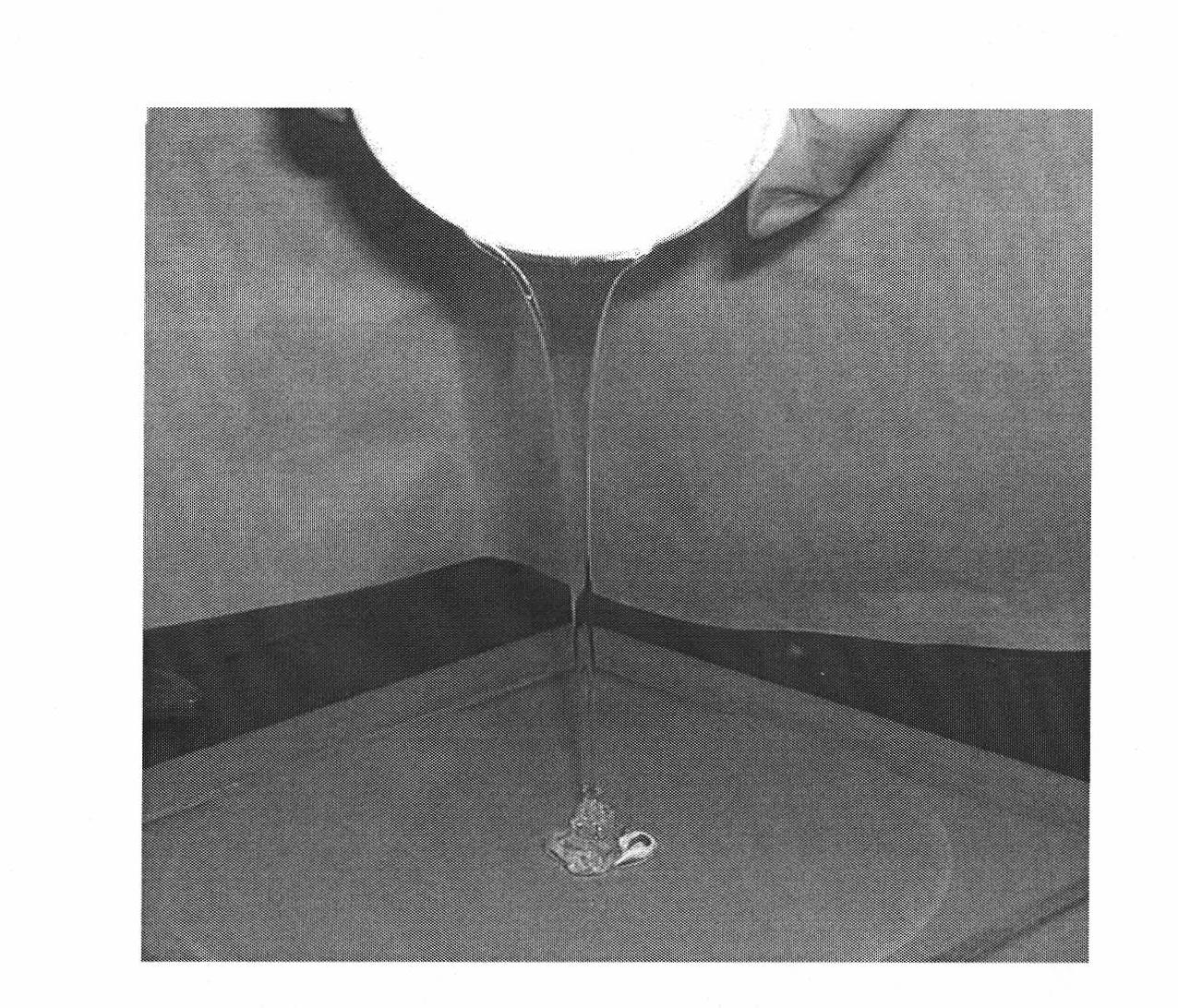

[0112] In the special polypropylene cup of 300ml speedmixer, add polymer A and 9.34g reactant B (trimethylolpropane-three [3-(2-methyl aziridinyl) propionic acid that 126g reference example 1 makes) ester], 0.02mol), and then stirred at 3000rpm in a speedmixer for 1.5min. Reactant A and reactant B are mixed and cured completely at room temperature (25°C) within 1 hour to obtain a silicone elastomer (5% weight loss temperature Td under nitrogen) 5 is 324.7°C, and the thermal decomposition temperature is 535.0°C). Before the curing reaction, the composition composed of polymer A and compound B has good fluidity and strong operability, see figure 2 . After the curing reaction, the obtained silicone elastomer is transparent, see image 3 .

Embodiment 2

[0114] Add polymer A and 78g reactant B (trimethylolpropane-three [3-(2-methyl aziridinyl) propionate] that 400g reference example 2 makes in the special-purpose polypropylene cup of 500ml speedmixer , 0.17mol), and then stirred for 1.5min at 3000rpm in a speedmixer mixer. Reactant A and reactant B are mixed and cured completely at room temperature for 0.5 h to obtain a silicone elastomer.

Embodiment 3

[0116] Add polymer A of 60g reference example 3 and 0.58g reactant B (trimethylolpropane-three [3-(2-methylazirinyl) propionate]) in the special polypropylene cup of 100ml speedmixer , and then stirred at 3000 rpm for 1.5 min in a speedmixer mixer. Polymer A and compound B are mixed and cured completely at room temperature for 24 hours to obtain a silicone elastomer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com