Modified graphene epoxy acrylate resin and preparation method thereof

A technology of alkene epoxy acrylate and propylene pimaric acid is applied in the field of modified graphene epoxy acrylate resin and its preparation, which can solve the problem of high cost of raw materials, and achieve the advantages of improving mechanical properties, enhancing stability and ensuring mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

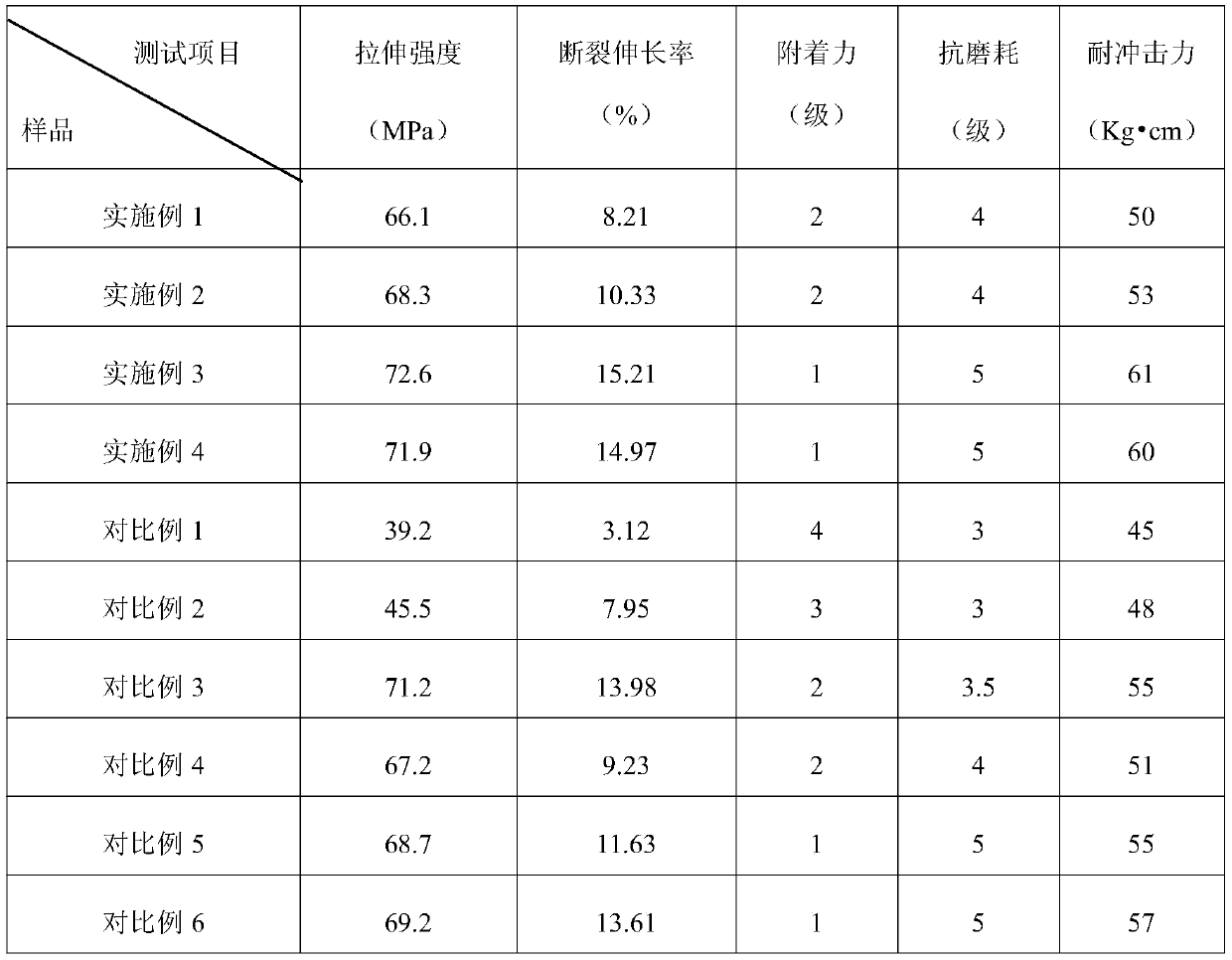

Examples

Embodiment 1

[0034] A modified graphene epoxy acrylate resin, comprising the following components by weight:

[0035] Propylenepimaric acid 60g;

[0037] Vinyl magnesium bromide 50g;

[0038] Graphene oxide 10g;

[0039] Epoxy soybean oil acrylate 100g;

[0040] Ethyl cellulose 50g;

[0041] Silane coupling agent 5g;

[0042] Methyl acrylate 20g;

[0043] tert-butyl benzoyl peroxide 5g.

[0044] A kind of preparation method of modified graphene epoxy acrylate resin, adds according to above-mentioned raw material addition, comprises the following steps:

[0045] (1) Dissolve propylene pimaric acid in 300 mL of dichloromethane, add thionyl chloride at -5°C, react at 0°C for 2 hours, and obtain propylene pimaric acid chloride after rotary evaporation;

[0046] (2) Add propylenepimaric acid chloride to 200mL tetrahydrofuran, add vinylmagnesium bromide, react at 60°C for 2 hours, distill under reduced pressure, remove tetrahydrofuran, and obtain propylenep...

Embodiment 2

[0051] A modified graphene epoxy acrylate resin, comprising the following components by weight:

[0052] Propylenepimaric acid 80g;

[0053] Thionyl chloride 30g;

[0054] Vinyl magnesium bromide 65g;

[0055] Graphene oxide 20g;

[0056] Epoxy soybean oil acrylate 150g;

[0057] Hydroxyethyl cellulose 75g;

[0058] Silane coupling agent 7g;

[0059] Methyl methacrylate 25g;

[0060] tert-butyl benzoyl peroxide 8g.

[0061] A kind of preparation method of modified graphene epoxy acrylate resin, adds according to above-mentioned raw material addition, comprises the following steps:

[0062] (1) Propylenepimaric acid was dissolved in 300mL of dichloromethane, after adding thionyl chloride at 0°C, reacted at 10°C for 4 hours, and obtained propylenepimaric acid chloride after rotary evaporation;

[0063](2) Add propylenepimaric acid chloride to 200mL tetrahydrofuran, add vinylmagnesium bromide, react at 70°C for 4h, distill under reduced pressure, remove tetrahydrofuran, a...

Embodiment 3

[0068] A modified graphene epoxy acrylate resin, comprising the following components by weight:

[0069] Propylenepimaric acid 100g;

[0070] Thionyl chloride 40g;

[0071] Vinyl magnesium bromide 80g;

[0072] Graphene oxide 30g;

[0073] Epoxy soybean oil acrylate 200g;

[0074] Carboxymethyl cellulose 80g;

[0075] Silane coupling agent 8g;

[0076] Epoxy acrylate 30g;

[0077] Benzoyl peroxide tert-butyl peroxide 10g.

[0078] A kind of preparation method of modified graphene epoxy acrylate resin, adds according to above-mentioned raw material addition, comprises the following steps:

[0079] (1) dissolving propylene pimaric acid in dichloromethane, adding thionyl chloride at 5°C, reacting for 6 hours at 25°C, and obtaining propylene pimaric acid chloride after rotary evaporation;

[0080] (2) Add propylene pimaric acid chloride to tetrahydrofuran, add vinylmagnesium bromide, react at 80°C for 6 hours, distill under reduced pressure, remove tetrahydrofuran, and obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com