Local loading forming-based optimization method for preformed blank of rib plate part

A technology of local loading and optimization method, which is applied in the field of hot forging and can solve problems such as folding and dissatisfaction of rib cavity filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

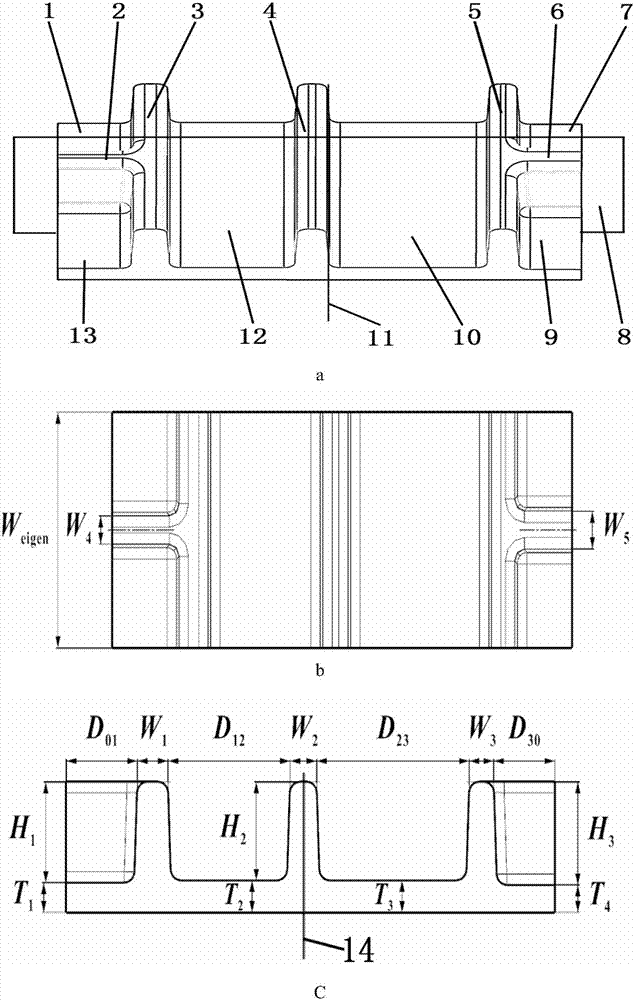

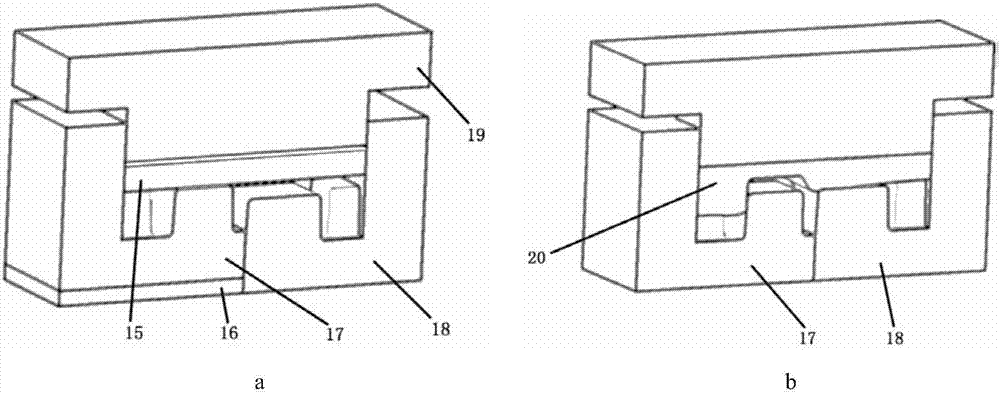

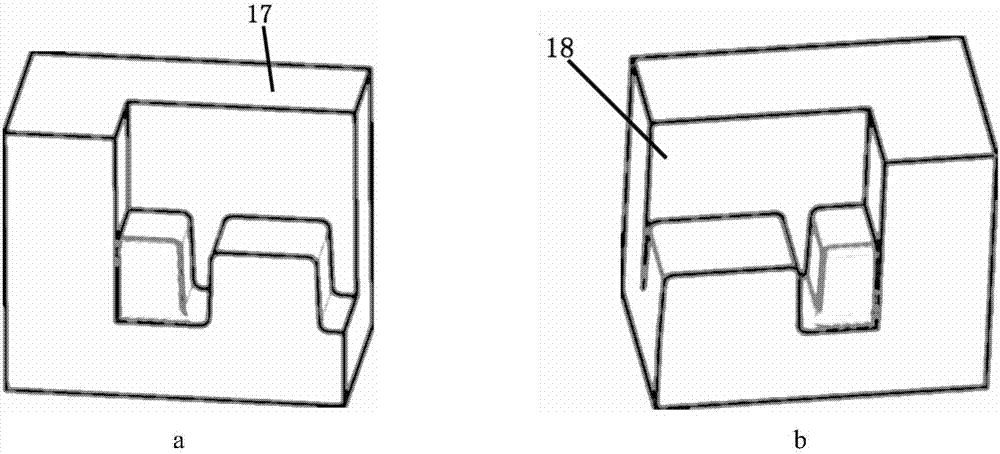

[0071] In this embodiment, based on the finite element simulation, a TA15 titanium alloy rib plate is formed by using the isothermal local loading method, and the shape of the preform in the transition zone is optimally designed. Then, the resulting optimized preforms were verified using physical experiments. The specific process is:

[0072] Step 1, extract the geometric structure of the transition zone.

[0073] Sun Zhichao et al. published "Study on Local Loading Partitions in Isothermal Forming of Titanium Alloy Integral Frames" published in Journal of Plastic Engineering, 2009, Volume 16, Issue 1, Pages 138-143. The effect of the loaded zone on the formed unloaded zone is a short-range effect, and its influence range is mainly concentrated in the area from the partition rib to its adjacent rib. In the area away from the partition ribs on the workpiece, it is little or even not affected by the deformation of the loading zone, so the forming characteristics of these areas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com