Patents

Literature

32results about How to "Avoid Folding Defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

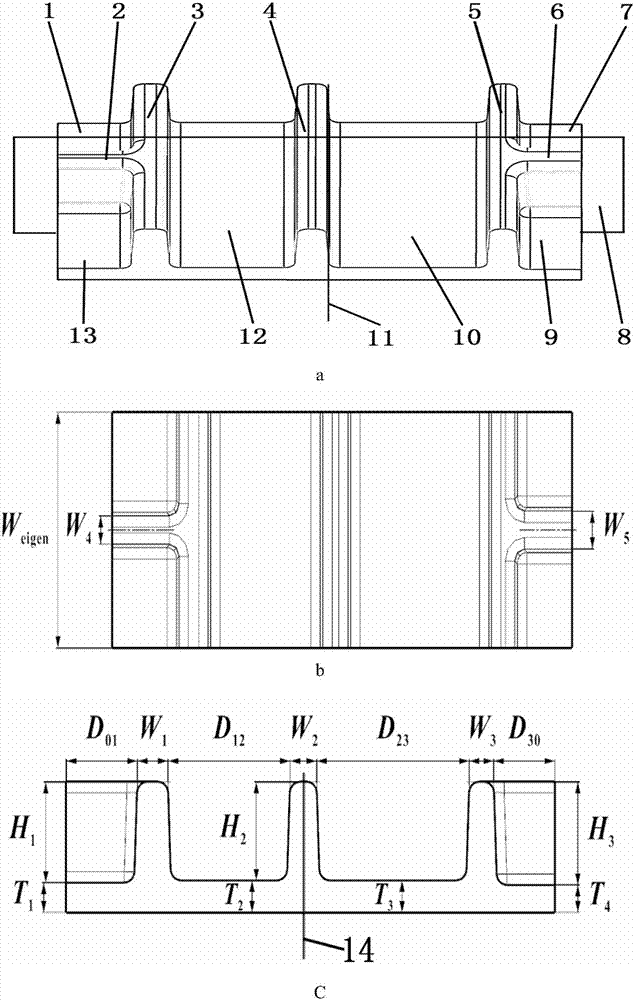

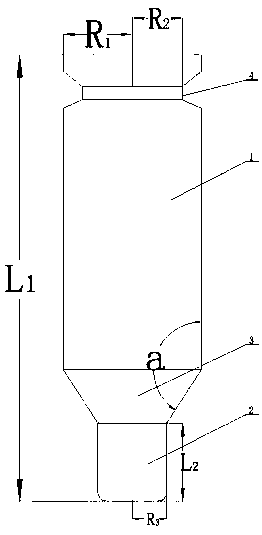

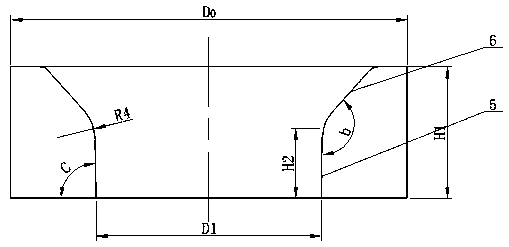

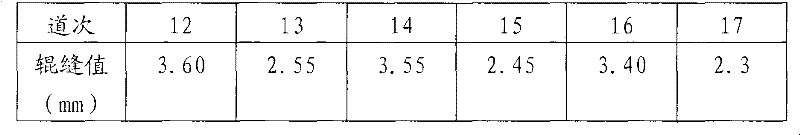

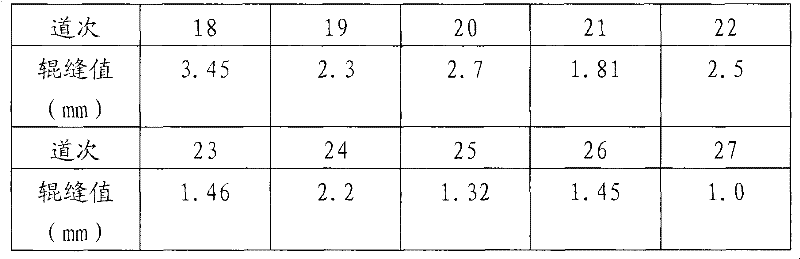

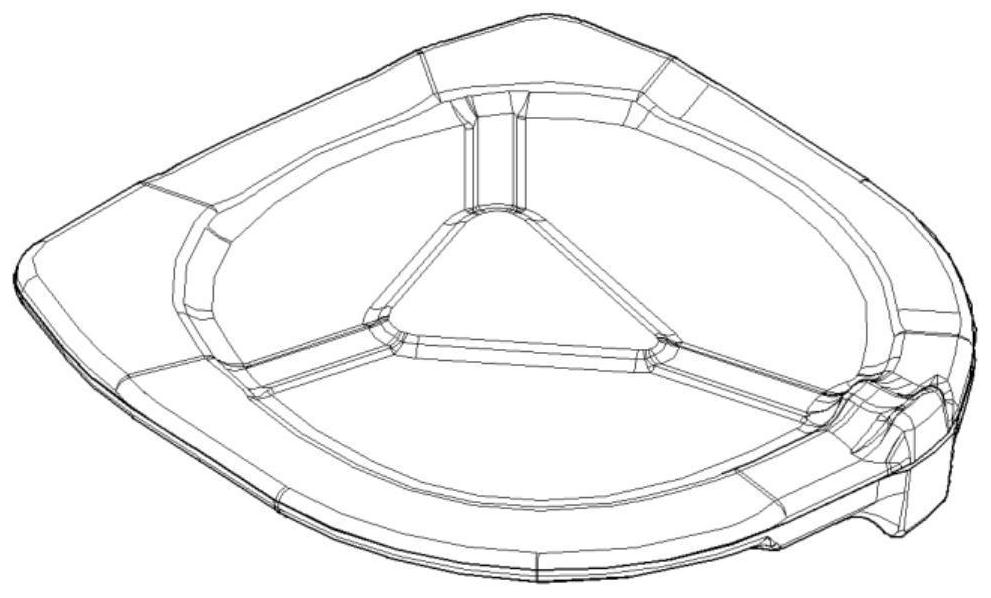

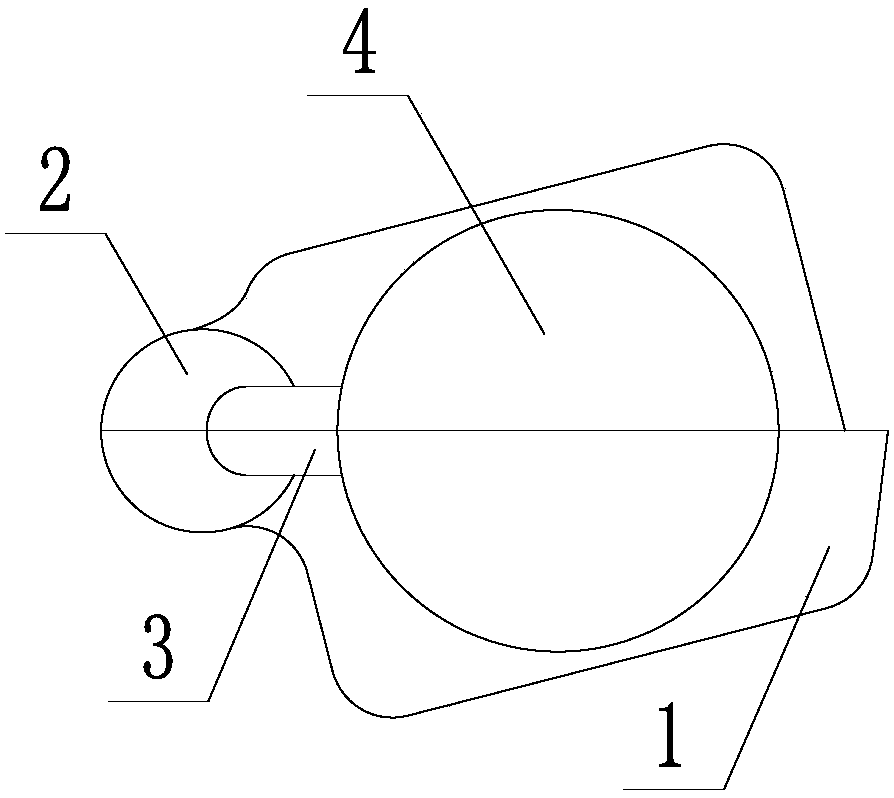

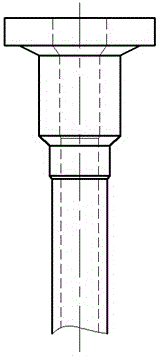

Bulb steel production technology

InactiveCN101190442ASmall fluctuations in section sizeSmall fluctuations in the size of the arcRollsMetal rolling arrangementsIron productionCompression ratio

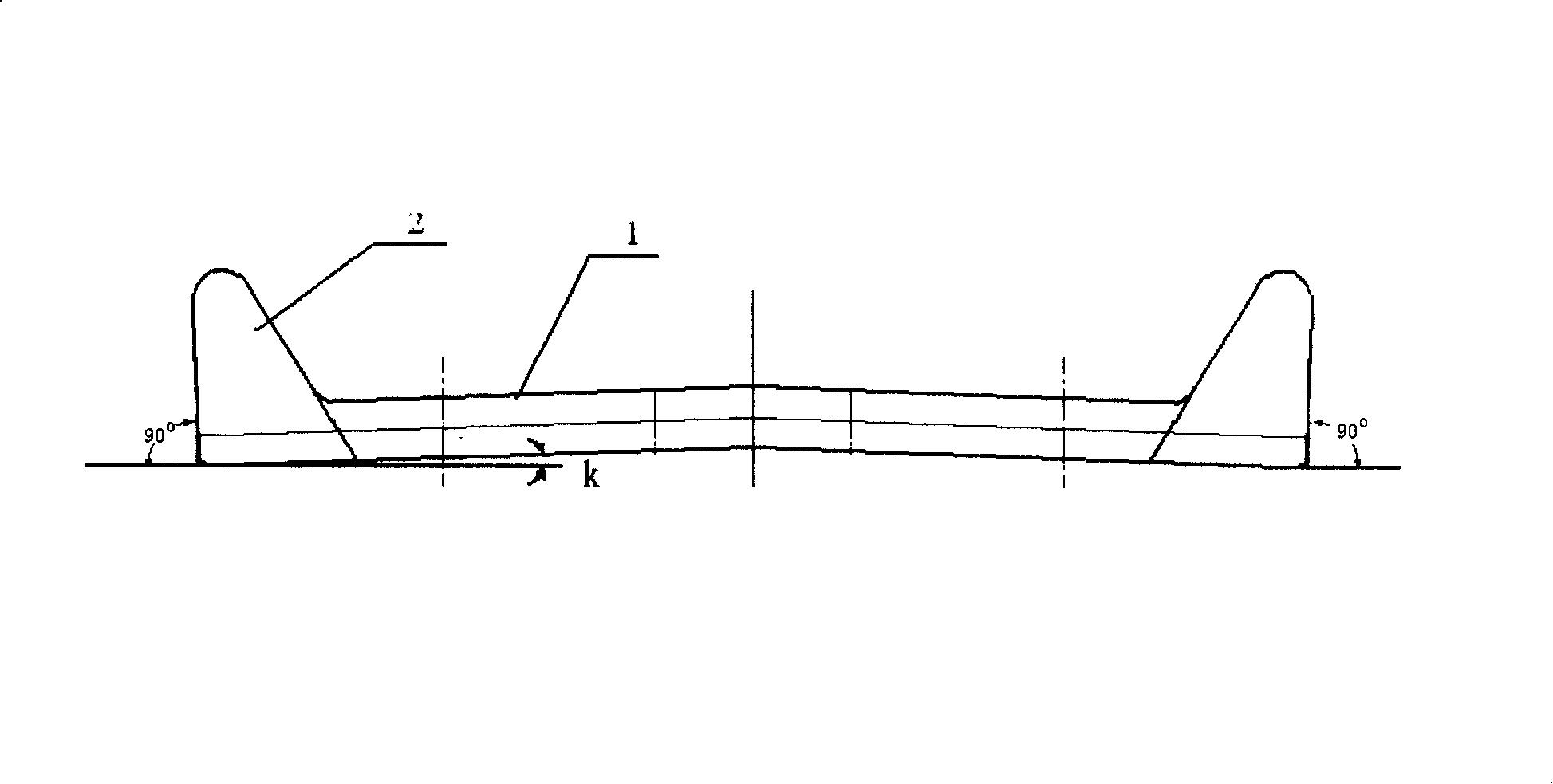

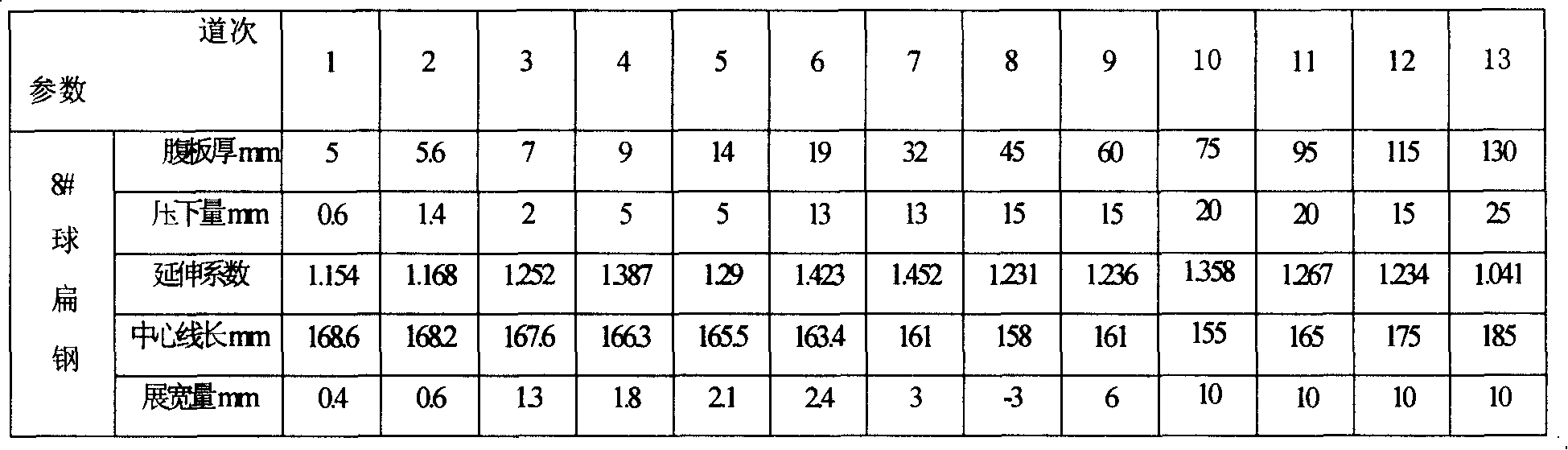

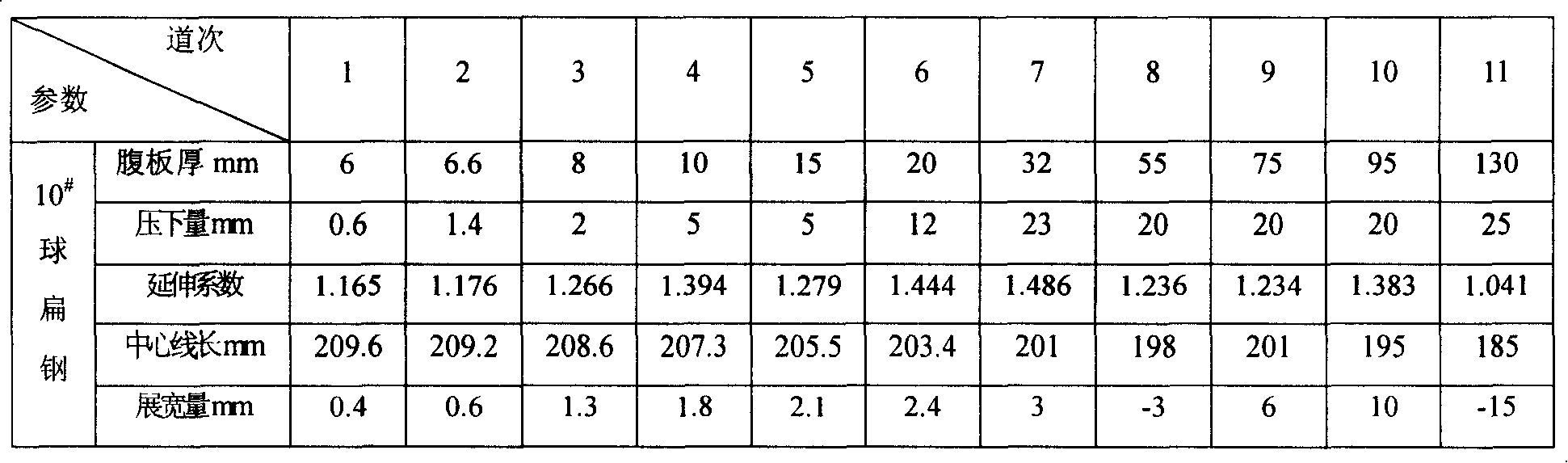

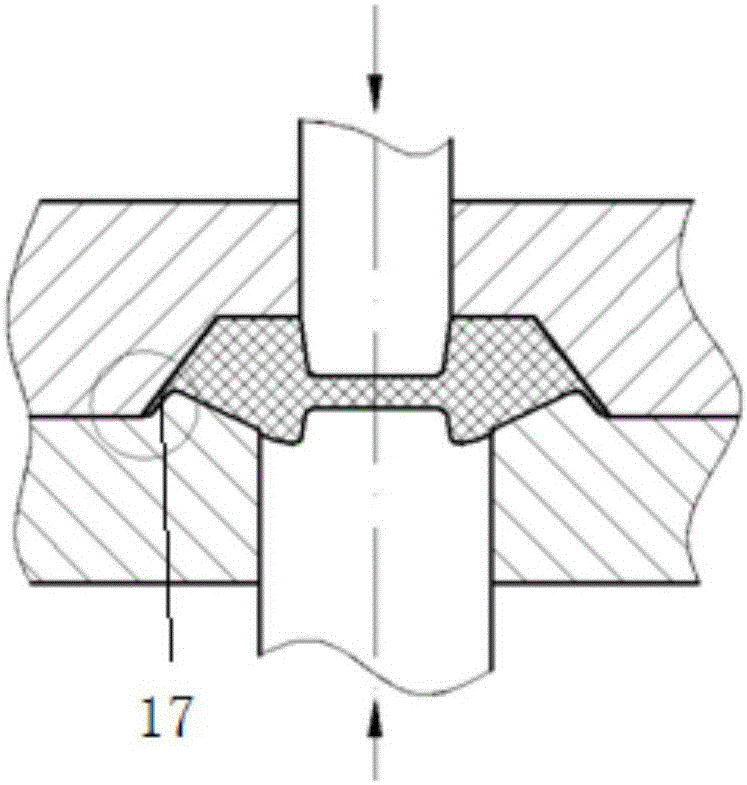

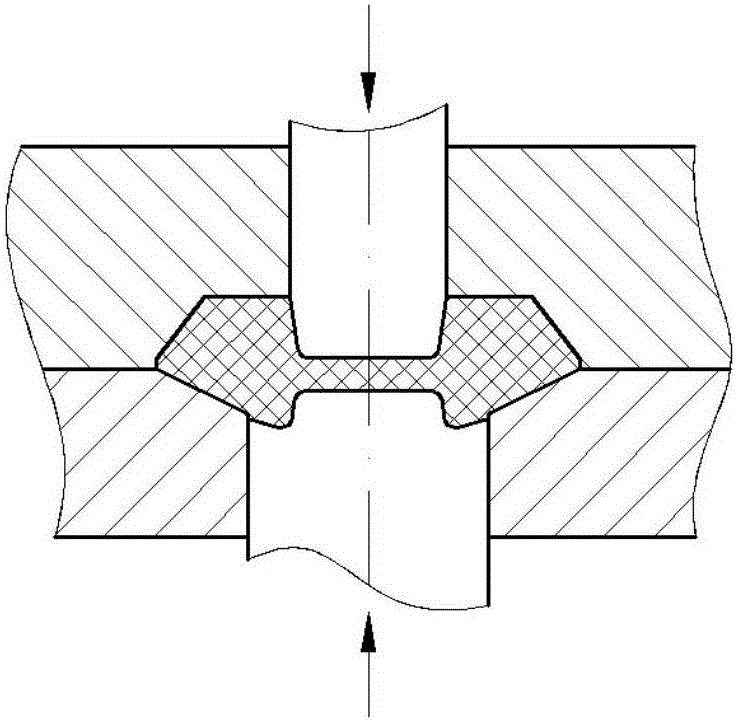

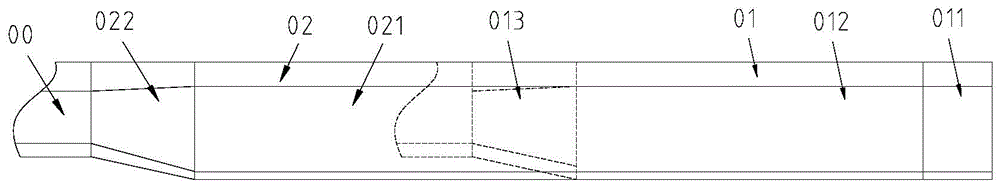

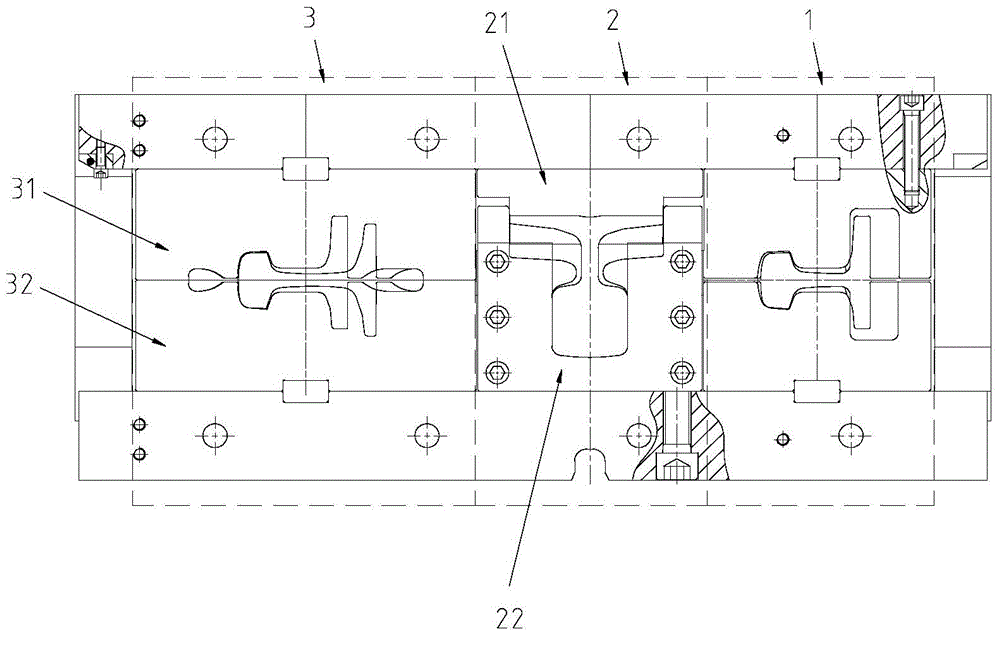

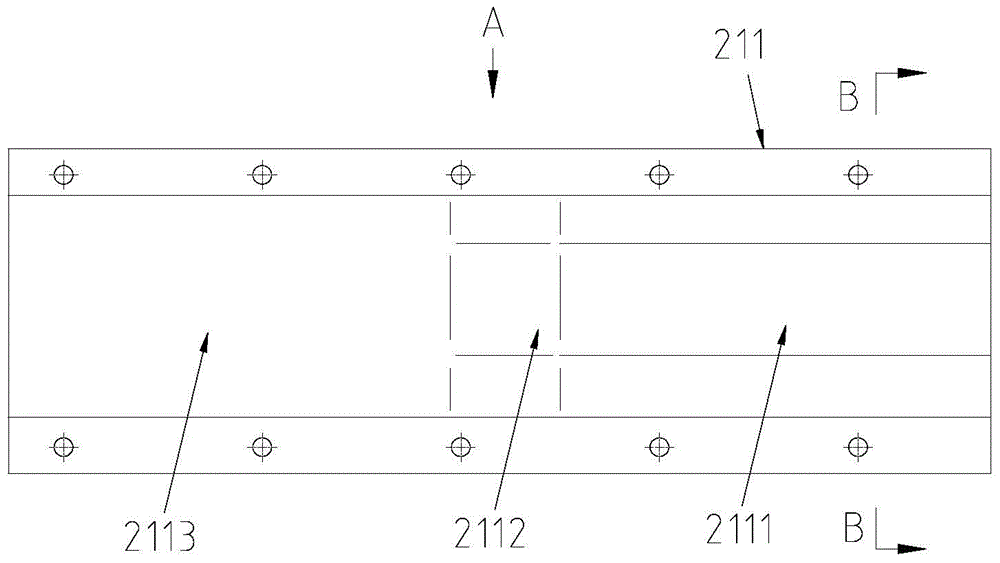

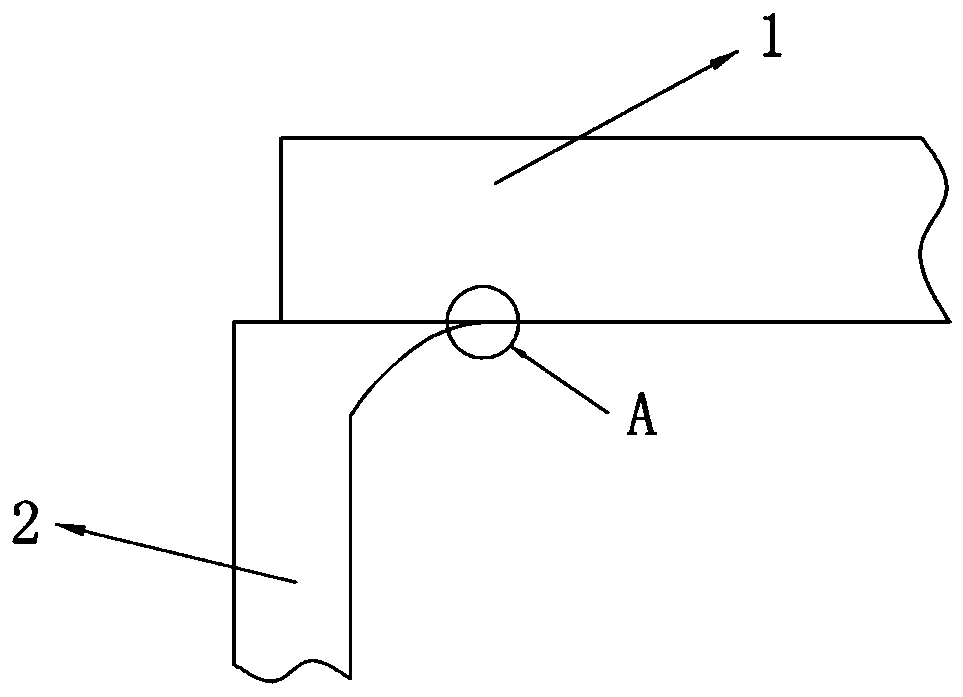

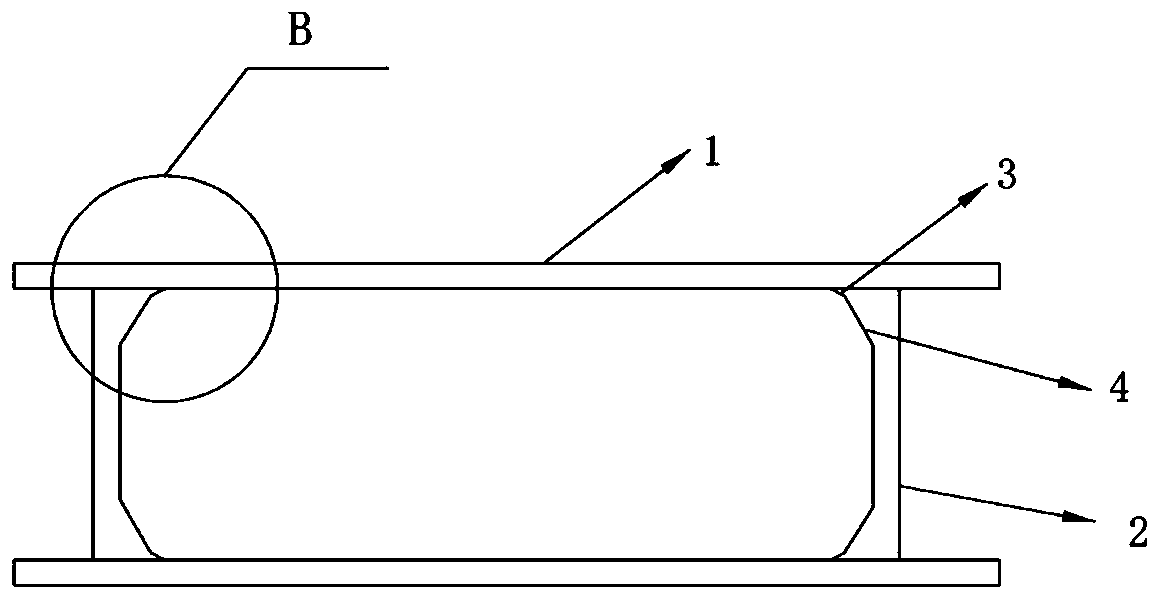

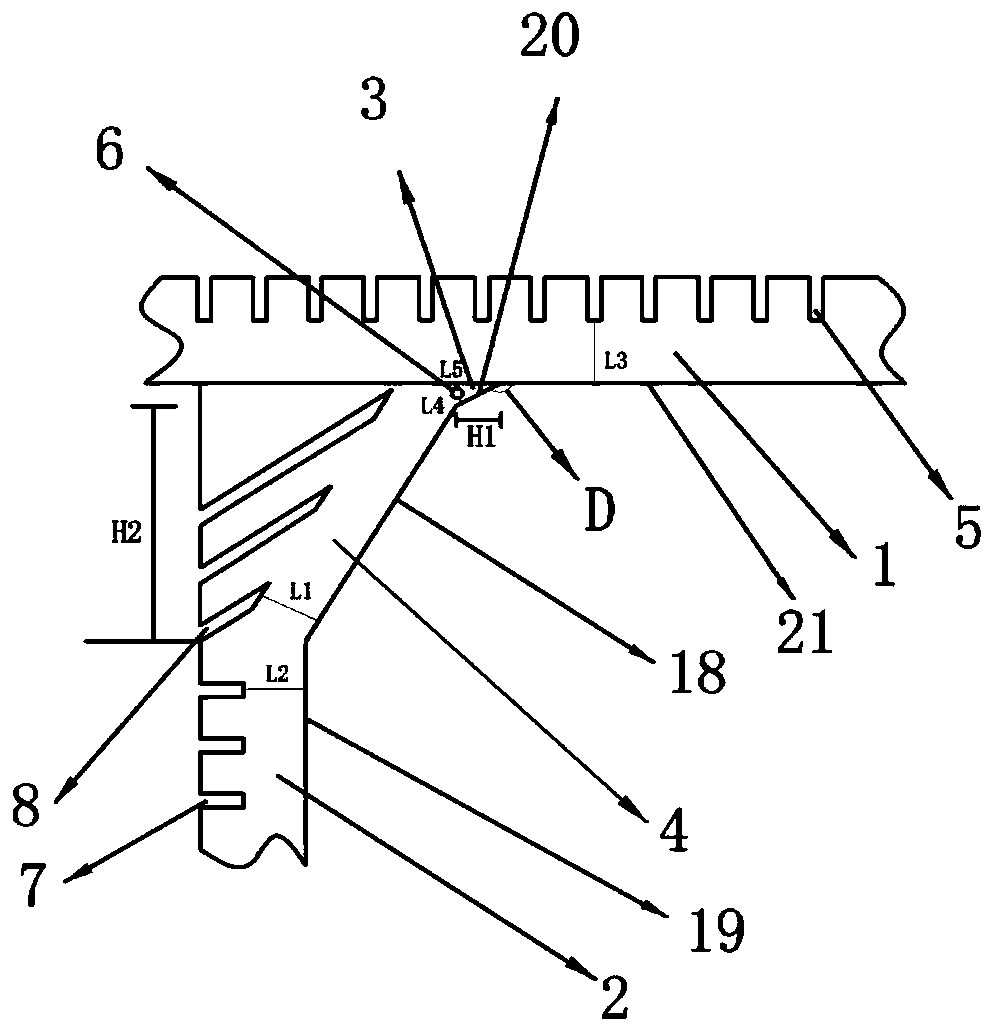

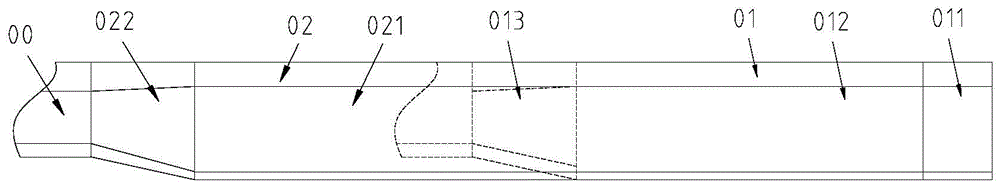

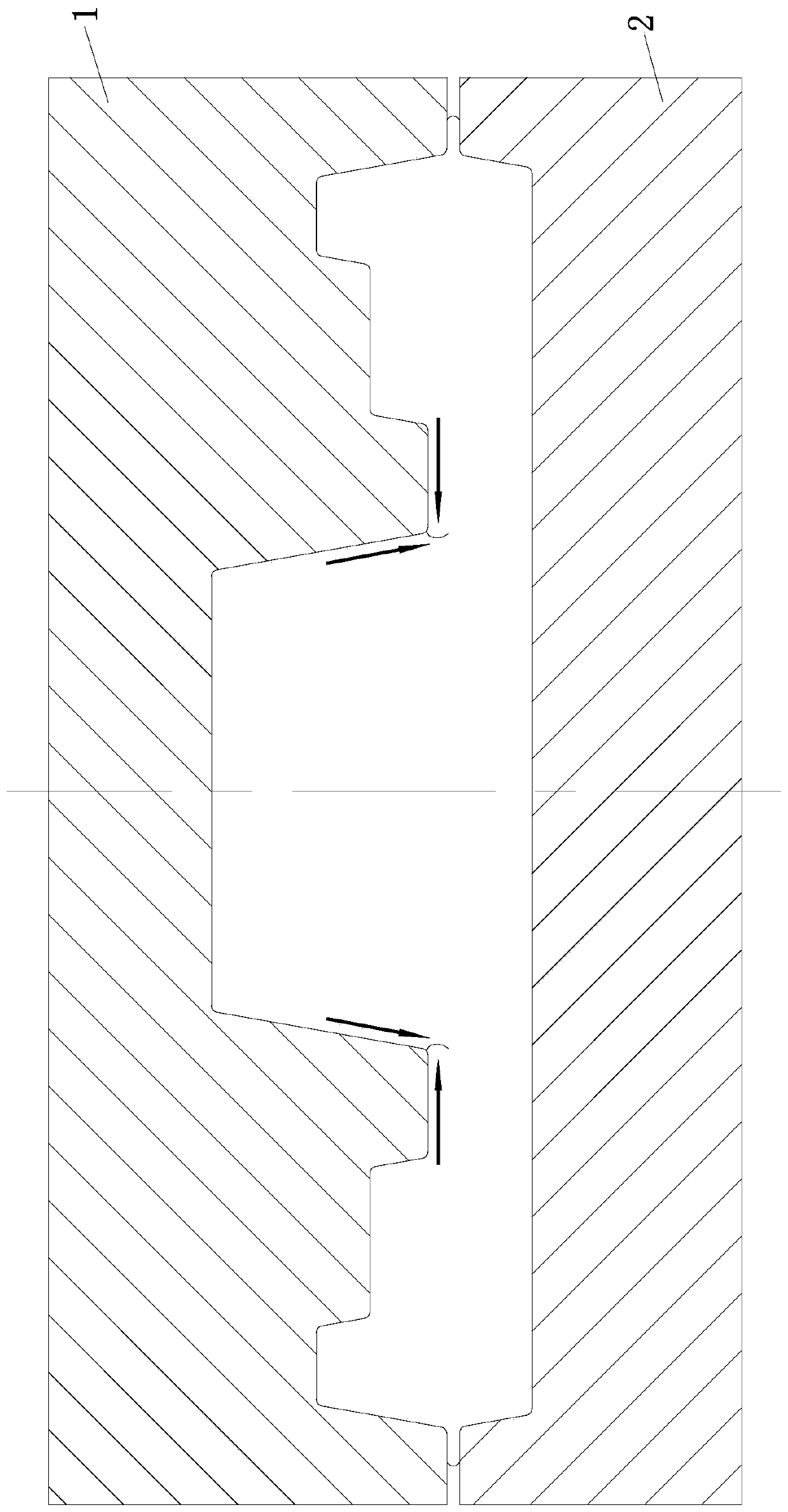

The invention discloses a ball flat iron production technique, comprising steps of billet, heating, symmetrical rolling, straightening and dissection. The invention is characterized in that the dissection process is carried out after the processes of symmetric rolling and straightening; hole shapes in all the passages of a rolling mill are constituted by two ball flat iron hole shapes which are symmetrically identical. By adopting the technique of symmetric rolling, the invention solves the problems that existing large and medium rolling mills can not produce small ball flat irons with symmetrical rolling and dissection technology. The invention has the advantages of the small size fluctuation of profiles when producing, particularly the small size fluctuation of width, thickness, ball filling and the lower arc of the ball flat iron, rollers subject to uniform forces, easy control in rolling process, greatly reducing the scraping, the rolling mark and the waves of the product by 50% to 70%, improving the quality of the product, enlarging the types of rolled products, leading large profiled bar rolling mill to produce small ball flat iron, enlarging the profile of the billet, large corresponding compression ratio, improving the comprehensive performance of the products, etc.

Owner:ANGANG STEEL CO LTD

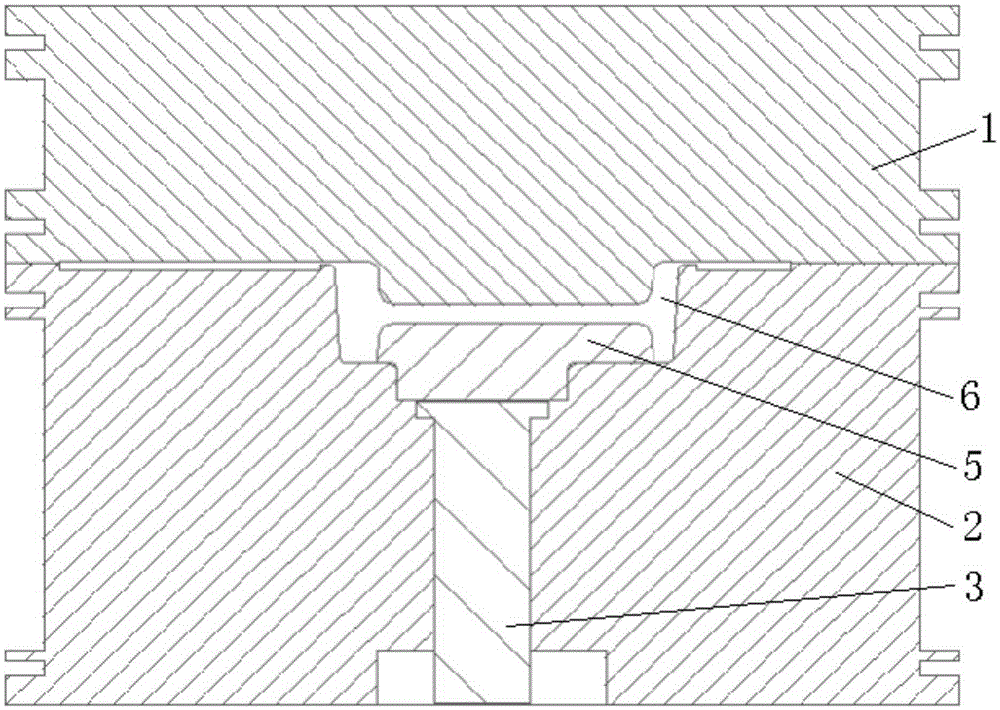

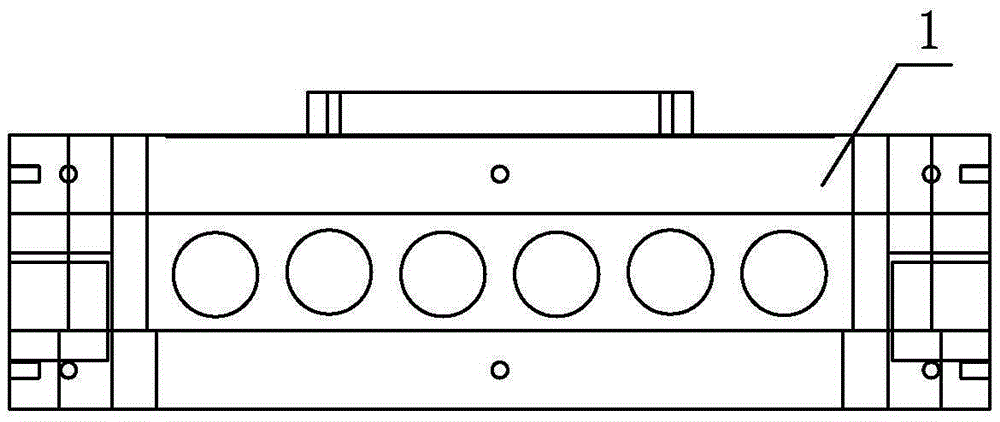

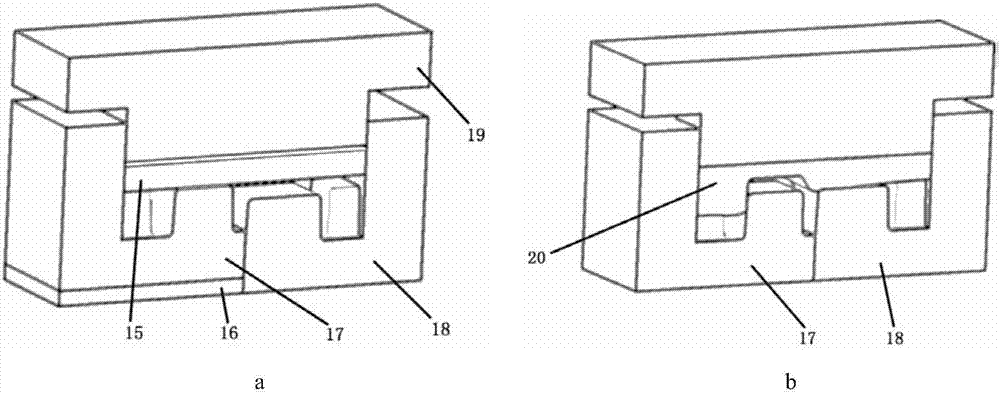

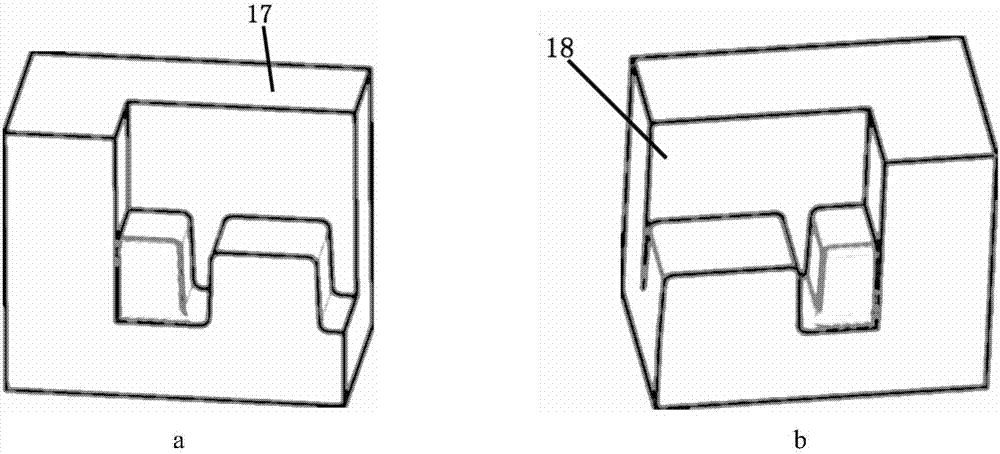

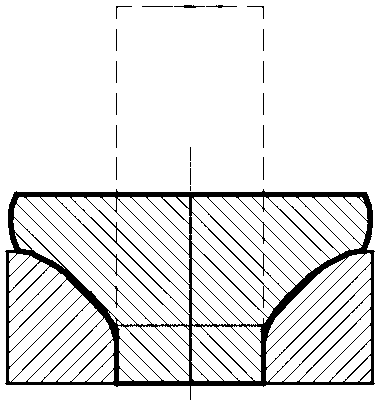

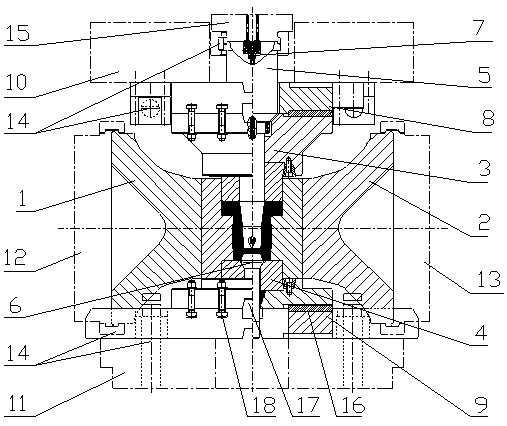

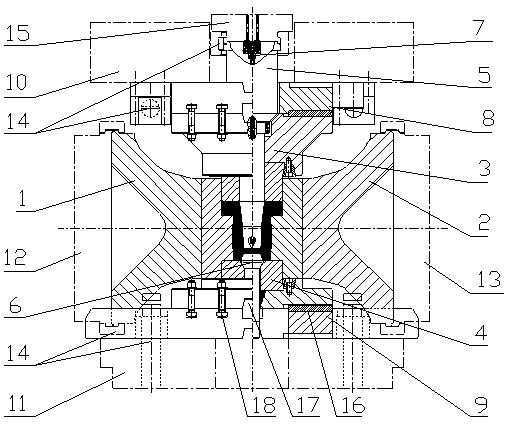

Isothermal die forging forming die and method for rare earth magnesium alloy thin webbed supporting fork

ActiveCN105397010AQuality improvementExtended service lifeForging/hammering/pressing machinesEngine componentsRare earthMagnesium alloy

The invention relates to a forming die and method for magnesium alloy thin webbed supporting fork forgings, in particular to an isothermal die forging forming die and method for a rare earth magnesium alloy thin webbed supporting fork. The problems that rare earth magnesium alloy thin webbed supporting fork forgings are prepared through conventional forging, blank manufacturing and forming are hard, forming defects are prone to occurring, the structure performance of the magnesium alloy forgings is hard to control, and the performance is low are solved. The forming method comprises the main steps that 1, blank manufacturing is carried out; 2, forging forming is carried out; 3, cooling is carried out; 4, primary acid pickling is carried out; 5, damage repairing is carried out; 6, final forging is carried out; 7, secondary acid pickling is carried out, wherein a magnesium alloy forging obtained in the sixth step is subjected to acid pickling, graphite on the surface is cleaned away, and a formed forging with the treated surface is obtained; and 8, the formed forging with the treated surface obtained in the seventh step is put into an aging oven to be subjected to aging treatment, and the finished rare earth magnesium alloy thin webbed supporting fork is manufactured. The forming die and method are used for preparing of the magnesium alloy thin webbed supporting fork.

Owner:HARBIN INST OF TECH

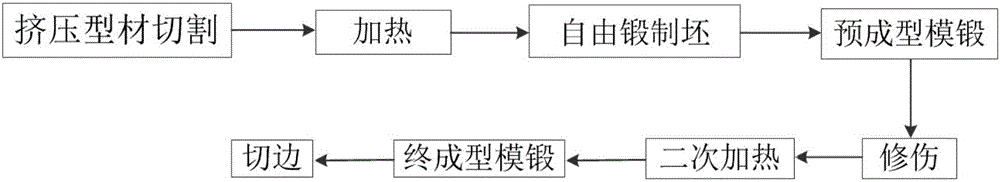

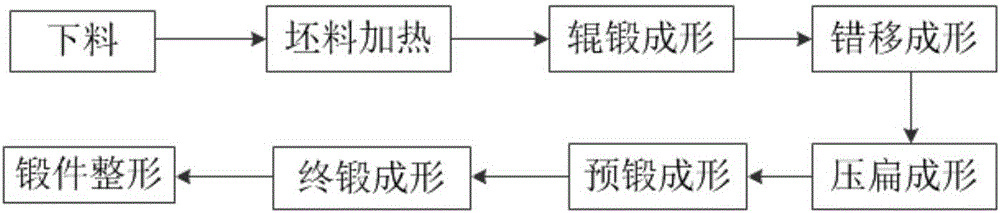

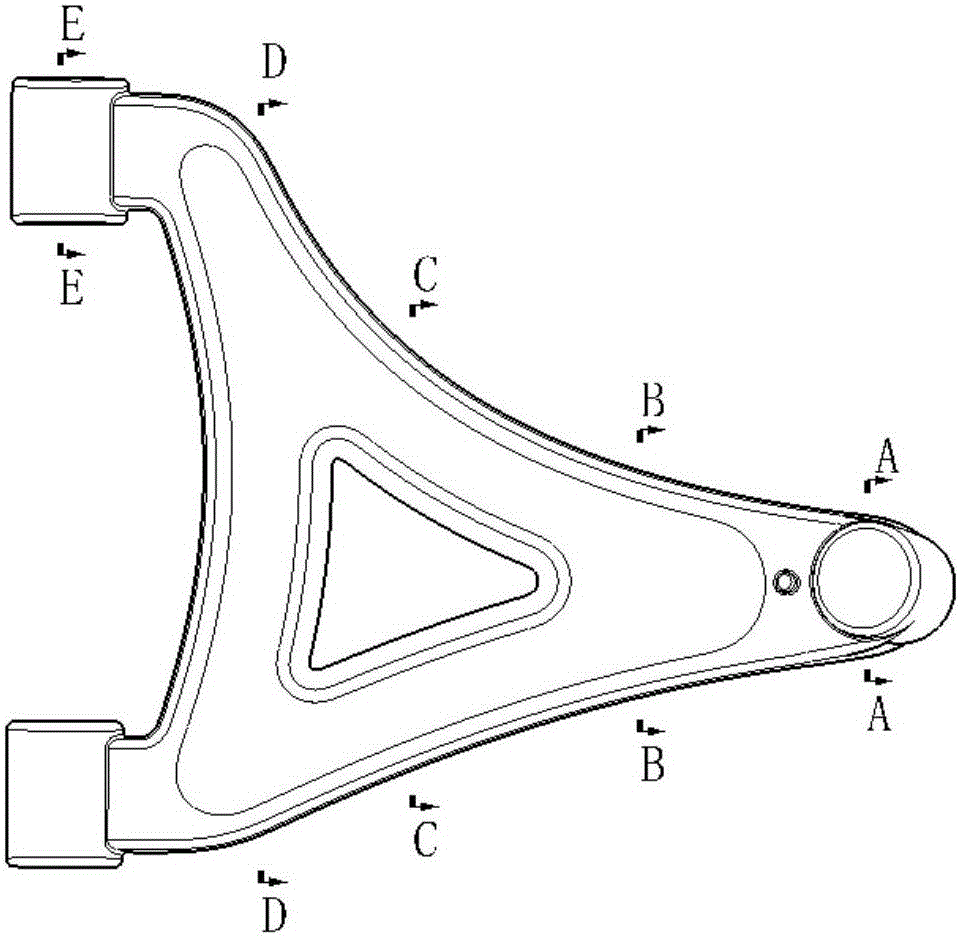

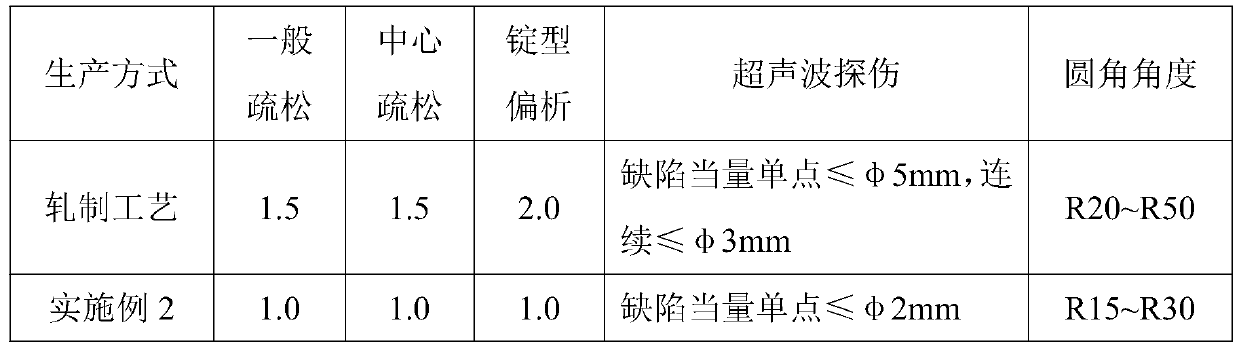

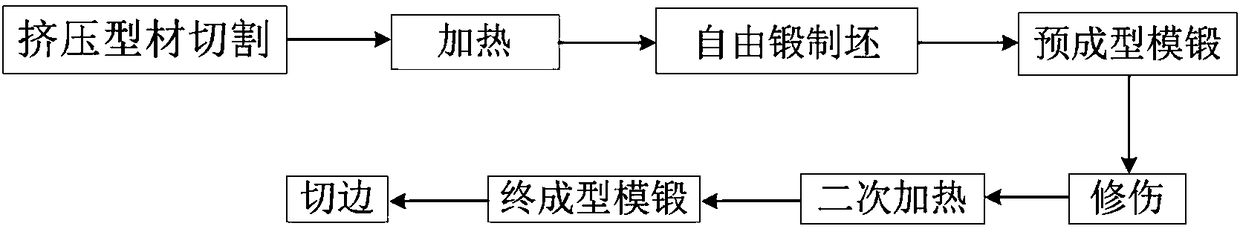

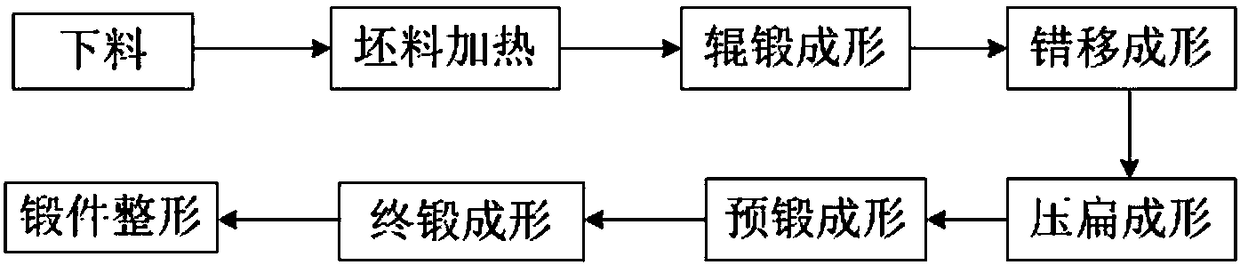

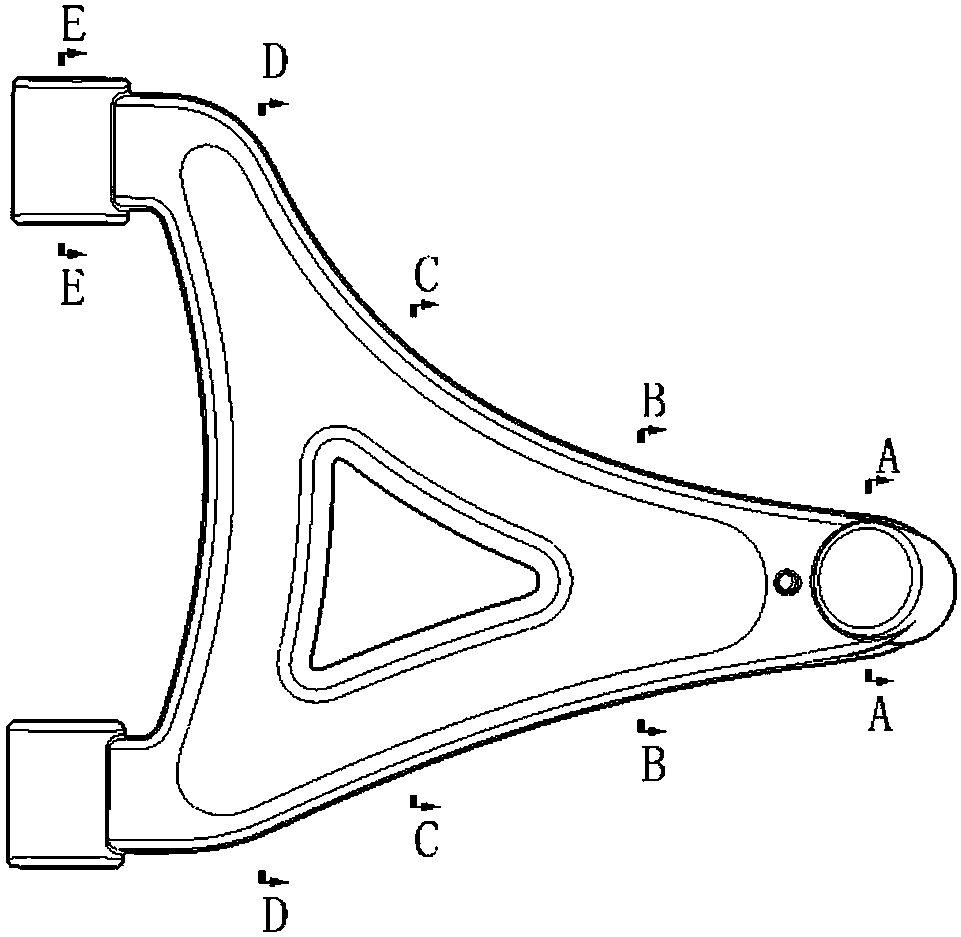

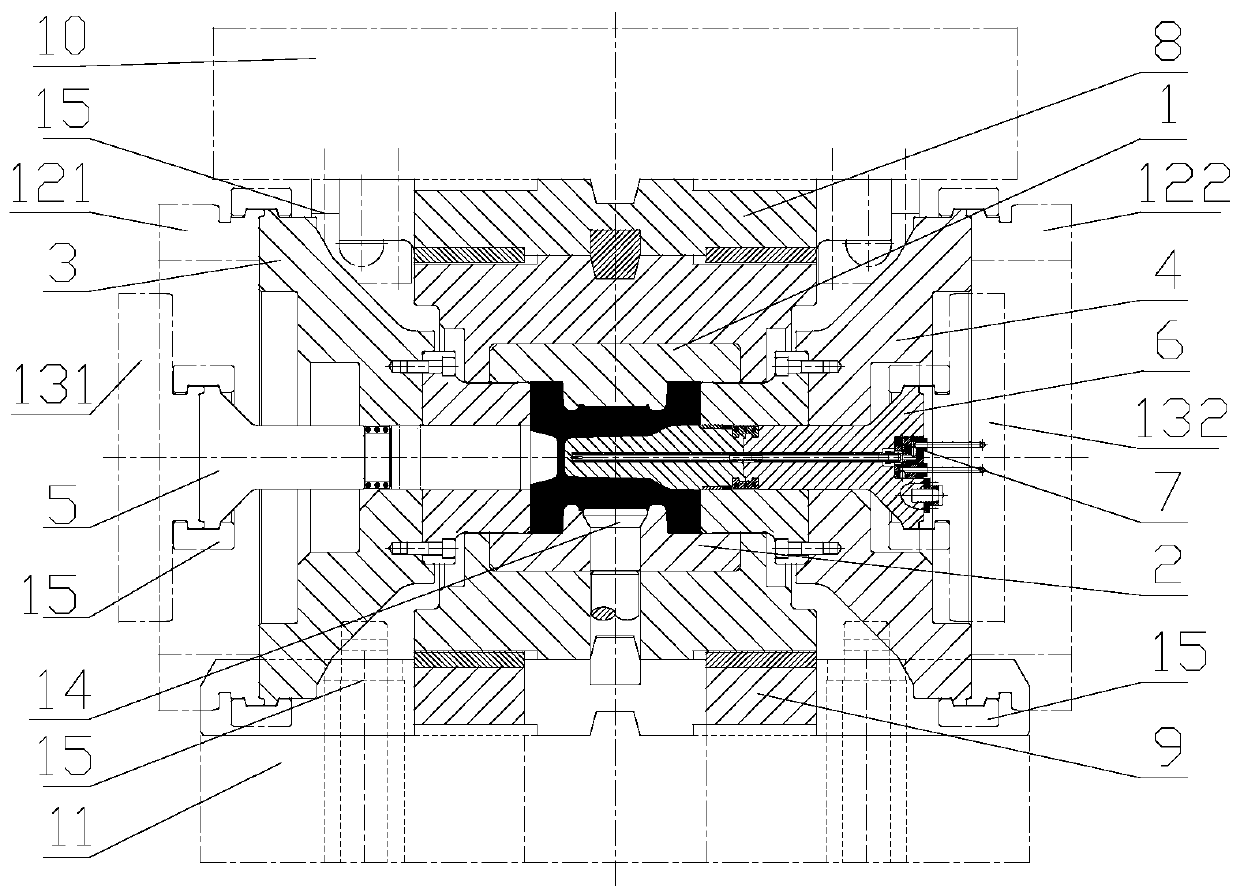

Forging forming method of triangular aluminum alloy control arm

ActiveCN106424529AAvoid Folding DefectsReduce repair workRailway componentsForging/hammering/pressing machinesControl armHeating furnace

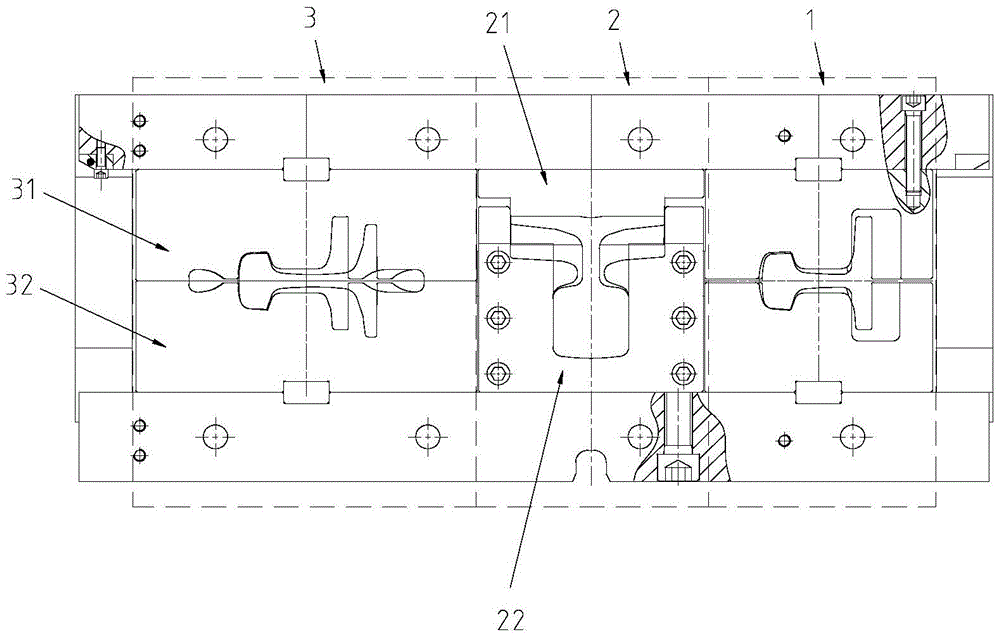

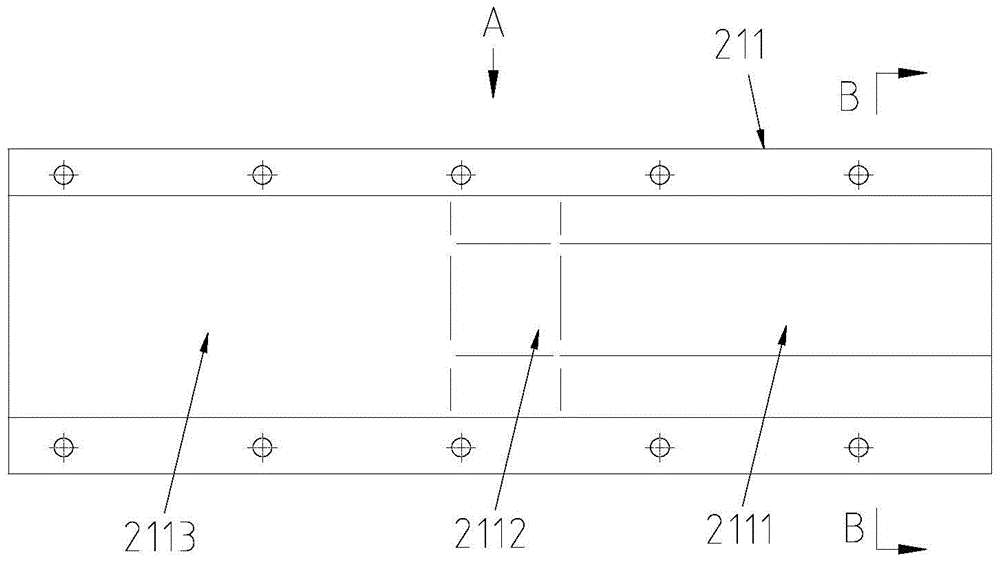

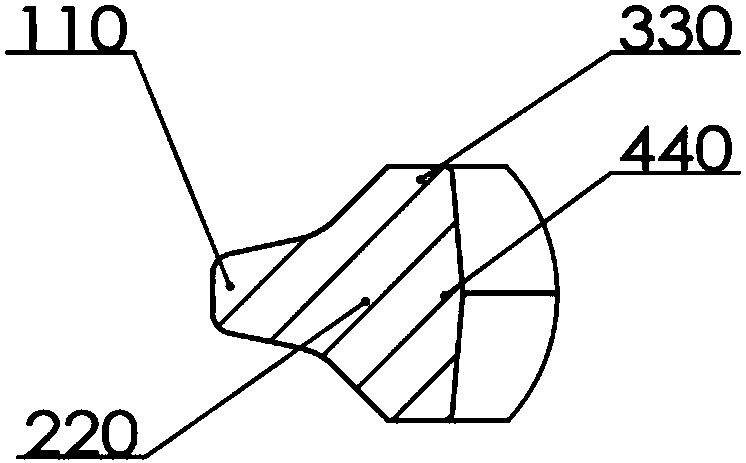

The invention discloses a forging forming method of a triangular aluminum alloy control arm and aims at solving the problems in the prior art of low quality of a product, low material utilization ratio and low production efficiency. The forging forming method comprises the following steps: 1, blanking; 2, heating a blank: heating the blank in the first step in an electric induction heating furnace at the heating temperature of 420-480 DEG C, keeping the temperature for 5-8min to enable the blank to be uniformly heated, and finishing dynamic recrystallization after finishing forging to obtain uniform microstructures; 3, roll forgingforming: 1) calculating a roll forging pass n; 2) roll forging forming: comprising the following steps: from (1) first-pass roll forgingforming to (4) fourth-pass roll forging forming; 4, mis-shifted forming; 5, flattening forming; 6, pre-forging forming; 7, finish forging forming: carrying out finish forging forming on the basis of pre-forging forming, designing a die according to a hot forging drawing during finish forging forming, putting a pre-forging into a mold cavity of the finish forging die, and then obtaining a part in finish forging forming under the action of a press; and 8, shaping the forging.

Owner:JILIN UNIV

Local loading forming-based optimization method for preformed blank of rib plate part

ActiveCN106971029AImprove carrying capacityAvoid Folding DefectsGeometric CADDesign optimisation/simulationTransitional RegionEngineering

The invention discloses a local loading forming-based optimization method for a preformed blank of a rib plate part. Isothermal local loading forming is realized by controlling material flow and macroscopic defects of a transitional region. The preformed blank subjected to optimization design can effectively improve the uniformity of the material flow, reduce transverse material flow of a cross rib in the transitional region, and improve the filling capability of a rib type cavity. In engineering application, the usage performance of members is improved, the production cost is reduced, and a foundation is laid for forming and integrated manufacturing of large complex members made of titanium alloy.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Hollow near-forming forging method of large MW wind power main shaft

InactiveCN109290503AAdd depthAvoid foldingMetal-working apparatusEngine componentsElectricityPunching

The invention discloses a hollow near-forming forging method of a large MW wind power main shaft. The method is characterized by comprising the following specific steps that 1, a steel ingot is heatedto 1200-1250 DEG C, heat preservation is carried out, then chamfering is carried out, water removing and upsetting are carried out, and blanking is carried out after the steel ingot is pulled out; 2,the steel ingot subjected to the first step is heated to 1200-1250 DEG C, heat preservation is carried out, then upsetting is carried out by adopting a special anti-extrusion leakage disc, then the hole is punched downwards to a certain height through a special punching core rod, and then the special punching core rod is used for drawing to a certain size; 3, the steel ingot subjected to the second step is heated to 1200-1250 DEG C, heat preservation is carried out, then upsetting is carried out by adopting a special anti-extrusion leakage disc, then the hole is punched downwards to a certainheight through a special punching core rod, and then a flange is printed out; and 4, the steel ingot subjected to the third step is heated to 1150-1250 DEG C, heat preservation is carried out, then locally upsetting the flange through the leakage disc, and finally the flange is formed and finished to obtain a finished product. According to the method, the problem that the small-head-end inner hole is very small in wind power main shaft production is solved, the waste of raw materials in the production process is greatly reduced, and the production cost is low.

Owner:SHANDONG LAIWU JINLEI WIND POWER TECH

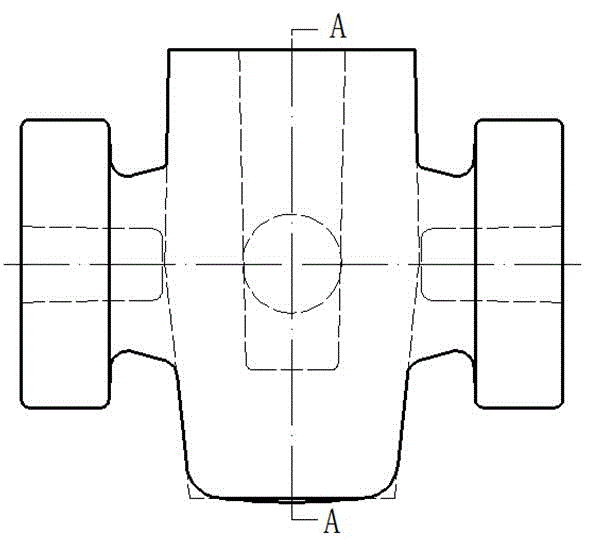

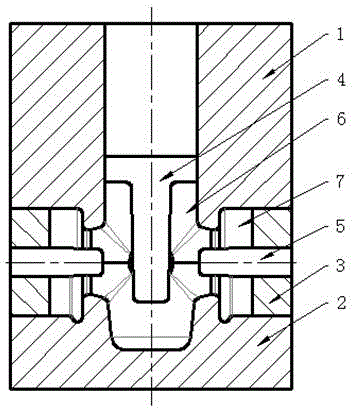

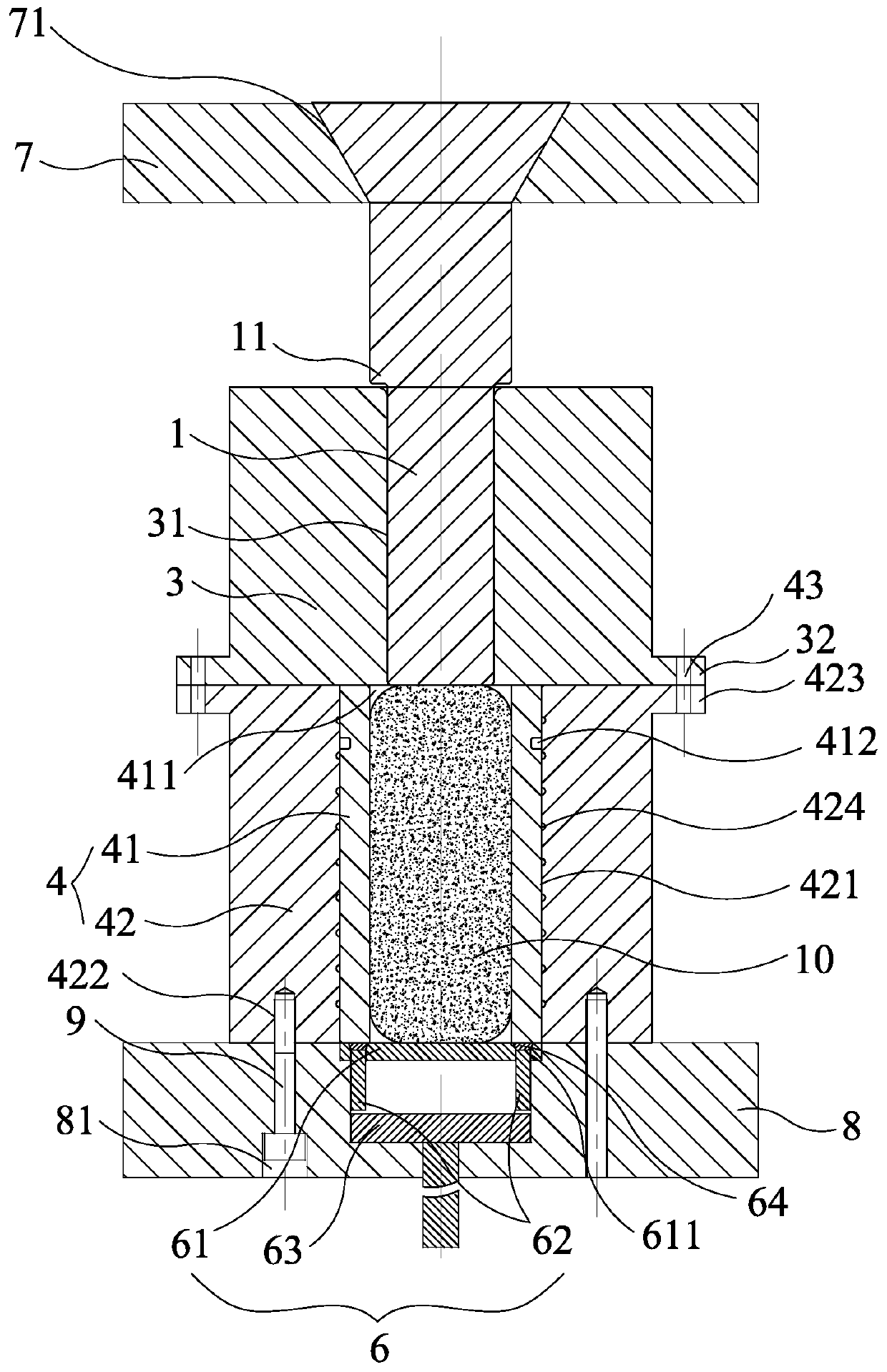

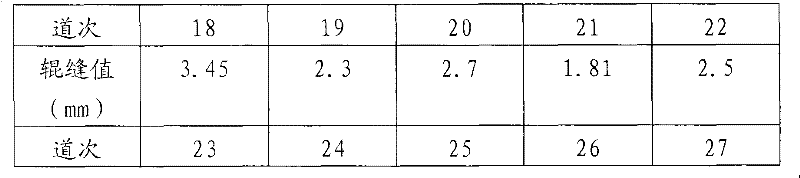

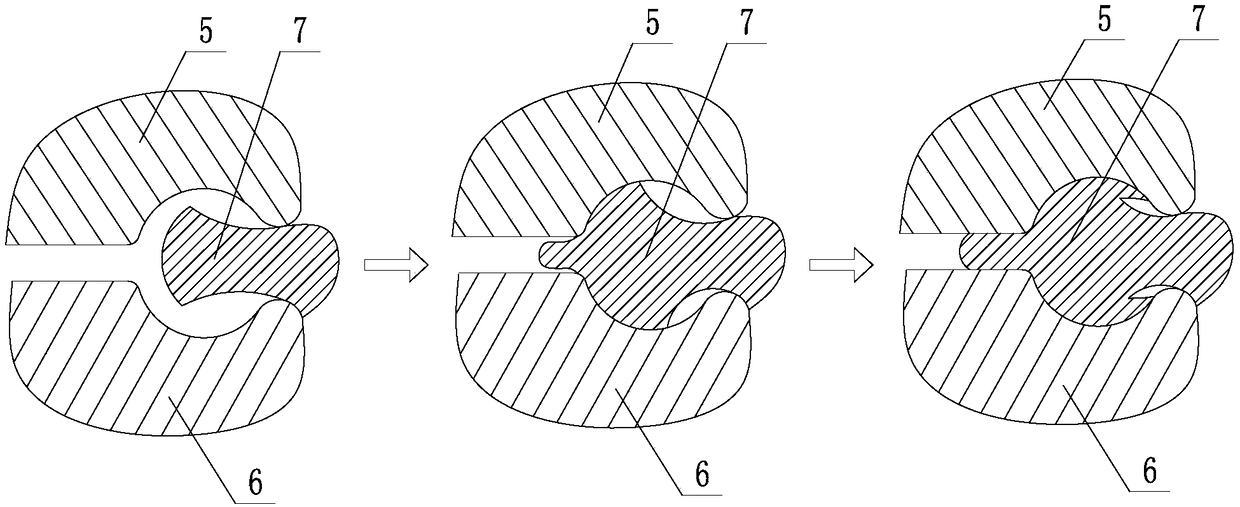

Multi-direction combined extrusion die and method for large-dimension flange three-way valve body

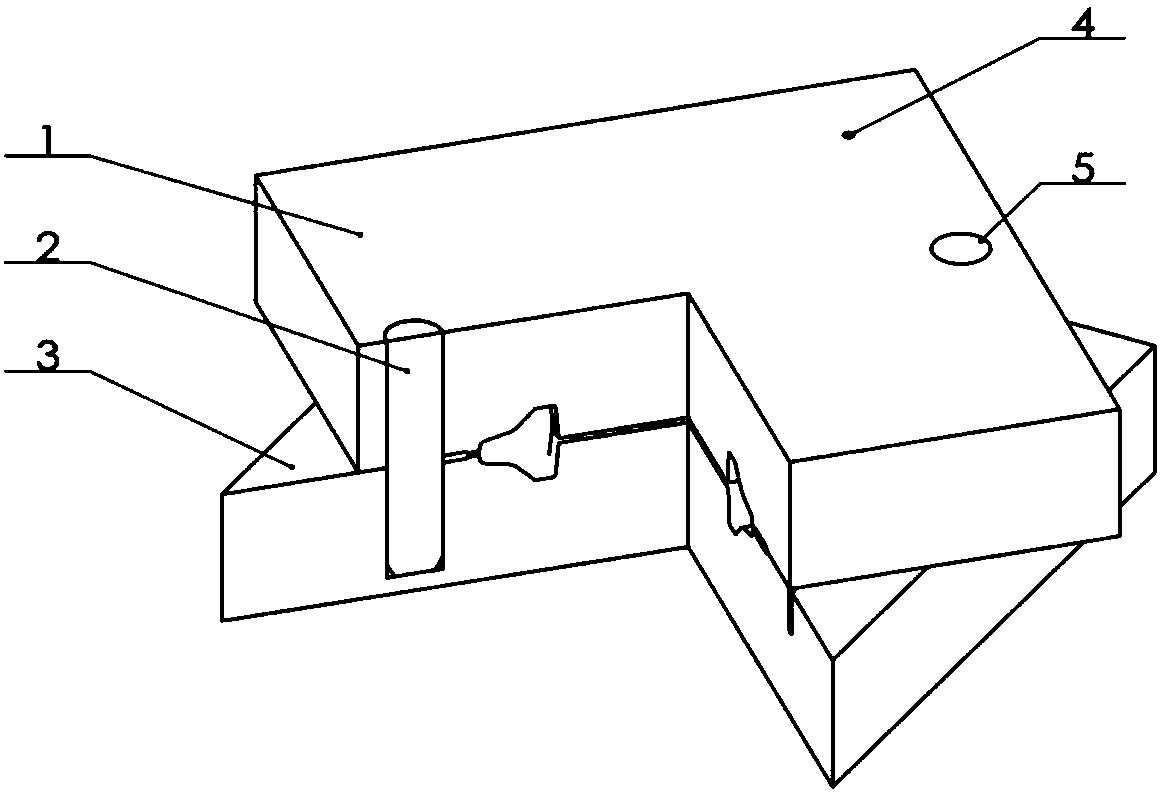

ActiveCN105127230ASimple structureEasy to useExtrusion diesMechanical engineeringIndustrial engineering

The invention discloses a multi-direction combined extrusion die for a large-dimension flange three-way valve body. A die chamber is partitioned into a middle die chamber and a side flange die chamber, the die is simple in structure and convenient to use, a blank does not need to be manufactured, metal in the molding process can be controlled to flow reasonably, the folding defect is effectively avoided, and the product quality is improved. The invention further discloses a multi-direction combined extrusion method for the large-dimension flange three-way valve body. The multi-direction combined extrusion die for the large-dimension flange three-way valve body is used, the middle die chamber and the side flange die chamber are used, the metal in the molding process can be controlled to flow reasonably, and the folding defect is effectively avoided; by means of the control method that a lower extrusion tray retreats first and then an upper extrusion tray carries out feeding, the metal die filling quality of the flange die chamber can be effectively improved; by means of the control method, the molding quality of materials can be effectively improved.

Owner:NANJING DEV ADVANCED MFG

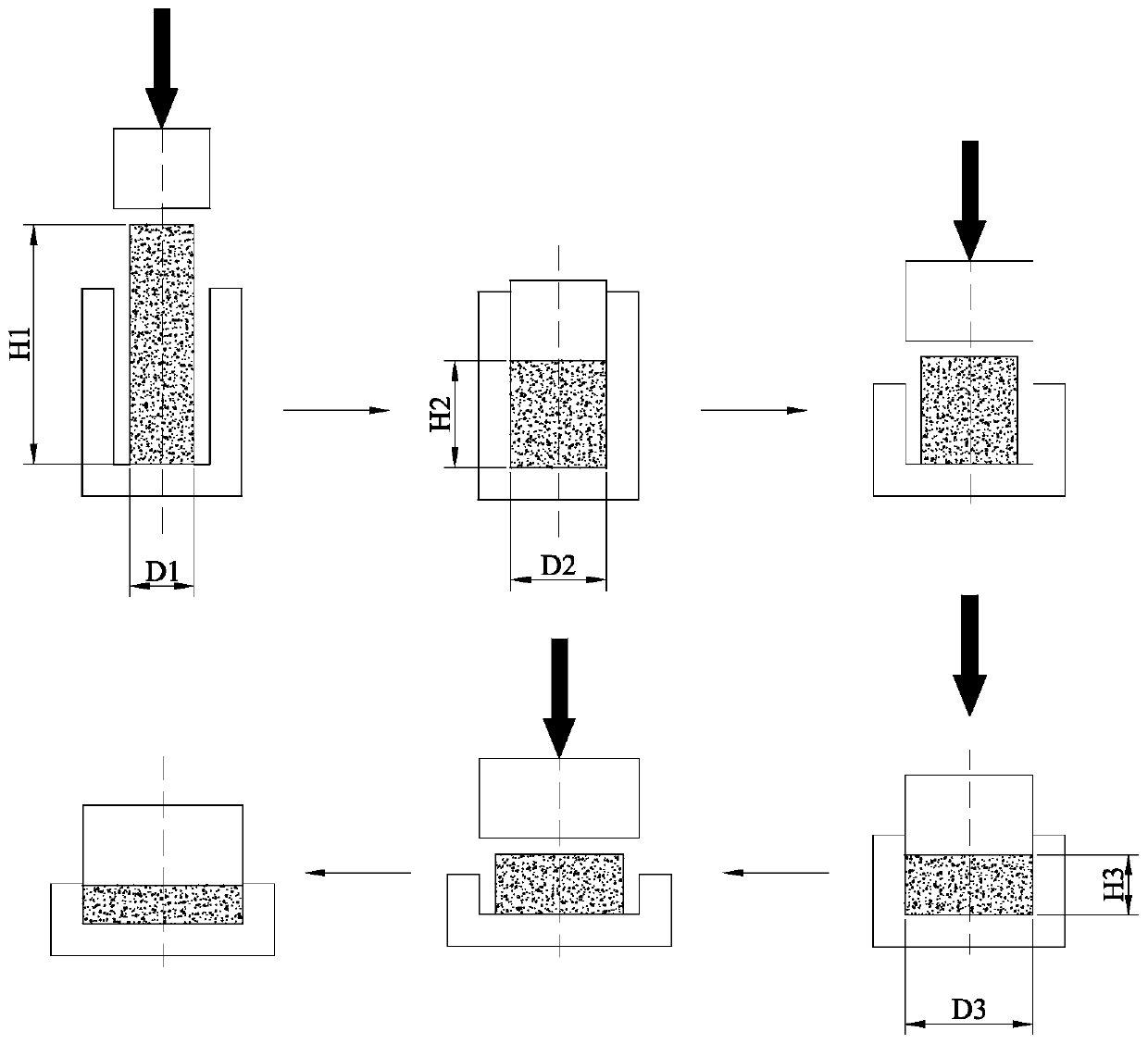

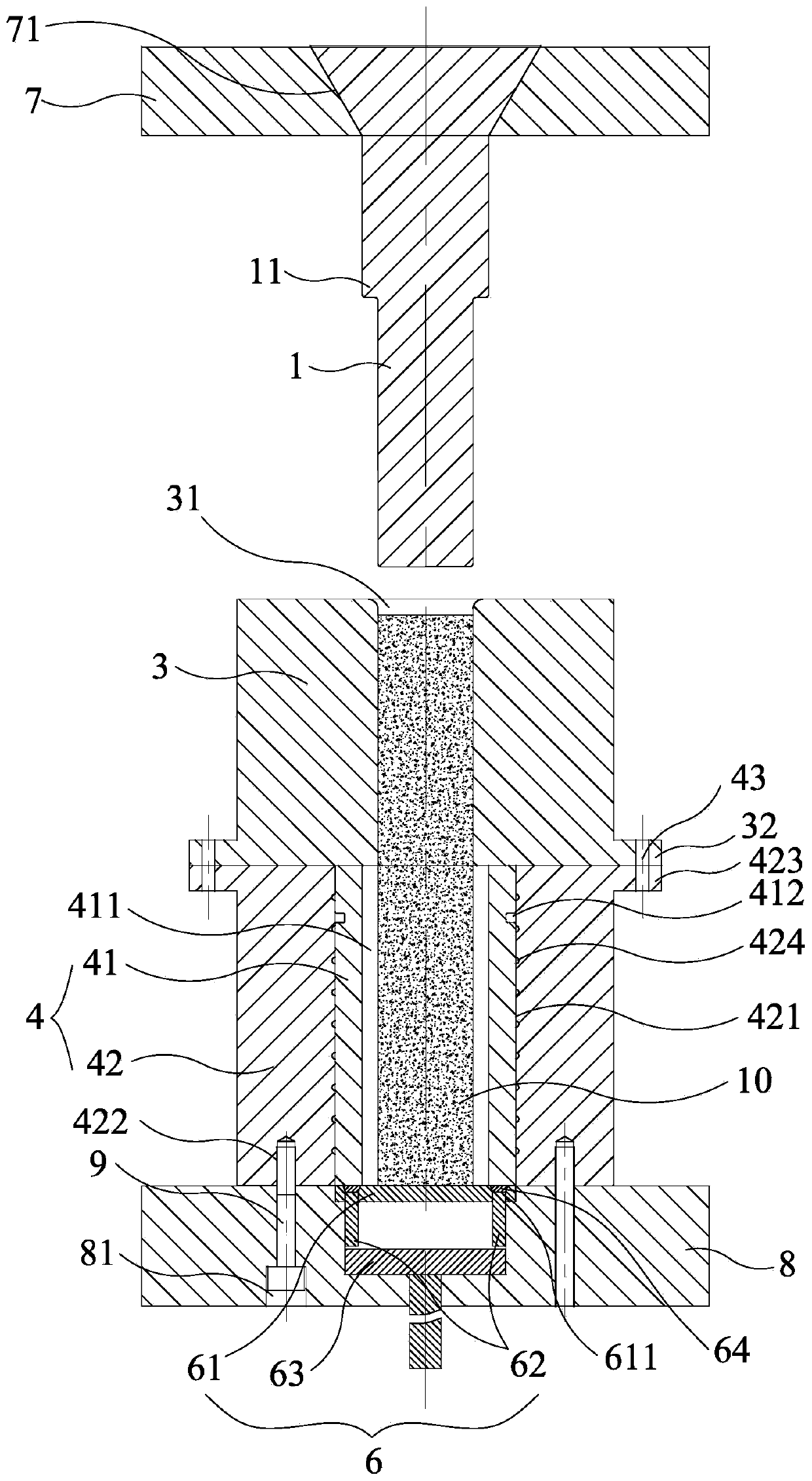

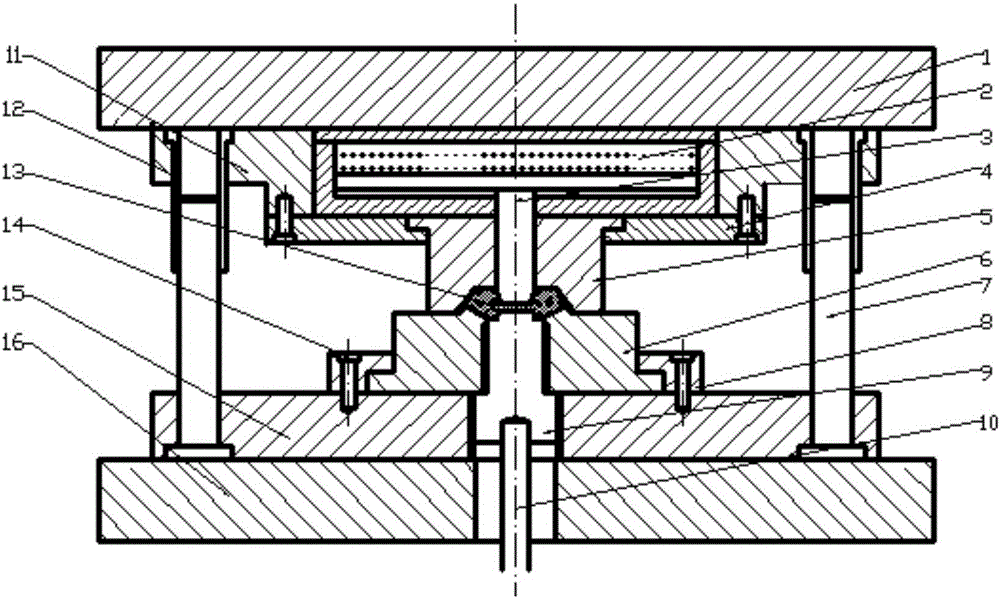

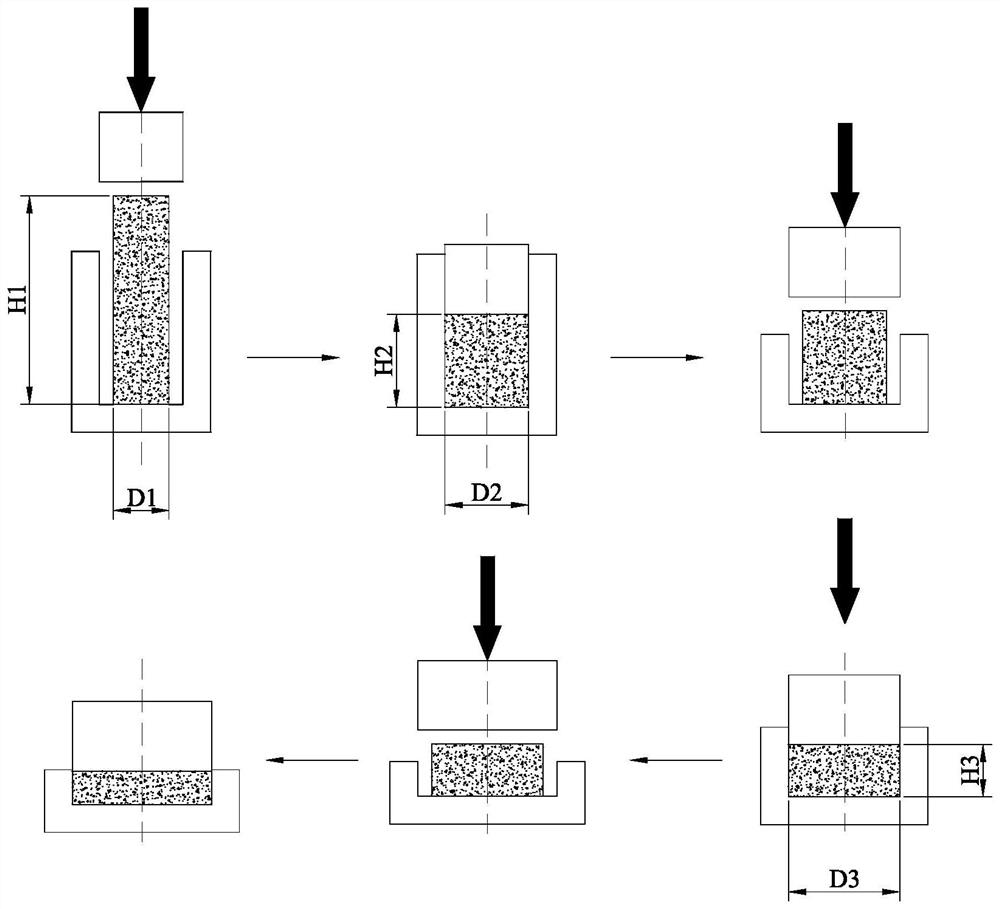

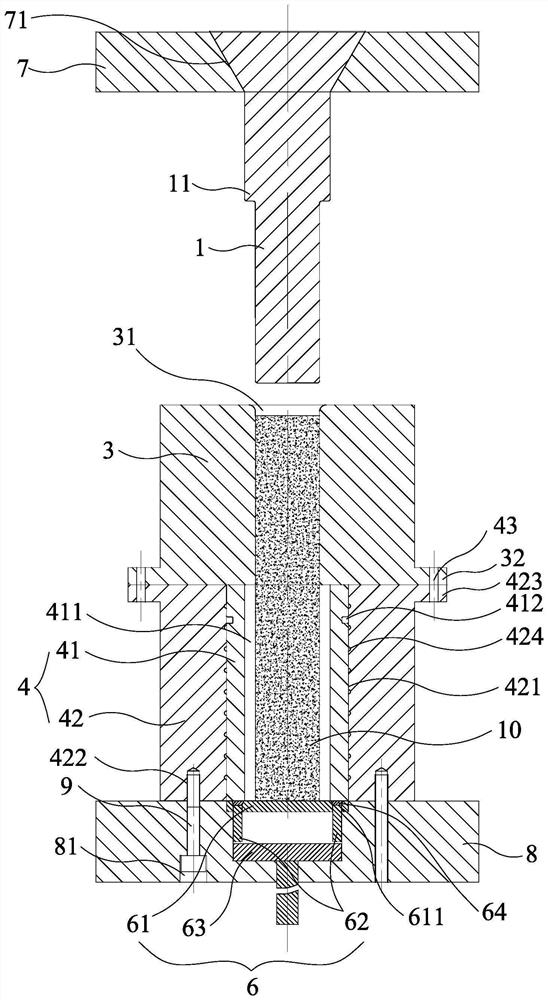

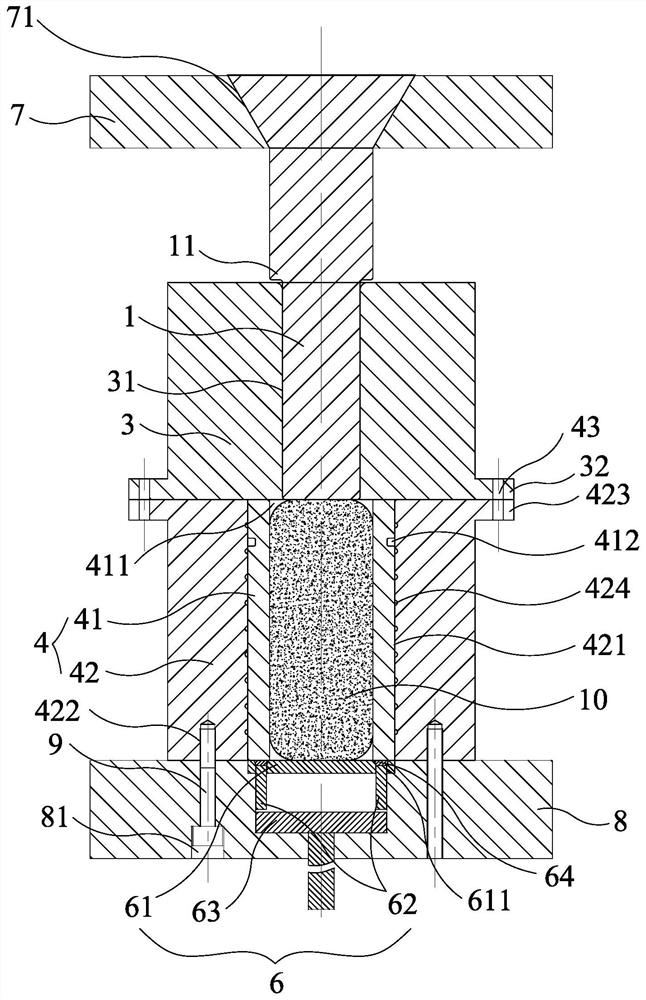

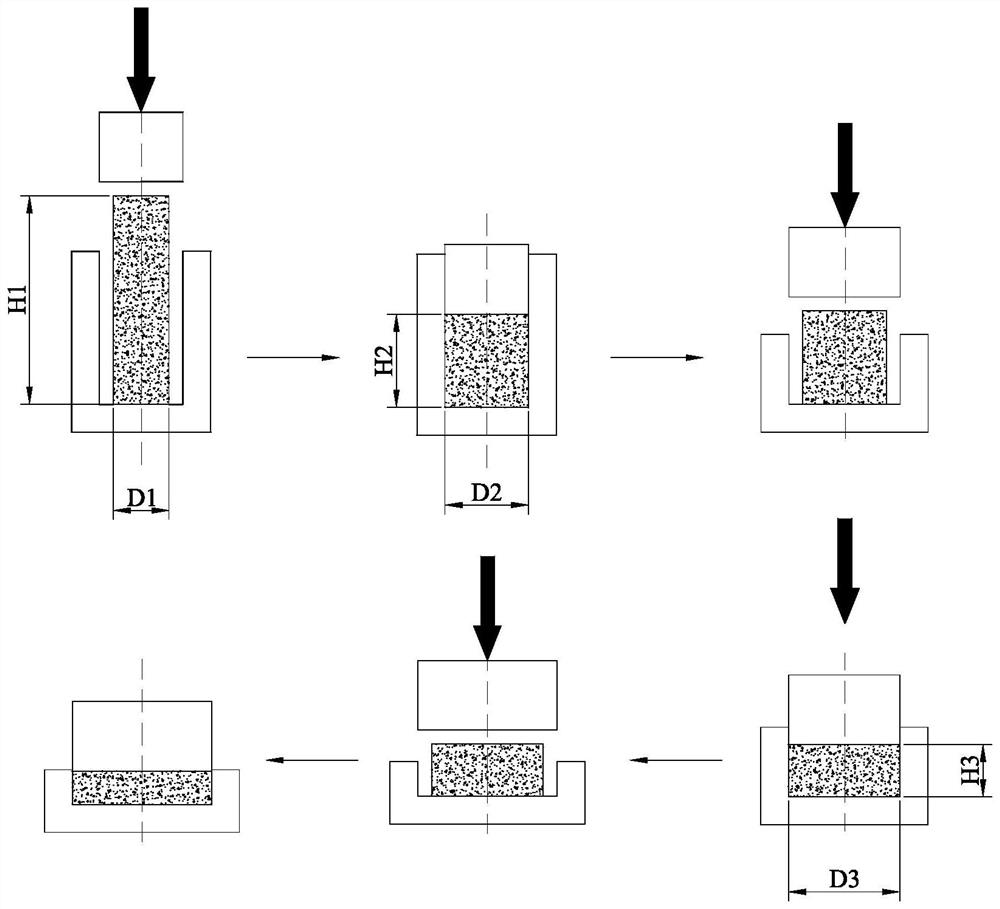

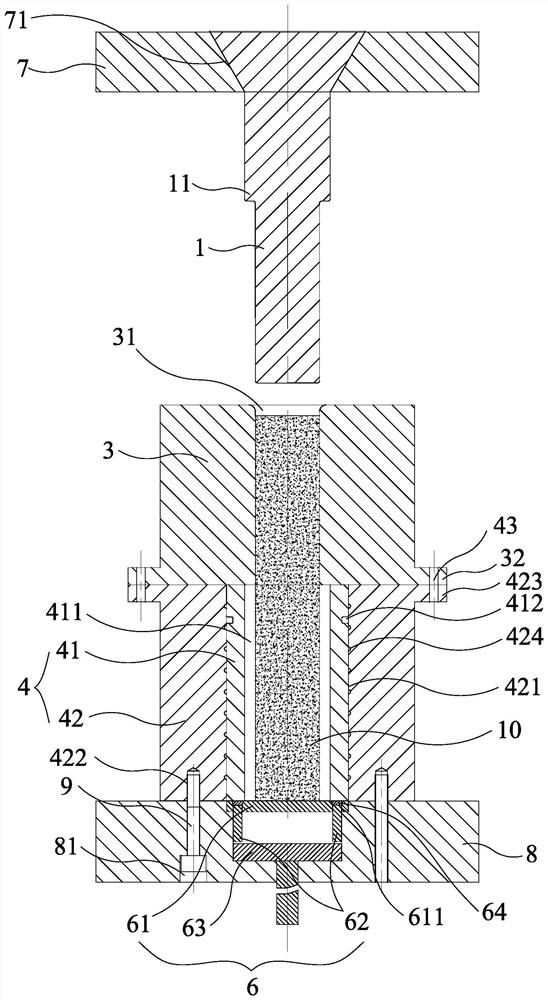

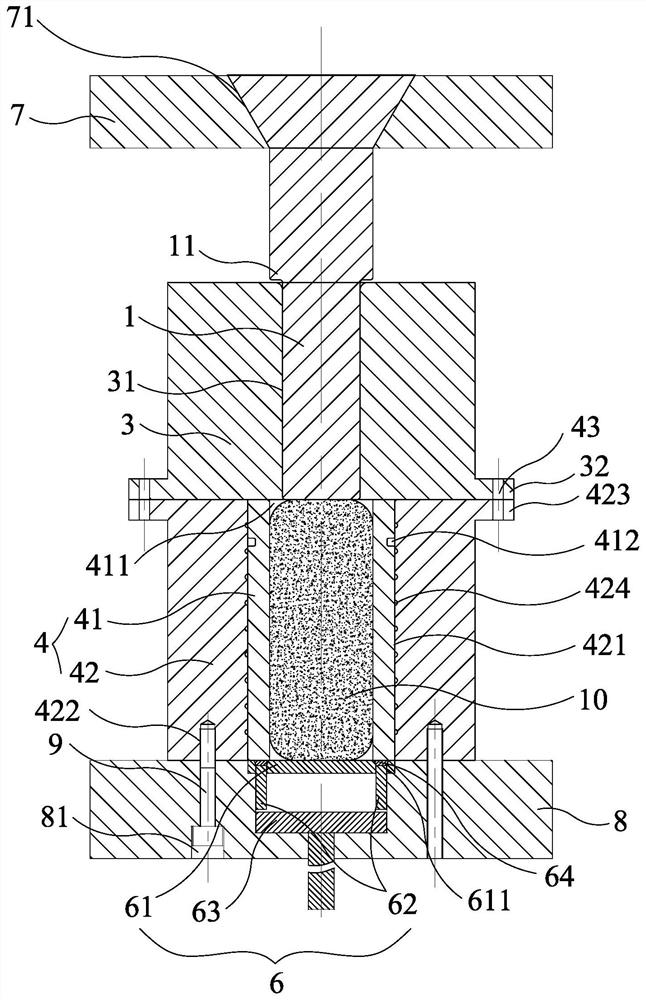

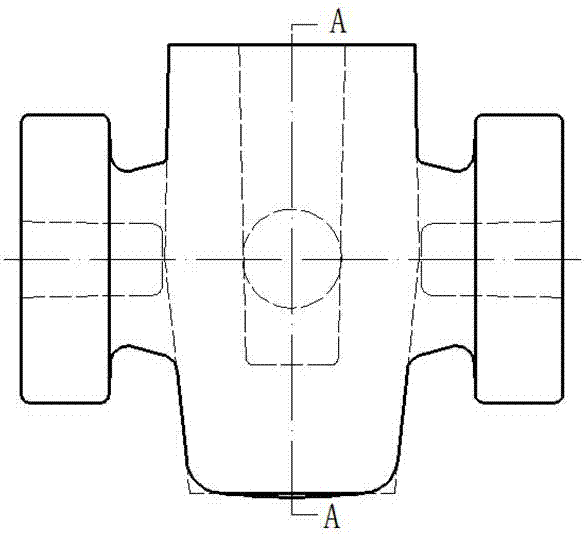

Large-specification large-height-diameter-ratio magnesium alloy casting rod continuous upsetting blank making method

ActiveCN111203503ARealize continuous upsetting large plastic deformationAvoid Folding DefectsForging/hammering/pressing machinesMetallurgyEngineering

The invention discloses a large-specification large-height-diameter-ratio magnesium alloy casting rod continuous upsetting blank making method. The large-specification large-height-diameter-ratio magnesium alloy casting rod continuous upsetting blank making method comprises the following steps that (1) blanking is conducted; (2) homogenization treatment is conducted; (3) a blank and a die are heated and heat preservation is conducted; (4) the blank is placed in a second lower cavity; (5) a male die downwards moves to extrude the blank to completely enter the second lower cavity; (6) an upper female die is firstly removed and a T-shaped ejector rod upwards moves, a vertical rod is pushed to extend upwards from a vertical groove and ejected out of an inner female die until a ring groove of the inner female die exposed out an external female die, and a clamping ring is clamped into the ring groove; (7) the ejector rod descends and resets to drive the vertical rod to contract and reset, the male die moves upwards and leaves the blank, and the lower part of the male die is sleeved with a male die lantern ring; and (8) the male die moves downwards and enters the second lower cavity to extrude the bottom of the blank to gradually fill the first lower cavity, and the blank of the first lower cavity is started being ejected upwards out of the inner female die, meanwhile, the first lowercavity is continuously filled with the bottom blank, and after the top height of the blank is flush, the male die stops moving downwards. According to the large-specification large-height-diameter-ratio magnesium alloy casting rod continuous upsetting blank making method, an ejector rod mechanism is ingeniously used for movably changing the cavity structure, forming is fuller, stability is higher, and materials are saved.

Owner:ZHONGBEI UNIV

Warm precise forging forming method for hollow gear shaft blank

InactiveCN104384428ADense and uniform internal tissueAvoid Folding DefectsMetal-working apparatusEngine componentsUltimate tensile strengthIndustrial engineering

The invention provides a warm precise forging forming method for a hollow gear shaft blank. The method is characterized by including the steps of 1) according to the shape and the size of a forge piece, optimizing the shape of a forging blank by simulation software and calculating the size of the forging blank by combining a volume invariant principle; 2) designing a forging die and a mandrel according to the size of the forging blank; 3) blanking, preliminary extrusion-upsetting and subjecting the blank to warm precise forging. The warm precise forging forming method for the hollow gear shaft blank has the advantages that the hollow gear shaft blank produced by the warm precise forging forming method enables a hollow gear shaft to be high in strength and precision, good in forming effect, compact and uniform in internal structure, good in surface quality and continuous and reasonable in forge piece streamline, so that general mechanical performances of the hollow gear shaft are improved; the method is high in material utilization ratio and efficiency, low in production cost, reliable in technology, stable in quality and the like.

Owner:CHONGQING UNIV OF TECH

Production method capable of reducing side part folding occurrence rate of wide plate

ActiveCN110076207AAddresses manufacturing defects with edge foldsFix Manufacturing DefectsMetal rolling arrangementsSheet steelUltimate tensile strength

The invention discloses a production method capable of reducing a side part folding occurrence rate of a wide plate, and relates to the technical field of steel material forming and control. Continuously-cast casting blank adopts big-chamfer crystallizer drawn steel, and the big-chamfer casting blank is subjected to secondary chamfering after a continuous casting section is discharged, wherein secondary chamfering pressure is set to be 70-80 bar, and a secondary chamfering dimension is 13-15 mm; according to a rolling schedule, a widening-pass single-pass pressing rate is set to be smaller than 10%, and phosphorous removal operation is not performed in a widening process; after forming pass and widening, phosphorous removal operation is a performed in fine-rolling pass; a widening ratio isgreater than 1.5 times, trimming amount of a rolled steel plate is greater than or equal to 80 mm, a widening ratio of all steel types is lower than or equal to 2.0 time; and a widening ratio is setto be lower than or equal to 1.8 times if the strength grade of the steel type is greater than 500 MPa, and trimming amount of the rolled steel plate is greater than or equal to 100 mm if a widening ratio is greater than 1.5 times. The production method solves the manufacturing defect of side part folding in a production process of an extra-wide steel plate.

Owner:NANJING IRON & STEEL CO LTD

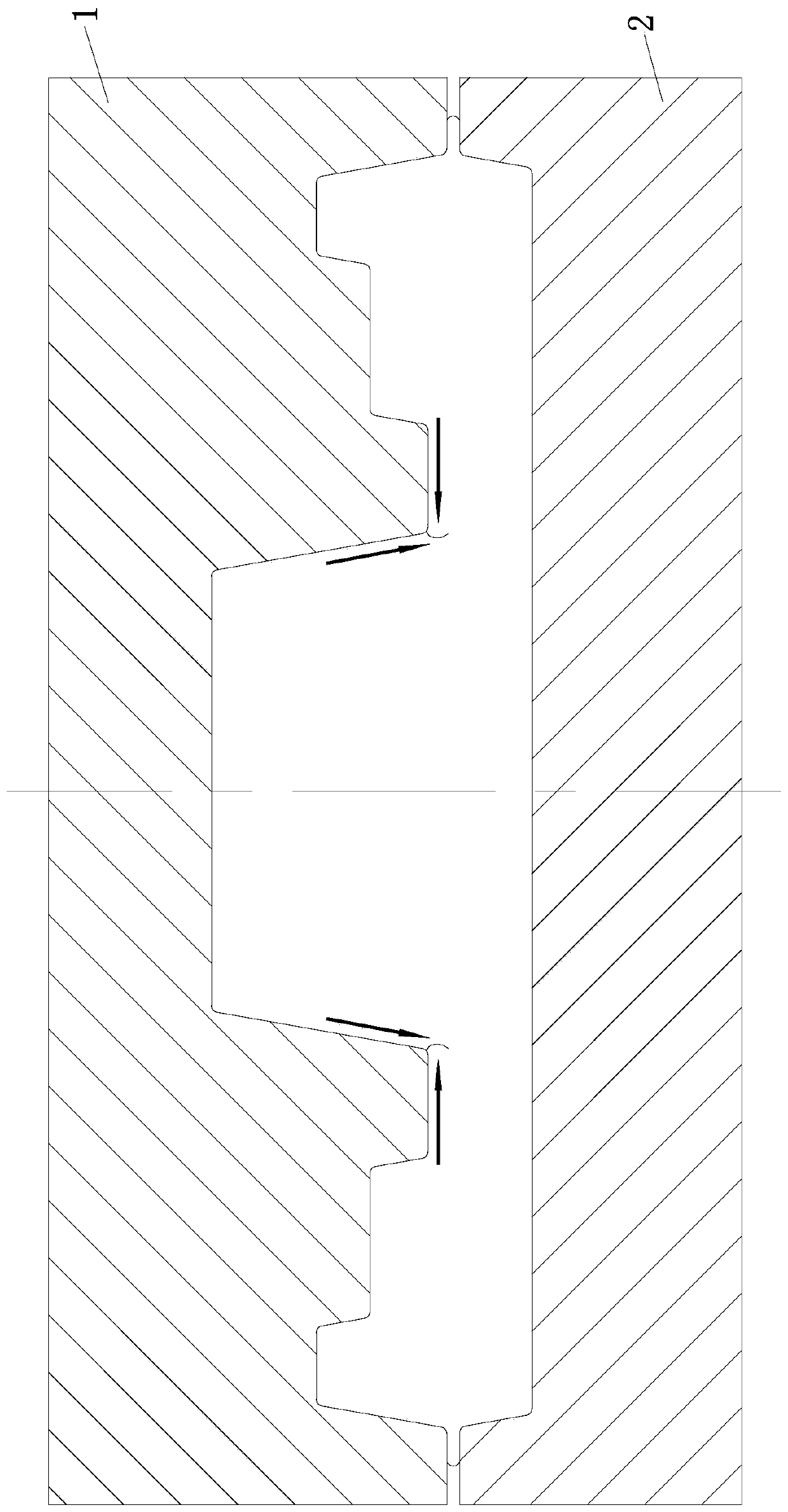

Combined split mold once extrusion forming method with large flange middle through body

ActiveCN109848236AShort process flowReduce energy consumptionShaping toolsPerforating toolsEngineeringEnergy consumption

The invention discloses a combined split mold once extrusion forming method with a large flange middle through body, and meanwhile, discloses a vertical double-acting extrusion combination mold of combined split molds. Left / right horizontal concave molds are closed to form a peripheral mold cavity; upper / lower vertical extrusion molds and the closed left / right horizontal concave molds form an axial mold cavity of a flange; upper / lower vertical perforating tools are arranged in the upper / lower vertical extrusion molds; and water cooling devices are arranged in perforating needles. The forming method comprises the steps of preheating of the combination mold, returning of the molds to a given initial position, placement and positioning of heated blanks, horizontal mold closing, vertical double-acting extrusion and demolding after extrusion shaping; the once extrusion forming of the vertical double-acting extrusion combination mold is realized; each mold can be independently operated to move; the reasonable flowing of metal can be flexibly controlled to prevent folding defects; the flange part is fully filled with metal, so that products only need one-fire heating and once extrusion forming; and the method is short in procedure flow, low in energy consumption, high in efficiency and precise in size of the products.

Owner:NANJING DEV ADVANCED MFG

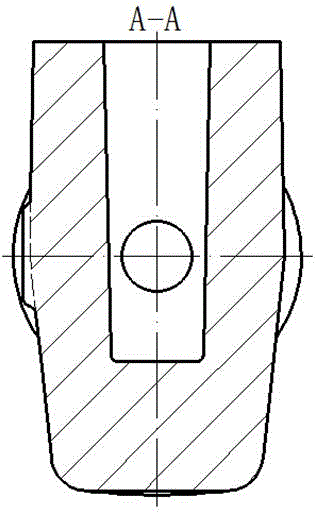

Semi-closed type forging die used for forging of bevel gear and forging method thereof

InactiveCN106001358AEasy to fillLarge forming forceForging/hammering/pressing machinesWheelsGear wheelEngineering

The invention discloses a semi-closed forging die for bevel gear forging and a forging method, comprising a toothed die, an upper punch, a back cone die and a lower punch, wherein the toothed die and the upper punch are matched and installed , the back cone mold and the lower punch are installed together; the closed space formed by the tooth mold and the back cone mold includes a cavity and a shunt structure located at the large end of the tooth mold. The shunt structure communicates with the cavity and is narrow. Clearance; when forging bevel gears, under the action of the upper punch, the blank first fills the cavity, and then presses into the shunt structure to ensure the filling fullness of the tooth profile. The mold adopts a semi-closed die forging structure, that is, the back cone die and the tooth-shaped die are closed to form a closed cavity, but a shunt structure is designed at the tooth top of the big end to make it easier to fill the cavity and avoid excessive of forming power.

Owner:SHANDONG UNIV +1

Forging and pressing method of steel rail heel and three-position molding die used thereby

ActiveCN104550593AQuality assuranceEnsure the quality is qualifiedForging/hammering/pressing machinesMaterials scienceHeel

The first purpose of the invention is to provide a forging and pressing method of steel rail heel; a steel rail heel comprises a pre-forging heel and a final forging heel; the pre-forging heel comprises a first section, a second section, and a third section; the final forging heel comprises a fourth section and a fifth section; the method specifically comprises the following steps: implementing a first stage forging and pressing after heating the first section, the second section and the third section, wherein the first two sections are molded by forging and pressing, the third section is pre-deformed; and implementing a second stage forging and pressing after heating the last three sections. The provided forging and pressing method adopts a measure of molding twice, thereby being able to solve the defect that the size of the molded final forging heel is unqualified, as well as greatly reducing the molding force in the entire steel rail heel product molding process. The second purpose of the invention is to provide a three-position molding die with a simple integral structure; a second upper die section inside a pre-forging rail molding cavity and a first pre-forging insert inside a final forging molding cavity are both in detachable structures, thereby meeting different requirements to the three-position molding die in the twice forging and pressing process; the three-position molding die is convenient to be assembled, and strong in practicability.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Equipment and method for eliminating edge black line defect of large-width steel rolled material

ActiveCN110405163AThe black line defect on the edge is not easy to appearLess prone to steel leakage accidentsSheet steelNarrow face

The invention provides equipment and a method for eliminating the edge black line defect of a large-width steel rolled material. The equipment comprises two opposite wide-face copper plates and two opposite narrow-face copper plates; the connection portions of the wide-face copper plates and the corresponding narrow-face copper plates are two continuous chamfers, each of which comprises a first crystallizer chamfer and a second crystallizer chamfer; and on the inner side of a crystallizer, an included angle between a first chamfer hot surface of each narrow-face copper plate and the corresponding wide-face copper plate is 155-165 degrees, and an included angle between a second chamfer hot surface of each narrow-face copper plate and the first chamfer hot surface of the corresponding narrow-face copper plate is 155-165 degrees. By utilizing the crystallizer and the method provided by the invention, a casting billet with a large-thickness chamfer surface can be produced, the corners of the casting billet during biting of each pass can be kept in a form of an obtuse angle at the whole broadening rolling stage, and the edge black line defect is not liable to occur on the rolled material.

Owner:SHANDONG IRON & STEEL CO LTD

Forming method of forging round square steel through precision forging machine

ActiveCN111151693AMeet product requirementsShorten working timeForging/hammering/pressing machinesHandling devicesHot workDimensional precision

The invention relates to a forming method of forging rounded square steel through a precision forging machine, and belongs to the technical field of steel forging. In order to solve the problem that the precision forging machine cannot forging the rounded square steel billet, the invention provides the forming method of forging rounded square steel by the precision forging machine. According to the method, a circular hammerhead is used for forging and forming, four passes are designed, the first to third passes are mainly circular deformation, and the fourth pass is the round billet which is transformed into the finished rounded square billet. According to the invention, the forging process parameters of the precision forging machine are optimized, the rounded square billet material finished product with high quality, high dimensional precision, dense and uniform structure and good surface quality are forged and used for hot processing such as forging, rolling, the folding defect of the products can be avoided, and the product qualification rate is improved. According to the forging method, the problem that the square hammerhead of the precision forging machine cannot produce the rounded square billet material is solved, the rounded square billet material is forged by using the round hammerhead, not only is the product requirement met, but also the working time of replacing thehammerhead is replace, the equipment production efficiency is improved, and flexible production organization is facilitated.

Owner:建龙北满特殊钢有限责任公司

Forging Forming Method of Triangular Aluminum Alloy Control Arm

ActiveCN106424529BAvoid Folding DefectsReduce repair workRailway componentsForging/hammering/pressing machinesControl armHeating furnace

The invention discloses a forging forming method of a triangular aluminum alloy control arm and aims at solving the problems in the prior art of low quality of a product, low material utilization ratio and low production efficiency. The forging forming method comprises the following steps: 1, blanking; 2, heating a blank: heating the blank in the first step in an electric induction heating furnace at the heating temperature of 420-480 DEG C, keeping the temperature for 5-8min to enable the blank to be uniformly heated, and finishing dynamic recrystallization after finishing forging to obtain uniform microstructures; 3, roll forgingforming: 1) calculating a roll forging pass n; 2) roll forging forming: comprising the following steps: from (1) first-pass roll forgingforming to (4) fourth-pass roll forging forming; 4, mis-shifted forming; 5, flattening forming; 6, pre-forging forming; 7, finish forging forming: carrying out finish forging forming on the basis of pre-forging forming, designing a die according to a hot forging drawing during finish forging forming, putting a pre-forging into a mold cavity of the finish forging die, and then obtaining a part in finish forging forming under the action of a press; and 8, shaping the forging.

Owner:JILIN UNIV

Isothermal die forging forming control method for radial rib shell forge piece

ActiveCN110000324AMeet high performance requirementsAvoid Folding DefectsForging press drivesForgeMetal

The invention discloses an isothermal die forging forming control method for a radial rib shell forge piece, and relates to a shell forge piece forming control method. The method comprises the following steps that 1, original blank materials are prepared; 2, upsetting is carried out to prepare a blank; 3, pre-forging is carried out for the first time; 4, pre-forging is carried out for the second time; and 5, final forging is carried out. According to the method, the blank is accurately prepared, the deformation degree is controlled, the deformation rate is controlled to enable the part, at therib part which is difficult to form, of a metal to partially flow, and the shape size and the size of a central recess hole are controlled, so that flowing and local deformation degree of the metal can be accurately controlled, the problems of folding, insufficient filling and streamline disorder are solved, and the forge piece can be stably manufactured in batches.

Owner:HARBIN INST OF TECH

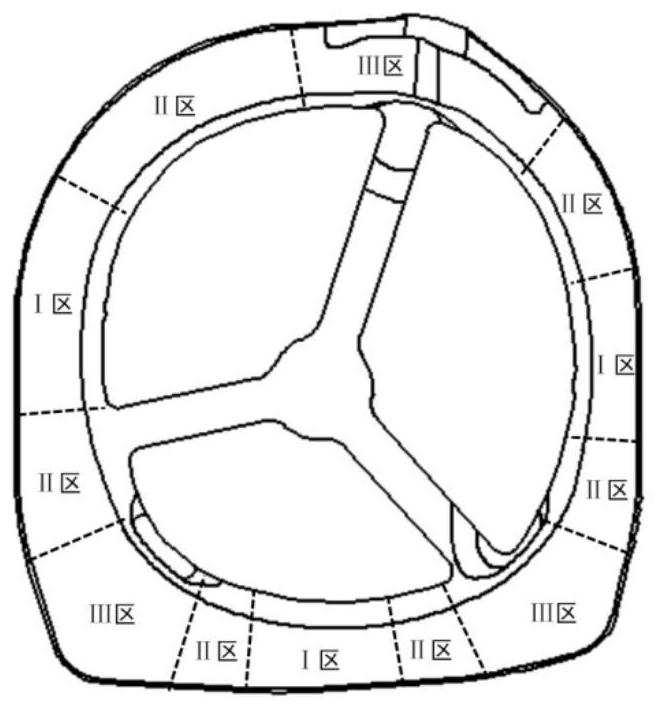

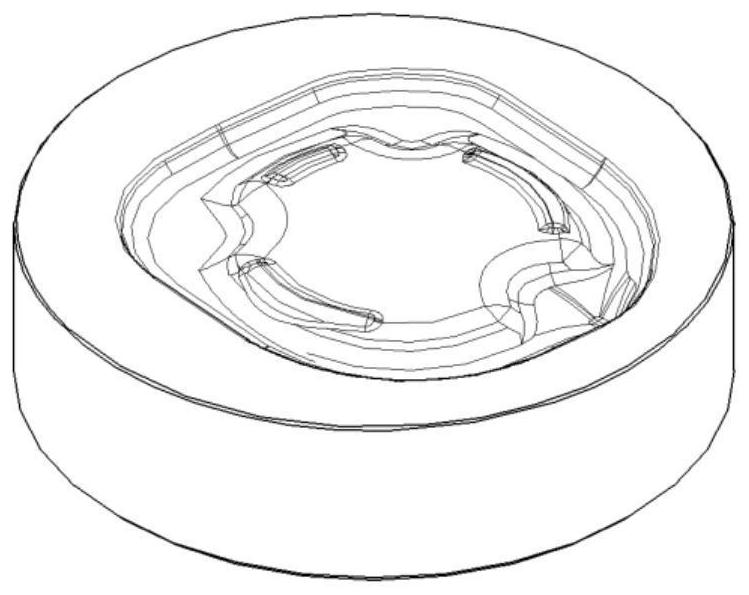

Inclined boss annular forge piece with special-shaped inside and outside and mold of inclined boss annular forge piece

The invention discloses an inclined boss annular forge piece with a special-shaped inside and outside and a mold of the inclined boss annular forge piece. The inclined boss annular forge piece with the special-shaped inside and outside and the mold of the inclined boss annular forge piece comprises a special-shaped section ring forge piece body with inclined bosses on the inner diameter and the outer diameter and a mold body for producing the special-shaped section ring forge piece body. A straight and flat boss is additionally arranged on the outer contour of the ring forge piece body, and the straight and flat boss and the special-shaped bosses are in transition through transition corners. The mold body comprises a special-shaped main roll, a blank and a servo core roll, a forge piece cavity is formed in the special-shaped main roll, the blank is arranged between the special-shaped main roll and the servo core roll, and the forge piece cavity is filled with the blank under the action of the special-shaped main roll and the servo core roll. In this way, according to the inclined boss annular forge piece with a special-shaped inside and outside and the mold of the inclined boss annular forge piece, the contact face of the blank and the main roll is added in the production process, so that the ring rolling process is more continuous and stable, the blank is prevented from being subjected to wavy warping or roll climbing well, the folding defect of a ring piece is effectively avoided, and product quality is ensured.

Owner:AVIC EXCELLENCE FORGING WUXI

A forging method for the heel end of a rail and the three-station forming die it adopts

ActiveCN104550593BQuality assuranceEnsure the quality is qualifiedForging/hammering/pressing machinesMaterials scienceHeel

The first purpose of the invention is to provide a forging and pressing method of steel rail heel; a steel rail heel comprises a pre-forging heel and a final forging heel; the pre-forging heel comprises a first section, a second section, and a third section; the final forging heel comprises a fourth section and a fifth section; the method specifically comprises the following steps: implementing a first stage forging and pressing after heating the first section, the second section and the third section, wherein the first two sections are molded by forging and pressing, the third section is pre-deformed; and implementing a second stage forging and pressing after heating the last three sections. The provided forging and pressing method adopts a measure of molding twice, thereby being able to solve the defect that the size of the molded final forging heel is unqualified, as well as greatly reducing the molding force in the entire steel rail heel product molding process. The second purpose of the invention is to provide a three-position molding die with a simple integral structure; a second upper die section inside a pre-forging rail molding cavity and a first pre-forging insert inside a final forging molding cavity are both in detachable structures, thereby meeting different requirements to the three-position molding die in the twice forging and pressing process; the three-position molding die is convenient to be assembled, and strong in practicability.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Continuous Upsetting Billet Making Method of Magnesium Alloy Cast Rod with Large Size and High Height-to-Diameter Ratio

ActiveCN111203503BRealize continuous upsetting large plastic deformationAvoid Folding DefectsForging/hammering/pressing machinesMetallurgyEngineering

The invention discloses a method for continuously upsetting a magnesium alloy cast rod with a large size and a large height-diameter ratio. ⑤The punch moves downward to extrude the billet into the second lower cavity completely. ⑥Remove the upper die first, then the T-shaped ejector rod goes up, pushes the vertical rod to protrude upward from the vertical groove and ejects the inner die until the inner die When the ring groove of the concave die is exposed to the outer die, snap the snap ring into the ring groove, ⑦The ejector rod is lowered and reset to drive the vertical rod to shrink and reset, the punch goes up and leaves the blank, and the punch collar is set on the lower part of the punch, ⑧The punch Go down and enter the second lower cavity to extrude the bottom of the billet to gradually fill the first lower cavity, and the billet in the first lower cavity begins to push out of the inner die upwards, and at the same time, the bottom billet continues to fill the first lower cavity. After leveling, the punch stops descending. The invention cleverly utilizes the ejector mechanism to change the structure of the cavity, so that the shape is fuller, the stability is stronger, and the material is saved.

Owner:ZHONGBEI UNIV

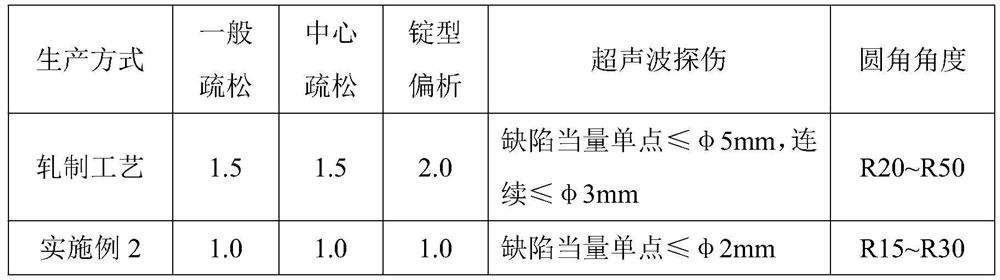

Ultra-clean low-carbon low-silicon steel wire rod controlled rolling process

ActiveCN101905245BHigh dimensional accuracyImprove rolling qualityRoll force/gap control deviceTemperature control deviceWire rodRejection rate

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

One-time extrusion forming method of horizontal double-acting combined mold of double-flange middle body

The invention discloses a one-time extrusion forming method of a horizontal double-acting combined mold of a double-flange middle body. Meanwhile, the method discloses a horizontal double-acting extrusion combined mold for vertical parting, the vertical upper female die and the vertical lower female die form a circumferential die cavity during die closing, the left horizontal extrusion die and theright horizontal extrusion die form an axial die cavity of the flange together with the vertical upper female die and the vertical lower female die after the die closing, the left horizontal punchingneedle and the right horizontal punching needle are arranged in the left horizontal extruding die and the right horizontal extruding die respectively, a water cooling device is arranged in each penetrating pin, the top head is arranged in the vertical downward concave die, wherein the vertical mold, the horizontal extrusion mold and the perforation tool can move independently. By utilizing the stroke of the extrusion head and the punching needle, the metal can be flexibly controlled to flow reasonably, and the folding defect is avoided, the metal filling of the flange part is full, the product can be formed only by one-time heating and one-time extrusion, the process flow is short, the energy consumption is low, the efficiency is high, and the product size is accurate.

Owner:NANJING DEV ADVANCED MFG

Die forging processing method for titanium alloy frame forgings with variable cross-section

ActiveCN111659842BQuality improvementImprove efficiencyForging/hammering/pressing machinesMetallic materialsMaterial distribution

The invention discloses a die forging processing method of a titanium alloy frame-like forging with variable cross-section. The titanium alloy frame-like forging with variable cross-section has a nearly circular frame structure. The cavity of the lower die of the forging die is provided with a concave structure distribution cavity corresponding to the difficult-to-form part of the designed forging during the forging process, and the distribution cavity on the billet mold and / or pre-forging die is used as a corresponding manufacturing The distribution of blanks and / or pre-forgings when they are formed by equal cross-section, equal radius to variable cross-section, and variable radius frame expansion during die forging. The invention can effectively adjust the flow speed and direction of the metal material during the forming process of the blank and / or pre-forging, so that the difficult-to-form parts and easy-to-form parts on the designed forging tend to be formed at the same time and with high quality, thereby reducing the forming pressure , To avoid the confluence of metal materials in forging in difficult-to-form parts and cause defects such as folding, and to ensure high-efficiency and high-quality forming of difficult-to-form parts of designed forgings.

Owner:SICHUAN ENG TECHN COLLEGE +1

A method for forming rounded square steel forged by a precision forging machine

ActiveCN111151693BImprove qualityHigh dimensional accuracyForging/hammering/pressing machinesHandling devicesHot workIndustrial engineering

The invention relates to a method for forming rounded square steel forged by a precision forging machine, which belongs to the technical field of steel forging. In order to solve the problem that the precision forging machine cannot forge the rounded square steel billet, the invention provides a method for forming the rounded square steel forged by the precision forging machine. The method uses a round hammer head for forging and forming, and a total of 4 passes are designed. The first ~The 3rd pass is dominated by circular deformation, and the 4th pass billet is deformed from a round billet to a finished round corner square steel billet. The invention optimizes the process parameters of the forging program of the precision forging machine to forge the finished product of rounded square steel billet with high quality, high dimensional accuracy, compact and uniform structure, and good surface quality, which can be used for thermal processing such as forging and rolling, which can avoid The product has folding defects and improves the product qualification rate. The invention solves the problem that the square hammer head of the precision forging machine cannot produce the rounded square steel billet, and uses the round hammer head to forge the rounded square steel billet, which not only meets the product requirements, but also saves the working time for replacing the hammer head, and improves the production efficiency of the equipment , to facilitate flexible organization of production.

Owner:建龙北满特殊钢有限责任公司

A preparation method of eccentric cylinder forging with abrupt cross-section

ActiveCN106391959BAvoid Folding DefectsAvoid tearingForging/hammering/pressing machinesBarrel ShapedHeight difference

The invention discloses a preparation method of a section mutation eccentric cylinder forging. The preparation method comprises the following steps: the structure of a blank is determined according to a final forging of a section mutation eccentric cylinder, and need to satisfy the following two conditions: (1) the blank has a section mutation eccentric part, and the section mutation eccentric part of the blank need to totally cover a spherical cylinder forming cavity of a final forging mold, so that the spherical cylinder forming cavity satisfies reverse filling formation during final forging, and the folding generated in refluxing of forging materials is prevented through reverse filling formation; and (2) the contacted point of the section mutation eccentric part of the blank with a lower mold of the final forging mold is A; the contacted point of the main body part of the blank with the lower mold of the final forging mold is B; the highest point of the spherical column forming cavity of the lower mold of the final forging mold is C; the lowest point of a forming cavity of the main body part of the lower mold of the final forging mold is D; the height difference between the point A and the point B is a; the height difference between the point C and the point D is d; the height difference a is equal to the height difference b; the positioning is performed through the height difference; the blank is machined; and the final forging is prepared.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Warm precision forging forming method of hollow gear shaft blank

InactiveCN104384428BDense and uniform internal tissueAvoid Folding DefectsMetal-working apparatusEngine componentsUltimate tensile strengthForge

The invention provides a warm precise forging forming method for a hollow gear shaft blank. The method is characterized by including the steps of 1) according to the shape and the size of a forge piece, optimizing the shape of a forging blank by simulation software and calculating the size of the forging blank by combining a volume invariant principle; 2) designing a forging die and a mandrel according to the size of the forging blank; 3) blanking, preliminary extrusion-upsetting and subjecting the blank to warm precise forging. The warm precise forging forming method for the hollow gear shaft blank has the advantages that the hollow gear shaft blank produced by the warm precise forging forming method enables a hollow gear shaft to be high in strength and precision, good in forming effect, compact and uniform in internal structure, good in surface quality and continuous and reasonable in forge piece streamline, so that general mechanical performances of the hollow gear shaft are improved; the method is high in material utilization ratio and efficiency, low in production cost, reliable in technology, stable in quality and the like.

Owner:CHONGQING UNIV OF TECH

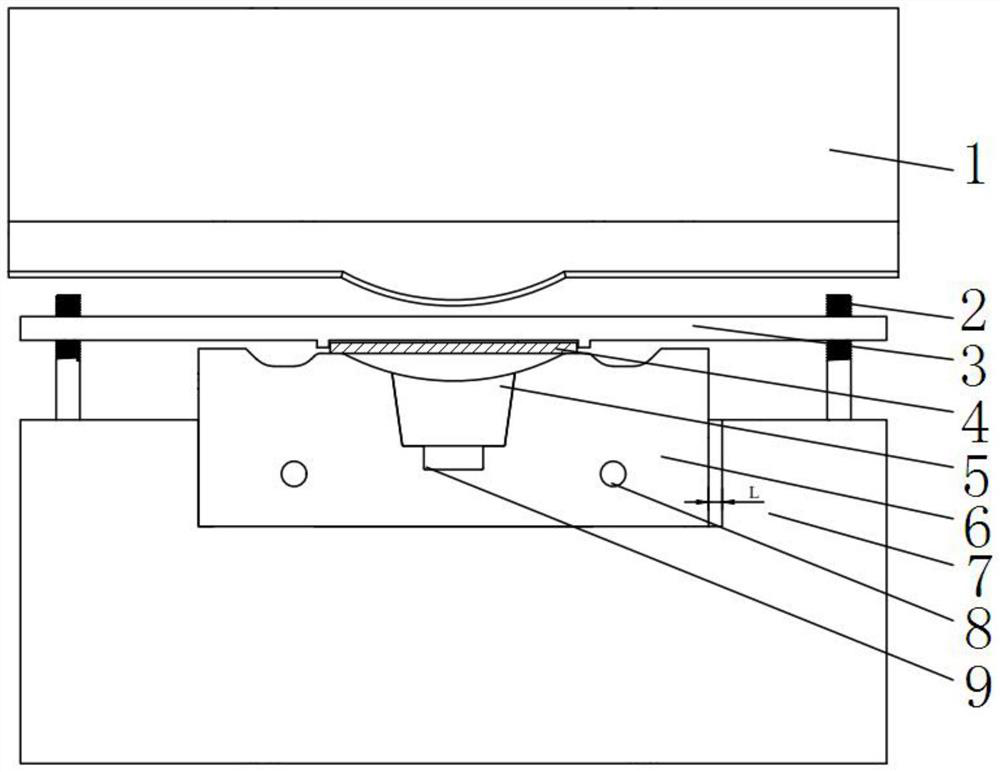

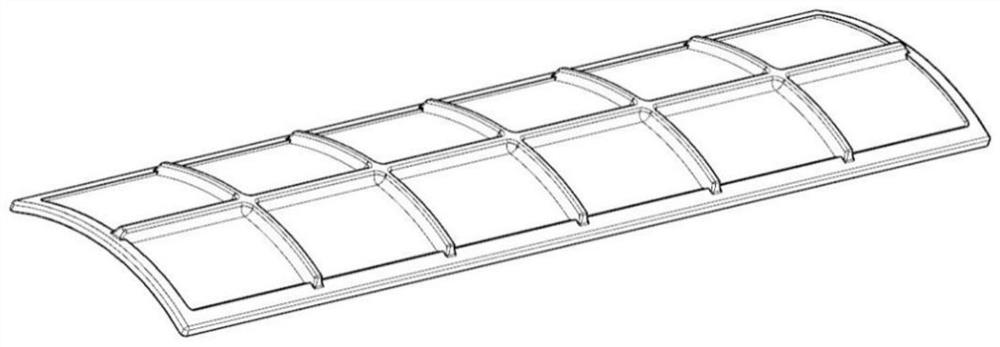

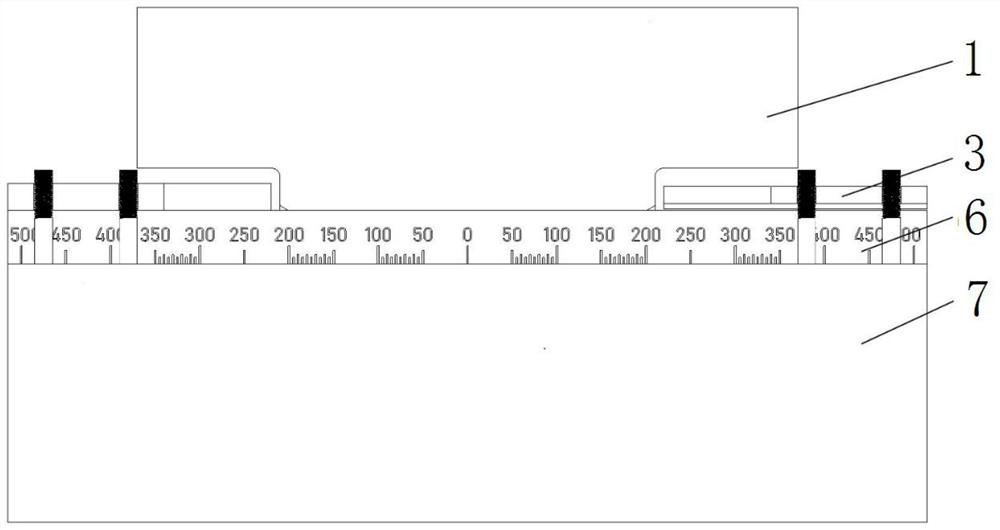

A progressive loading precision forming die device and process method for complex components of ultra-long grid high-rib wall panels

ActiveCN111872300BLess materialReduce forging costForging/hammering/pressing machinesHeating/cooling devicesEngineeringMesh grid

Owner:HARBIN INST OF TECH +1

Magnesium Alloy Cast Rod Continuous Upsetting Blank Die

ActiveCN111203508BRealize continuous upsetting large plastic deformationAvoid Folding DefectsForging/hammering/pressing machinesMetallurgyMechanical engineering

Owner:ZHONGBEI UNIV

A multi-directional compound extrusion die and method for a large-size flange three-way valve body

Owner:NANJING DEV ADVANCED MFG

A kind of isothermal die forging forming control method for radial rib shell forgings

ActiveCN110000324BMeet high performance requirementsAvoid Folding DefectsForging press drivesIndustrial engineeringMetal

The invention discloses an isothermal die forging forming control method for a radial rib shell forge piece, and relates to a shell forge piece forming control method. The method comprises the following steps that 1, original blank materials are prepared; 2, upsetting is carried out to prepare a blank; 3, pre-forging is carried out for the first time; 4, pre-forging is carried out for the second time; and 5, final forging is carried out. According to the method, the blank is accurately prepared, the deformation degree is controlled, the deformation rate is controlled to enable the part, at therib part which is difficult to form, of a metal to partially flow, and the shape size and the size of a central recess hole are controlled, so that flowing and local deformation degree of the metal can be accurately controlled, the problems of folding, insufficient filling and streamline disorder are solved, and the forge piece can be stably manufactured in batches.

Owner:HARBIN INST OF TECH

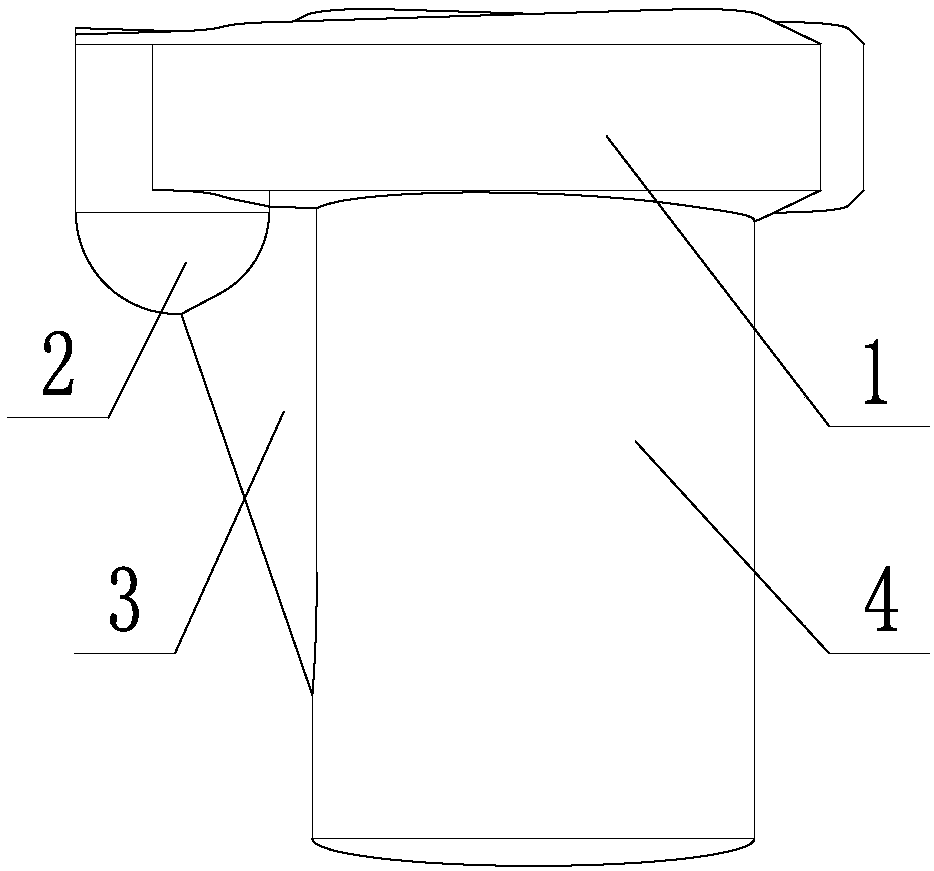

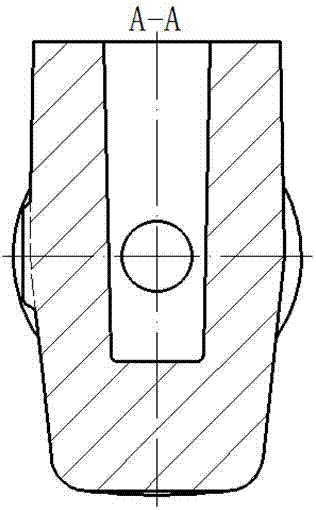

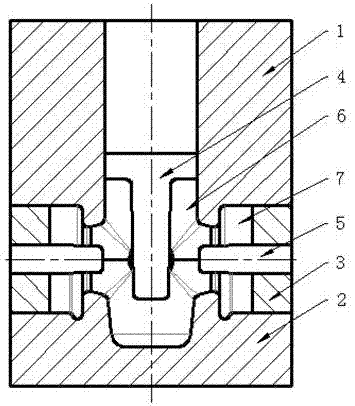

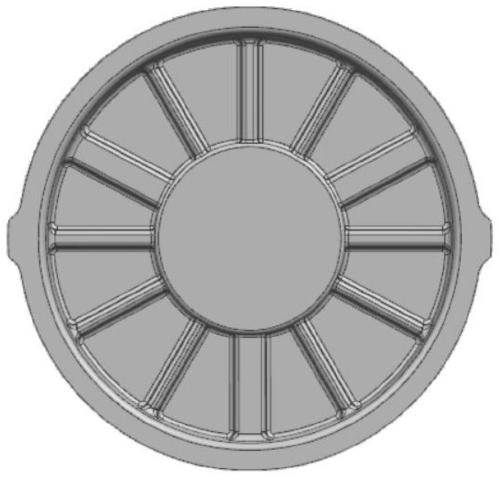

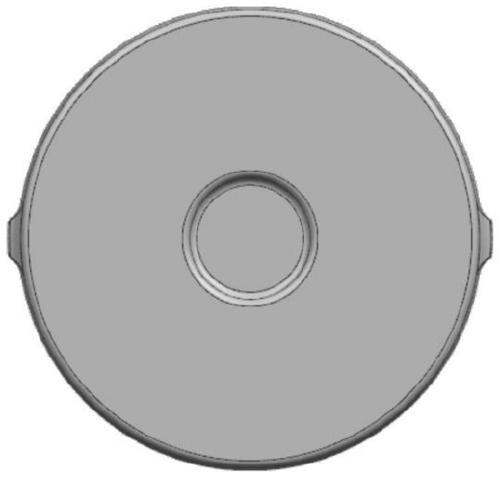

A kind of hob cutter ring forging mold and forging method for shield machine

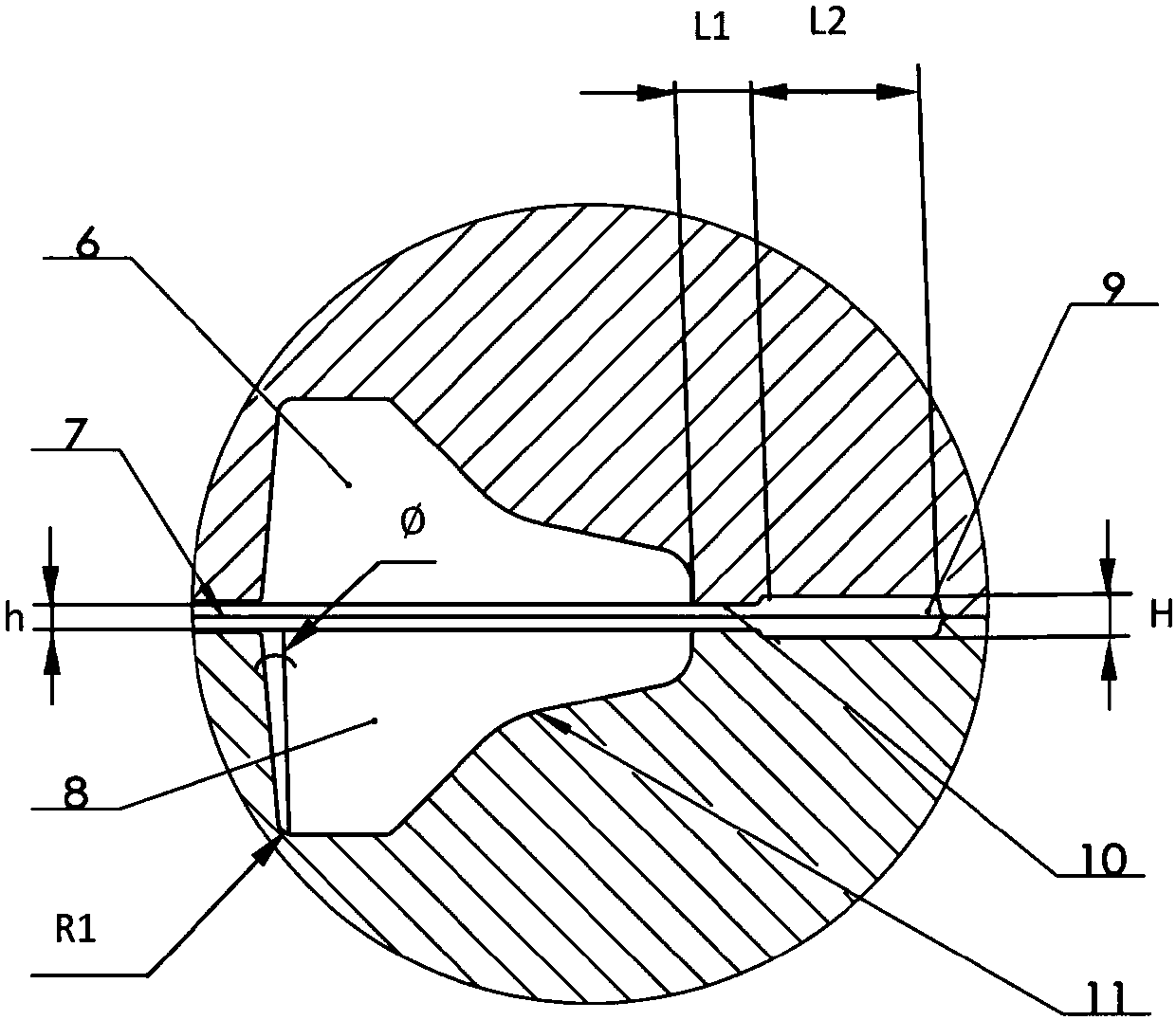

ActiveCN105798222BNo crackAvoid Folding DefectsForging/hammering/pressing machinesCutleryHobbingShield tunneling

The invention belongs to the field of forging and particularly relates to a hobbing cutter ring forging mold and forging method for a shield tunneling machine. The hobbing cutter ring forging mold and forging method for the shield tunneling machine are applicable to the designing and manufacturing process of the hobbing cutter ring forging mold for the shield tunneling machine. The forging mold comprises an upper mold for forging, a lower mold for forging, guiding and positioning pins, guiding and positioning holes, a hanging lug screw head hole, an upper mold cavity, a lower mold cavity, a parting surface, a flash bin part, a flash bridge part and the like. According to the connection manner of the whole set of mold, after the guiding and positioning holes of the upper mold for forging and the lower mold for forging are aligned, the guiding and positioning pins are inserted in. After the upper mold for forging and the lower mold for forging are closed, the shape of an inner cavity formed by combining the upper mold cavity and the lower mold cavity is the same as the external shape of a forge piece. A mold vice jaw position and an ejecting device are omitted for the forging mold, the structure is simple, and the forging mold can be conveniently obtained in engineering. A forging flow line of the forge piece produced by the adoption of the forging mold and forging method is closed and uniform, the compactness of the forge piece is high, and the structure mechanical property is good.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com