Equipment and method for eliminating edge black line defect of large-width steel rolled material

A large-width, steel plate technology, applied in the field of equipment for eliminating black line defects on the edge of large-width steel plate rolled products, can solve problems such as sharp tangent angles of narrow-faced copper plates, and achieve the effect of high service life and difficult mold breakout accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

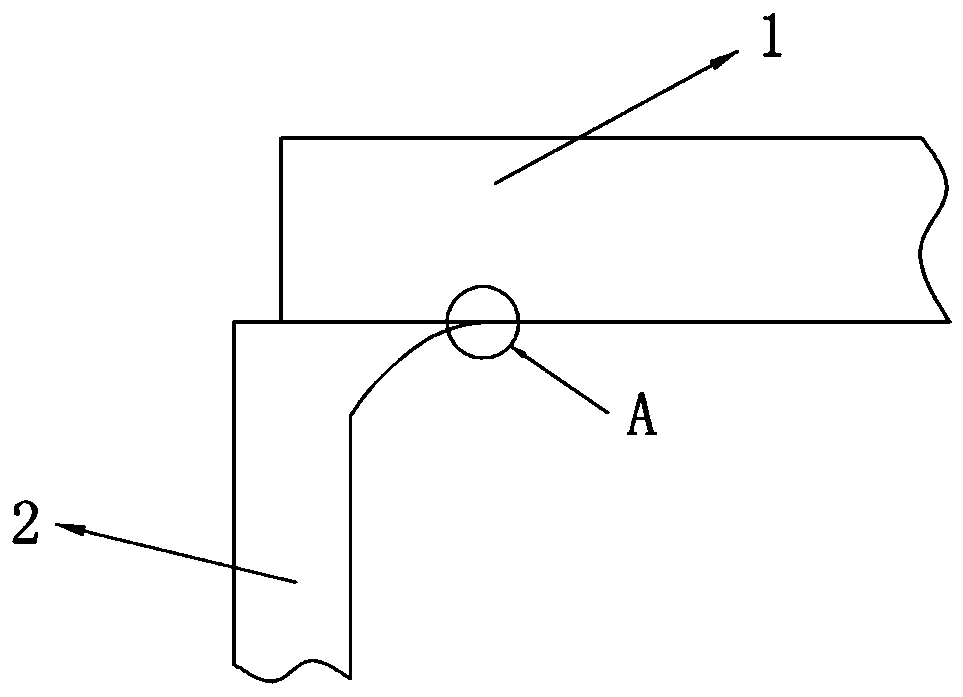

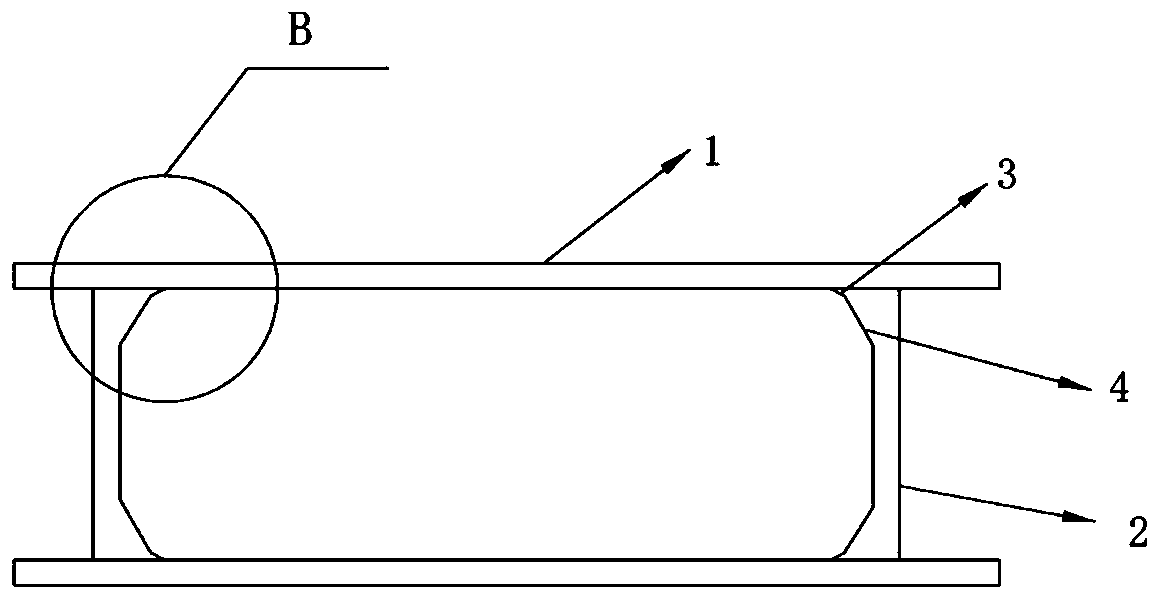

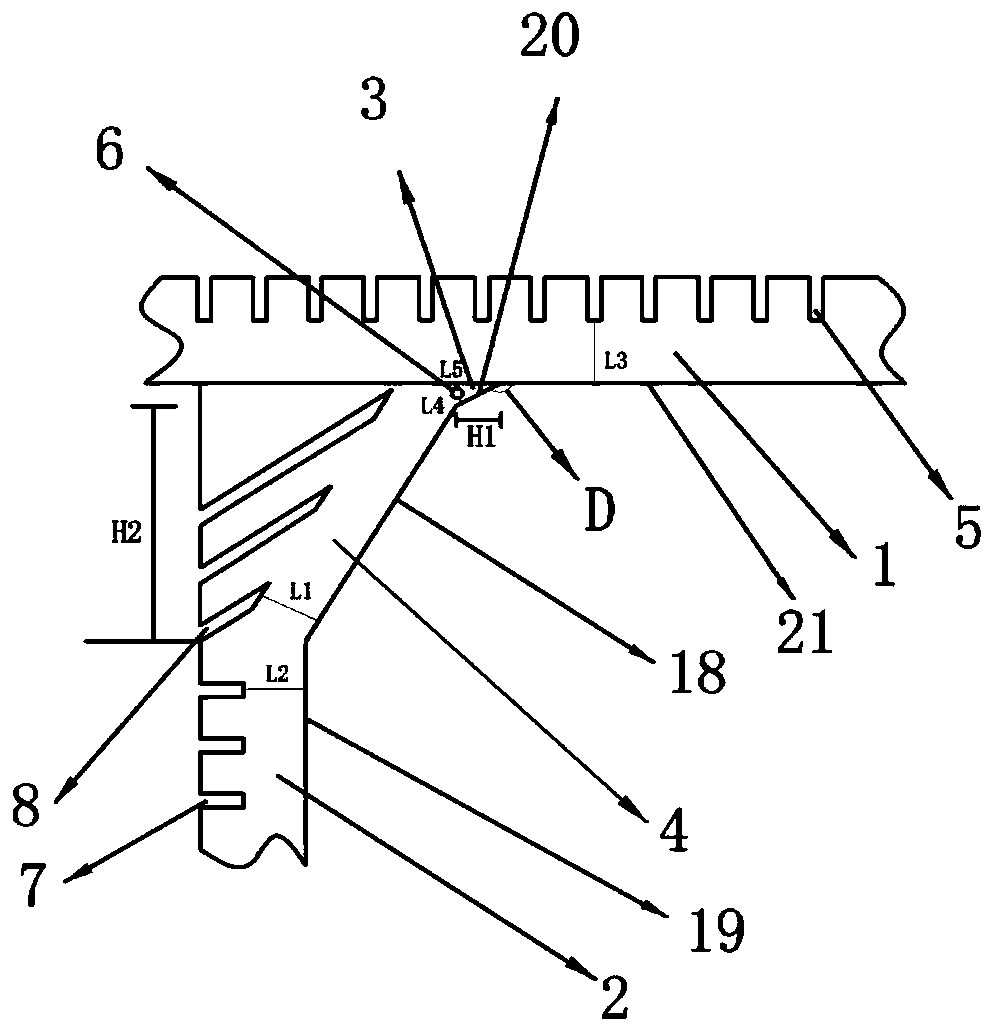

[0041] Such as Figure 2~3 As shown, it is a structural schematic diagram of a crystallizer for eliminating black line defects at the edges of large-width steel rolled products according to an embodiment of the present invention, including two relatively wide copper plates 1 and two relatively narrow copper plates 2, the narrow copper plates 1 The part that is connected with the wide copper plate 2 is the first chamfer 3 of the crystallizer and the second chamfer 4 of the crystallizer, and the chamfered surface of the first chamfer 3 of the crystallizer (i.e. the first chamfer of the narrow copper plate) The angle between the surface 20) and the wide copper plate 1 is 155-165°, the chamfering surface of the second chamfer 4 of the crystallizer (i.e. the second chamfer hot surface 18 of the narrow copper plate) and the first chamfer 3 of the crystallizer The angle between the chamfered surfaces is 155-165°; the back of the narrow copper plate 2 includes the straight cooling wat...

Embodiment 2

[0049] This embodiment provides a method for eliminating the black line defect at the edge of a large-width steel rolled product. First, the crystallizer described in Embodiment 1 is used to obtain a slab 9 with a large chamfer thickness. The corners of the slab 9 are two There are two consecutive chamfers, which are respectively the first chamfer of the slab and the second chamfer of the slab. When the slab 9 is just pulled out of the roller section of the second cooling chamber, the flame spray gun 10 moving back and forth is used to heat the first chamfer surface 15 of the slab to soften the first chamfer of the slab, as Figure 4 shown. The flame spray gun 10 is arranged at the first chamfering surface 15 of the casting slab, and the high temperature flame 11 sprayed out by the flame spraying gun 10 faces the first chamfering surface 15 of the casting slab. The combustion gas of the flame spray gun 10 is acetylene or coal gas. Heating increases the temperature at the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com