A progressive loading precision forming die device and process method for complex components of ultra-long grid high-rib wall panels

A precision forming and meshing technology, applied in metal processing equipment, forging/pressing/hammer devices, manufacturing tools, etc., can solve problems such as billet flow burr, metal flow folding, upper die size limit, etc., to save die usage materials, flexible modifications, and reduced forging costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

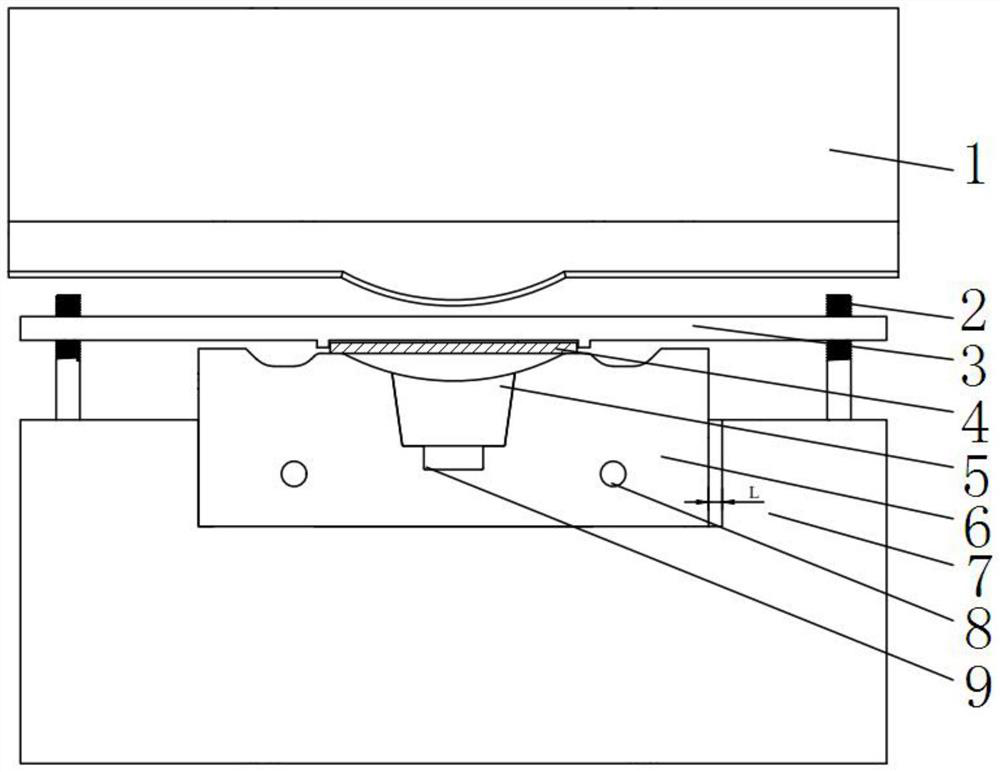

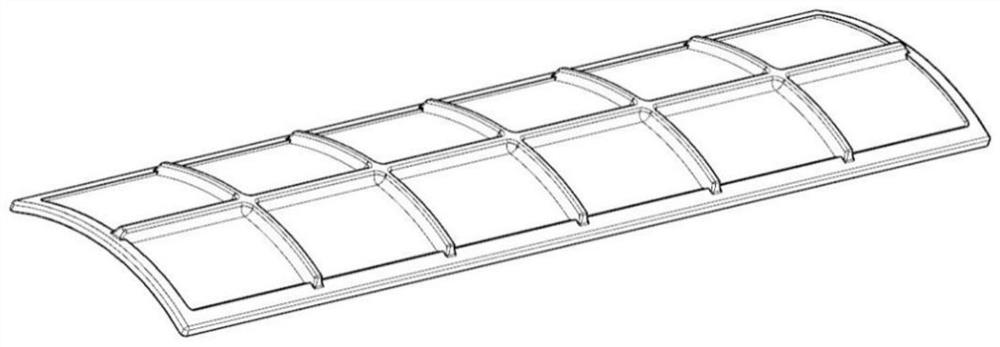

[0068] like Figure 1-10 As shown in the figure, taking a large mesh rib plate aluminum alloy member as an example, its shape is as follows figure 2 As shown, the part material is 5A06 aluminum alloy, the length of the component is 1100mm, the radius of the curved surface arc is 180mm, the central angle is 60°, there are 12 grids, each grid is 170mm long, 75mm wide, 4mm thick, and the ribs Height 10mm, rib width 10mm.

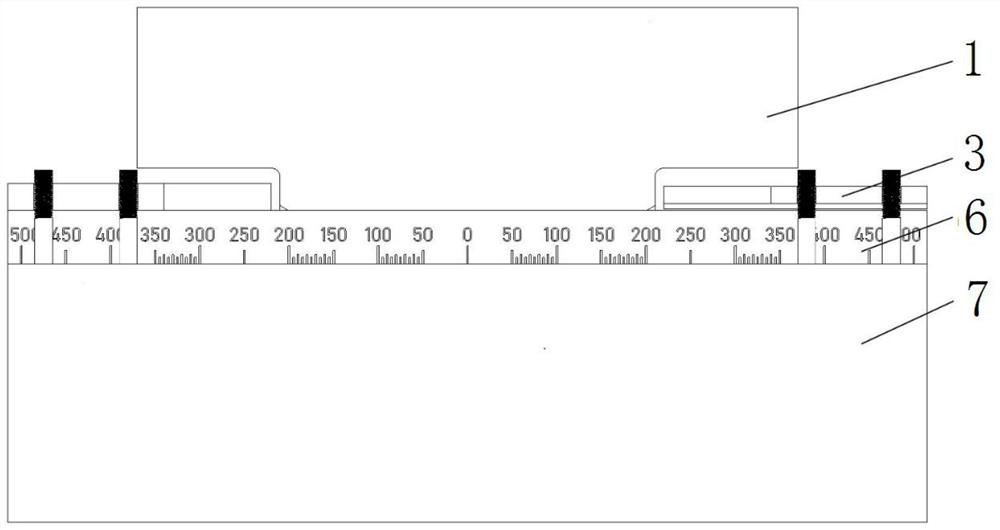

[0069] The progressive loading precision forming mold device for the complex component of the ultra-long grid high-rib wall plate in this embodiment includes a platen bolt 2, an insert 5, a mold core 6, a mold base 7, an upper mold 1, a first pressure plate 3, and a second pressure plate 12. , wedge iron 13, tie rod 14, the specific forming process is as follows image 3 and Figure 4 shown.

[0070] First, determine the blank size, the specific number of local loading and the order of local loading, loading length and loading zone location.

[0071] Dete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com