A kind of isothermal die forging forming control method for radial rib shell forgings

A technology of isothermal die forging and control method, which is applied to the driving device of the forging press, etc., can solve the problems of complex metal flow, failure to meet the requirements of rib shape and dimension accuracy, and flow line disorder, so as to avoid long-distance uncontrollable metal The effect of flow, good internal tissue performance and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1. Prepare the original billet: Preliminarily inspect the original extruded bar, cut it with a sawing machine, remove the coarse crystal ring of the outer skin, and obtain a bar of Φ235mm×60mm;

[0046] 2. Upsetting billet: heat the Φ235mm×60mm bar to 420°C for 90 minutes, heat the mold flat anvil to 400°C-450°C, and upsetting to Figure 7 The cake base of Φ320mm×30mm shown;

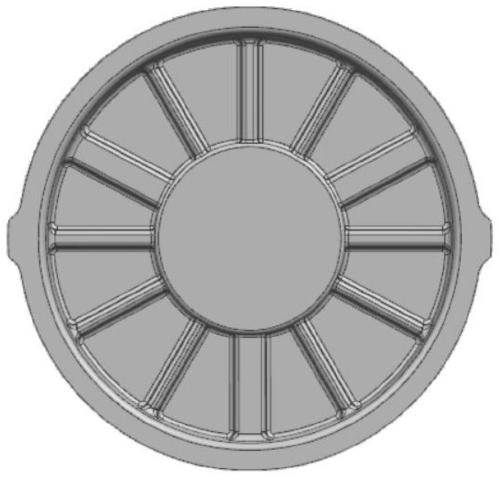

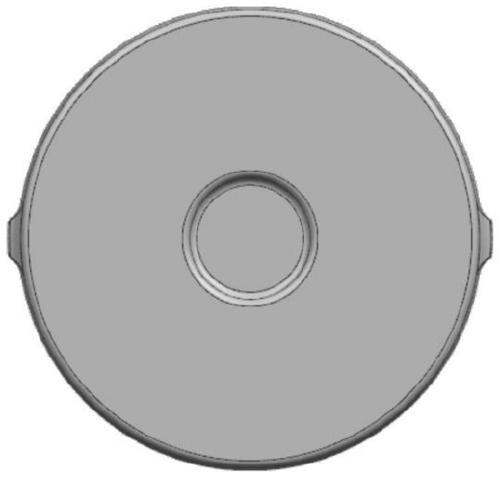

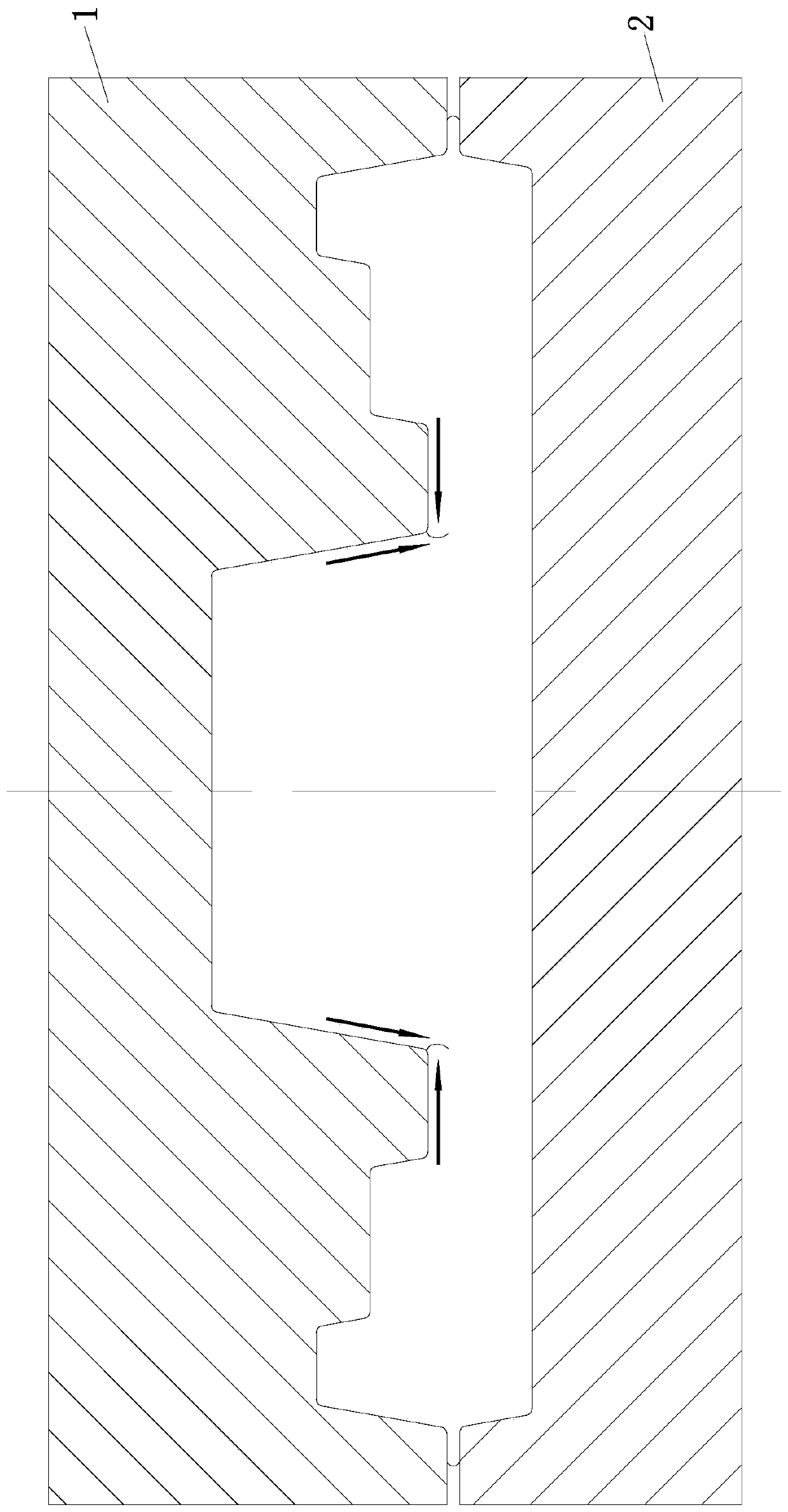

[0047] 3. The first pre-forging: use Figure 8 Shown on the upper die 1 and Figure 9 The final forging die formed by the lower die 2 shown in the figure forms the 2A12 (LY12) cake base obtained by upsetting with a size of Φ320mm×30mm, heats the blank, the upper die 1 and the lower die 2, and the upper die 1 and the lower die 2 The temperature range is 400°C-450°C, and the billet temperature is about 410°C-430°C;

[0048] The upper die 1 is pressed down at a speed of 12.8mm / s until there is 6-8mm remaining between the upper die 1 and the lower die 2. At this time, the tonnage is 2200 tons, and ...

Embodiment 2

[0052] 1. Prepare the original billet: Preliminarily inspect the original extruded bar, cut it with a sawing machine, remove the coarse crystal ring of the outer skin, and obtain a bar of Φ235mm×60mm;

[0053] Two, upsetting billet: the The bar material is heated to 420°C for 90 minutes, the flat anvil die is heated to 425°C, and upsetting to Figure 7 The cake base of Φ320mm×30mm shown;

[0054] 3. The first pre-forging: use Figure 8 Shown on the upper die 1 and Figure 9 The size of the final forging die formed by the shown lower die 2 to upsetting is The 2A12 (LY12) cake blank is formed, and the blank and the upper mold 1 and the lower mold 2 are heated. The temperature range of the upper mold 1 and the lower mold 2 is 425 ° C, and the blank temperature is 420 ° C;

[0055] The upper die 1 is pressed down at a speed of 12.8mm / s until there is 7mm left between the upper die 1 and the lower die 2. At this time, the tonnage is 2200 tons, and the first pre-forging is obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com