Die forging processing method for titanium alloy frame forgings with variable cross-section

A technology of die forging processing and variable section, applied in metal processing equipment, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of reduced efficiency, uneven distribution of pre-forgings, poor process control consistency, etc. The effect of forming pressure and stable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

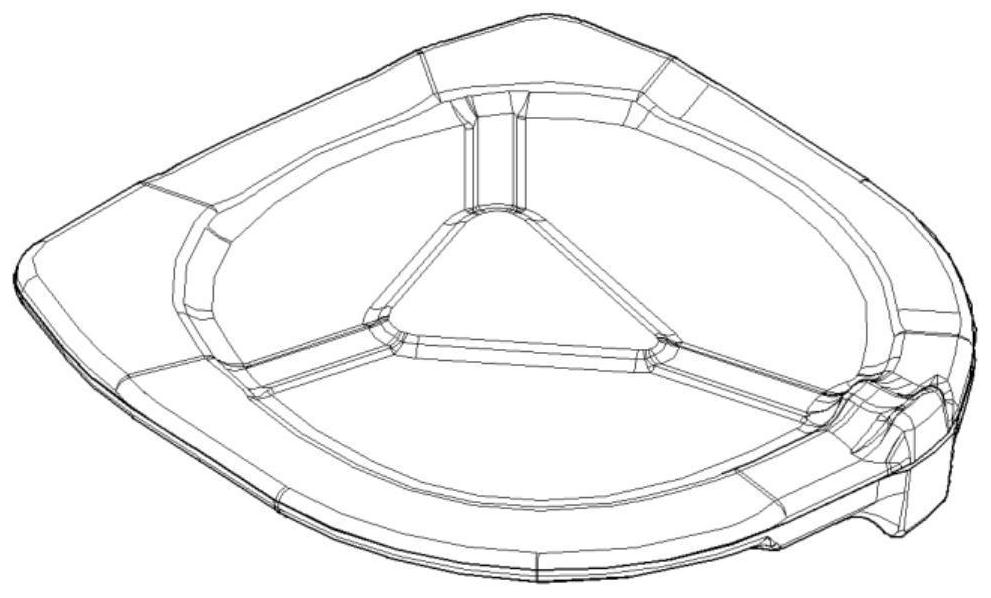

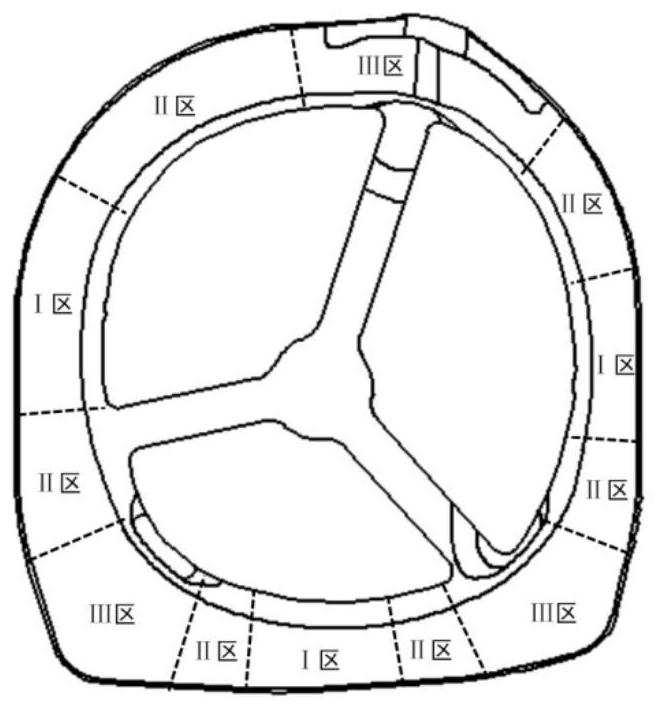

[0041] Since the design forging of the present invention has a nearly circular frame structure with irregular variable cross-section and variable radius, there must be easy-to-form parts and difficult-to-form parts in the die forging process, and the difficult-to-form parts are the forging parts of the design forging. Technical difficulties in processing.

[0042] Die forging processing method of the present invention comprises following process measure:

[0043] -According to the size and structural characteristics of the designed forging, as well as the size of the equipment forming force and the deformation of the forging, it is determined that the frame expansion size ratio of the designed forging in the final forging process section, pre-forging process section, billet making process section and billet process section is about 1:0.97:0.93:0.55;

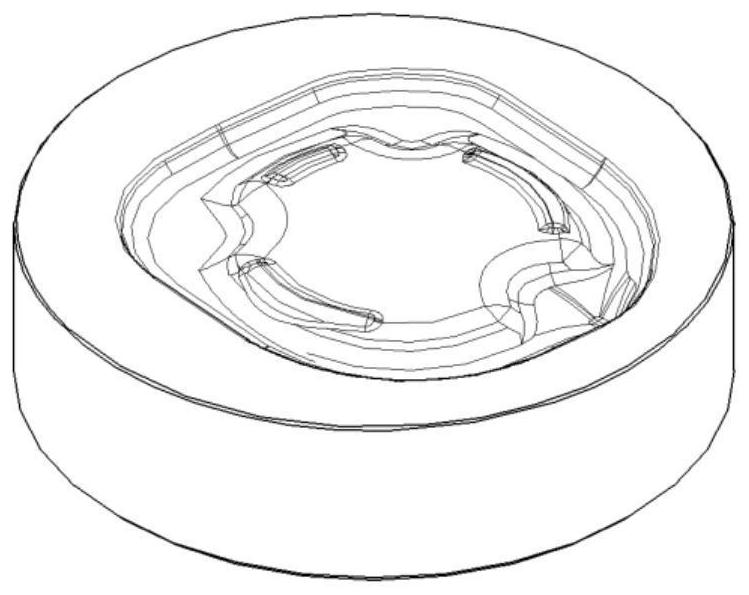

[0044] -In the process of designing forgings, the billet process section uses free forging to upset the bar material into a ca...

Embodiment 2

[0055] Since the design forging of the present invention has a nearly circular frame structure with irregular variable cross-section and variable radius, there must be easy-to-form parts and difficult-to-form parts in the die forging process, and the difficult-to-form parts are the forging parts of the design forging. Technical difficulties in processing.

[0056] Die forging processing method of the present invention comprises following process measure:

[0057] -According to the size and structural characteristics of the designed forging, as well as the size of the equipment forming force and the deformation of the forging, it is determined that the frame expansion size ratio of the designed forging in the final forging process section, pre-forging process section, billet making process section and billet process section is about 1:0.98:0.94:0.6;

[0058] -In the process of designing forgings, the billet process section uses free forging to upset the bar material into a cak...

Embodiment 3

[0069] Since the design forging of the present invention has a nearly circular frame structure with irregular variable cross-section and variable radius, there must be easy-to-form parts and difficult-to-form parts in the die forging process, and the difficult-to-form parts are the forging parts of the design forging. Technical difficulties in processing.

[0070] Die forging processing method of the present invention comprises following process measure:

[0071] -According to the size and structural characteristics of the designed forging, as well as the size of the equipment forming force and the deformation of the forging, it is determined that the frame expansion size ratio of the designed forging in the final forging process section, pre-forging process section, billet making process section and billet process section is about 1:0.96:0.92:0.52;

[0072] -In the process of designing forgings, the billet process section uses free forging to upset the bar material into a ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com