A kind of hob cutter ring forging mold and forging method for shield machine

A shield machine and mold technology, applied in the field of forging, can solve problems such as poor structure and mechanical properties, unclosed metal streamlines, and low degree of metal deformation, and achieve good tissue mechanical properties, closed forging streamlines, and metal streamlines. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

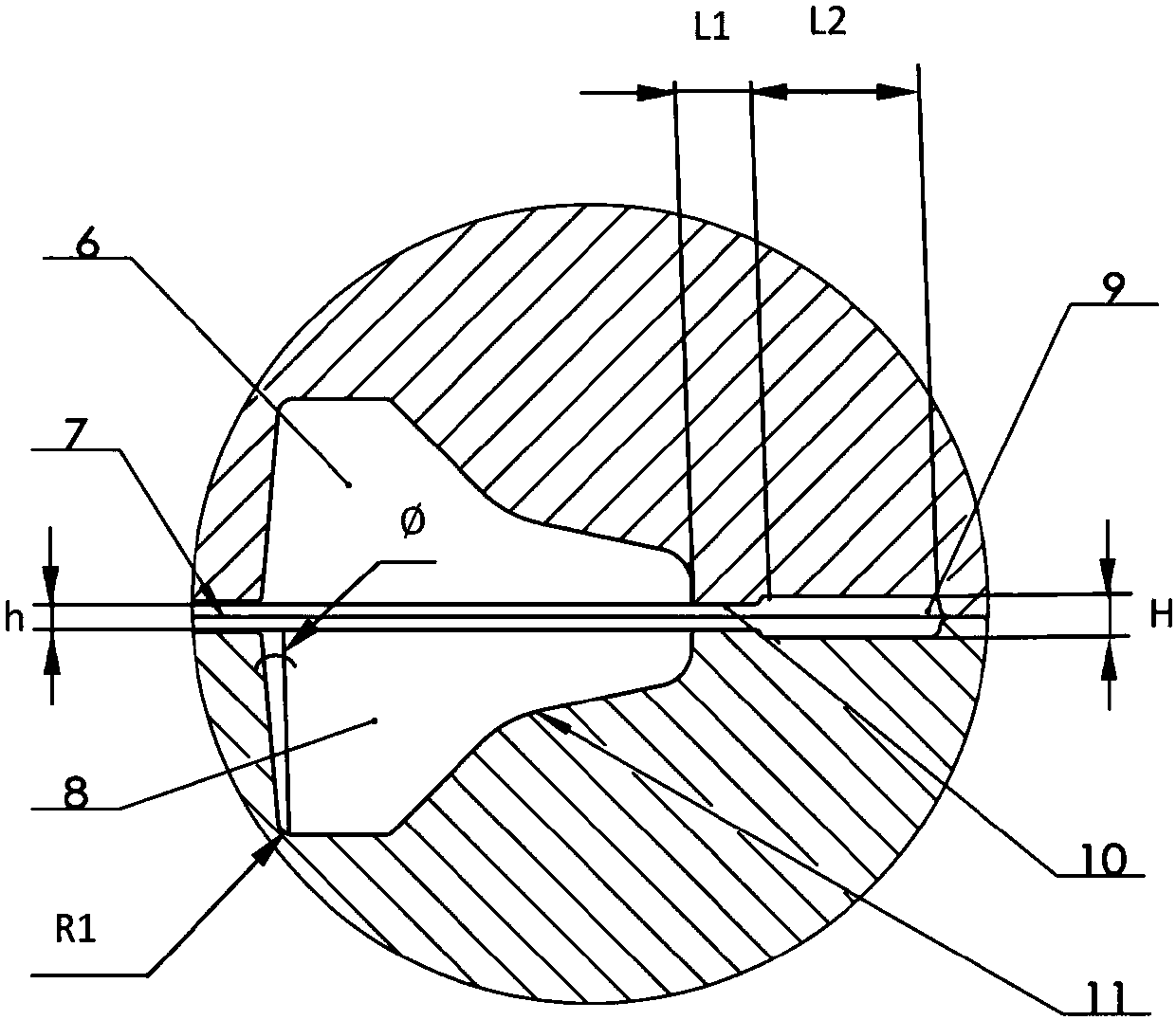

[0033] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments. The accompanying drawings constituting a part of the present invention are used to provide a further understanding of the present invention. The schematic embodiments of the present invention and their descriptions are used to explain the present invention, not to constitute an improper limitation of the present invention. For those skilled in the art, other drawings can be obtained based on these drawings without creative effort.

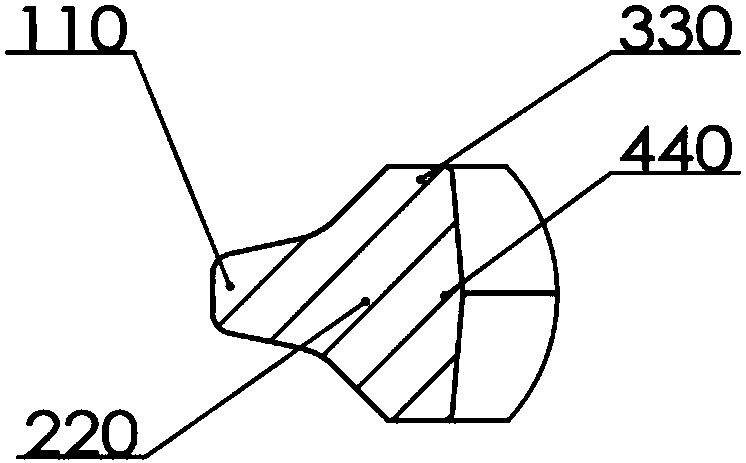

[0034] like figure 1 As shown, the hob cutter ring forging for shield machine is an integrated structure formed by sequentially combining the forging edge position 110, the forging middle position 220, and the forging bottom position (forging bottom edge position 330, forging bottom center position 440), etc., generally Processed by ring rolling in traditional technology. The forging is at the forging...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com