Patents

Literature

40results about How to "Metal flow line is complete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

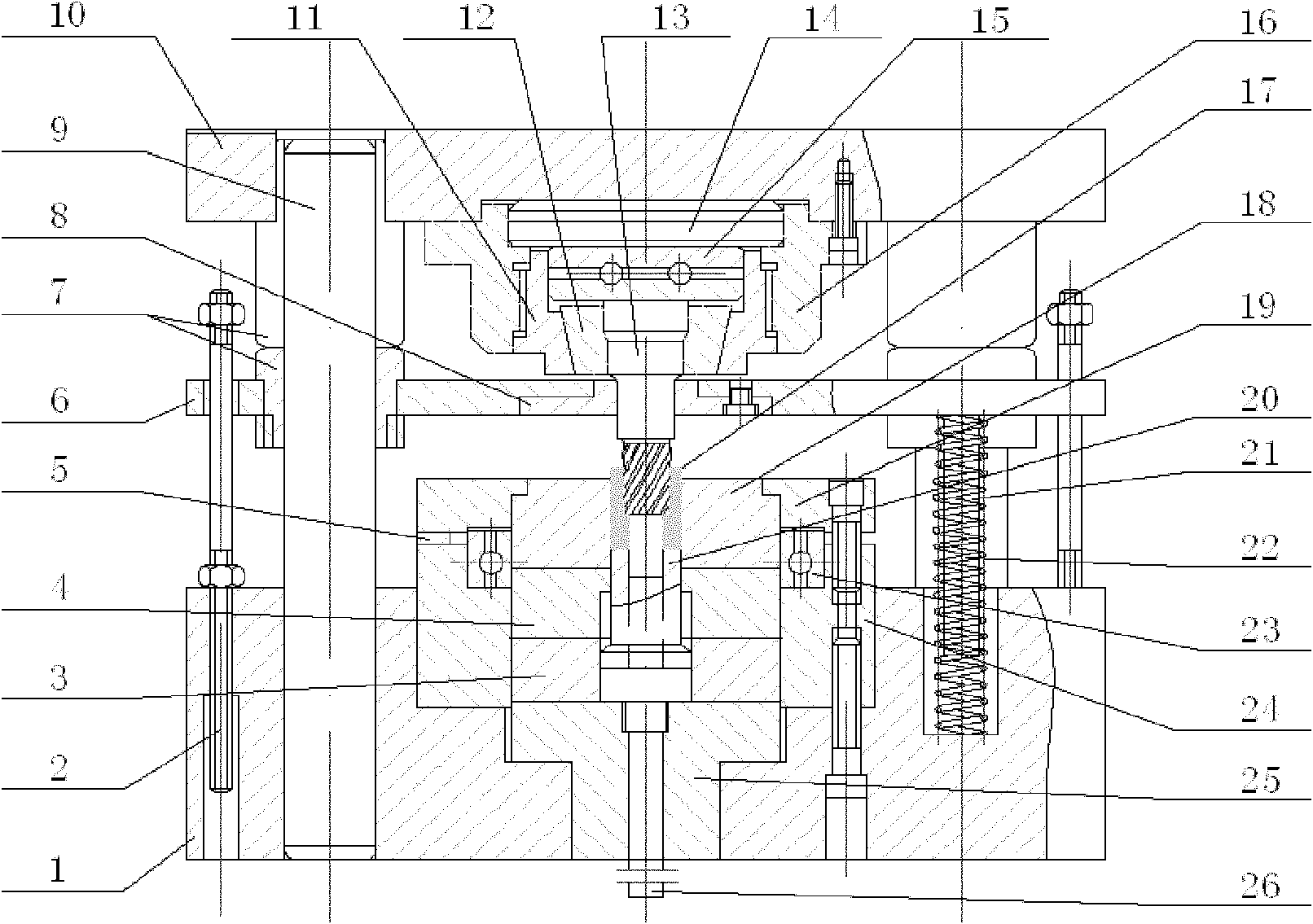

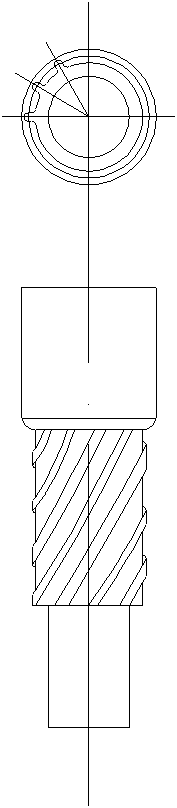

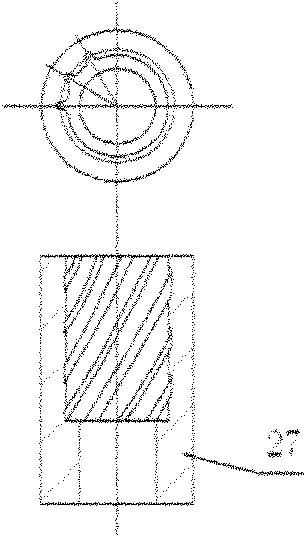

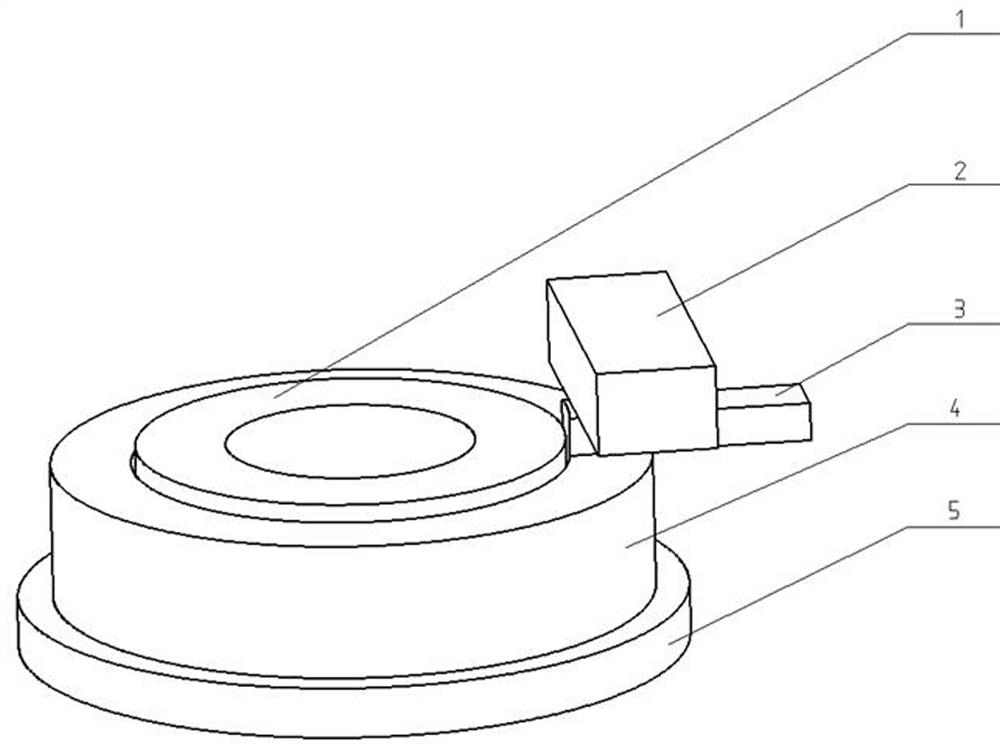

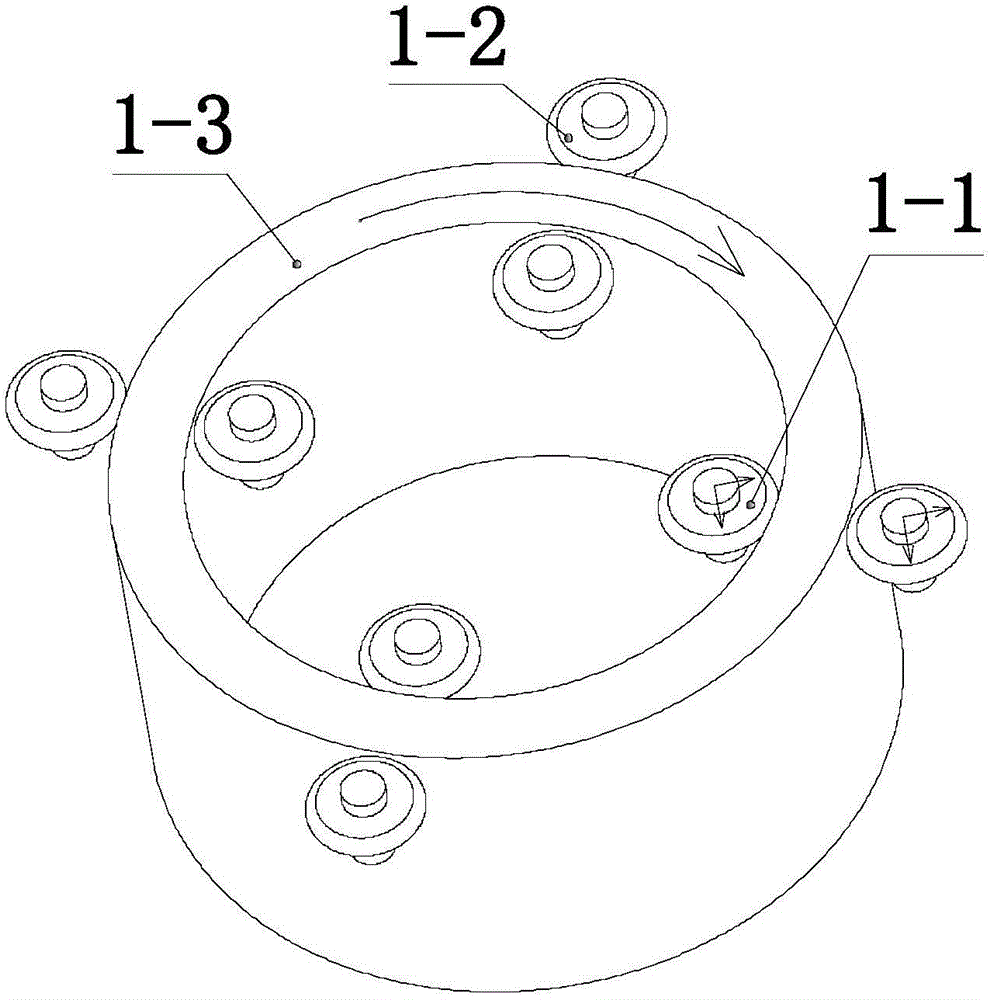

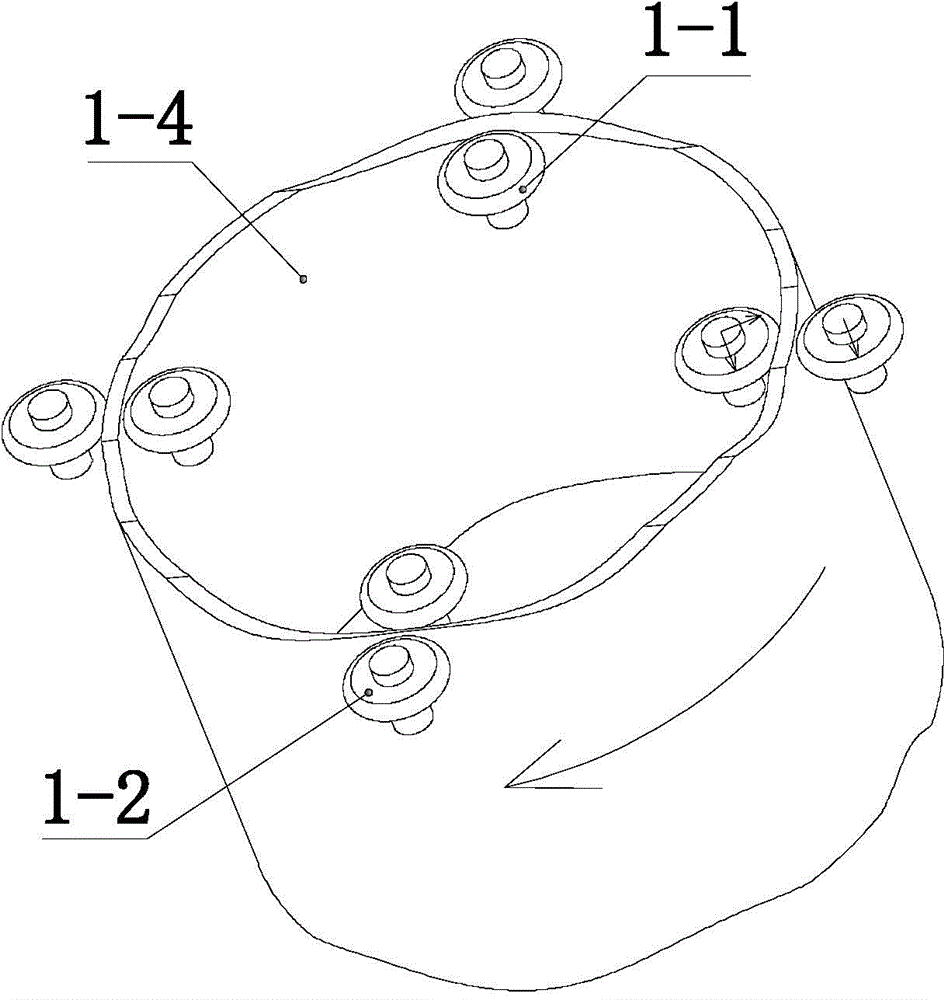

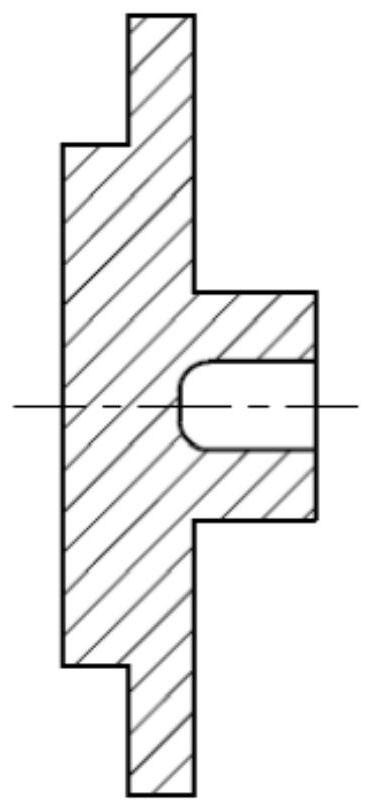

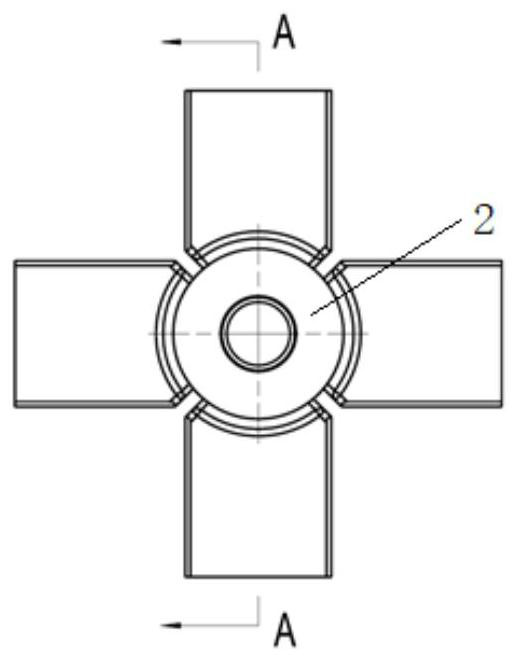

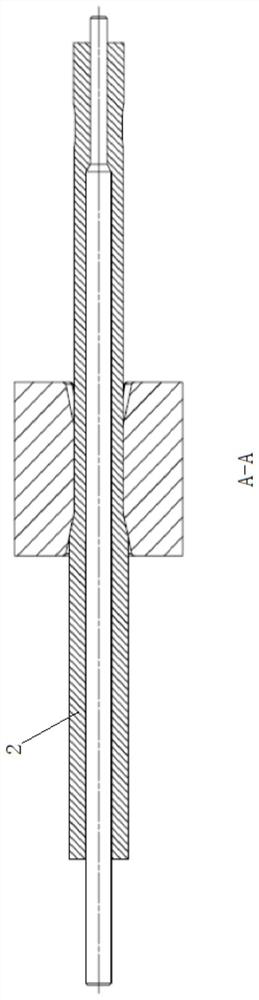

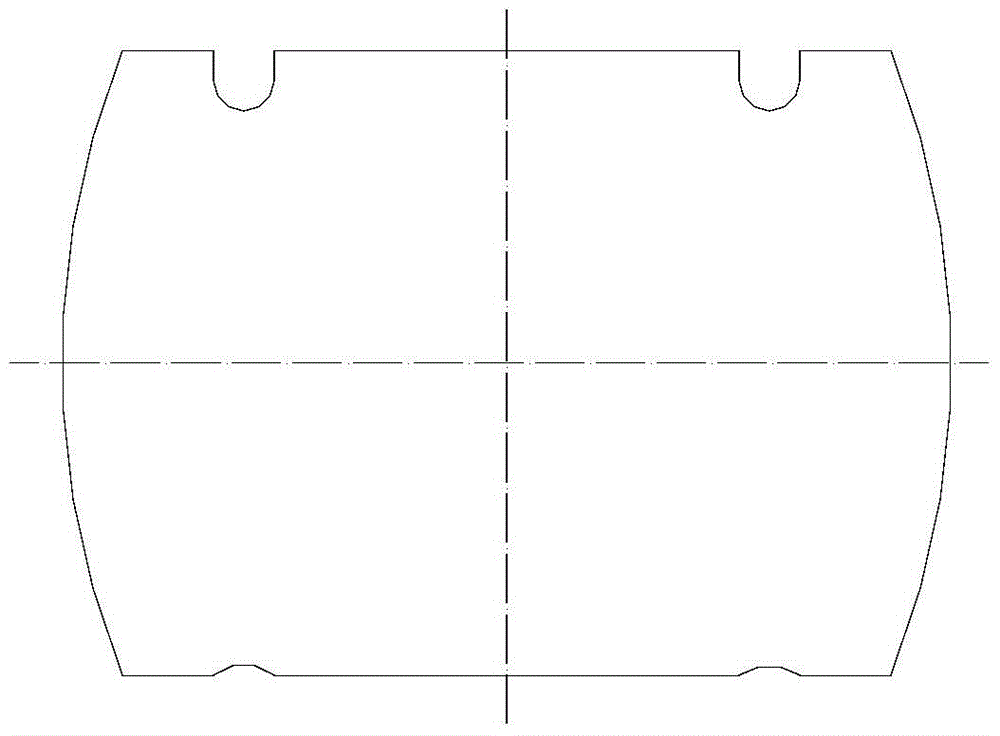

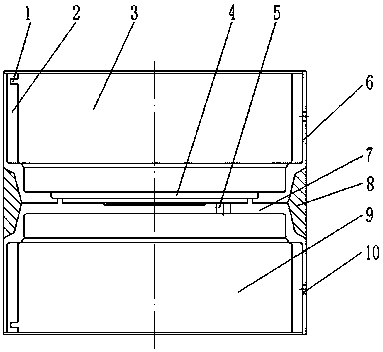

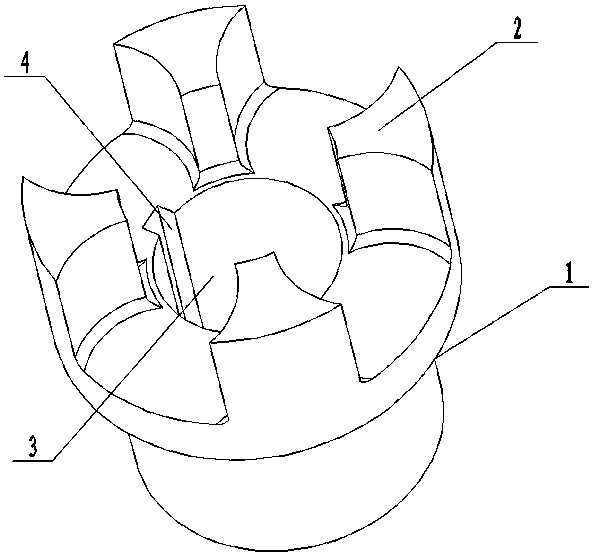

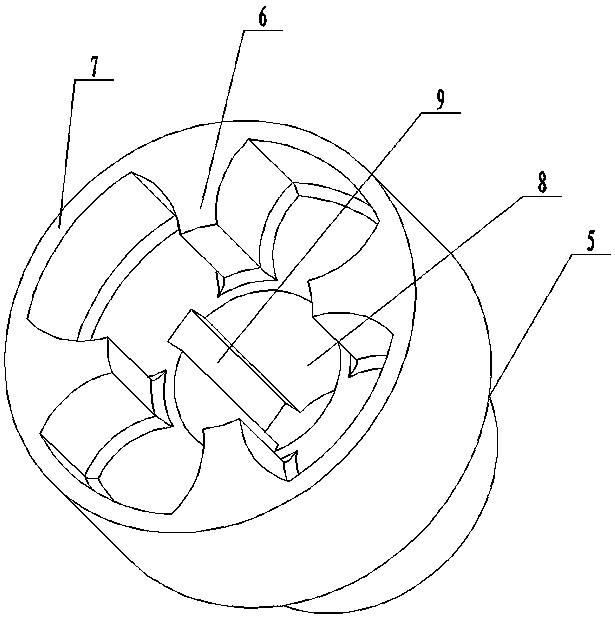

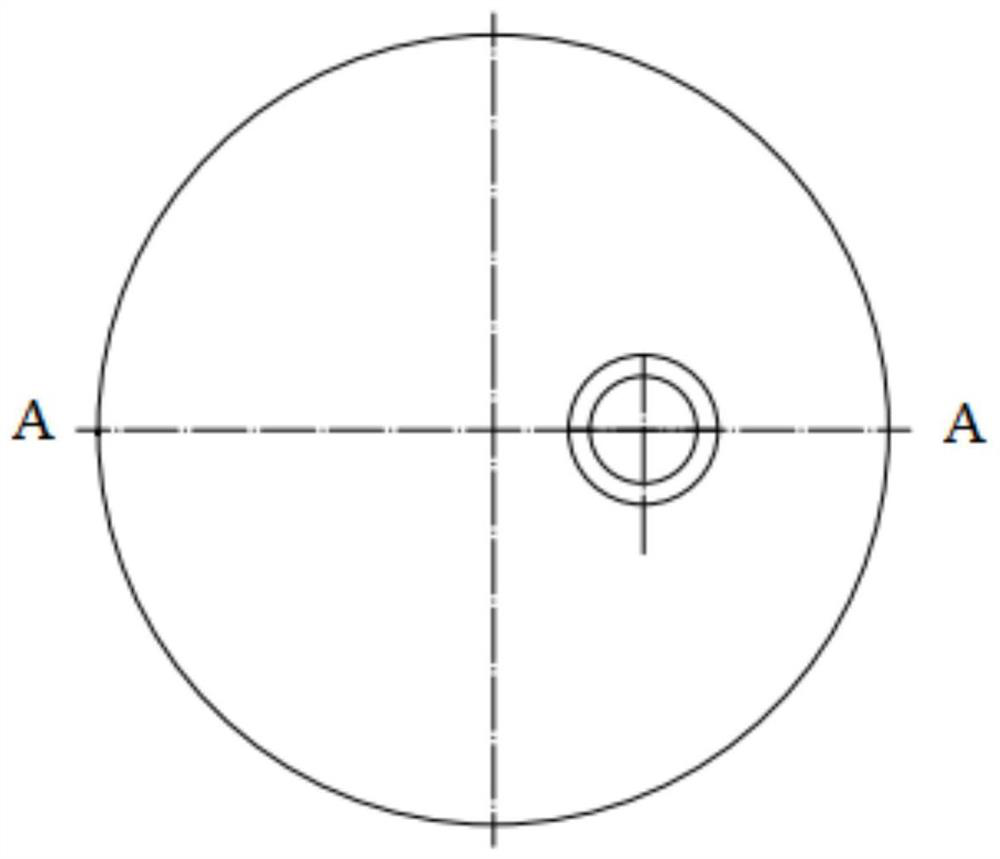

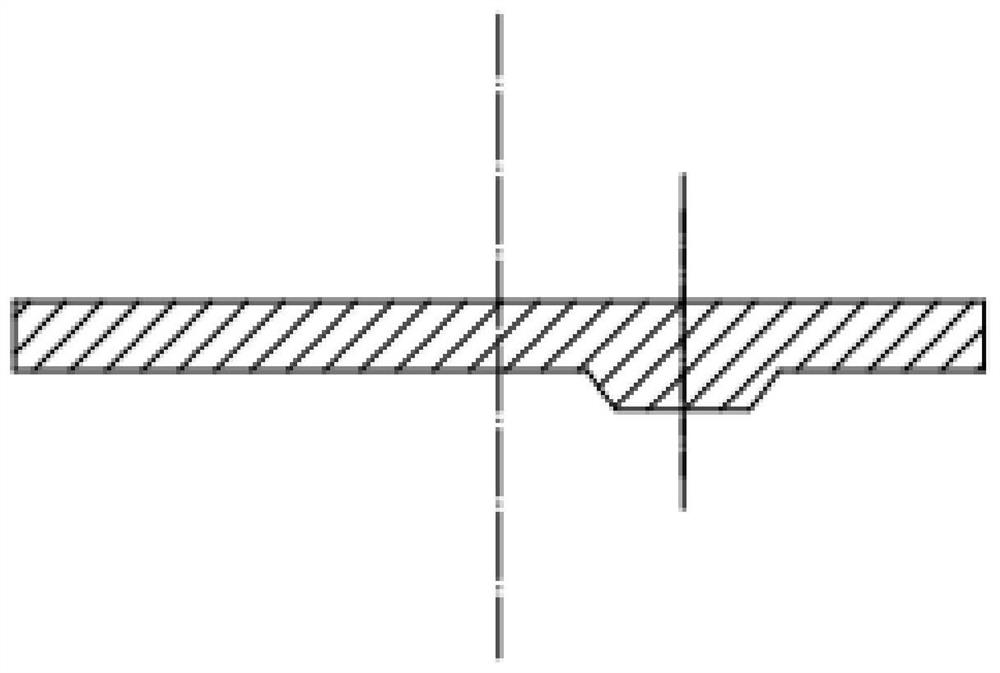

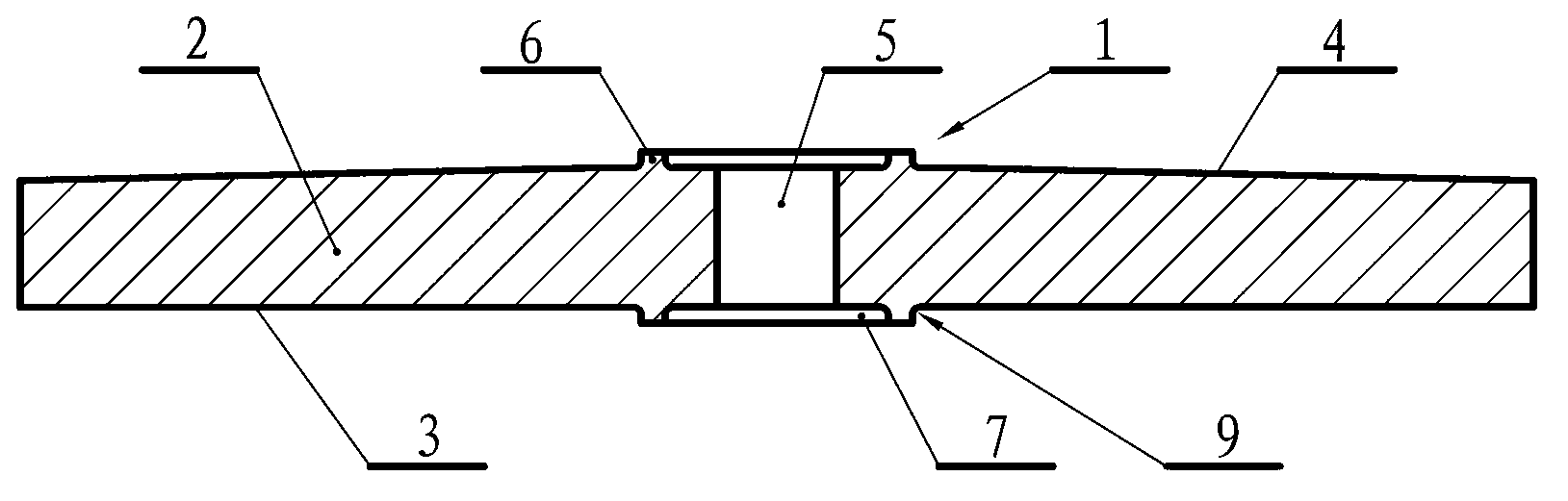

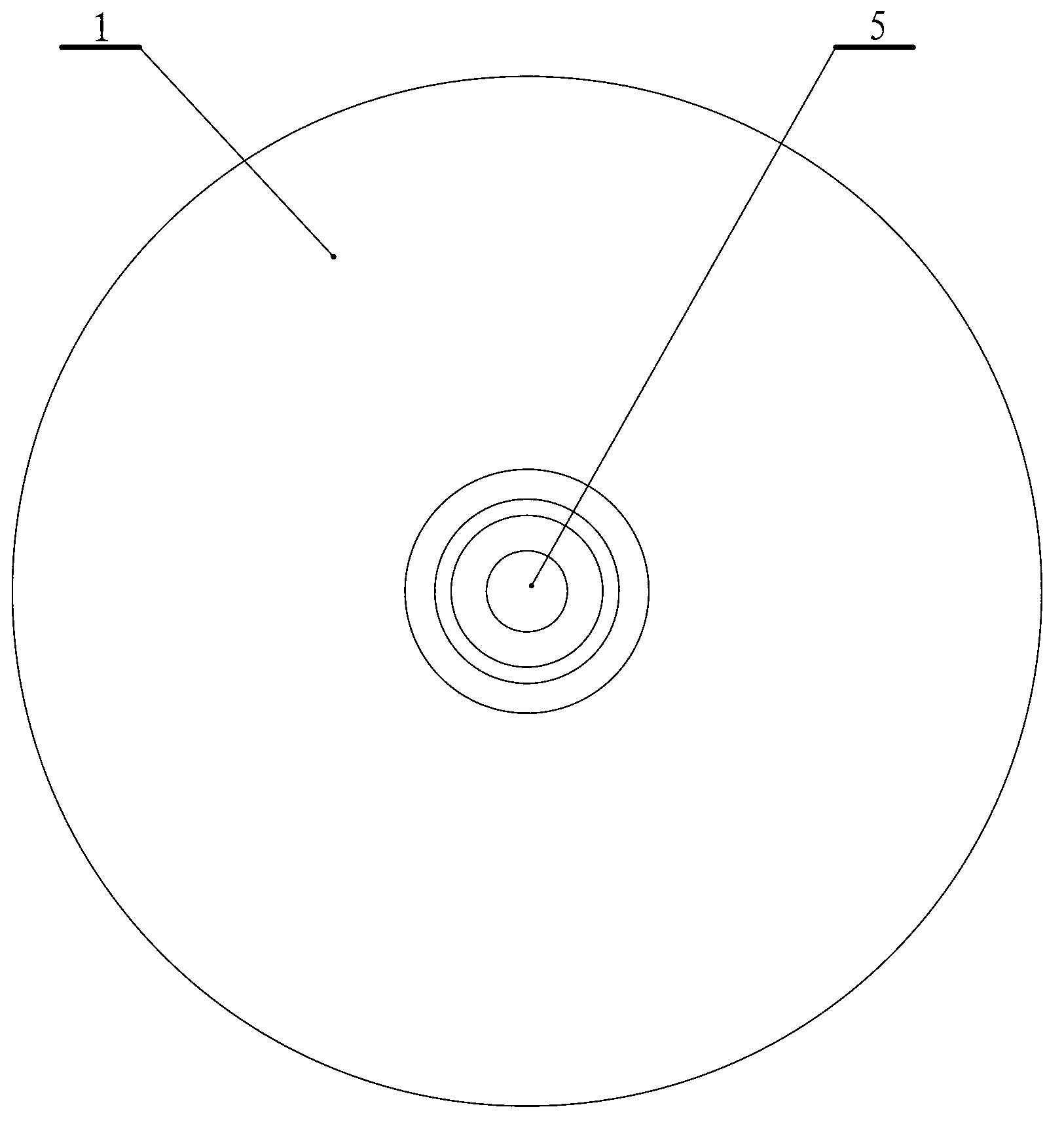

Inside screw cylindrical gear rotary cold extruding die

InactiveCN102059267AMetal flow line is completeImproved strength and overall mechanical propertiesExtrusion diesCost savingsEngineering

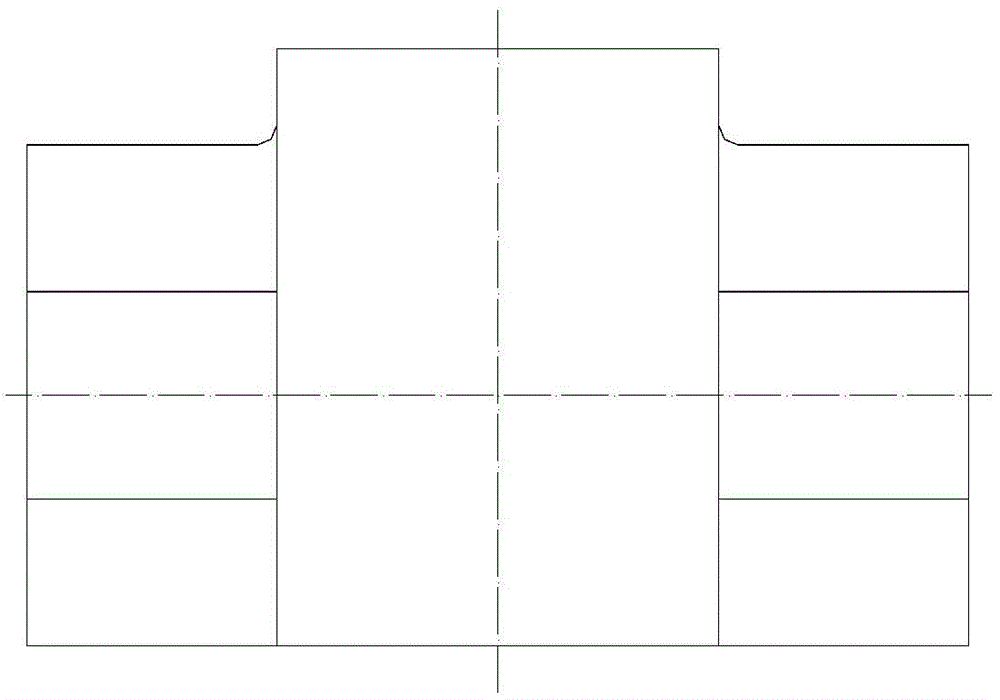

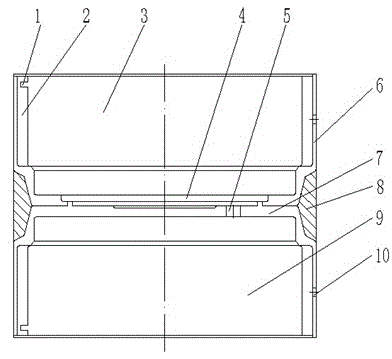

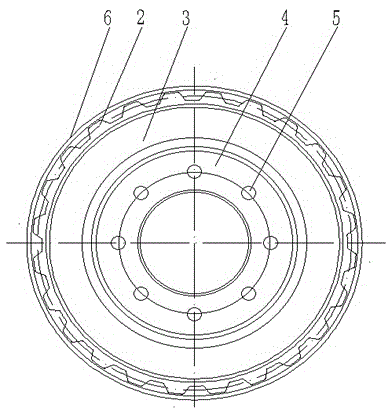

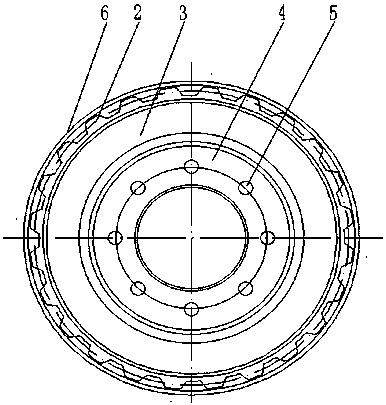

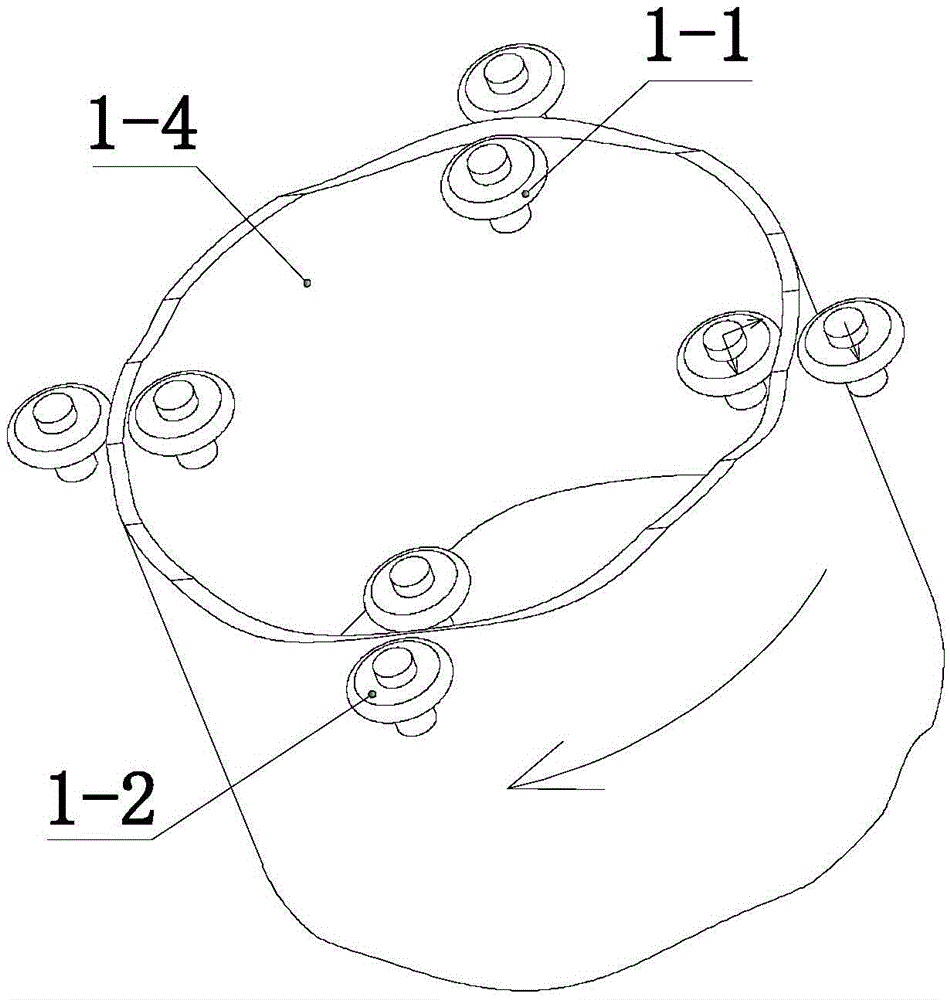

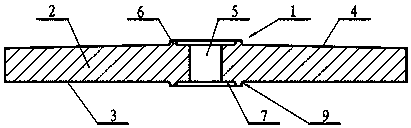

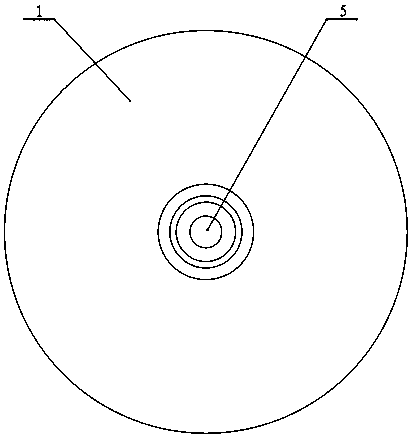

The invention discloses an inside screw cylindrical gear rotary cold extruding die in the technical field of gear machining, which comprises an upper die structure and a lower die structure, wherein the upper die structure comprises a terrace die, a terrace die positioning ring, a terrace die fixing ring, a terrace die base, a terrace die upper padding plate, a thrusting bearing and an upper die base; and the lower die structure comprises a discharging plate, a cavity die, a cavity die positioning ring, a cavity die lower padding plate, a limit block, a mandril sleeve, a mandril and a lower die base. The inside screw cylindrical gear rotary cold extruding die is convenient for production and operation and is beneficial to cost saving; and the defects in the traditional mechanical cutting method and the traditional hobbing method are improved, and the production efficiency, the material utilization rate and the product accuracy can be improved simultaneously.

Owner:SHANGHAI DIE TECH INST

Automobile gearbox P-gear gear manufacturing method

The invention provides an automobile gearbox P-gear gear manufacturing method. An automobile gearbox P-gear gear is finally formed by conducting cold extruding after warm forging is conducted in a warm forging manufacturing mode. The automobile gearbox P-gear gear is characterized in that positive and negative combined extrusion is adopted for cold extruding, and outer teeth are extruded while extrusion forming of the petal portion in a product is finished. The product made through the method is high in accuracy, less in oxidation, good in internal metal organization and more refined in crystalline grain, and harmful structures of coarse crystals, mixed crystals and the like can be avoided; the required equipment is small in tonnage and less in forming force, tooth filling is easier, unit intensity of pressure born by a die is remarkably lowered, the service life of the die is very long, the process can be reduced, and the manufacturing time is greatly shortened (increased by 10 times compared with a gear hobbing machine). The product hardness ranges from HB 140 to HB 180, the tooth profile is fully filled and full, and it is guaranteed that large deformation cannot be generated in subsequent heat treatment of cold extrusion forming.

Owner:CHONGQING CHUANGJING WARM FORGING FORMING

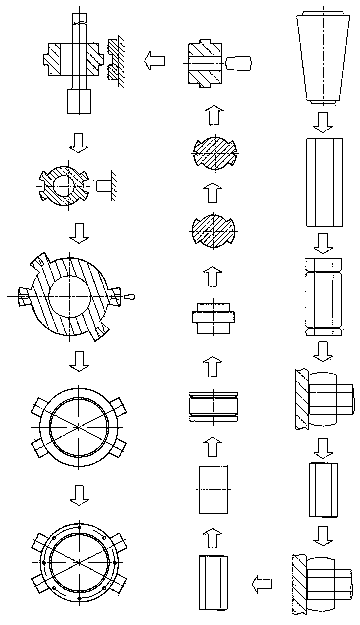

Integrated forging and forming method for reactor pressure vessel barrel flange adapter tube section

ActiveCN110090914AReduce potential riskWork stress homogenizationEngine componentsReactor pressure vesselIngot

The invention discloses an integrated forging and forming method for a reactor pressure vessel barrel flange adapter tube section. The integrated forging and forming method for the reactor pressure vessel barrel flange adapter tube section comprises the steps of (1) heating a steel ingot, and pressing the steel ingot to obtain an eight-edge prism steel billet; (2) blanking a forging billet: cutting a head part and a tail part of the eight-edge prism steel billet so as to obtain an eight-edge prism forging billet; (3) upsetting and drawing the forging billet: upsetting and drawing out the forging billet; (4) carrying out upsetting and rolling: upsetting and rolling the forging billet to obtain a short cylindrical forging billet; (5) carrying out marking and dividing in the circumferential direction: cutting two marking and dividing grooves at two ends of the short cylindrical forging billet; (6) carrying out rolling and necking: forming an adapter tube billet with a convex ring in the middle section; (7) carrying out marking and dividing in the axial direction: cutting four axial dividing grooves arranged along the axial direction; (8) circularly pressing a hemline; (9) marking anddividing a hemline boss: forming four sections of bosses on a hemline adapter tube billet; (10) punching a main hole; (11) carrying out chambering and forming; (12) carrying out shaping and chambering; (13) punching an adapter tube hole; (14) carrying out heat treatment after forging; (15) roughly machining the billet; (16) carrying out quenching; (17) carrying out hardening and tempering; and (18) processing a finished product. According to the method, integrated forming and forming is realized, the structure is uniform and dense, and a metal flow line is complete.

Owner:SHANGHAI XINMIN DONGTAI HEAVY FORGING

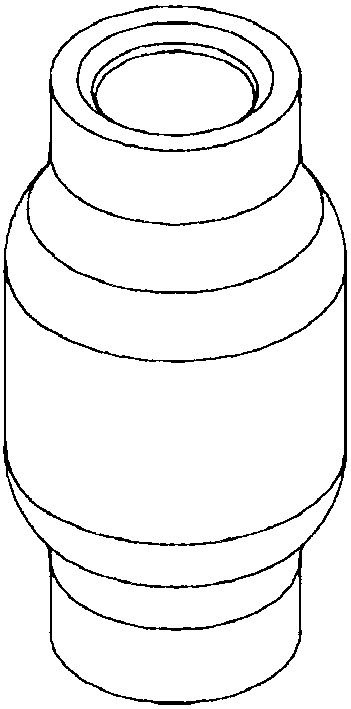

Valve body forging method

ActiveCN104439032ADense microstructureBeautiful appearanceValve arrangementsPressure grooveMaterials science

The invention relates to the field of valve body manufacturing, in particular to a valve body forging method. The valve body forging method saves materials and energy and reduces consumption on the condition of meeting the requirement of customers for product diversification. At first, blank forming is achieved by utilizing free forging for executing the following steps of A, selecting round steel with the weight being 1.15-1.25 times the weight of a finished valve body, riveting the two ends of the round steel, conducting indentation material separation, and forging the round steel into the preset size; B, enabling the two ends of the round steel to get off a table, forging eccentricity of the middle and the two ends, and forging the two ends into 260-degree octagons; C, then utilizing pressing blocks for making octagonal pressure grooves in the two ends into the preset size, and ensuring that flanges and grooves of a green body are within the design size range. Then, final forming is achieved by adopting semi-die forging for executing the following steps of a, forging the middle octagon of the green body in a vertical die buckling and pressing mode; b, after the middle octagon is formed, controlling the height of the flanges at the two ends through cushion blocks and forging the flanges to be rounded; c, finally, trimming the sizes of all parts of the forged piece into the designed sizes.

Owner:CHENGDU SHUANGLIU HENGSHENG FORGING

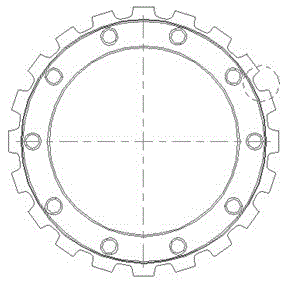

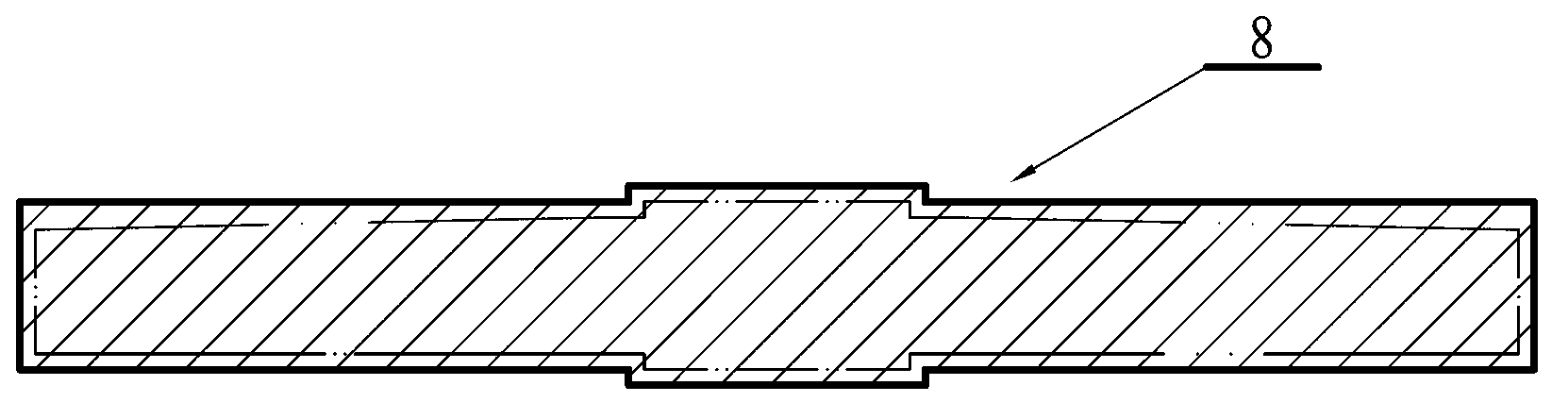

Making technology for transmission double-end internal-teeth ring of electric forklift

ActiveCN104439995AReduce MachiningMetal flow line is completeSolid state diffusion coatingFurnace typesPlastic moldingEngineering

The invention discloses a making technology for a transmission double-end internal-teeth ring of an electric forklift. The making technology comprises the following steps: 1, performing warm forging and plastic molding: 2, spheroidizing annealing; 3, performing blank making, shot blasting and saponifying; 4, performing cold-extruding on internal teeth of a central hole; 5, machining; 6, performing salt bath tufftriding. A product prepared by the technology is stable in quality, small in accumulated errors among the teeth, high in yield, and short in production cycle; the production efficiency is improved; the problem that a traditional transmission gear shaping is large in lathe equipment investment of multiple, low in production efficiency, high in manufacture cost and difficult to realize massive production, is solved, and the defects that the quality of the product is unstable and the rejection rate of the product is high which are caused by the fact that two gear rings are formed by welding and the generated deformation is large, are overcome.

Owner:江苏威鹰机械有限公司

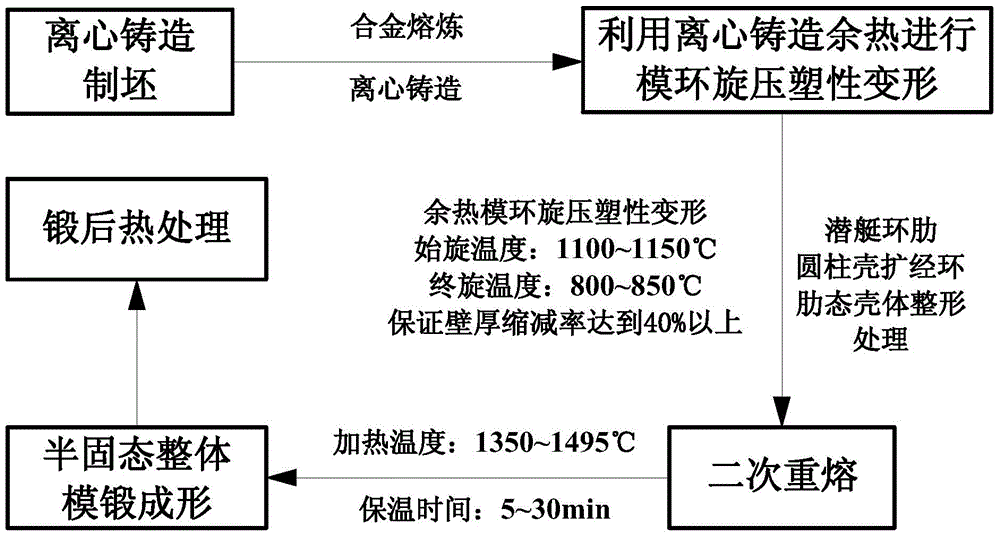

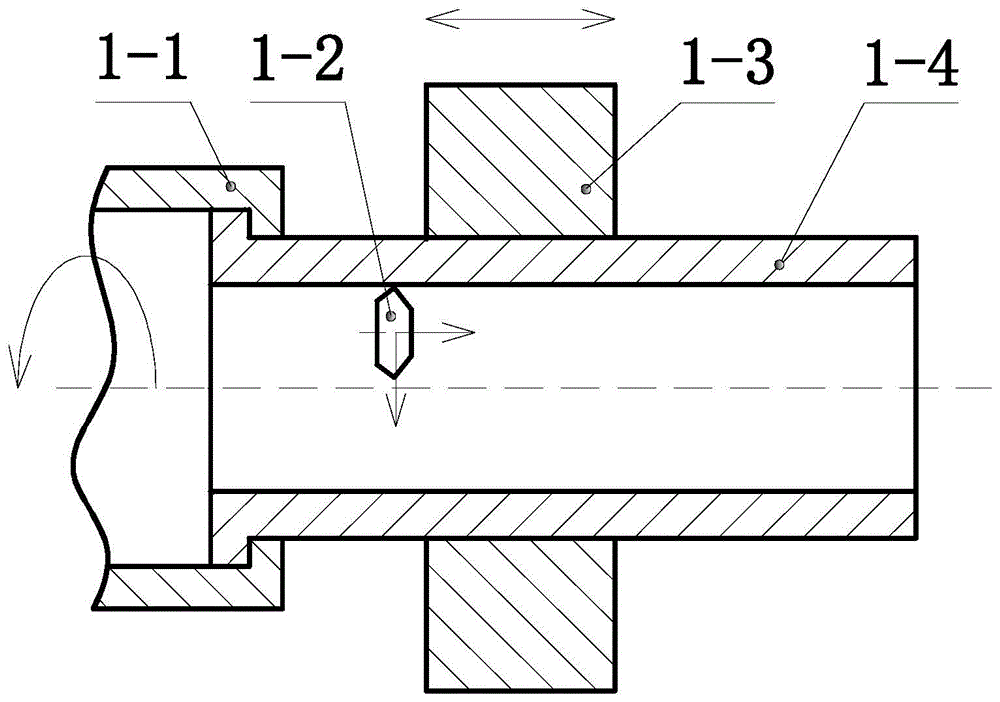

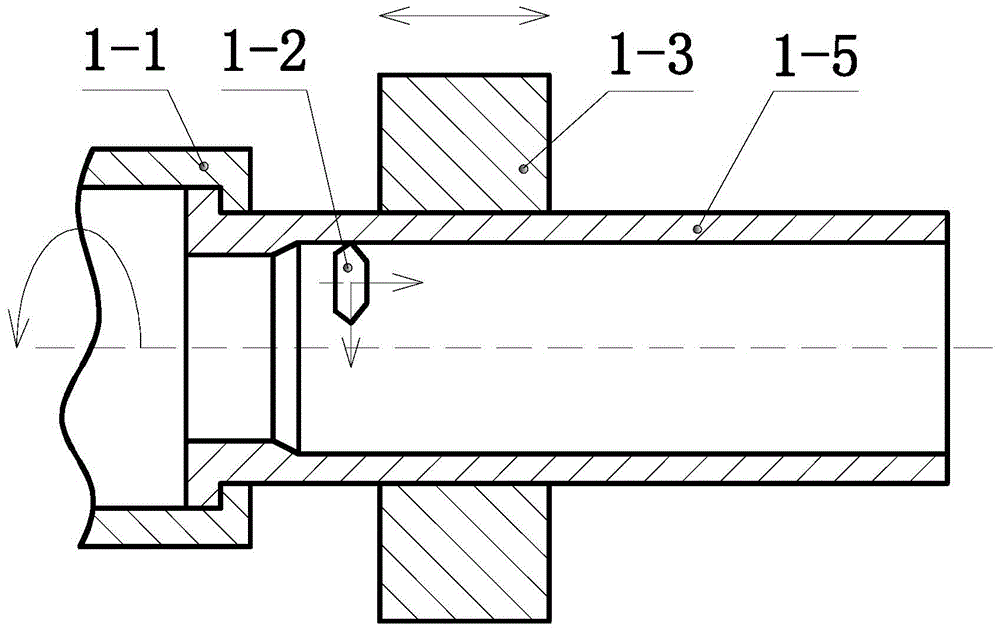

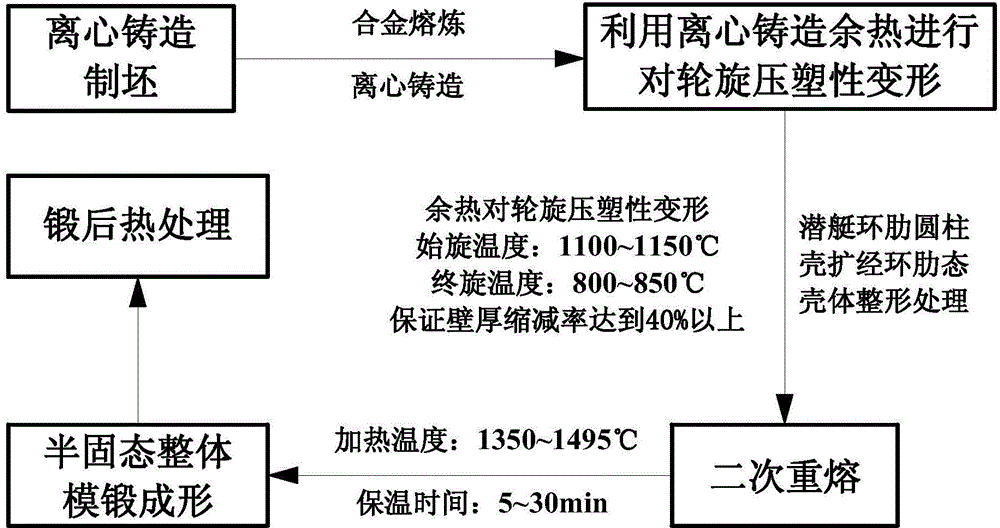

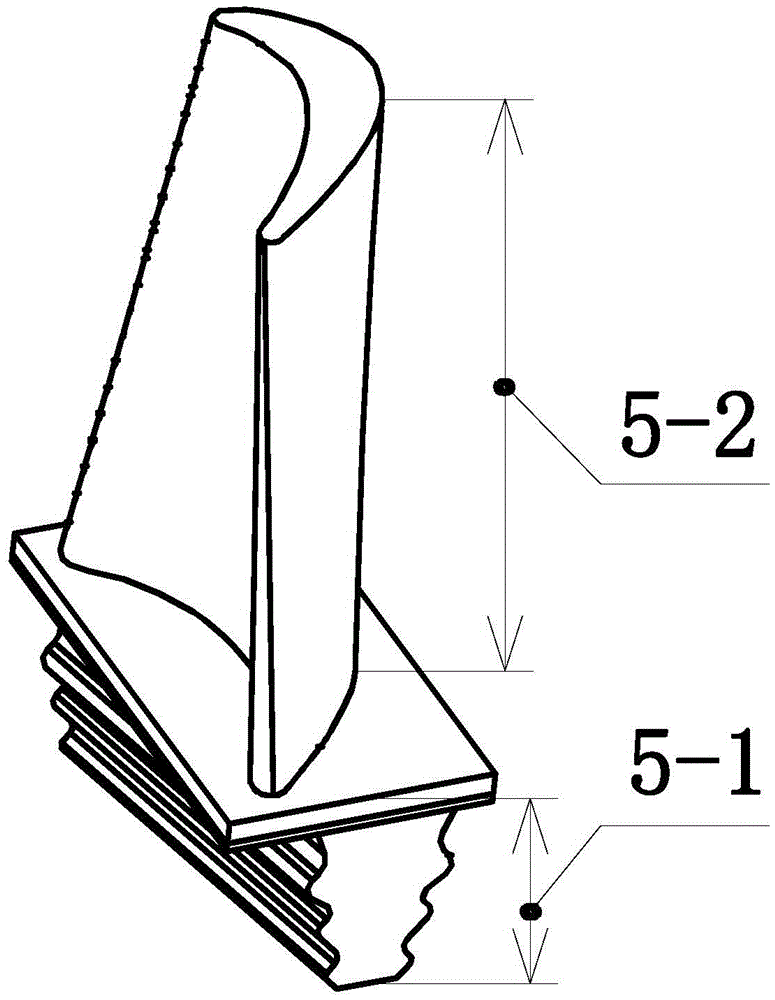

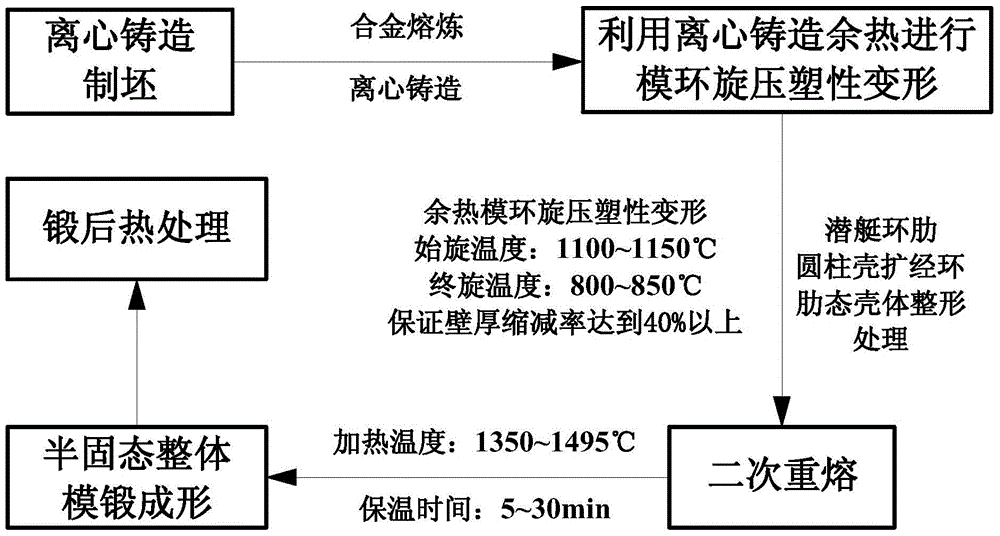

Semisolid manufacturing technology for mold ring spinning strain inducing method for submarine ring rib cylindrical shell

InactiveCN104625633AIncrease profitHigh strengthMetal-working apparatusMicro structureManufacturing technology

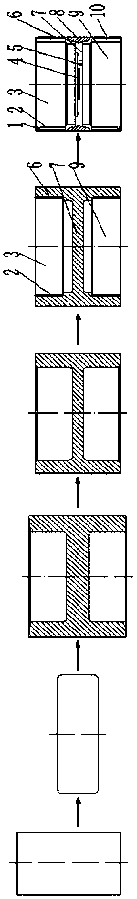

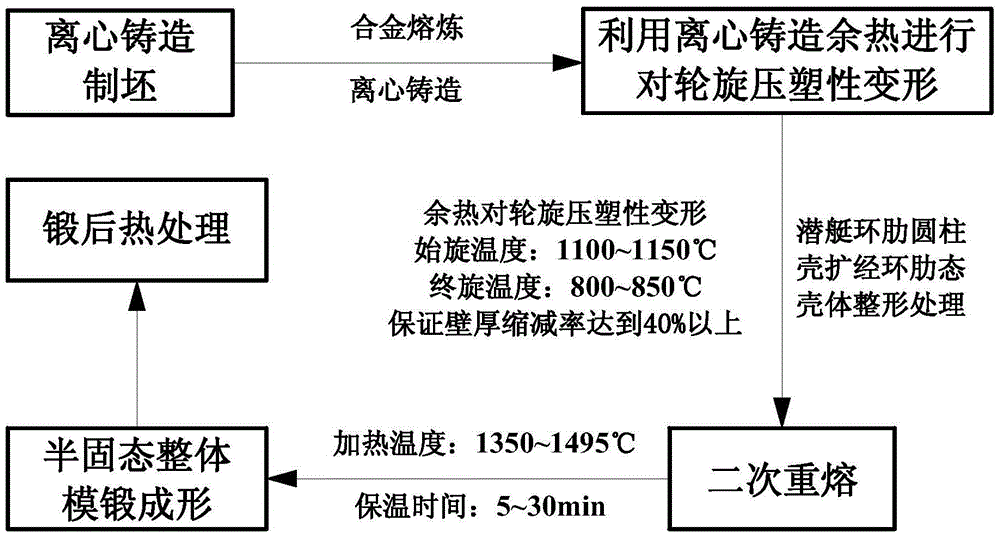

A semisolid manufacturing technology for a mold ring spinning strain inducing method for a submarine ring rib cylindrical shell includes the steps that on the basis of smelting alloy, a centrifugal casting technology is adopted for manufacturing an as-cast shell body of the submarine ring rib cylindrical shell; a mold ring spinning deformation technology is adopted to carry out large-deformation plastic deformation and shape-correction treatment on the as-cast shell body; an obtained distortion blank of the submarine ring rib cylindrical shell is remelted to obtain a semisolid blank, with a fine, even and spherical micro structure, of the submarine ring rib cylindrical shell; semisolid overall stamp forging and shape-correction are carried out on the semisolid blank; heat treatment after forging is performed to complete manufacturing the submarine ring rib cylindrical shell. The submarine ring rib cylindrical shell with the non-dendritic crystal fine and even spherical micro structure can be manufactured, and the semisolid manufacturing technology has the advantages that the technological process is simple, the material use ratio is large, and the mechanical property of the cylindrical shell is high.

Owner:XI AN JIAOTONG UNIV

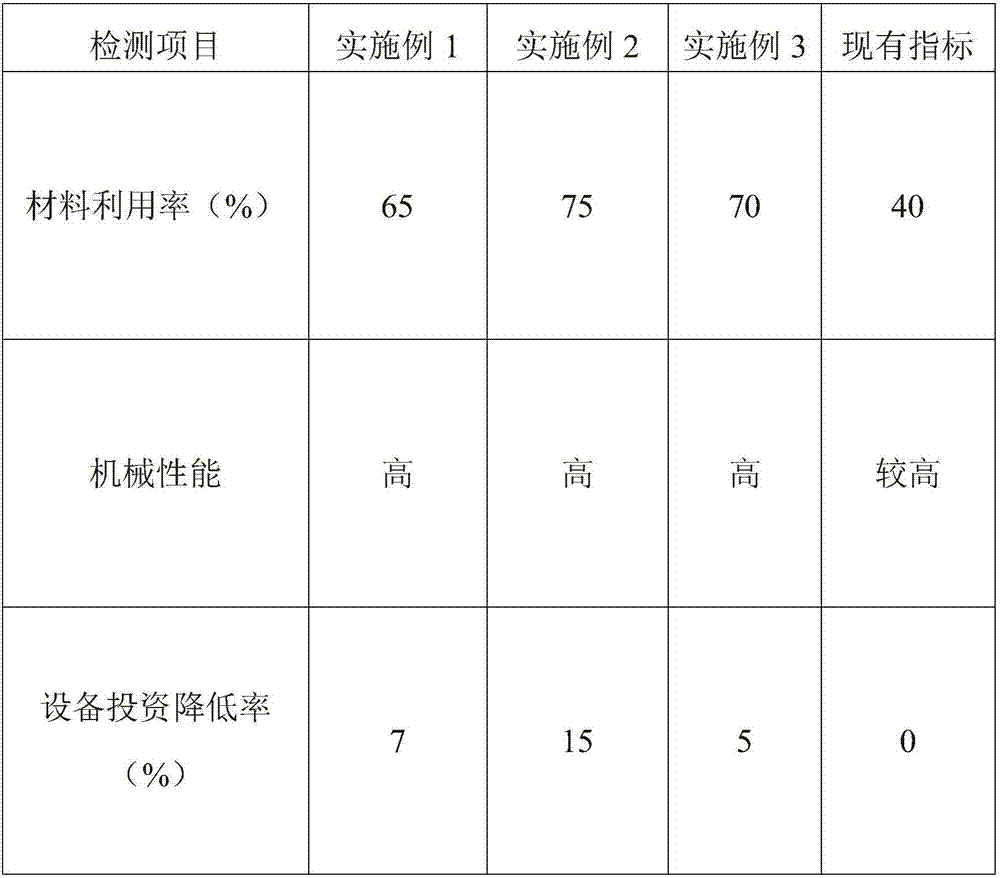

Steering knuckle molding process

InactiveCN107214288AIncrease profitImprove mechanical propertiesRailway componentsMetal-working apparatusBrake padMaterials science

The invention discloses a steering knuckle forming process. The material utilization rate of the steering knuckle can reach more than 70% after adopting the new forming process, the mechanical properties of the product are improved, the metal streamlines are complete, and the mechanical properties and corrosion resistance of the product are obviously improved. The control of final forging temperature and forming force can simplify the process, and the final forging can be completed on ordinary hot die forging presses, reducing equipment investment. The production process of this brake pad has the advantages of high material utilization rate and small equipment investment. The market prospect broad.

Owner:ANHUI CAREMIC CONSULTING CO LTD

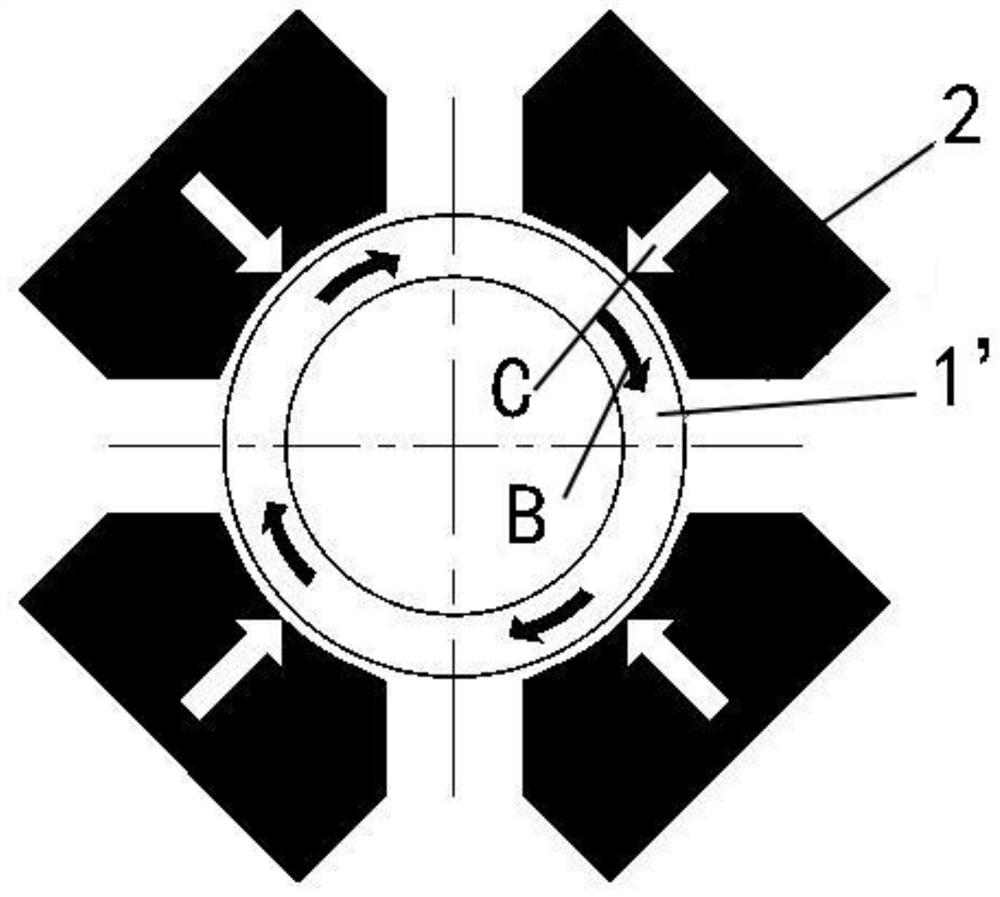

Extra-large annular forge piece forming die forging method

ActiveCN111822633AAchieving problems beyond the limits of the pressImprove overall utilizationMetal-working apparatusProcess efficiency improvementPunchingIngot

The invention provides an extra-large annular forge piece forming die forging method. The extra-large annular forge piece forming die forging method comprises the following steps of steel ingot WHF method upsetting and drawing-out, blanking, blank upsetting, punching, saddle forging and forming die fixing blank inner hole spinning, a forming die is fixed to an annular blank inner hole in the finalforming process, then a forging press applies pressure to a wide anvil, stress is transmitted to a spinning anvil through the wide anvil, the spinning anvil spins in the radial direction of the annular blank to enable metal to mainly flow in the radial direction, due to the resistance effect of the forming die, under the condition that the blank height is reduced and the inner hole size is not changed, only the outer diameter size is increased, and finally forming of the ultra-large annular forge piece forming die is achieved. According to the method, the inner hole is adopted for fixing theforming die, and the spinning anvil is used for spinning the height direction of the blank, so that the flowing direction of metal is changed, the forming method of the extra-large annular forge pieceis achieved, the thought of a traditional free forging extra-large annular piece saddle forging forming method is changed, and the problem that the forging machinery of the extra-large annular forgepiece is limited is solved.

Owner:洛阳中重铸锻有限责任公司 +1

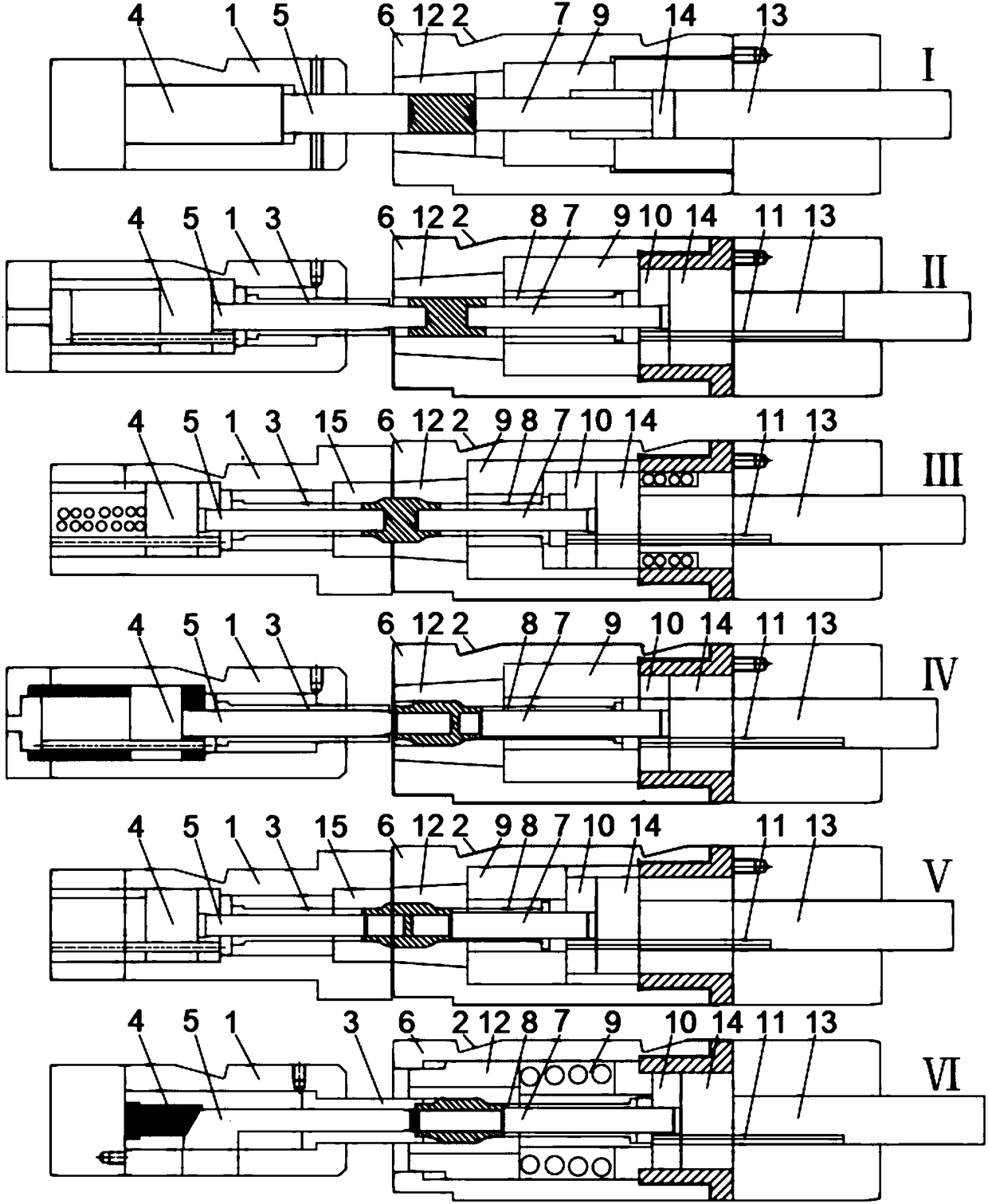

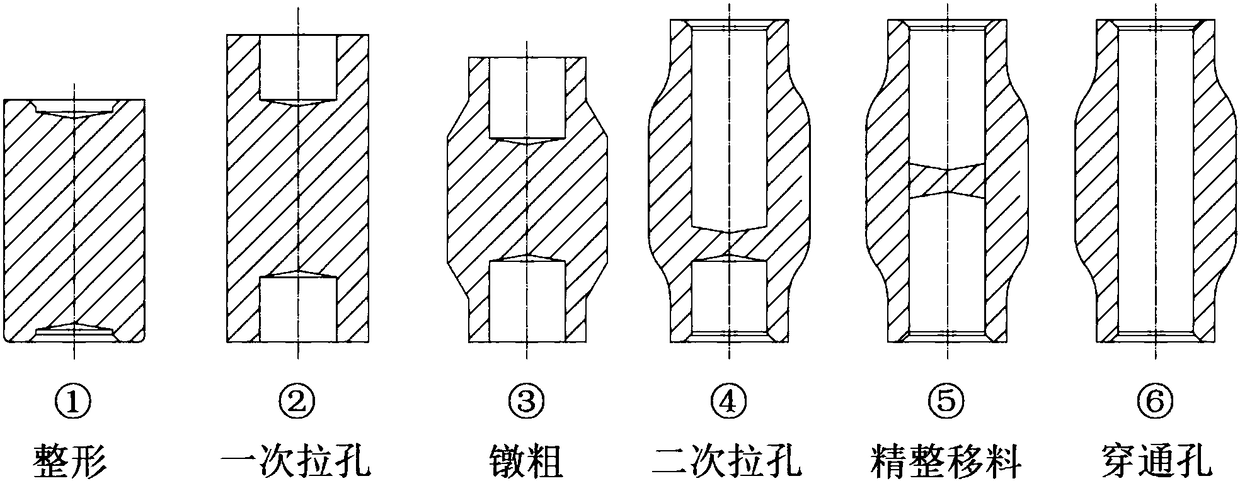

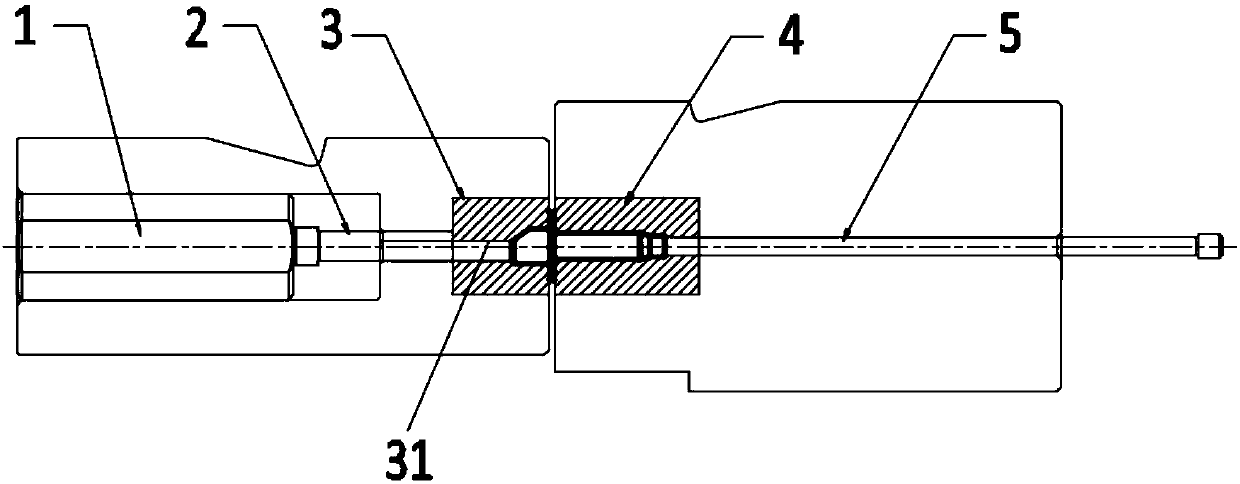

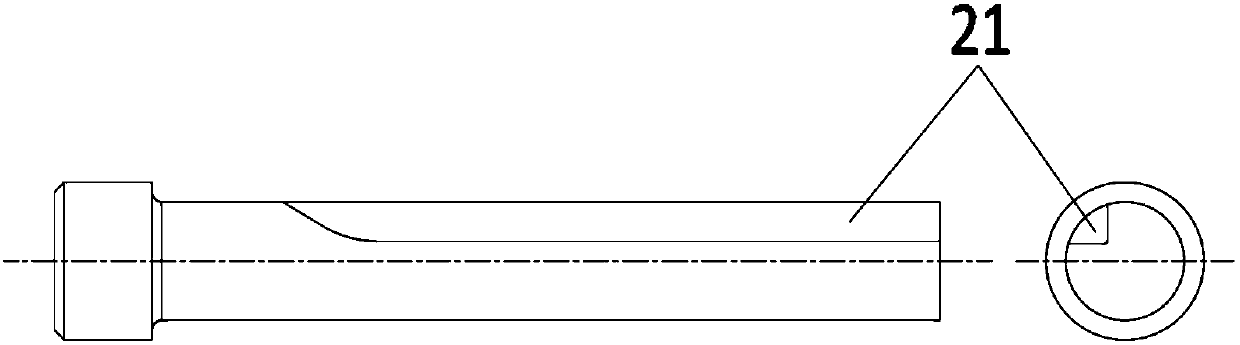

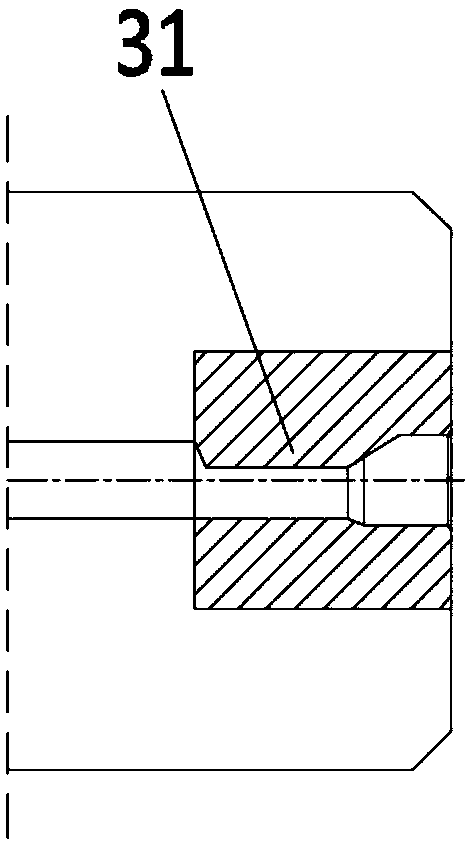

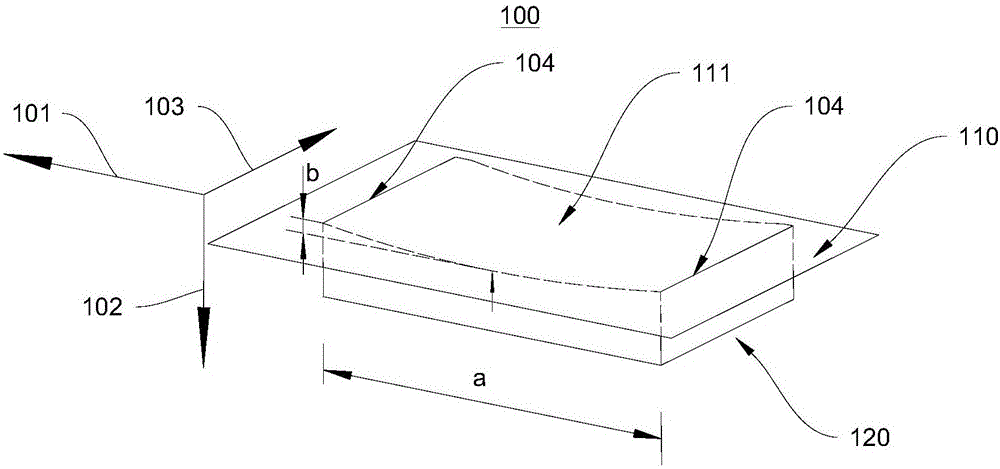

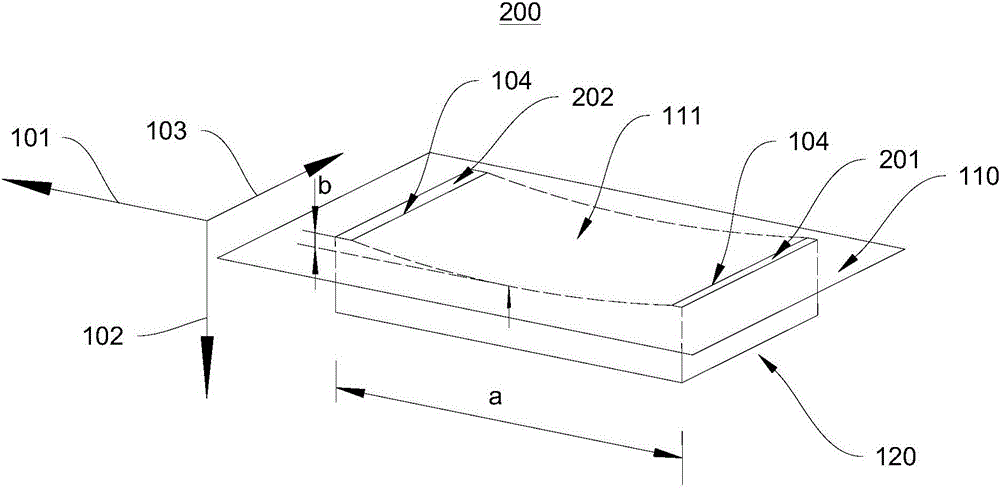

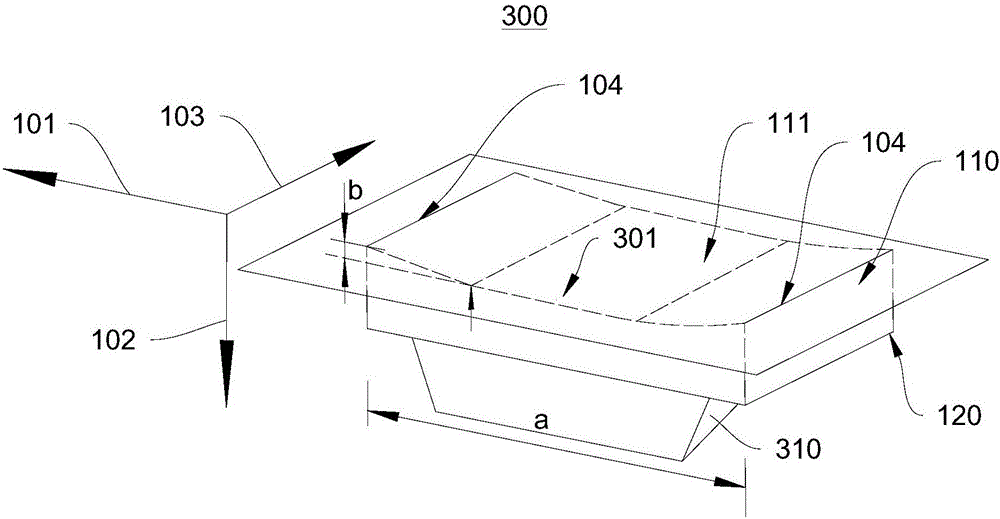

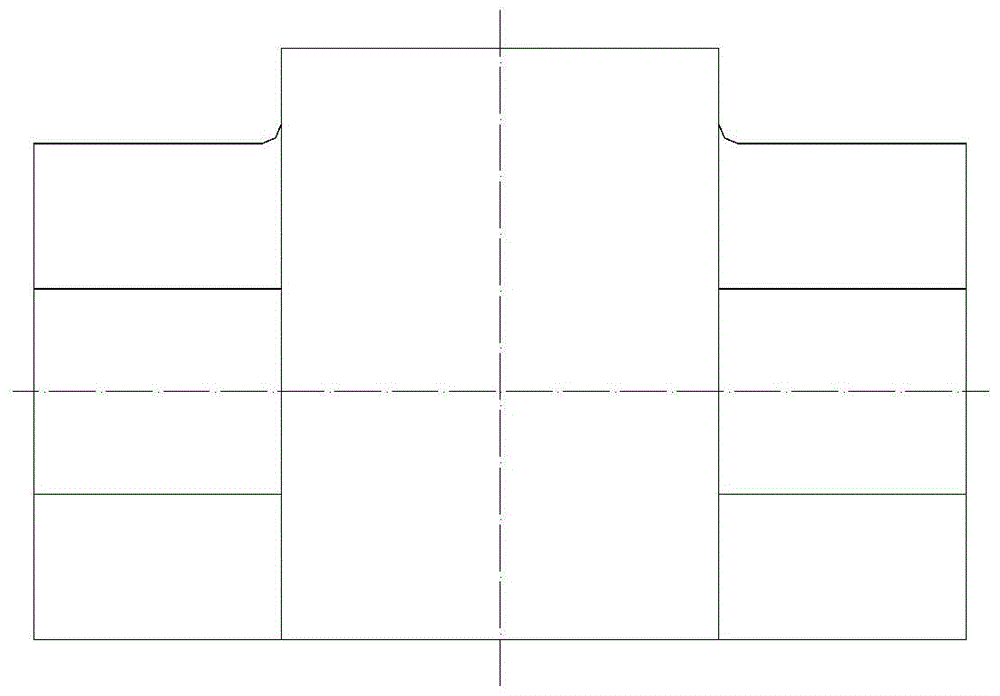

Cold heading molding process for vehicle steering system sleeves and cold heading module

PendingCN108057839ASimple structureEasy to operateForging/hammering/pressing machinesEngine componentsWire rodBroaching

The invention relates to a cold heading molding process for vehicle steering system sleeves and a cold heading module. The cold heading molding process for the vehicle steering system sleeves molds the vehicle steering system sleeves and cold heading module through shaping, primary broaching, upsetting, secondary broaching, finish shifting and through hole penetration by the cold heading module after shearing of wires. The cold heading module is a six-mold six-punch cold heading mold, and comprises a first mold for shaping, a second mold for primary broaching, a third mold for upsetting, a fourth mold for secondary broaching, a fifth mold for finish shifting and a sixth mold for through hole penetration. The cold heading molding process for the vehicle steering system sleeves and the coldheading module adopt the cold heading mode to machine the sizes of the sleeves and inner holes to achieve material saving, complete metal flowing line, improvement of the part strength, reduction of machining procedures, improvement of the machining efficiency; and the adopted cold heading module is simple in structure, easy to operate and high in production efficiency.

Owner:SUZHOU INDAL PARK XINKAI PRECISION FASTENERSCO

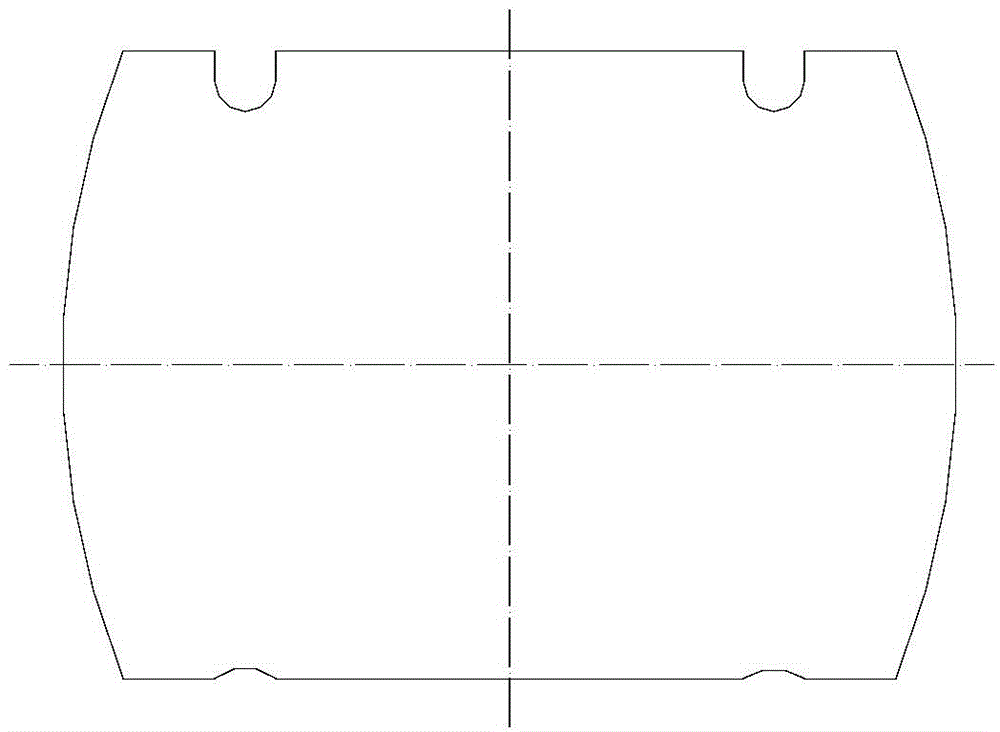

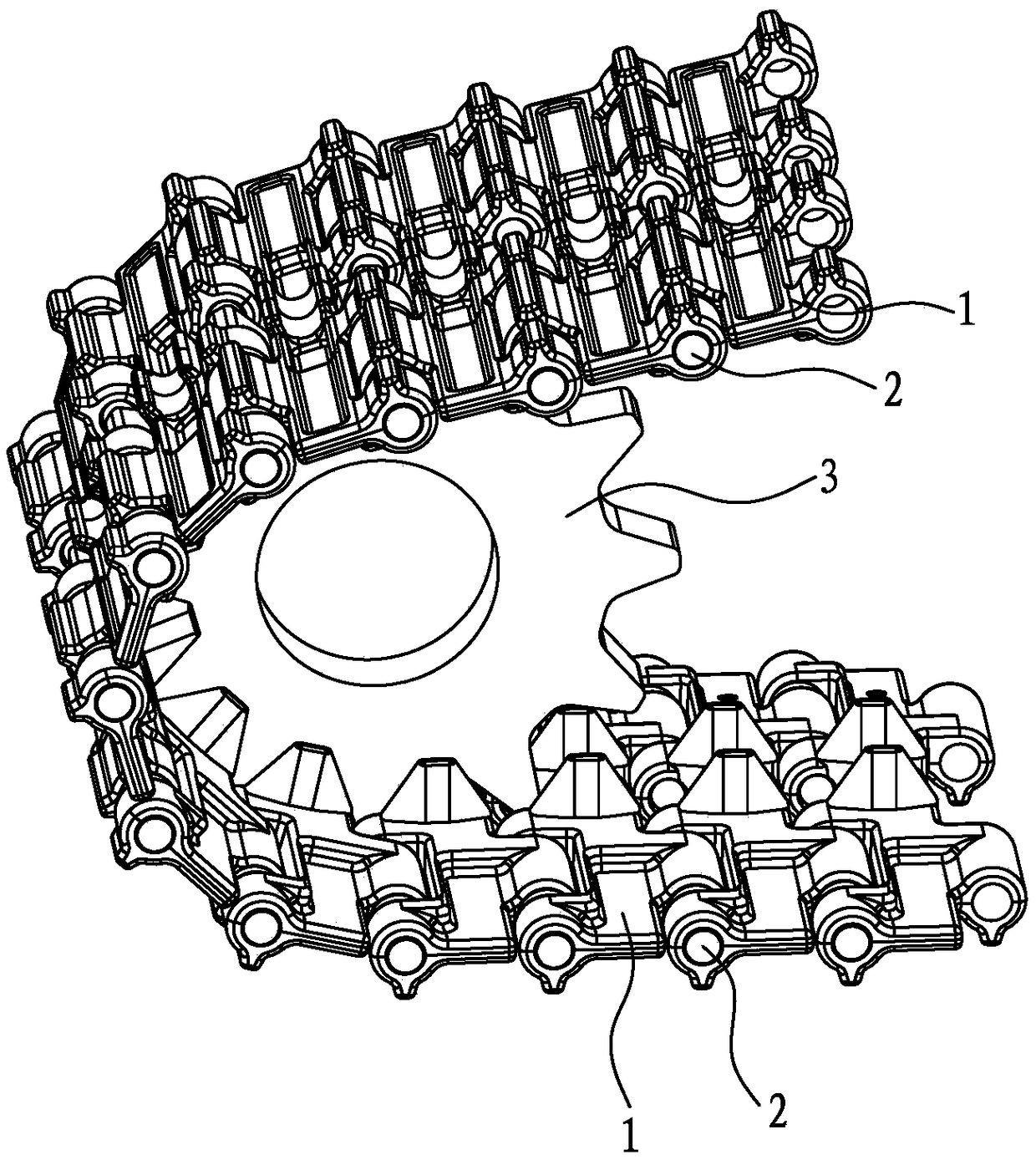

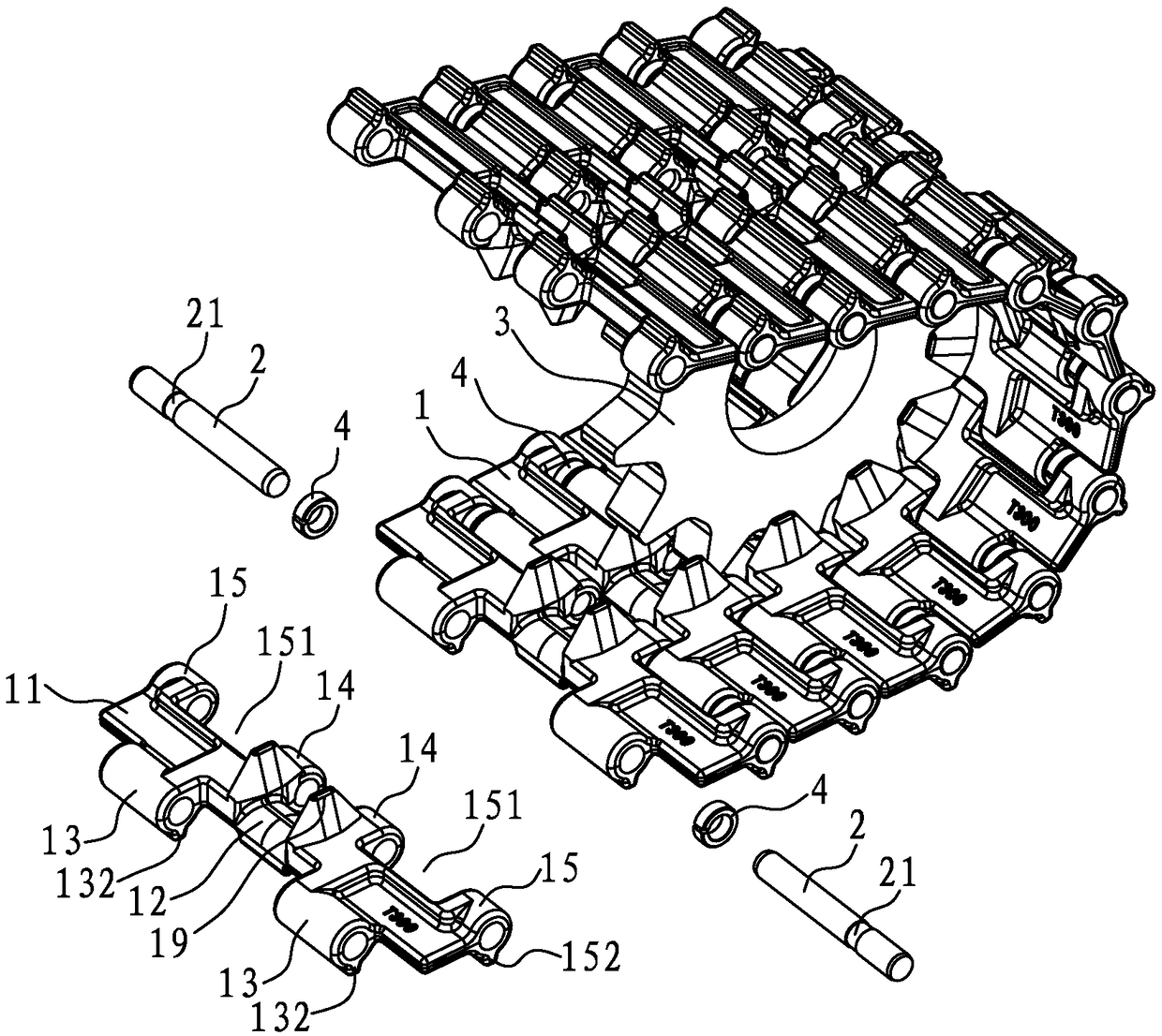

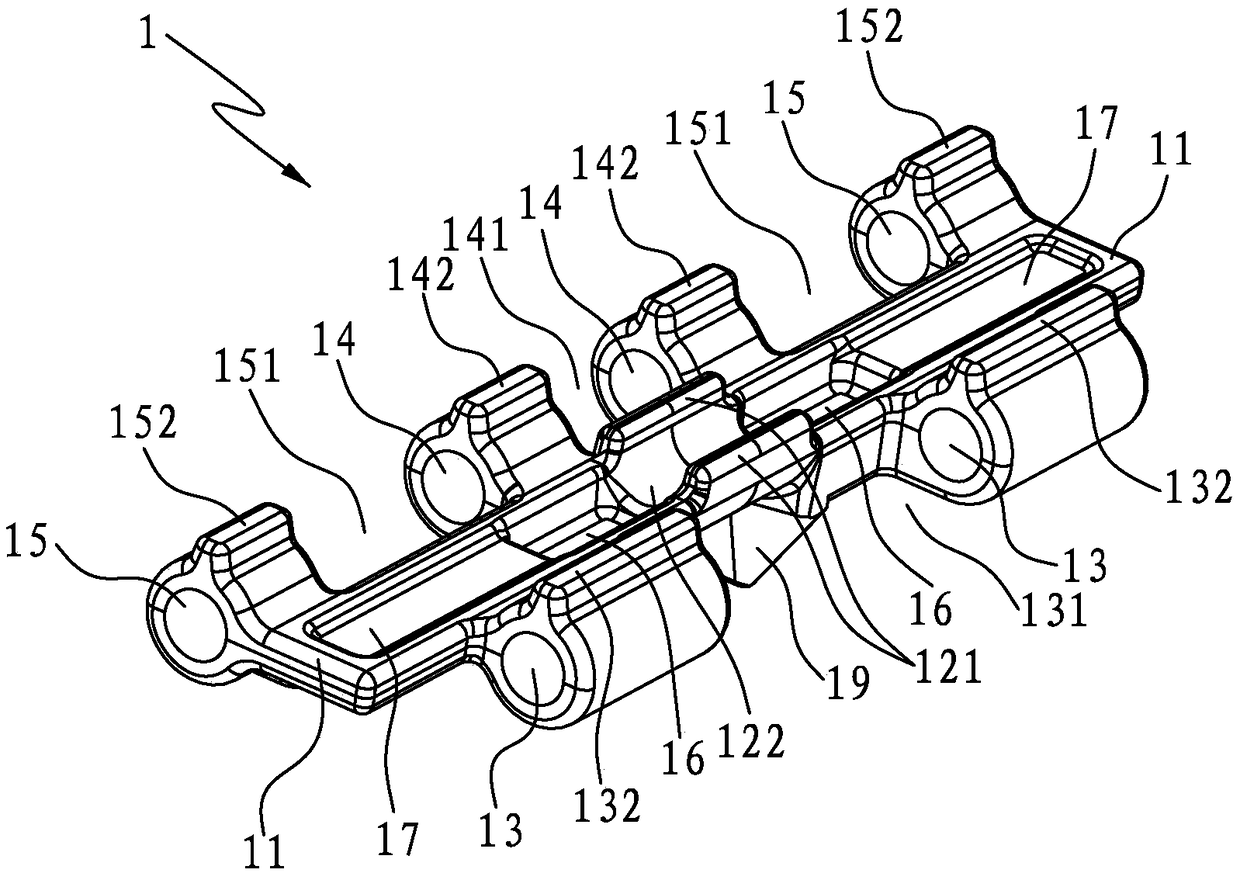

Caterpillar band and walking device with caterpillar band

PendingCN108773424AExtended service lifeSufficient service lifeEndless track vehiclesEngineeringCaterpillar

The invention discloses a caterpillar band and a walking device with the caterpillar band. The caterpillar band comprises multiple forged and formed caterpillar band boards and hinge pins, wherein every two adjacent caterpillar band boards are in pivot joint through the corresponding hinge pin. Each caterpillar band board comprises two first boards and a connecting board connected with the two first boards and engaged with a gear. First pivot joint holes are formed in one side of each first board, second pivot joint holes are formed in the other side of each first board, a first pivot joint groove is formed between every two first pivot joint holes, and the interval between every two second pivot joint holes is a tooth groove where the gear is inserted. When two adjacent caterpillar band boards are in pivot joint, two corresponding second pivot joint holes are inserted in the corresponding first pivot joint groove and coaxial with the corresponding first pivot joint holes, and the twoadjacent caterpillar band boards are in pivot joint together through the first pivot joint holes and the second pivot joint holes in the two sides of the corresponding tooth groove via the corresponding hinge pins. By the adoption of the above structure, the overall structural strength of the caterpillar band can be improved, the service life of the caterpillar band can be prolonged, and the walking device with the caterpillar band can stably walk.

Owner:姜炳福

Cold heading forming process for manufacturing dowel slotted screws and cold heading module

PendingCN107671218AHigh strengthIncrease productivityBoltsForging/hammering/pressing machinesProcess efficiencyEngineering

The invention relates to a cold heading forming process for manufacturing dowel slotted screws and a cold heading module. The cold heading forming process for manufacturing dowel slotted screws comprises the steps of conducting first-time beam intensification, second-time beam intensification, beam cutting of tail grooves, flange upsetting and cold-heading edge cutting through a cold heading module after wire rods are sheared off; and finally conducting thread rolling and electroplating to obtain the dowel slotted screws. The cold heading module is a four-die four-stroke cold heading machine platform and comprises a first die used for first-time beam intensification, a second die used for second-time beam intensification, a third die used for flange upsetting and beam cutting of the tail grooves and a fourth die used for conducting edge cutting on flanges of the dowel slotted screws. According to the cold heading forming process for manufacturing the dowel slotted screws, through the size of the screws, hexagonal flanges and the slotted grooves, the strength of parts is enhanced, the machining procedures are reduced, and the machining efficiency is improved. The cold heading moduleis simple in structure, easy to operate and high in production efficiency.

Owner:SUZHOU INDAL PARK XINKAI PRECISION FASTENERSCO

Semisolid manufacturing process of opposite roller spinning strain induction method of submarine ring rib cylindrical shell

Provided is a semisolid manufacturing process of an opposite roller spinning strain induction method of a submarine ring rib cylindrical shell. The process comprises the steps that firstly, on the basis of alloy smelting, an as-cast shell of the submarine ring rib cylindrical shell is manufactured through a centrifugal casting process; secondly, high-degree plastic deformation and shaping are carried out on the as-cast shell through an opposite roller spinning deformation process; thirdly, re-melting is carried out on an obtained distorted blank of the submarine ring rib cylindrical shell to obtain a semisolid blank, of a fine, uniform and spherical micro structure, of the submarine ring rib cylindrical shell; fourthly, integrated semisolid die forging forming is carried out on the semisolid blank; fifthly, heat treatment after forging is carried out to complete manufacturing of the submarine ring rib cylindrical shell. By means of the process, the submarine ring rib cylindrical shell of the non-dendrite fine, uniform and spherical micro structure can be obtained. The process has the advantages of being simple and high in material utilization rate and guaranteeing that the product is good in mechanical performance.

Owner:XI AN JIAOTONG UNIV

Manufacturing method of hollow half shaft of heavy-load automobile and hollow half shaft

The invention relates to a manufacturing method of a hollow half shaft of a heavy-load automobile and the hollow half shaft. The manufacturing method comprises the following steps: a steel bar is forged to form a flange plate blank; a seamless steel pipe is subjected to rotary swaging to be machined into a variable-cross-section hollow pipe; the hollow pipe and the flange plate blank are welded; machining and heat treatment are conducted on the welded hollow pipe and the flange plate blank to form the hollow half shaft. By the adoption of the rotary swaging process, the machined hollow pipe ishigh in precision, uniform in wall thickness and good in straightness, and meanwhile due to the fact that precision rotary swaging belongs to cold forming, the inner surface and the outer surface ofthe hollow pipe obtained through the process are good in quality, decarburization is basically avoided, a metal flow line is complete, and strength is high.

Owner:DONGFENG COMML VEHICLE CO LTD

Forging method of Cr18Mn18N steel forge piece and forge piece

The invention provides a forging method of a Cr18Mn18N steel forge piece and the forge piece and relates to the manufacturing field. The forging method of the Cr18Mn18N steel forge piece comprise the following steps of: heating a Cr18Mn18N steel ingot to a heating moulding temperature of 1190-1210 DEG C; carrying out heat preservation at the heating moulding temperature; carrying out repeated firing forging moulding; and then cooling. In the repeated firing forging moulding step, firing deformation during each firing is 10-20%, and final forging temperature is 850-950 DEG C. The forging method has the advantages that multiple steps coordinate with each other, so that the finally obtained forge piece is free of cracks on the surface, fibrous tissues of the forge piece are consistent with shape of the forge piece, and a metal streamline is complete; and defects are small, demands can be met, and machining dimension can be guaranteed.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

Concave anvil used for forging and forging device

ActiveCN106424512AReduce unevennessEliminate elasticityForging/hammering/pressing machinesEngineeringFiber structure

The invention provides a concave anvil used for forging and a forging device and belongs to the field of machinery. The concave anvil used for forging is provided with a concave surface, and a reference plane opposite to the concave surface is defined on the concave anvil. The distance between the concave surface and the reference plane is gradually and synchronously decreased from the center to the two ends of the concave surface. The difference value between the maximum distance and the minimum distance between the concave surface and the reference plane is 3.5 mm-6.5 mm. The forging device comprises the concave anvil used for forging. According to the concave anvil used for forging, the defect problem of a forging is solved, so that the fiber structure of the forging and the shape of the forging are kept consistent, the metallurgical quality of the forging is improved, and meanwhile, the forging cost is also reduced.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

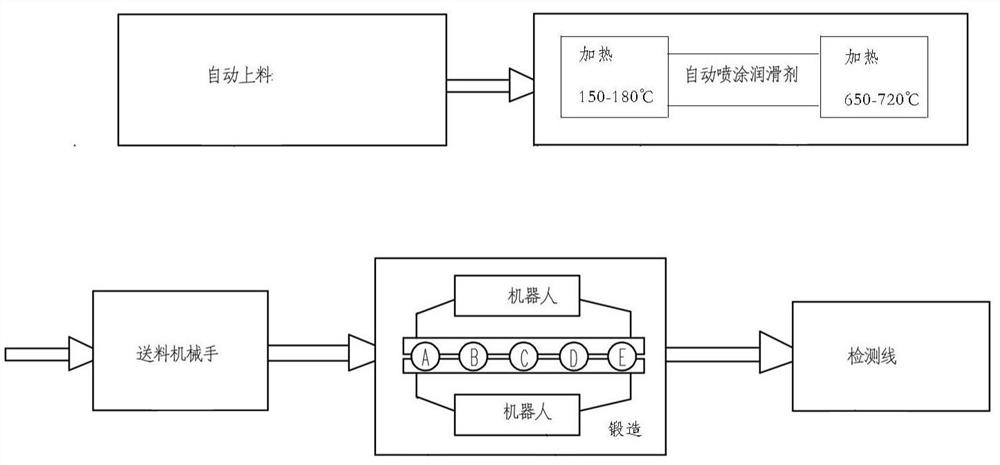

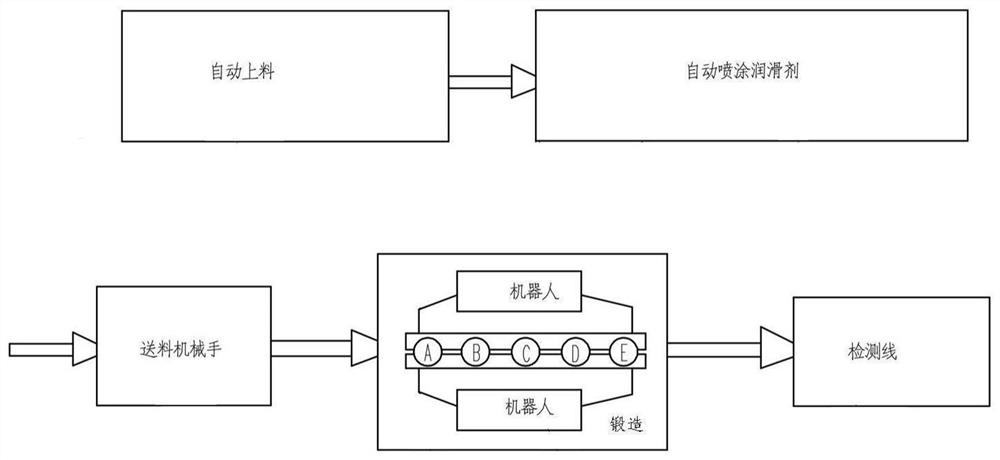

A production process of bearing roller warm forging

ActiveCN111531116BQuality assuranceIncrease profitMetal-working apparatusEngine componentsSteel barHeating furnace

The invention discloses a warm forging production process of a bearing roller. A warm forging production process for bearing rollers, the specific steps are as follows: a) feed the steel bar into the heating furnace; b) spray lubricant on the steel bar and continue heating; c) carry out multiple Station forging; d) Forging surface quality inspection; e) Grinding after quenching; f) Entering the inspection line for inspection. The invention has the advantages of no flash and edge trimming in precise forging, and the forging blank does not need to be cut, and can be ground directly after quenching.

Owner:江苏恩诺轴研科技有限公司

A kind of forging method of cr18mn18n steel forging and forging

The invention provides a forging method of a Cr18Mn18N steel forge piece and the forge piece and relates to the manufacturing field. The forging method of the Cr18Mn18N steel forge piece comprise the following steps of: heating a Cr18Mn18N steel ingot to a heating moulding temperature of 1190-1210 DEG C; carrying out heat preservation at the heating moulding temperature; carrying out repeated firing forging moulding; and then cooling. In the repeated firing forging moulding step, firing deformation during each firing is 10-20%, and final forging temperature is 850-950 DEG C. The forging method has the advantages that multiple steps coordinate with each other, so that the finally obtained forge piece is free of cracks on the surface, fibrous tissues of the forge piece are consistent with shape of the forge piece, and a metal streamline is complete; and defects are small, demands can be met, and machining dimension can be guaranteed.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

Bearing roller cold forging production process

ActiveCN111531115ADense tissue structureMetal flow line is completeForging/hammering/pressing machinesEngine componentsPhysicsGrinding

The invention discloses a bearing roller cold forging production process. A bearing roller, especially a conical roller, with a small diameter (phi is smaller than 29 mm) is formed by upsetting with acold header, and the bearing roller, especially the conical roller, with a large diameter (phi is larger than 30 mm) is usually machined by a lathe. The structure of the bearing roller formed throughcutting is not compact enough, a metal flow line is cut, and the material utilization rate is low. In large mechanical bearings of wind power generation, mining machinery and the like, once the quality of the bearing roller is not qualified, the replacement of the bearing roller after being installed and used is time-consuming, labor-consuming, and extremely high in cost. The bearing roller coldforging production process has the advantages that no flash exists in the precision forging process, edge trimming is not needed, a forging stock does not need to be cut, and grinding can be conductedafter direct quenching.

Owner:江苏恩诺轴研科技有限公司

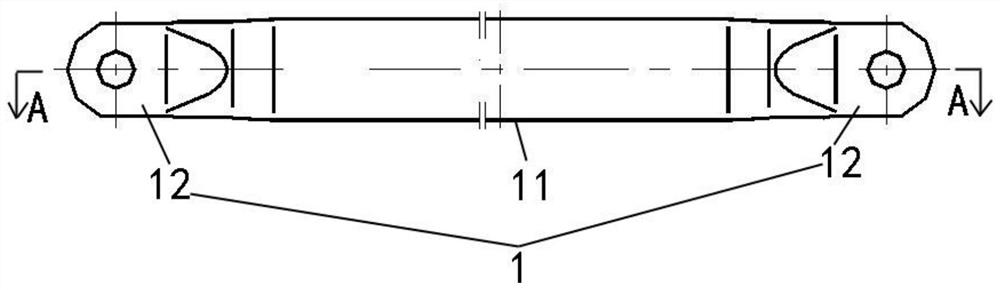

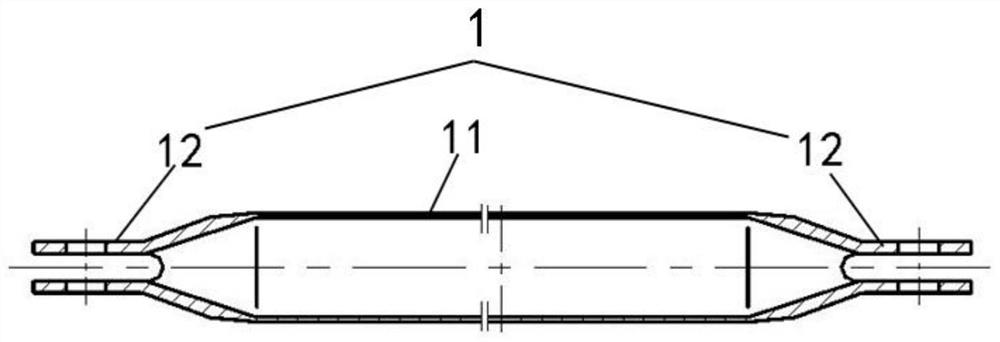

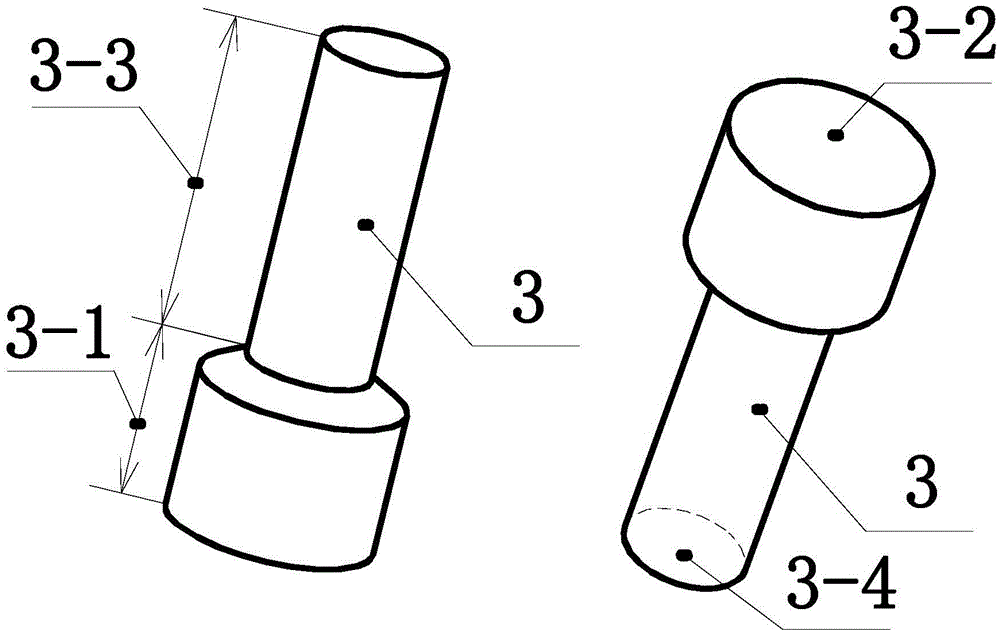

Precision forging near-net forming technology for light alloy non-revolving body special-shaped integral pull rod

PendingCN112170773AImprove microstructureMetal flow line is completeRailway componentsVehicle componentsTitanium alloyMachining

The invention provides a precision forging near-net forming technology for a light alloy non-revolving body special-shaped integral pull rod. The precision forging near-net forming technology is characterized in that the size of a to-be-forged thick-wall pipe is designed according to the drawing requirement; a radial precision forging machine is adopted, and a forging hammer is used for forging and drawing out a pull rod part; after forging and drawing out are completed, the forging hammer is replaced, and then the radial precision forging machine is adopted for forging and reducing forming ofan end of the pull rod; after forging and reducing are completed, the forging hammer is replaced, and then the radial precision forging machine is adopted for forging and flattening forming of the end of the pull rod; and after forging is completed, machining forming of the end of the pull rod is carried out. For a titanium alloy pull rod needing hot forging, the radial precision forging machineis adopted to be combined with a three-hot-method technology of heating in a furnace before forging, feeding induction heat supplementing and induction heat preservation during forging to implement precision radial near-net forming forging of the titanium alloy integral pull rod. According to the precision forging near-net forming technology, the comprehensive performance is improved while the shape of the integral rod is obtained, and the purpose of less machining after forming is achieved.

Owner:FUJIAN LONGXI BEARING (GROUP) CO LTD

Valve body forging method

ActiveCN104439032BDense microstructureBeautiful appearanceValve arrangementsPressure grooveMaterials science

The invention relates to the field of valve body manufacturing, in particular to a valve body forging method. The valve body forging method saves materials and energy and reduces consumption on the condition of meeting the requirement of customers for product diversification. At first, blank forming is achieved by utilizing free forging for executing the following steps of A, selecting round steel with the weight being 1.15-1.25 times the weight of a finished valve body, riveting the two ends of the round steel, conducting indentation material separation, and forging the round steel into the preset size; B, enabling the two ends of the round steel to get off a table, forging eccentricity of the middle and the two ends, and forging the two ends into 260-degree octagons; C, then utilizing pressing blocks for making octagonal pressure grooves in the two ends into the preset size, and ensuring that flanges and grooves of a green body are within the design size range. Then, final forming is achieved by adopting semi-die forging for executing the following steps of a, forging the middle octagon of the green body in a vertical die buckling and pressing mode; b, after the middle octagon is formed, controlling the height of the flanges at the two ends through cushion blocks and forging the flanges to be rounded; c, finally, trimming the sizes of all parts of the forged piece into the designed sizes.

Owner:CHENGDU SHUANGLIU HENGSHENG FORGING

Manufacturing process of double-end internal gear ring for electric forklift transmission

ActiveCN104439995BHigh densityReduce post-cutting operationsSolid state diffusion coatingFurnace typesRejection rateMachine tool

The invention discloses a making technology for a transmission double-end internal-teeth ring of an electric forklift. The making technology comprises the following steps: 1, performing warm forging and plastic molding: 2, spheroidizing annealing; 3, performing blank making, shot blasting and saponifying; 4, performing cold-extruding on internal teeth of a central hole; 5, machining; 6, performing salt bath tufftriding. A product prepared by the technology is stable in quality, small in accumulated errors among the teeth, high in yield, and short in production cycle; the production efficiency is improved; the problem that a traditional transmission gear shaping is large in lathe equipment investment of multiple, low in production efficiency, high in manufacture cost and difficult to realize massive production, is solved, and the defects that the quality of the product is unstable and the rejection rate of the product is high which are caused by the fact that two gear rings are formed by welding and the generated deformation is large, are overcome.

Owner:江苏威鹰机械有限公司

Semi-solid Manufacturing Process of Submarine Ring Ribbed Cylindrical Shell by Wheel Spinning Strain Induction Method

Provided is a semisolid manufacturing process of an opposite roller spinning strain induction method of a submarine ring rib cylindrical shell. The process comprises the steps that firstly, on the basis of alloy smelting, an as-cast shell of the submarine ring rib cylindrical shell is manufactured through a centrifugal casting process; secondly, high-degree plastic deformation and shaping are carried out on the as-cast shell through an opposite roller spinning deformation process; thirdly, re-melting is carried out on an obtained distorted blank of the submarine ring rib cylindrical shell to obtain a semisolid blank, of a fine, uniform and spherical micro structure, of the submarine ring rib cylindrical shell; fourthly, integrated semisolid die forging forming is carried out on the semisolid blank; fifthly, heat treatment after forging is carried out to complete manufacturing of the submarine ring rib cylindrical shell. By means of the process, the submarine ring rib cylindrical shell of the non-dendrite fine, uniform and spherical micro structure can be obtained. The process has the advantages of being simple and high in material utilization rate and guaranteeing that the product is good in mechanical performance.

Owner:XI AN JIAOTONG UNIV

Annular heating furnace large bottom plate adopting rolled blank

InactiveCN107782137ASimplify the manufacturing processAdapt to work needsFurnace typesSolution treatmentCircular cone

The large bottom plate of the annular heating furnace adopts rolling blanks. The main body of the large bottom plate is a disc structure. One side of the disc structure is a plane, the center of the other side of the disc structure is a plane, and the outer periphery of the plane is a conical surface. A center hole is arranged in the center of the bottom plate, and circular bosses are respectively arranged around the center hole, and the blank of the large bottom plate is a rolling blank. The material of the large bottom plate is heat-resistant stainless steel. The material is cast into a billet by steel mold casting. The billet is solid solution treated and then rolled into a rolled plate. The rolled plate is subjected to non-destructive inspection after rough machining and fine machining. , The products that pass the non-destructive testing inspection are finished large base plates. The large bottom plate of the annular heating furnace adopting rolling blanks of the present invention can improve the structure of the blank by utilizing the characteristics of the rolling process, greatly improve the high temperature strength and high temperature stability of the large bottom plate of the annular heating furnace, and adapt to the working needs of the annular heating furnace. The effect is remarkable.

Owner:QINGDAO RUNCHENG VEHICLE FITTINGS CO LTD

Warm forging forming technology of plum coupling

The invention discloses a warm forging forming technology of a plum coupling. The technology comprises the technical steps of performing material selecting, material feeding, shot blasting and heatingon a driving shaft coupling and a driven shaft coupling; upsetting head parts of the driving shaft coupling and the driven shaft coupling; reversely extruding to form the driving shaft coupling and the driven shaft coupling; and setting the length of the driving shaft coupling and the driven shaft coupling as requirement to obtain the forged driving shaft coupling and the forged driven shaft coupling. The technology has the advantages that the driving shaft coupling and the driven shaft coupling processed by the technology remain the strength and toughness of steel parts, and the allowance for machining is reduced; and the organization structure and the mechanical performance of the steel parts can be improved after the warm forging processing.

Owner:盐城中德精锻股份有限公司

Bearing roller warm forging production technology

ActiveCN111531116AQuality assuranceIncrease profitMetal-working apparatusEngine componentsHeating furnaceQuenching

The invention discloses a bearing roller warm forging production technology. The bearing roller warm forging production technology comprises the following specific steps that (a), feeding is carried out, and steel bars are fed into a heating furnace; (b), a lubricant is sprayed on the steel bars, and continuous heating is carried out; (c), multi-station forging is carried out at 700-800 DEG C; (d), the forging surface quality is detected; (e), grinding process is carried out after quenching; and (f), detection is carried out entering a detection line. The bearing roller warm forging productiontechnology has the advantages of precision forging without trimming and scrap edge, forging stock without cutting, and grinding process after direct quenching.

Owner:江苏恩诺轴研科技有限公司

Titanium alloy head and its preparation method and application

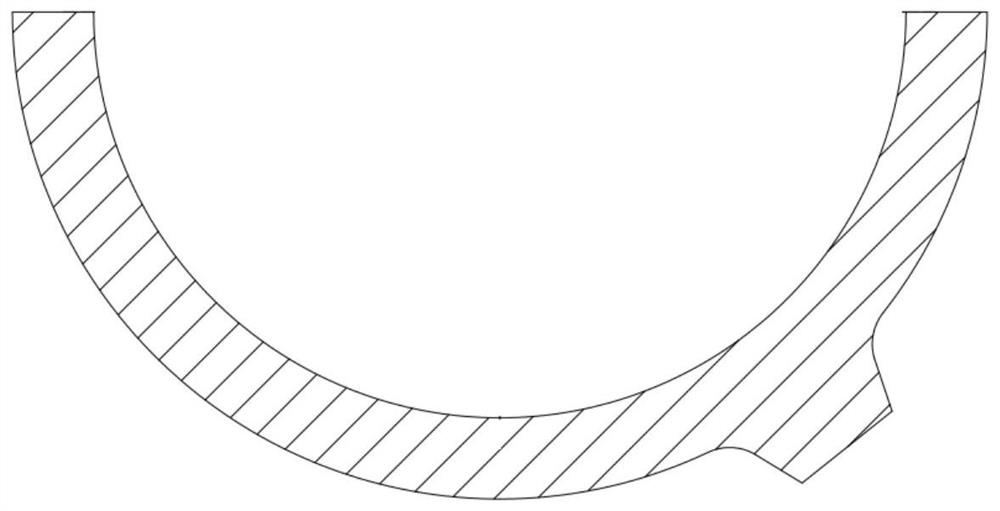

ActiveCN113441645BExtended service lifeMetal flow line is completeWaterborne vesselsHollow articlesTitanium alloyStamping process

The invention involves a titanium alloy head and its preparation methods and applications.In this preparation method, the titanium alloy plate blanks include the main board blanks and the convex blocks located on the bottom of the main plate blank; the molded molds include upper and lower molds.The first groove and the second groove for the convex block, the second groove is located on the bottom wall of the first groove and connects to the first groove.The groove and the second groove are coordinated to form a cavity; heating titanium alloy plate blanks to T β 20 ° C, then placed in the molding cavity of the punch for N 1 Secondary stamping; During the last stamping process, the temperature of the first grant of the first grant of the mold under the control is 700 ° C to 750 ° C, and the temperature at the control of the second seedy is higher than the temperature at the tank at the first seminar.50 ℃ ~ 80 ℃.The titanium alloy sealed heads that have been made in this preparation method have integrated titanium alloy sealed heads and titanium alloy sea seals. It has a complete metal streamline and improves the comprehensive mechanical properties of the titanium alloy sealed head.Essence

Owner:湖南湘投金天科技集团有限责任公司 +1

A kind of bearing roller cold forging production process

ActiveCN111531115BQuality assuranceIncrease profitForging/hammering/pressing machinesEngine componentsMachineIndustrial engineering

The invention discloses a cold forging production process of a bearing roller. Bearing rollers, especially tapered rollers with small diameters (below Φ29 mm) are formed by heading with cold heading machines; while large diameters (above Φ30 mm) are mostly processed by lathe cutting. The structure of the cut bearing roller is not tight enough, the metal flow line is cut, and the material utilization rate is low. In wind power generation, mining machinery and other large-scale mechanical bearings, once the quality of the bearing rollers is not satisfactory, it will be time-consuming and costly to replace them after installation and use. The invention has the advantages of no flash and edge trimming in precision forging, and the forging billet does not need to be cut, and can be ground directly after quenching.

Owner:江苏恩诺轴研科技有限公司

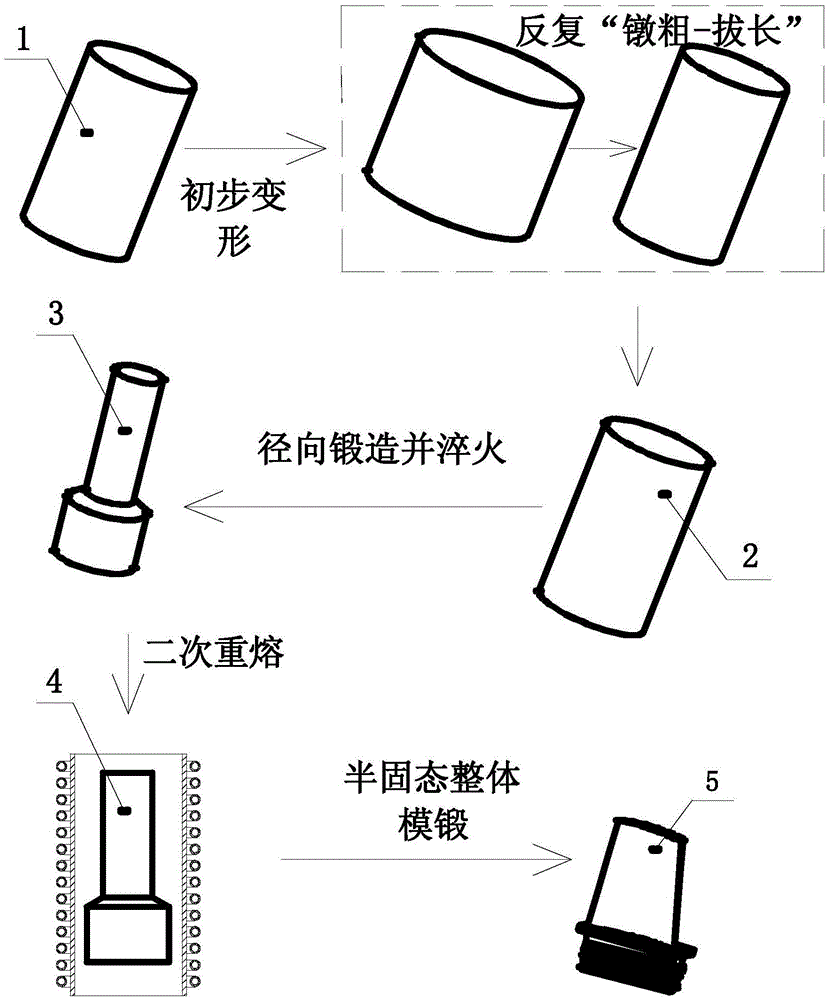

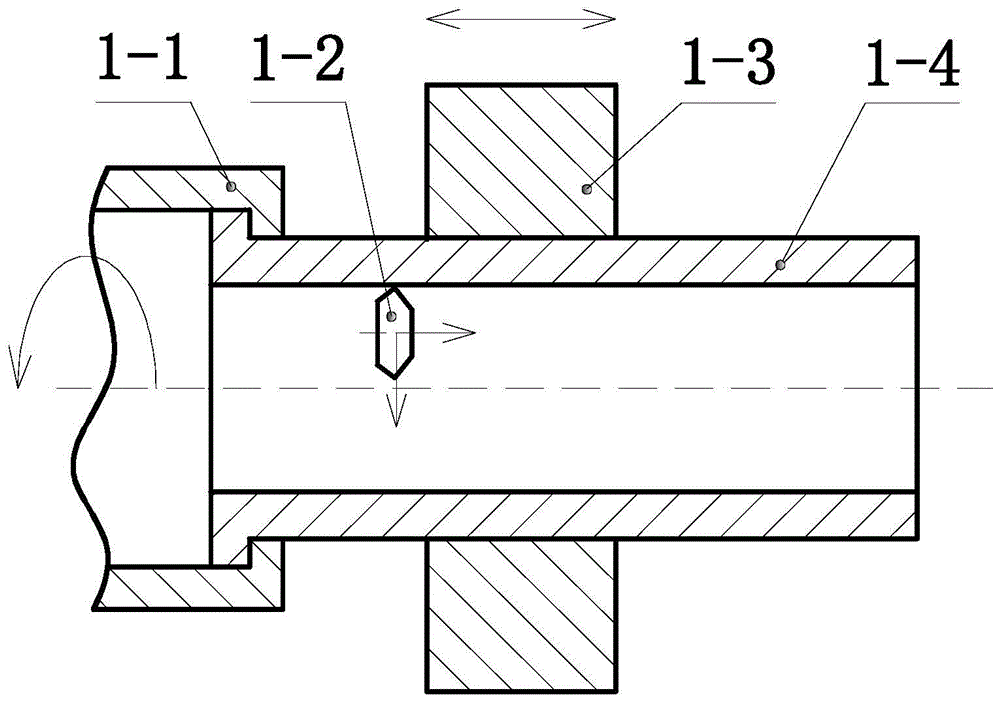

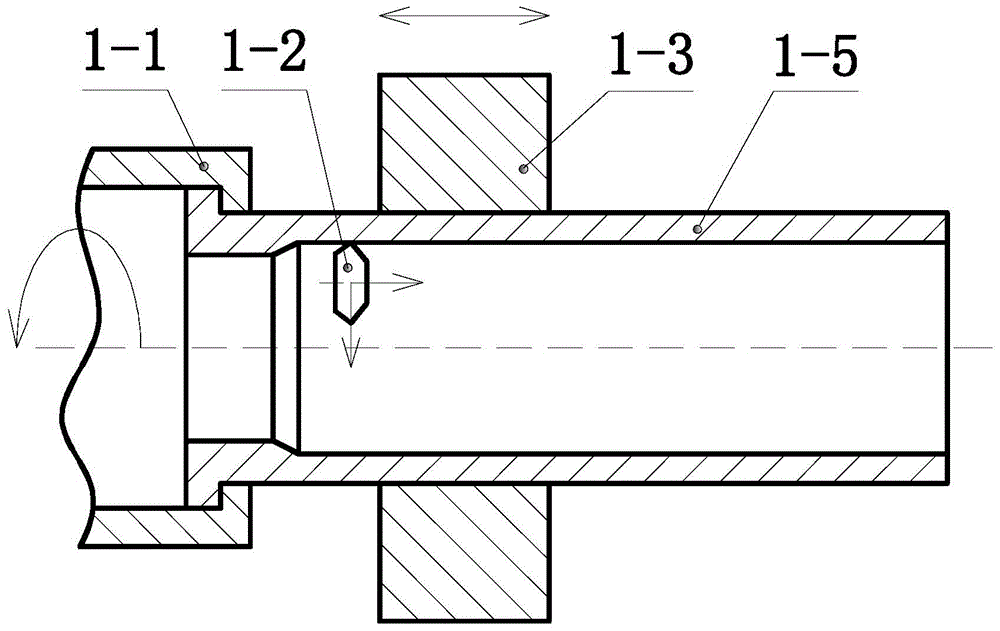

Radial forging strain-induced semi-solid integral die forging process for blades

The invention relates to a radial forging type strain-induced semi-solid integral die forging process of a blade. The radial forging type strain-induced semi-solid integral die forging process comprises the following steps: pre-heating and repetitively upsetting and drawing out an ultra-high strength steel or titanium alloy-made metal bar for forming an outer cylinder forge piece of an undercarriage so as to obtain a distorted metal rod for storing distortion energy at first; then, radially forging the distorted metal rod by utilizing waste heat so as to obtain a radial forging distorted blank having a ladder shape, and quenching; secondarily remelting a second radial forging distorted blank so as to obtain a semi-solid blank of the blade with the solid phase ratio of 40-60%; and finally, carrying out semi-solid integral die forging of the semi-solid blank of the blade so as to obtain a blade forming part. The radial forging type strain-induced semi-solid integral die forging process disclosed by the invention has the characteristics of being simple in process, low in forming force, high in material utilization rate and good in mechanical property of the product.

Owner:XI AN JIAOTONG UNIV

Semi-solid Manufacturing Process of Die Ring Spinning Strain Induced Method for Submarine Ribbed Cylindrical Shell

InactiveCN104625633BIncrease profitHigh strengthMetal-working apparatusMicro structureManufacturing technology

A semisolid manufacturing technology for a mold ring spinning strain inducing method for a submarine ring rib cylindrical shell includes the steps that on the basis of smelting alloy, a centrifugal casting technology is adopted for manufacturing an as-cast shell body of the submarine ring rib cylindrical shell; a mold ring spinning deformation technology is adopted to carry out large-deformation plastic deformation and shape-correction treatment on the as-cast shell body; an obtained distortion blank of the submarine ring rib cylindrical shell is remelted to obtain a semisolid blank, with a fine, even and spherical micro structure, of the submarine ring rib cylindrical shell; semisolid overall stamp forging and shape-correction are carried out on the semisolid blank; heat treatment after forging is performed to complete manufacturing the submarine ring rib cylindrical shell. The submarine ring rib cylindrical shell with the non-dendritic crystal fine and even spherical micro structure can be manufactured, and the semisolid manufacturing technology has the advantages that the technological process is simple, the material use ratio is large, and the mechanical property of the cylindrical shell is high.

Owner:XI AN JIAOTONG UNIV

Large bottom plate made of forged blank for annular heating furnace and method for manufacturing large bottom plate

InactiveCN103063025AAdapt to work needsImprove work performanceFurnace typesSolution treatmentEngineering

Disclosed is a large bottom plate made of a forged blank for an annular heating furnace. A main body of the large bottom plate is of a disc structure, the surface of one side of the disc structure is a plane, the center of the other side of the disc structure is another plane, outer peripheries of the planes are conical surfaces, a center hole is arranged in the center of the large bottom plate, circular bosses respectively encircle the center hole, and a blank of the large bottom plate is the forged blank. The large bottom plate is made of heat-resistant stainless steel, the heat-resistant stainless steel is cast by a steel die to form a cast blank, the cast blank is subjected to solution treatment and then is forged to form the forged blank, the forged blank is subjected to nondestructive flaw detection after being roughly machined and finely machined sequentially, and a product which is qualified in the nondestructive flaw detection is the finished large bottom plate. The large bottom plate made of the forged blank for the annular heating furnace and a method for manufacturing the large bottom plate have the advantages that the structure of the blank can be improved by the aid of characteristics of a forging process, the high-temperature strength and the high-temperature stability of the large bottom plate for the annular heating furnace are greatly improved, working requirements of the annular heating furnace are met, and an effect is obvious.

Owner:NANJING UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com