A method for forming rounded square steel forged by a precision forging machine

A forming method and forging forming technology, which is applied in the field of steel forging, can solve the problems that precision forging machines cannot forge rounded square steel blanks, etc., and achieve the effects of improving equipment production efficiency, good surface quality, and avoiding folding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A forming method for forging rounded square steel with a precision forging machine. A 16MN horizontal precision forging machine is used. The programming software for automatic control is BarForge. The model of the round hammer is R120.

[0026] Put the continuous casting billet into the gas heating furnace and heat it. The heating temperature is 1190-1210°C, and the holding time is 6-8h. The heating process in this embodiment increases the heating temperature by 20°C and extends the holding time by 2 hours compared with the normal billet, mainly to homogenize the billet at high temperature, reduce composition segregation, and prepare for metallurgical defects in the center of forging and welding.

[0027] In this embodiment, the precision forging machine adopts the forging deformation mode: circle→circle→circle→square, the total forging ratio from billet to finished square steel billet with round corners is 4.7, and the size of finished square steel is calculated accor...

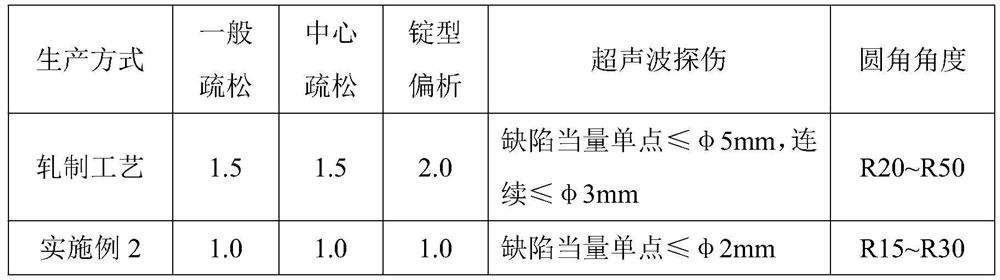

Embodiment 2

[0033] A forming method for forging rounded square steel with a precision forging machine. A 16MN horizontal precision forging machine is used. The programming software for automatic control is BarForge. The model of the round hammer is R120.

[0034] The continuous casting billet is put into a gas heating furnace for heating, the heating temperature is 1190-1210°C, and the holding time is 6-8h.

[0035] In this embodiment, the precision forging machine adopts the forging deformation mode: circle → circle → circle → circle → square, the total forging ratio from the billet to the finished square steel billet with round corners is 4.7, and the size of the finished square steel is A=(0.81~0.82)D For calculation, A is the side length of the rounded square steel, and D is the diameter of the circle before the finished product.

[0036] In this embodiment, the precision forging machine uses a round hammer head for forging forming, and the forging frequency of the round hammer head...

Embodiment 3

[0047] A forming method for forging rounded square steel with a precision forging machine. A 16MN horizontal precision forging machine is used. The programming software for automatic control is BarForge. The model of the round hammer is R120.

[0048] Put the continuous casting billet into the gas heating furnace and heat it. The heating temperature is 1190-1210°C, and the holding time is 6-8h.

[0049] In this embodiment, the precision forging machine adopts the forging deformation method: circle → circle → circle → circle → square, the total forging ratio from the billet to the finished square steel billet with round corners is 4.7, and the size of the finished square steel is A=(0.81~0.82)D For calculation, A is the side length of the rounded square steel, and D is the diameter of the circle before the finished product.

[0050] In this embodiment, the precision forging machine uses a round hammer head for forging forming, and the forging frequency of the round hammer hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com