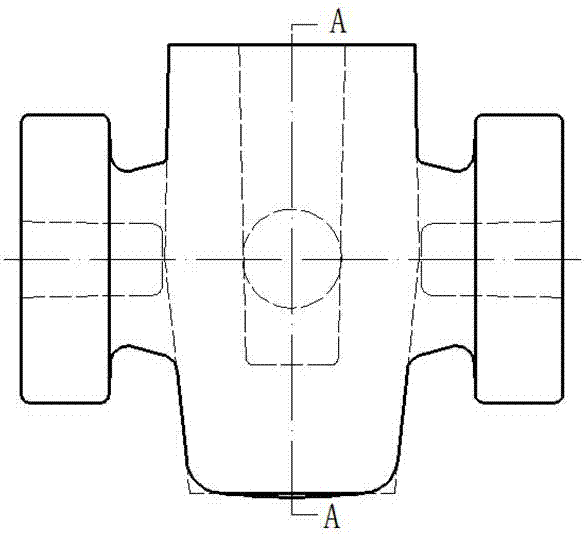

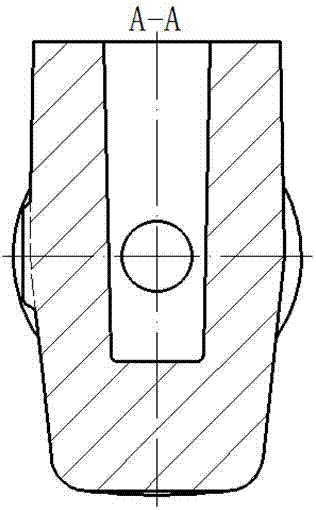

A multi-directional compound extrusion die and method for a large-size flange three-way valve body

A three-way valve body and compound extrusion technology, applied in the direction of metal extrusion dies, etc., can solve the problems of reducing material utilization, increasing trimming process, and difficulty in die cavity, so as to avoid folding defects, improve forming quality, and improve The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

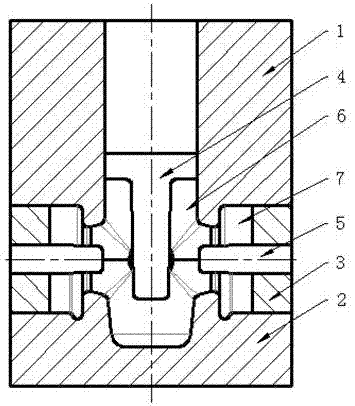

[0026] The mold of the present invention is installed on the multi-directional compound extrusion press with vertical perforation cylinder and horizontal perforation cylinder, the lower die 2 is fixed on the workbench of the press, the upper die 1 is fixed on the movable beam, and the upper extrusion plate 4 is installed on the plunger of the vertical piercing cylinder of the press, and the side flange 3 and the lower extrusion disk 5 are respectively installed on the horizontal cylinder and the plunger of the horizontal piercing cylinder of the multi-directional composite extrusion press; Independent movement can be realized under the control of the press.

[0027] During the extrusion process, firstly preheat the extrusion die to 300°C, then heat the round bar billet with a suitable size to 1230°C and put it into the lower die 2 fixed on the workbench, the upper die 1 moves downward and the lower die Die 2 is closed. At this time, the lower extrusion plate 5 is located in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com