Semi-closed type forging die used for forging of bevel gear and forging method thereof

A semi-closed, bevel gear technology, which is applied in the field of mold design, can solve the problems of uneven metal streamlines, unfulfilled tooth shape filling, and poor tissue uniformity, so as to avoid folding defects, smooth metal streamlines, and uniform tissue. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

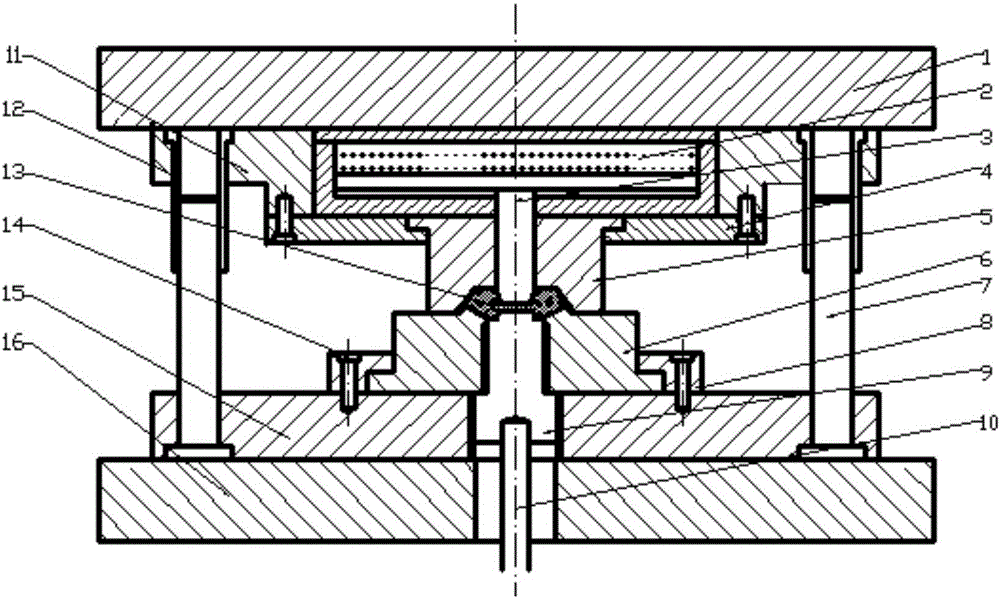

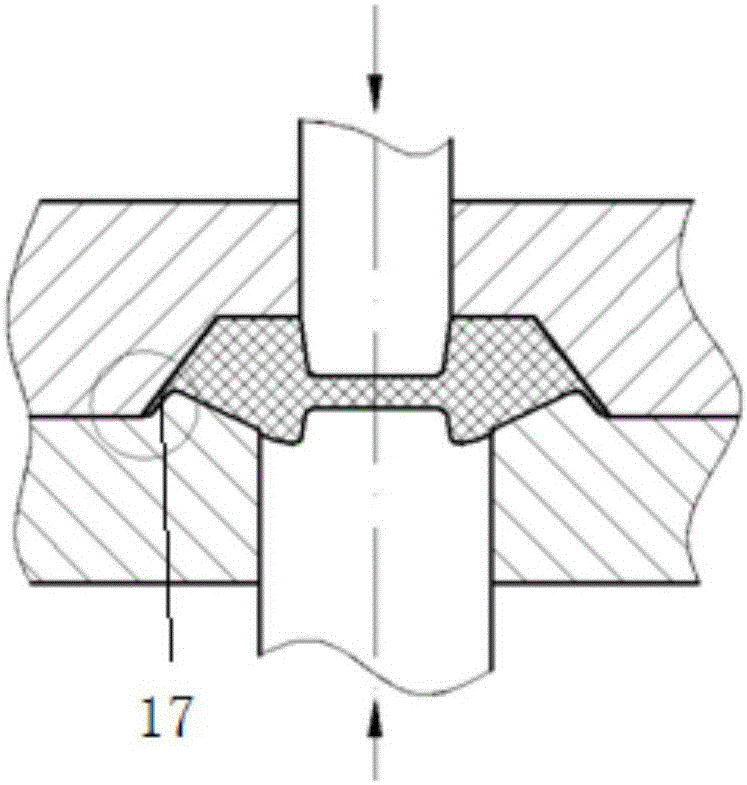

[0036] Such as figure 1 and Figure 2a As shown, a semi-closed forging die for bevel gear forging includes a toothed die 5, an upper punch 3, a back cone die 6 and a lower punch 9, wherein the toothed die 5 and the upper punch 3 Cooperate installation, the back cone die 6 is installed in cooperation with the lower punch 9; the closed space formed by the cooperation of the tooth shape die 5 and the back cone die 6 includes a cavity and a shunt structure 17 located at the tooth top of the big end of the cavity, the shunt structure 17 communicates with the cavity, which is a narrow gap; when forging bevel gears, under the action of the upper punch 3, the billet first fills the cavity, and then presses into the shunt structure 17 to ensure the filling fullness of the tooth shape.

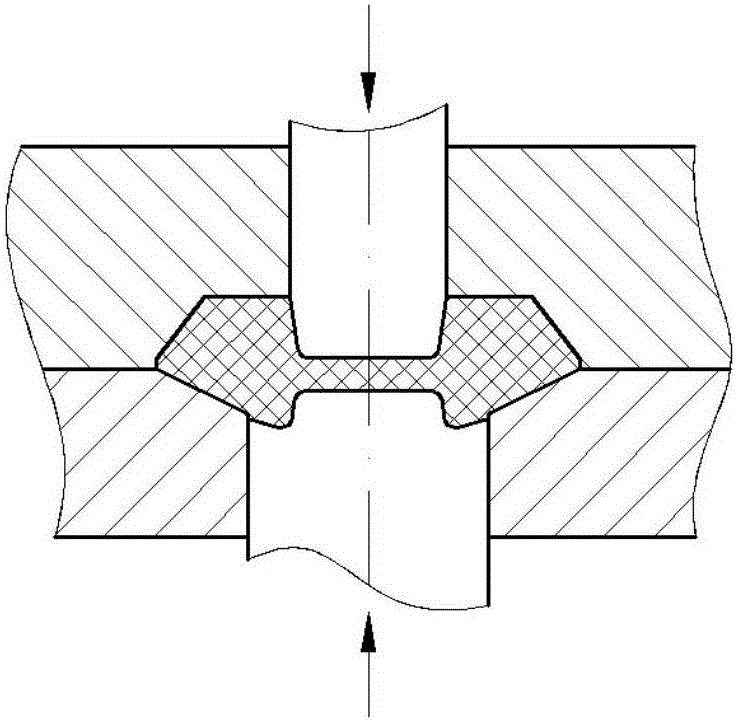

[0037] compared to Figure 2b In the traditional fully closed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com