Magnesium Alloy Cast Rod Continuous Upsetting Blank Die

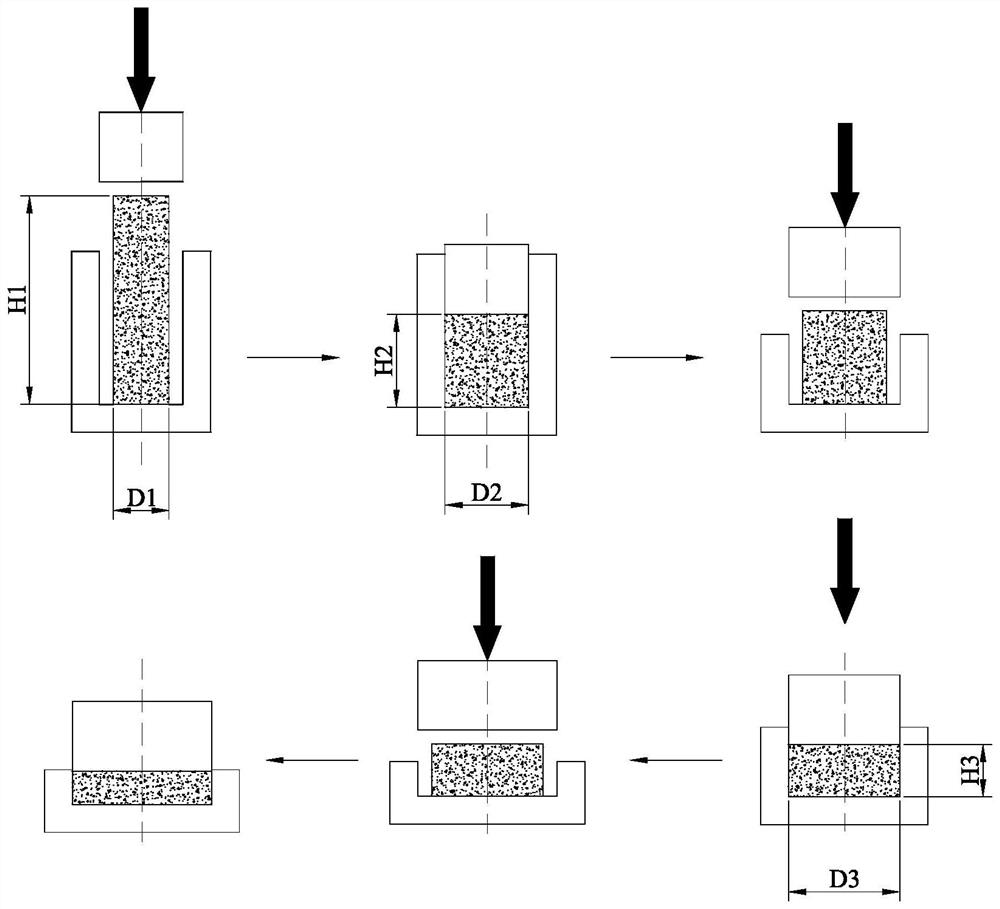

A magnesium alloy and rod casting technology, which is applied in the field of continuous large deformation billet making, can solve problems such as inability to carry out deformation, double drum shape, and instability of cylindrical billets, so as to increase cleaning work, reduce volume, and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

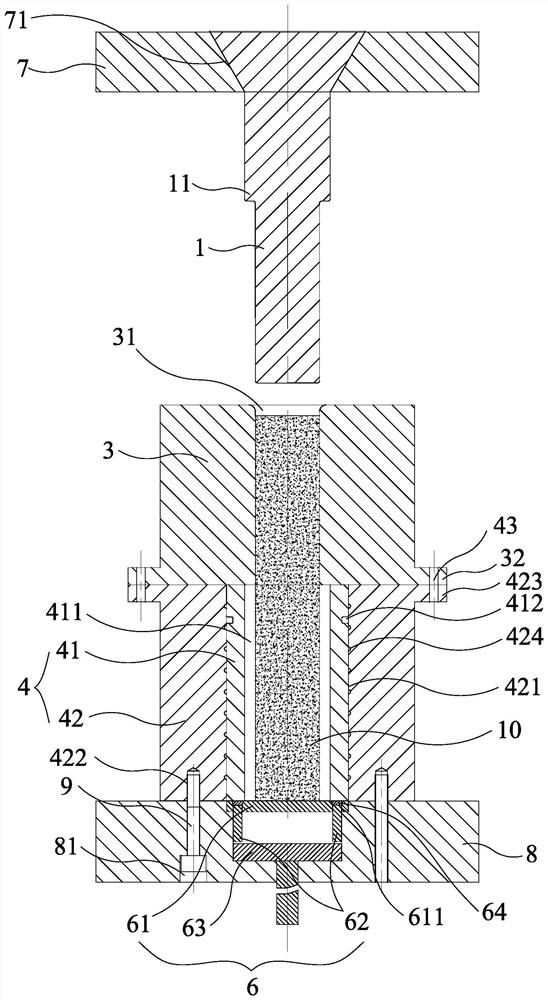

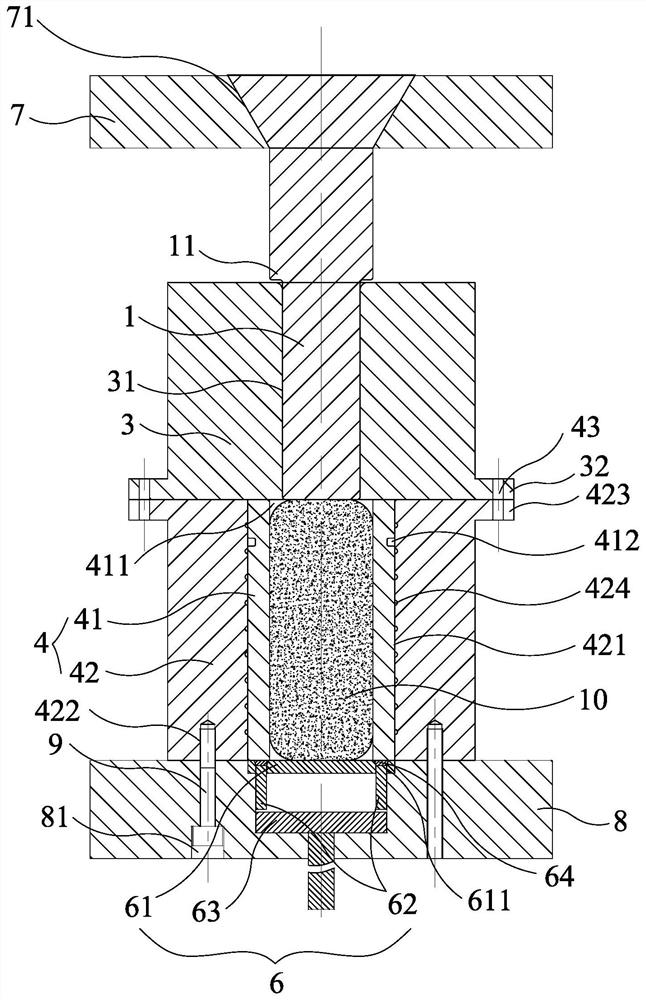

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] The invention provides a magnesium alloy cast rod continuous upsetting billet mold, comprising a punch 1 installed on the upper workbench (not shown in the figure) of the press, a punch collar 2, an upper die 3, a lower concave Die 4, snap ring 5, ejector rod mechanism 6, fastener (not shown in the figure), punch fixed plate 7, die fixed plate 8 and bolt 9, as figure 2 As shown; the punch fixing plate 7 is fixed on the upper workbench, and the middle part of the punch fixing plate 7 is provided with a funnel-shaped through hole 71, and the top of the punch 1 is funnel-shaped, and the punch 1 is inserted from the through hole 71 and connected with the through hole 71. The holes 71 are closely matched, and the funnel-shaped design simplifies and stabilizes the installation of the punch 1 .

[0035] The upper die 3 is coaxially installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com