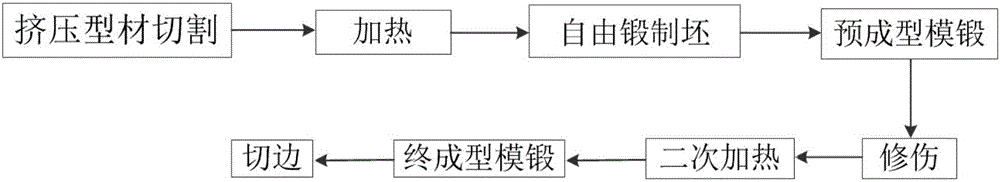

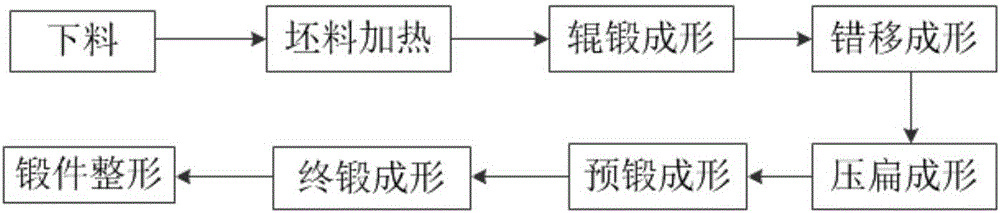

Forging forming method of triangular aluminum alloy control arm

A technology of aluminum alloy and control arm, which is used in manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of low production efficiency, low material utilization rate, low product quality, etc. The material flow is uniform and reasonable, and the effect of reducing the processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0209] 1. Cutting

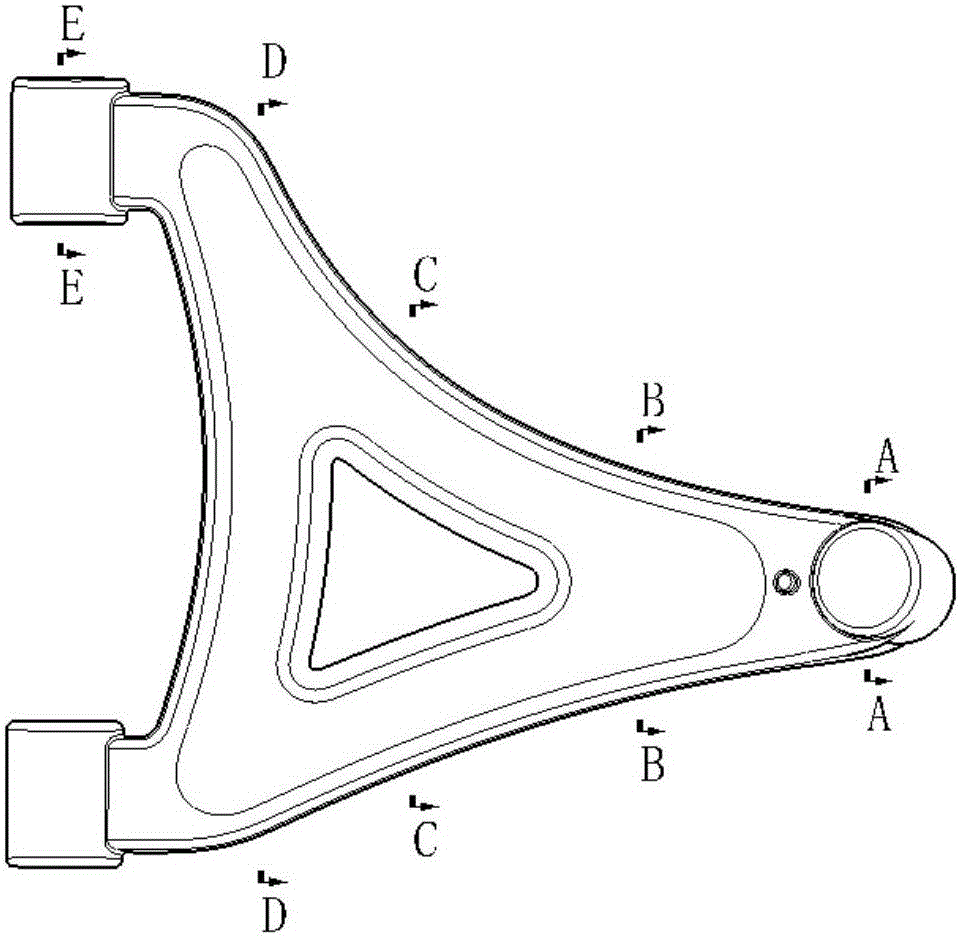

[0210] refer to image 3 and Figure 3-a to Figure 3-e , according to the area of each section on the blank is equal to the area of the corresponding section on the forging plus the area of the flash, which is shown in the following formula (1):

[0211] A j =A d +A f (1)

[0212] In the formula: A j Calculate the cross-sectional area of the blank for any position;

[0213] A d is the cross-sectional area of the corresponding forging;

[0214] A f is the cross-sectional area of the corresponding flash; according to the size of the corresponding section of the triangular control arm and the size of the set flash, the section diameter of the largest part is taken as the diameter of the round bar is 115mm, and the length of the round bar is calculated as 132mm according to the principle of equal volume , using band sawing machine for cutting;

[0215] 2. Blank heating

[0216] Heat the billet obtained in step 1 in an electric induction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com