Warm precise forging forming method for hollow gear shaft blank

A hollow gear shaft and forming method technology, applied in mechanical equipment, engine components, metal processing equipment, etc., can solve the problems of low tooth surface roughness, high tooth profile accuracy, large deformation resistance, etc., to achieve good surface quality, flow Line integrity, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

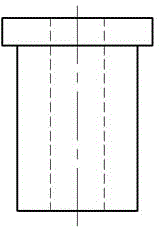

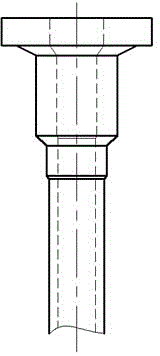

[0017] Such as Picture 1-1 , 1-2 , 1-3 shows the schematic flow chart of the hollow gear shaft blank warm precision forging forming process: first, according to the three-dimensional simulation forming software to simulate the warm precision forging process, design mold making and material preparation, the raw material of the hollow gear shaft blank in this embodiment is 27MnCr5 Round steel hollow bars. Such as Picture 1-1 As shown, the 27MnCr5 round steel hollow bar is sawed and cut. After cutting, the weight of the raw material billet is greater than 8%-10% of the weight of the finished forging billet. The weight of the billet is 2%-4% greater than the weight of the finished forging billet. Adsorb a layer of coating agent (lubricating effect) on the surface of the forging billet to provide good lubrication for the pre-extrusion flow of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com