Alloyed material modified by nanometer rare earth oxide, alloyed layer and preparation method thereof

A nano-rare earth and oxide technology, applied in metal material coating process, metal processing equipment, coating and other directions, can solve the problem of difficult graphite retention, reduce inclusions and pores, improve wear resistance, and reduce friction coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

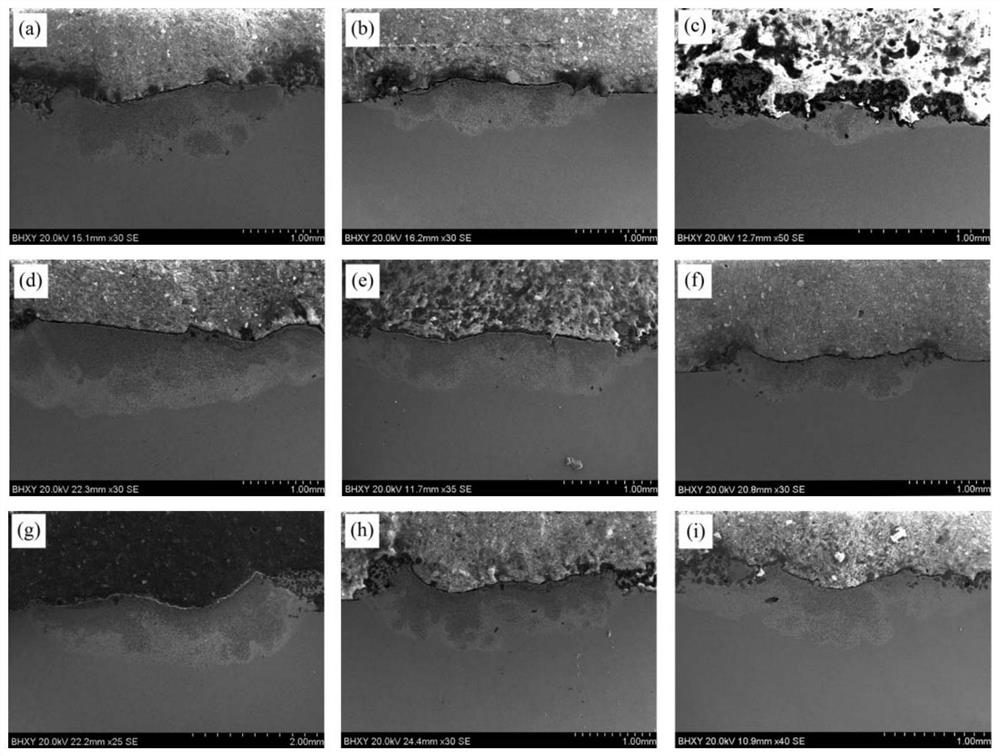

[0067] A method for preparing an alloyed layer, comprising the steps of:

[0068] Cut the Ti-6Al-4V plate into a certain volume of sample block, and use SiO 2 Grind the surface of the sample with sandpaper to remove the oxide skin on the surface of the sample, clean the sample with alcohol, and dry it for later use. The alloyed powder is directly pre-spread on the surface of the sample without adding a binder, and the thickness is controlled to be about 1 mm, and then laser alloyed. The laser process parameters are: laser power 3.5kW, scanning speed 300mm / min, spot diameter 3.5mm, argon flow rate 12L / min, overlap rate 30%, and thickness of pre-set powder 1mm.

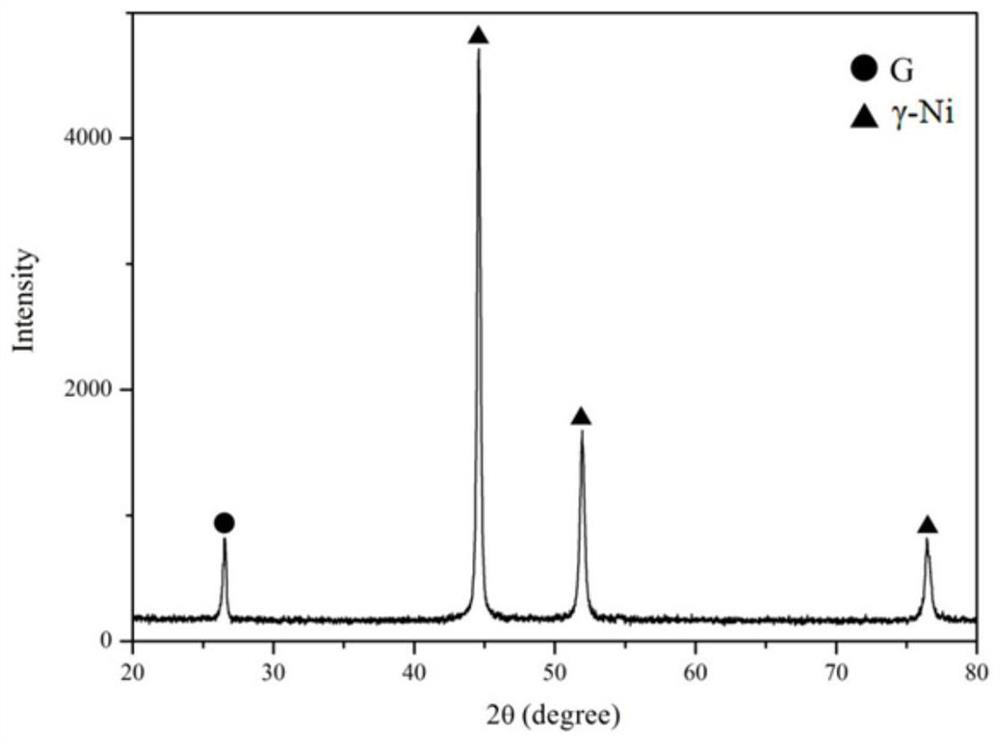

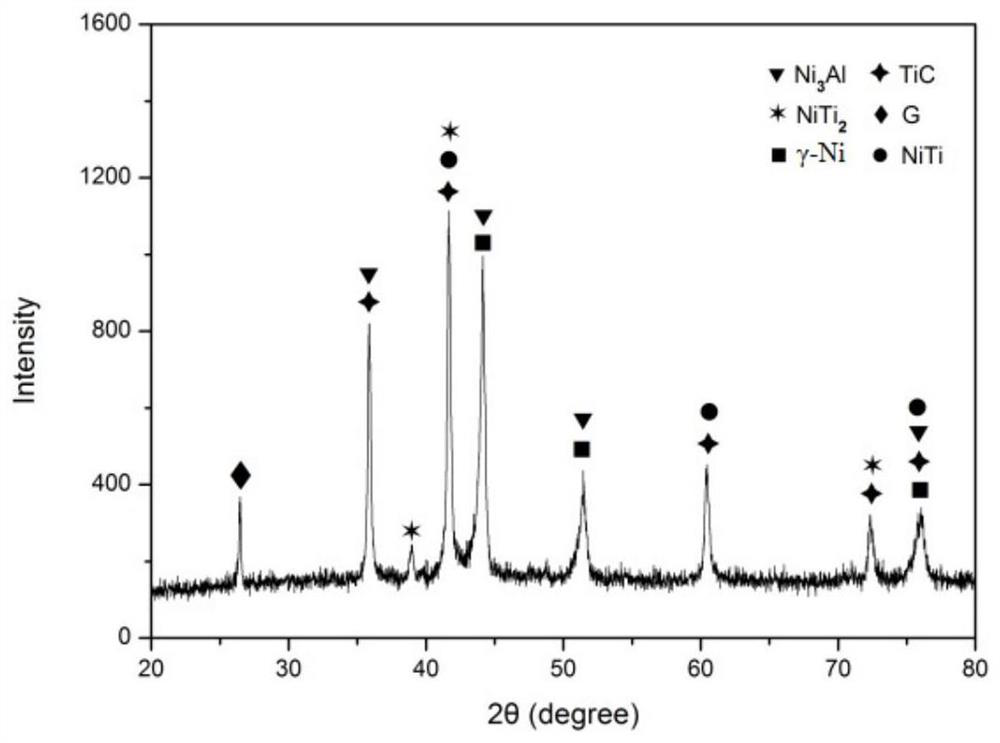

[0069] The alloying powder is nickel-coated graphite powder or mixed powder of nickel-coated graphite powder and nano-NdO, n-Nd 2 o 3 The particle size range is 40-60nm. The pre-experiment uses nickel-coated graphite powder with different ratios of nickel and graphite. The influence of nickel and graphite content on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com