Isothermal die forging forming die and method for rare earth magnesium alloy thin webbed supporting fork

A technology of isothermal die forging and forming dies, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of difficult control of the microstructure and properties of magnesium alloy forgings, difficulties in blank making and forming, and forming defects. To avoid the sharp growth of grains, reduce the forging temperature, and improve the effect of mold design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

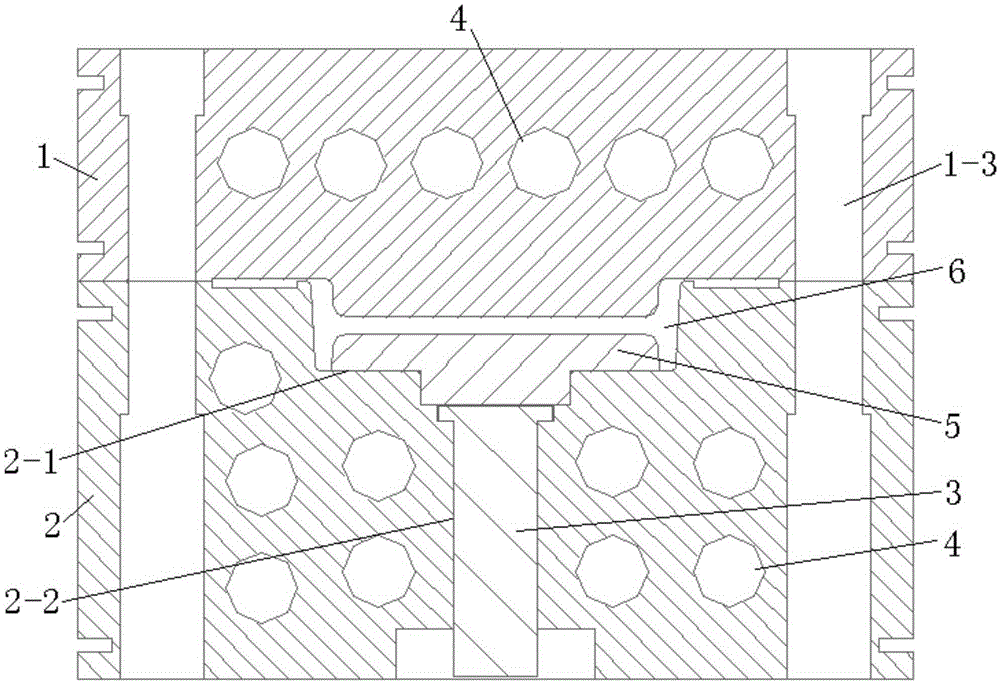

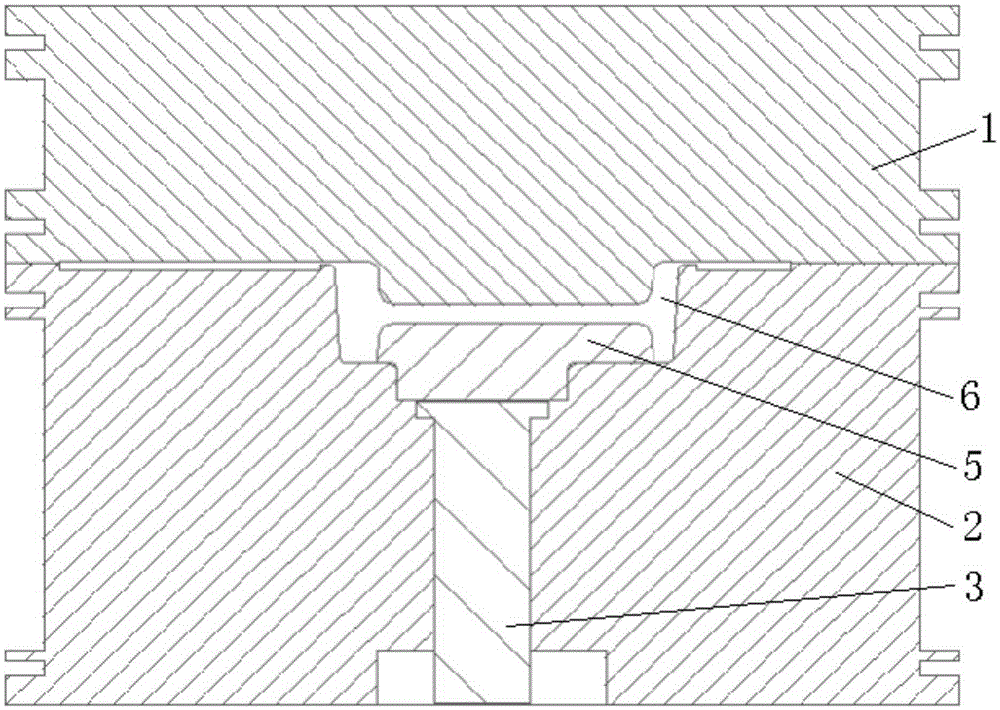

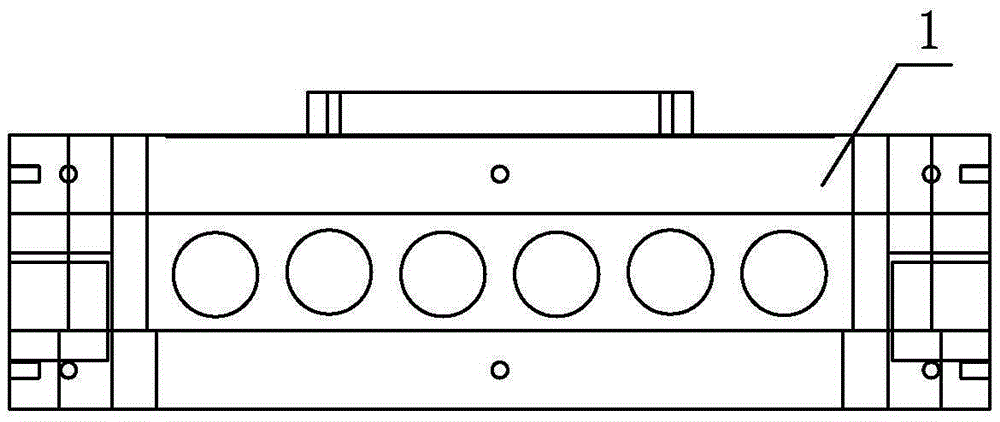

[0026] Specific implementation mode one: combine Figure 1-Figure 2 Explain that the isothermal forging die of a rare earth magnesium alloy thin-bellied fork in this embodiment includes an upper die 1, a mandrel 3 and a lower die 2, and the middle part of the upper surface of the lower die 2 is sequentially processed with a cavity from top to bottom 2-1 and the ejection hole 2-2, the mold cavity 2-1 and the ejection hole 2-2 are connected;

[0027] A die insert 5 is arranged in the cavity 2-1, the die insert 5 is a stepped die insert, the small end of the die insert 5 is placed in the ejection hole 2-2, and the lower end of the upper die 1 The middle part of the surface is processed with a punch 1-1 matching the cavity 2-1, the shape of the big end of the punch 1-1 and the die insert 5 is set in cooperation with the thin-belly fork to be formed, the punch 1- 1 extends into the mold cavity 2-1, the ejector rod 3 extends into the ejection hole 2-2, and the upper surface of the ...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination Figure 9 Illustrate that the push rod 3 of the present embodiment consists of an upper cylinder 3-1 and a lower cylinder 3-2 that are coaxially arranged and made into one body from top to bottom in sequence, and the upper end of the lower cylinder 3-2 is connected to the bottom of the upper cylinder 3-1. The lower end surface is fixed, the upper cylinder 3-1 is inserted into the ejection hole 2-2, and the upper surface of the upper cylinder 3-1 leans against the die insert 5. With such a setting, it is convenient and reliable to use. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: combination Figure 1-Figure 14 In this embodiment, a kind of isothermal die forging forming die of specific embodiment 1 or 2 is used to realize an isothermal die forging forming method of rare earth magnesium alloy thin-bellied fork. Fork isothermal die forging forming method is to realize according to the following steps:

[0031] 1. Billet making: The rare earth magnesium alloy raw material is extruded bar with a diameter of 155mm and a length of 160mm, which is compositely formed by upsetting and elongating process, and free forging is obtained into a curved magnesium alloy sheet blank;

[0032]2. Forging and forming: put the rare earth magnesium alloy blank obtained in step 1 into a box-type heating resistance furnace for heating, take it out when heated to 160-180°C, and spray graphite emulsion solution evenly on the surface of the blank; Put the blank of the good graphite emulsion solution into a box-type heating resistance f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com