A preparation method of eccentric cylinder forging with abrupt cross-section

An eccentric and cross-sectional technology, applied in the field of forging, to achieve the effect of saving raw materials, improving material utilization, and improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

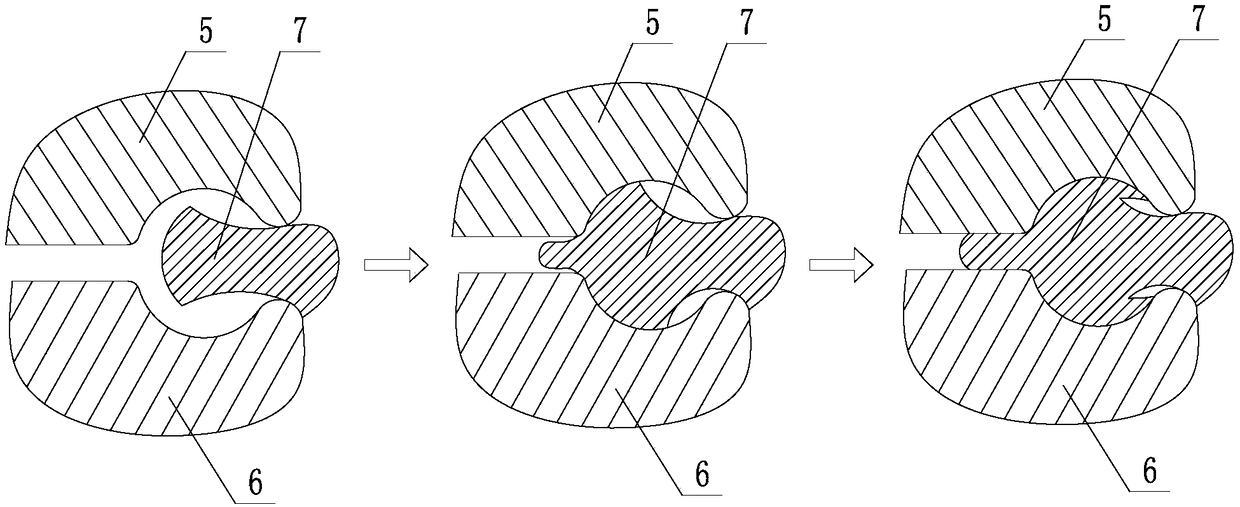

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

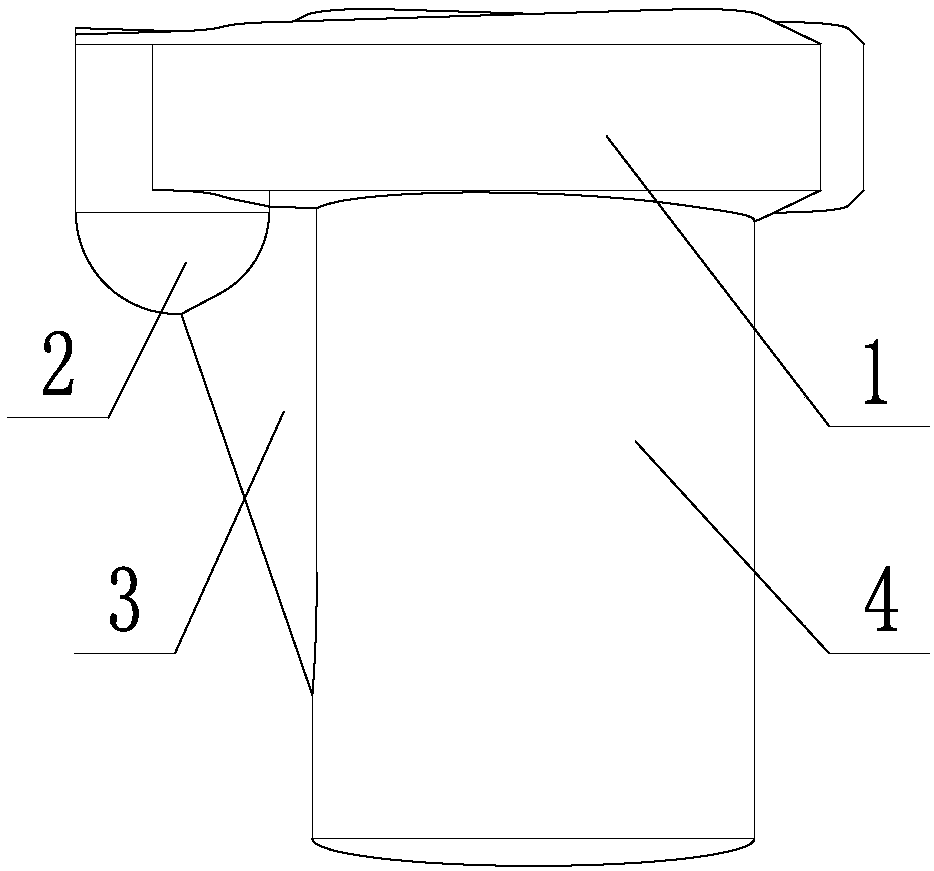

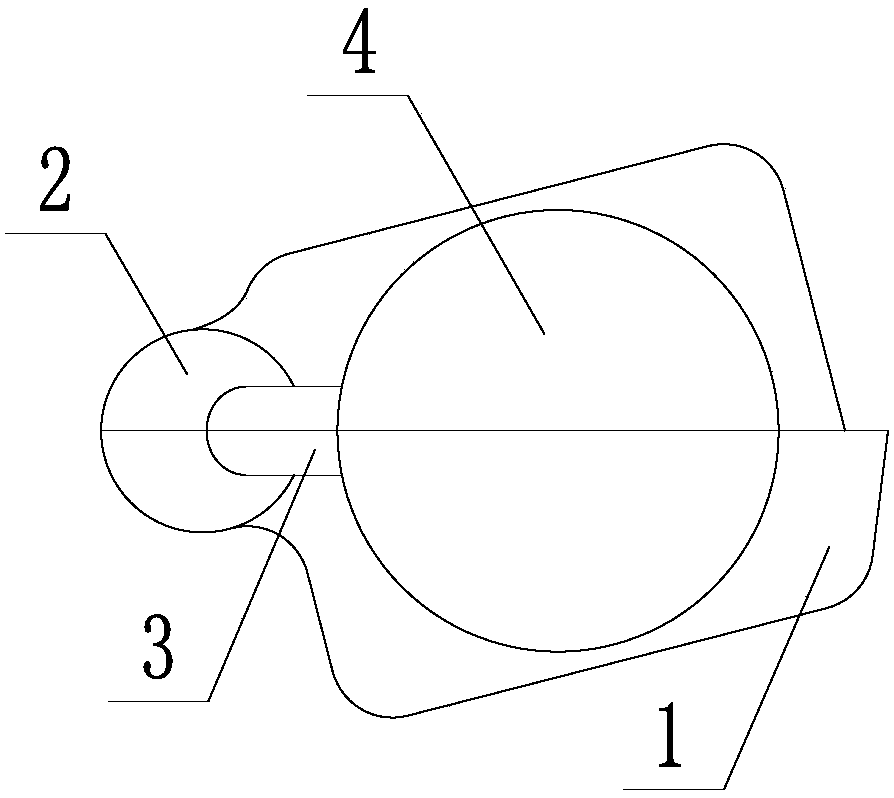

[0026] A method for preparing an eccentric cylinder forging with a sudden cross-section, comprising the following steps:

[0027] Step 1: Determine the structure of the blank according to the final forging of the eccentric cylinder with a sudden cross-section. The structure of the blank must meet the following two conditions:

[0028] ①The blank should have a sudden eccentric section, and the eccentric section 9 of the blank should fully cover the ball column forming cavity of the final forging die, so that the ball column forming cavity can meet the reverse filling forming during final forging. Filling to prevent folding when the forging material reflows;

[0029] ② The contact point between the eccentric part 9 of the cross section of the blank and the lower die of the final forging die is marked as A, the contact point between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com