Bacteriostatic and degradable food packaging film and preparation method thereof

A food packaging and film technology, which is applied in the field of antibacterial and degradable food packaging film and its preparation, can solve the problems of poor antibacterial effect, high hygroscopicity, and poor air permeability, and achieve the effect of improving mechanical properties and antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

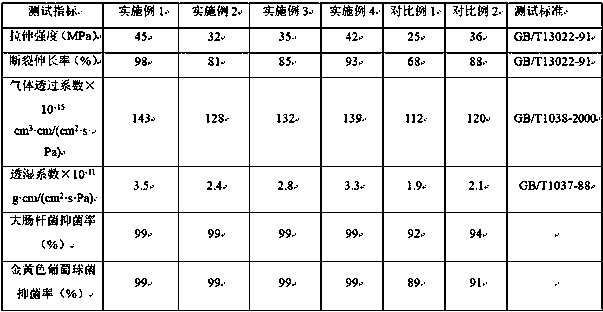

Examples

Embodiment 1

[0022] An antibacterial and degradable food packaging film, prepared from the following raw materials in parts by weight: 65 parts of crop straw, 15 parts of succinate, 15 parts of polybutylene succinate, 17 parts of polylactic acid, polyvinyl alcohol 12 parts, 9 parts of sepiolite, 8 parts of zinc oxide, 12 parts of silicon dioxide, 6 parts of γ-aminopropyltriethoxysilane, 5 parts of dispersant, 12 parts of tea polyphenols, 13 parts of chitosan, 12 parts of sodium benzoate, 23 parts of N-methylmorpholine-N-oxide NMMO / water, 7 parts of dodecyltrimethylammonium chloride, 5 parts of 1-ethyl-3-methylimidazolium tetrafluoroborate Parts, 11 parts of isopropanol, 15 parts of water.

[0023] The dispersant is polyvinylpyrrolidone.

[0024] The water content of the Nmethylmorpholine-N-oxide NMMO / water is 13%.

[0025] The crop stalks are crushed and passed through a 150-mesh sieve.

[0026] The preparation method of the bacteriostatic degradable food packaging film of the present i...

Embodiment 2

[0034] An antibacterial and degradable food packaging film, prepared from the following raw materials in parts by weight: 50 parts of crop straw, 10 parts of succinate, 10 parts of polybutylene succinate, 12 parts of polylactic acid, polyvinyl alcohol 8 parts, 6 parts of sepiolite, 5 parts of zinc oxide, 8 parts of silicon dioxide, 4 parts of γ-aminopropyltriethoxysilane, 3 parts of dispersant, 8 parts of tea polyphenols, 10 parts of chitosan, 9 parts of sodium benzoate, 15 parts of N-methylmorpholine-N-oxide NMMO / water, 4 parts of dodecyltrimethylammonium chloride, 2 parts of 1-ethyl-3-methylimidazolium tetrafluoroborate Parts, 8 parts of isopropanol, 10 parts of water.

[0035] The dispersant is sodium carboxymethylcellulose.

[0036] The water content of the Nmethylmorpholine-N-oxide NMMO / water is 10%.

[0037] The crop stalks are crushed and passed through a 100-mesh sieve.

[0038] The preparation method of the bacteriostatic degradable food packaging film of the present...

Embodiment 3

[0046] An antibacterial and degradable food packaging film, prepared from the following raw materials in parts by weight: 60 parts of crop straw, 12 parts of succinate, 12 parts of polybutylene succinate, 15 parts of polylactic acid, polyvinyl alcohol 10 parts, 8 parts of sepiolite, 6 parts of zinc oxide, 10 parts of silicon dioxide, 5 parts of γ-aminopropyltriethoxysilane, 4 parts of dispersant, 10 parts of tea polyphenols, 12 parts of chitosan, 12 parts of sodium benzoate, 18 parts of N-methylmorpholine-N-oxide NMMO / water, 5 parts of dodecyltrimethylammonium chloride, 4 parts of 1-ethyl-3-methylimidazolium tetrafluoroborate 10 parts, 10 parts of isopropanol, 13 parts of water.

[0047] The dispersant is sodium dodecylsulfonate.

[0048] The water content of the Nmethylmorpholine-N-oxide NMMO / water is 12%.

[0049] The crop stalks are crushed and passed through a 120-mesh sieve.

[0050] The preparation method of the bacteriostatic degradable food packaging film of the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com