Waterborne polyurethane emulsion as well as preparation method and application thereof

A water-based polyurethane and polyurethane film technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor mechanical properties, poor water resistance, and inability to meet environmental protection requirements, so as to improve dispersion and stability, reduce The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

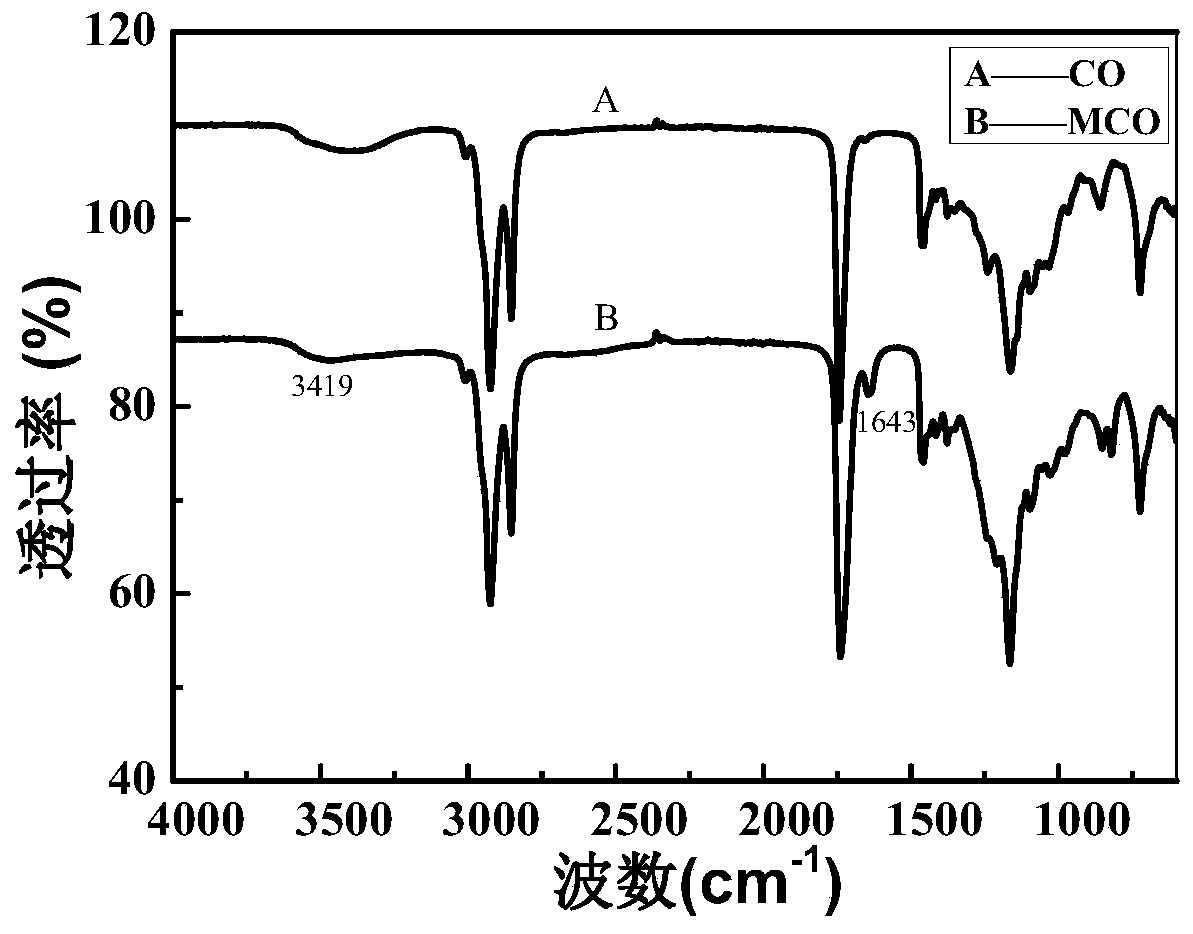

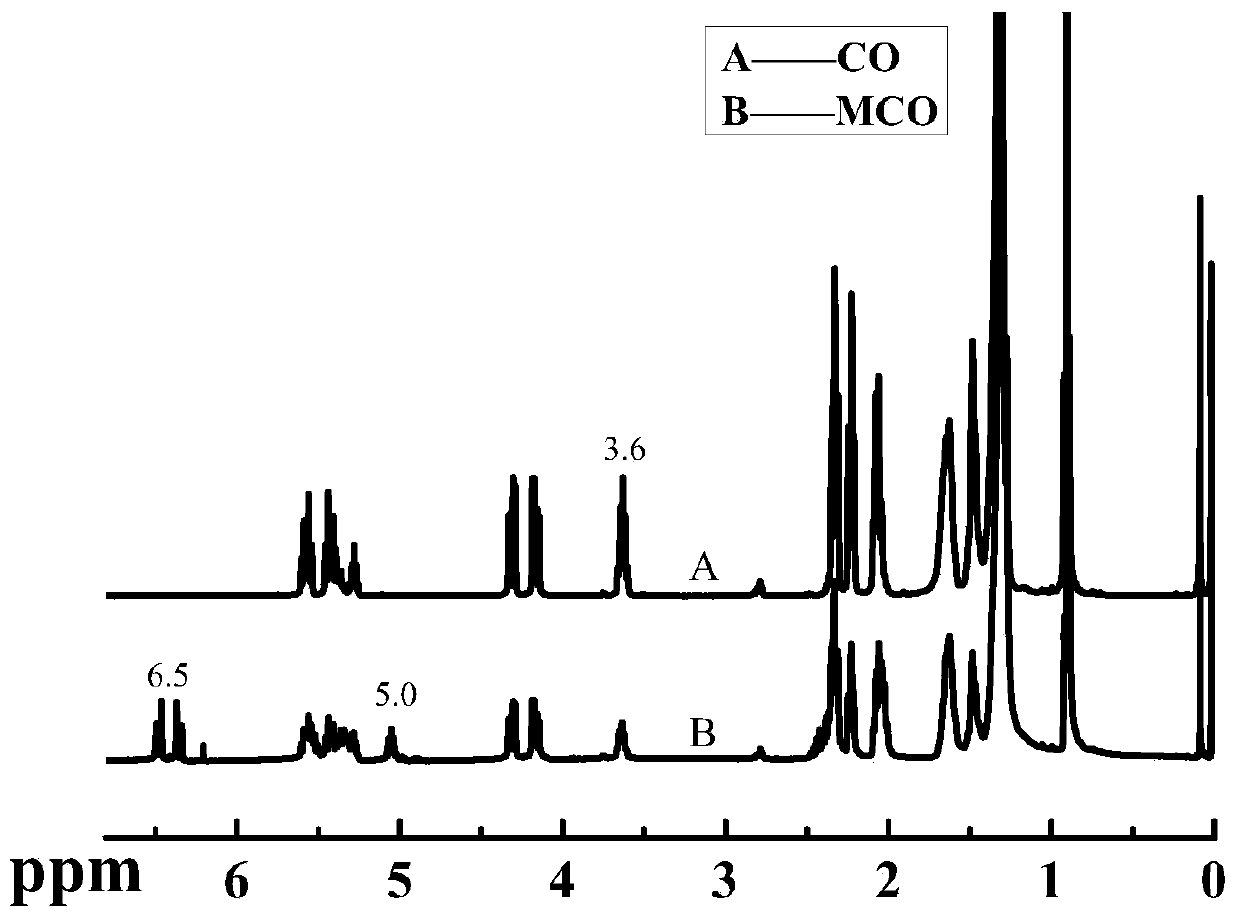

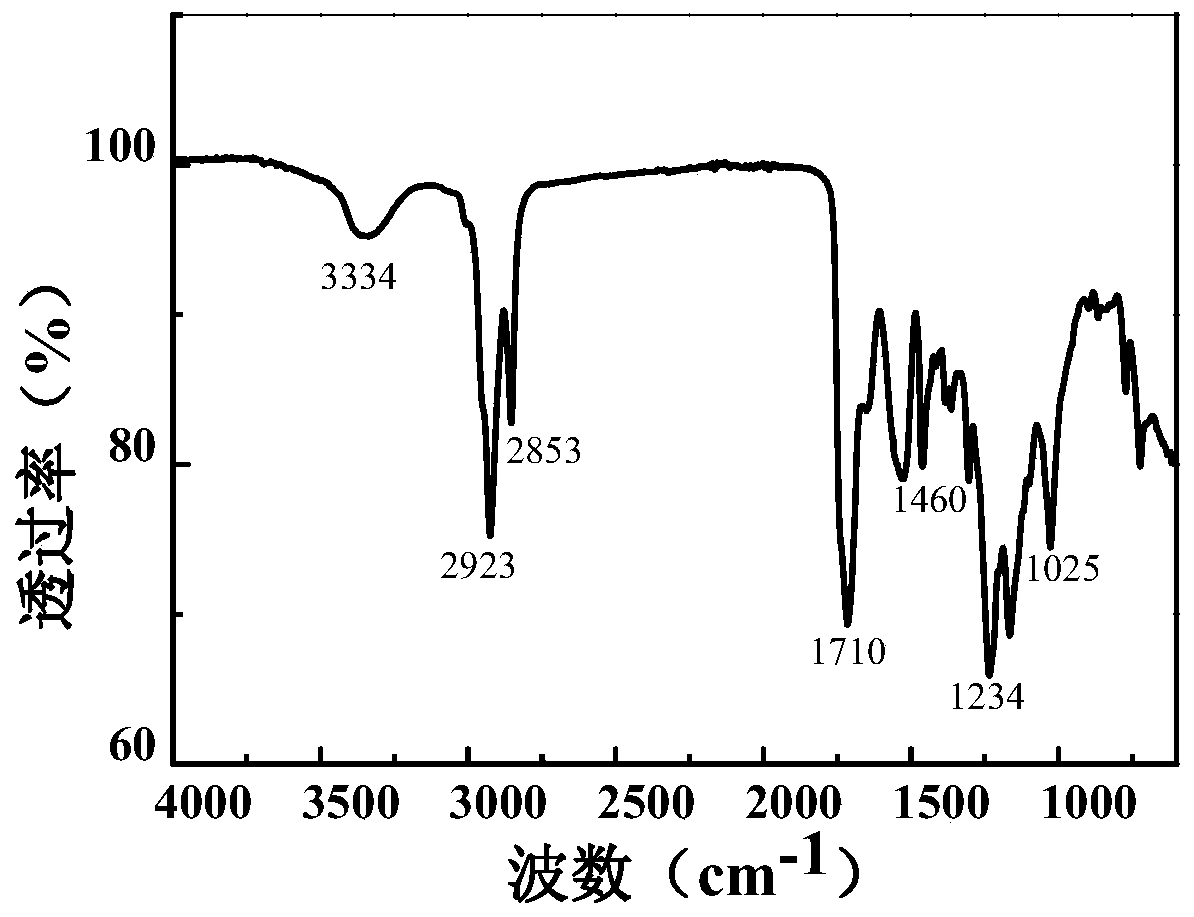

[0101] This embodiment provides a water-based polyurethane emulsion, the raw materials of which are composed of bio-based emulsifier, isophorone diisocyanate, 1,4-butanediol, triethylamine, acetone, ethylenediamine and deionized water.

[0102] The preparation method is as follows:

[0103] (1) Preparation of bio-based emulsifier:

[0104] 40.00g of castor oil and 6.00g of maleic anhydride were added into the reactor and mixed respectively, the temperature was adjusted to 120°C, the stirring speed was 800rpm for 5h, and then cooled to 25°C to obtain the bio-based emulsifier.

[0105] The hydroxyl value of the bio-based emulsifier prepared above is 80 mgKOH / g, and the acid value is 52 mgKOH / g.

[0106] (2) Preparation of water-based polyurethane emulsion:

[0107] a) Bio-based emulsifier (MCO) 3.8155g (the molar number of hydroxyl group is 0.00544mol, the molar number of carboxyl group is 0.0036mol), 2.2228g of isophorone diisocyanate (the molar number of isocyanate is 0.02mo...

Embodiment 2

[0112] This embodiment provides a water-based polyurethane emulsion, the preparation raw materials of which are composed of bio-based emulsifier, toluene diisocyanate, 1,4-butanediol, triethylamine, acetone, ethylenediamine and deionized water.

[0113] The preparation method is as follows:

[0114] (1) Preparation of bio-based emulsifier:

[0115] 40.0 g of castor oil and 7.01 g of maleic anhydride were added into the reactor for mixing, and the temperature was adjusted to 110° C., and stirred at 900 rpm for 6 hours, and then cooled to 23° C. to obtain the bio-based emulsifier.

[0116] The hydroxyl value of the bio-based emulsifier prepared above is 67 mgKOH / g, and the acid value is 60 mgKOH / g.

[0117] (2) Preparation of water-based polyurethane emulsion:

[0118] a) 4.1881g of bio-based emulsifier (MCO) (the molar number of hydroxyl group is 0.0050mol, the molar number of carboxyl group is 0.004479mol), 1.7415g of toluene diisocyanate (the molar number of isocyanate is 0...

Embodiment 3

[0123] This embodiment provides a water-based polyurethane emulsion, the raw materials of which are composed of bio-based emulsifier, diphenylmethane diisocyanate, glycerin, triethylamine, acetone, ethylenediamine and deionized water.

[0124] The preparation method is as follows:

[0125] (1) Preparation of bio-based emulsifier:

[0126] 40.0g of modified soybean oil (hydroxyl value 192mg KOH / g) and 6.9938g of maleic anhydride were added to the reactor and mixed respectively, the temperature was adjusted to 100°C, and the stirring speed was reacted at 900rpm for 5h, and then cooled to 18°C to obtain The bio-based emulsifier.

[0127] The hydroxyl value of the bio-based emulsifier prepared above is 93 mg KOH / g, and the acid value is 56 mg KOH / g.

[0128] (2) Preparation of water-based polyurethane emulsion:

[0129] a) 4.6636g of bio-based emulsifier (the molar number of hydroxyl group is 0.007731mol, the molar number of carboxyl group is 0.004655mol), 2.5024g of diphenyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com