Production process for formaldehyde-free multi-layer solid-wood composite floor and floor

A technology of solid wood composite floor and production process, which is applied in the joining of wooden veneers, wood processing appliances, manufacturing tools, etc., can solve problems such as poor stability, and achieve the effects of low cost, simple production process and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

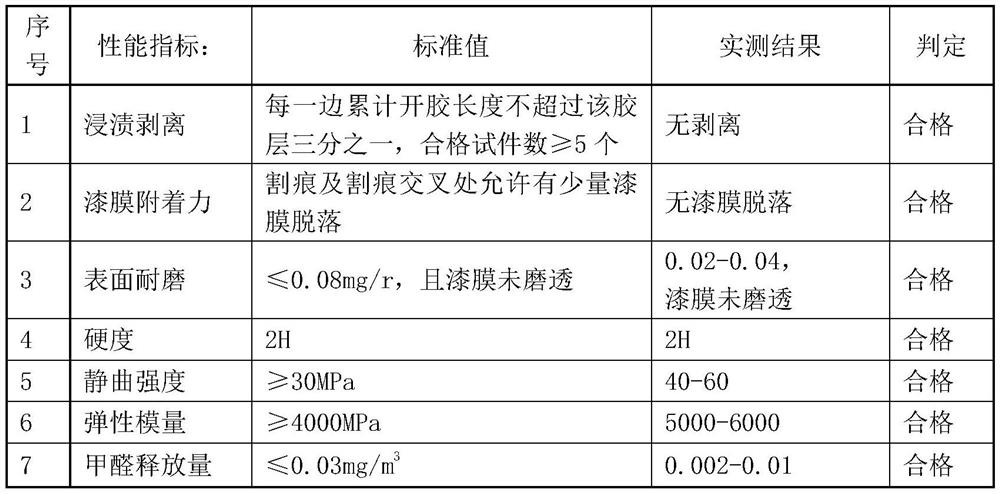

Examples

Embodiment 1

[0025] Take the product of 1.2mm oak veneer as an example. The veneer and the base material of corresponding specifications are glued, veneered, cold pressed for 50-60 minutes, (hot pressed) and then balanced for health. After 80-85 hours, the raw material is cut and sanded to form a plain board. Then carry out forming and groove processing. After that, the primer and topcoat are applied; finally, the finished product is packaged and rolled off the assembly line.

Embodiment 2

[0027] Take the product of 1.2mm oak veneer as an example. The wood veneer and the base material of corresponding specifications are adjusted, and the ratio of glue to curing agent is about 100: (10-20); then glue is applied, one side is glued, and the amount of glue applied is about 140-160g / m2 by roller coating 2 , Then after veneering, cold pressing, (hot pressing) and rebalancing health preservation, after 80-85 hours, it will be cut and sanded to form a plain board. Then carry out forming and groove processing. After that, the primer and topcoat are applied; finally, the finished product is packaged and rolled off the assembly line.

Embodiment 3

[0029] Take the product of 1.2mm oak veneer as an example. The veneer and the base material of the corresponding specifications, after the glue adjustment and glue application process, adopt artificial veneer, and the veneer after strict sorting, go through the cutting process, cut it into the required specifications, and use manual pushing The method is to paste it on the surface of the glued substrate, cold press for 50-60 minutes, (hot press) and then balance the health. After 80-85 hours, it will be cut and sanded to form a plain board. Then carry out forming and groove processing. After that, the primer and topcoat are applied; finally, the finished product is packaged and rolled off the assembly line.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com