Multi-element ionic liquid as well as preparation method and application thereof

A multi-ion and ionic liquid technology, applied in the preparation of carboxylate, the preparation of carboxylate, organic chemical methods, etc., can solve the problems of complex synthesis steps of imidazolium-based ionic liquids, a large number of toxic gases and waste water, severe environmental problems, etc., To achieve the effect of favorable dissolution, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Synthesis and characterization of the present invention's gained polynary ionic liquid:

[0035]

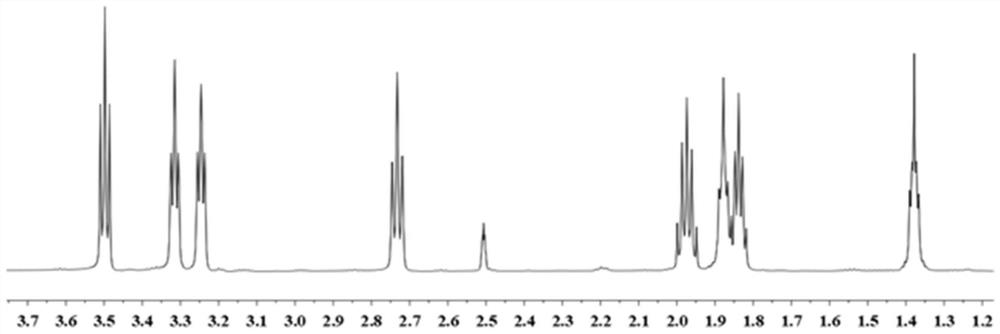

[0036] Synthesis of ionic liquid DBNH-AdA: Take adipic acid 14.6g (0.1mol, 1.0eq.) and 1,5-diazabicyclo[4,3,0]non-5-ene 24.8g (DBN, 0.2mol , 2.0eq.) in a 150mL flask, heated to 90°C and stirred for 3h. After the reaction, without separation and purification, the product was cooled to room temperature, and 38.8 g of a light pink solid was precipitated, with a yield of 98.5%, which was sealed and stored for later use. The NMR spectrum of the product DBNH-AdA is shown in the attached figure 1 Shown, indicating the correct synthesis of the structure of the ionic liquid.

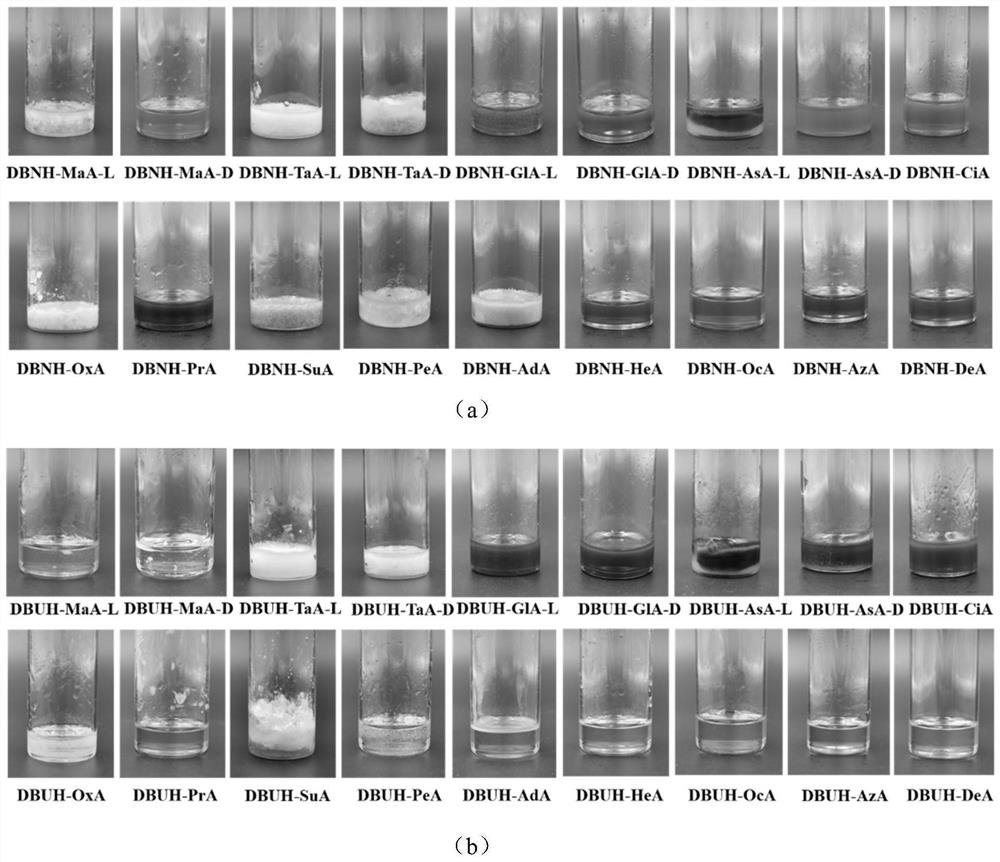

[0037] The synthesis of other polybasic ionic liquids can be replaced with different superbases, dibasic acids and tribasic acids according to the above steps, according to the molar ratio (organic base: dibasic acid = 2: 1, organic base: tribasic acid = 3: 1 ) synthesized to get, figure 2 (a) and (b) ...

Embodiment 2

[0043] The dissolving of cellulose by solvent system of the present invention gained, concrete steps are as follows:

[0044] 1. Preparation of solvent system: Take 16 g of multi-component ionic liquid DBNH-AdA obtained in Example 1 in a 100 mL flask, add 12 g of auxiliary agent dimethyl sulfoxide, heat to 80 ° C and stir evenly to obtain a solvent system with a mass fraction of 57.1%. , denoted as DBNH-AdA / DMSO-57.1.

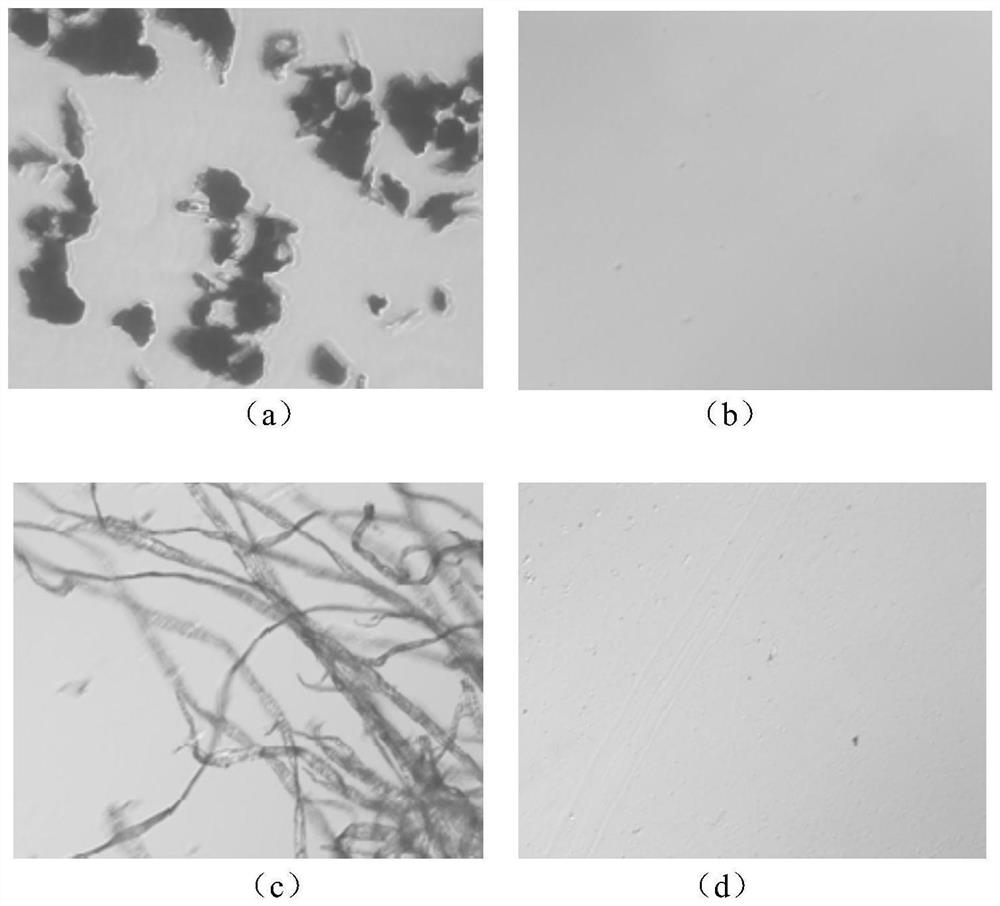

[0045]2. Microcrystalline cellulose dissolving: take DBNH-AdA / DMSO-57.1 (14g) obtained in step 1, add 0.56g of microcrystalline cellulose (DP=180), heat to 80°C, and stir for 0.5h at a speed of 180rmp to obtain Clear cellulose solution. Take a little sample before and after dissolution and observe under the microscope, as shown in image 3 (a) As shown in (b), there is no microcrystalline cellulose in the solution sample, indicating that the solvent system completely dissolves microcrystalline cellulose.

[0046] 3. Maximum solubility test: Take 6g of part o...

Embodiment 3

[0054] The preparation of the gained regenerated cellulose film of the present invention, concrete steps are as follows:

[0055] Solvent systems DBNH-AdA-DMSO-60%, DBNH-PeA-DMSO-60%, DBUH-AdA-DMSO-60%, and DBUH-PeA-DMSO-60% were respectively prepared according to the method in step 3 of Example 2. Take 20 g of the prepared cellulose solvent system, raise the temperature to 85° C., add 0.40 g of wood pulp cellulose under stirring at 200 rpm, and continue stirring for 2 hours to obtain a clear and transparent cellulose solution. After dissolving, put the cellulose solution at 80°C for static defoaming, then pour it into a glass petri dish (diameter 5cm, 4.5g per dish) to form a film, then immerse it in the coagulation bath for a period of time, take it out, and continue to use water to form a film. After fully rinsing and drying, a regenerated cellulose film is obtained. The obtained regenerated cellulose is obtained by XRD spectrum through X-ray diffraction instrument, tensil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com