Sewage treatment system

A sewage treatment system and technology of the treatment system are applied in the system field of sewage treatment and recycling in steel rolling mills, which can solve the problems of excess water in the turbid ring system of the casting machine, overflowing water in the circulating water pool, etc. The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

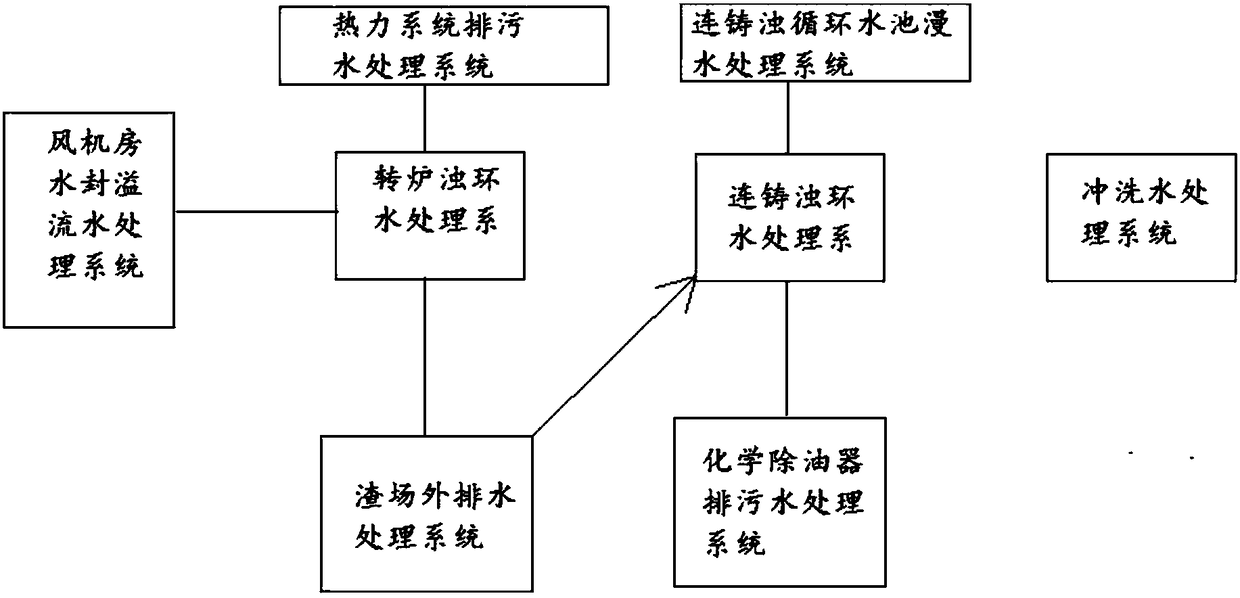

[0016] Such as figure 1 As shown, the present invention includes a converter turbid ring water treatment system, a continuous casting turbid ring water treatment system, and a flushing water treatment system.

[0017] The converter turbid ring water treatment system includes the thermal system sewage treatment system, the fan room water seal overflow water treatment system, and the slag yard external drainage treatment system.

[0018] The thermal system sewage treatment system includes a collection device for collecting and summarizing converter gas bag and fume hood sewage. The collection device discharges sewage into the converter turbid ring water purification system through an elevated water tank. Reduce water discharge by 4m3 / h, about 100 tons ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com