Recycling method of cellulose ether production wastewater

A technology for the production of wastewater and cellulose ether, which is applied in chemical instruments and methods, biological water/sewage treatment, alkali metal chlorides, etc., can solve the problems of increasing hazardous waste treatment costs, environmental hazards, and large limitations, and achieves The effect of reducing production and operation costs, reducing costs, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

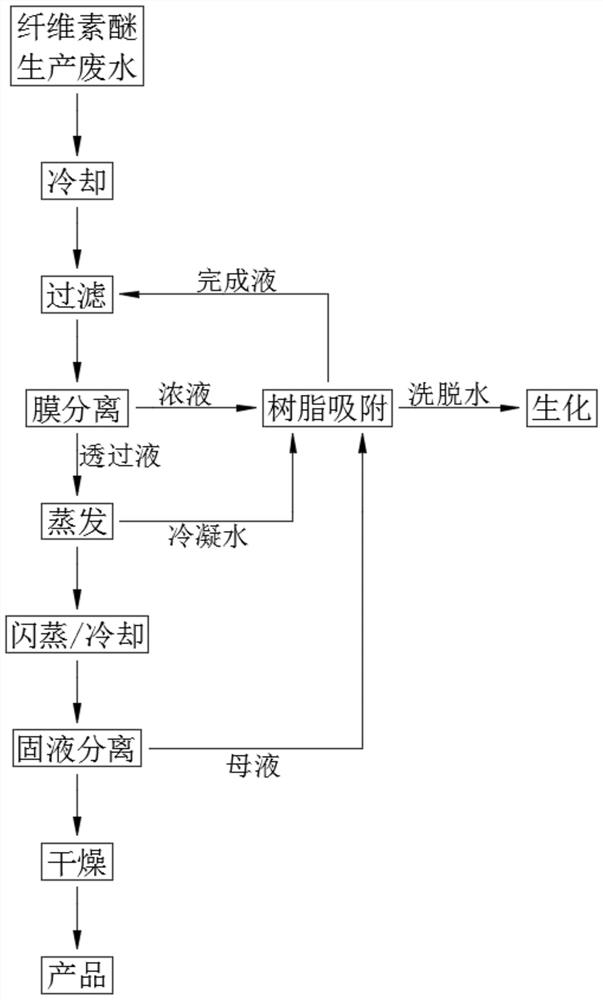

[0031] refer to Figure 1-Figure 2 , a method for recycling waste water from cellulose ether production, comprising the steps of:

[0032] S1. Cool the cellulose ether production wastewater resources, and filter after cooling to filter out visible particles;

[0033] S2. The filtered cellulose ether production wastewater resource enters the membrane separation system, and the dope and filtrate are produced through membrane separation;

[0034] S3. The permeate after membrane separation is evaporated, flashed / cooled, solid-liquid separated, and dried to produce condensed water, crystallized salt, and mother liquor;

[0035] S4. After mixing the dope and the mother liquor, it enters the resin for adsorption, and returns to the membrane separation system after adsorption;

[0036] S5. After adsorption, elution is performed, and after elution, it is discharged to the biochemical process.

[0037] The waste water produced in the cellulose ether production process involved in the...

Embodiment 2

[0047] A Science and Technology Development Co., Ltd. is a high-tech enterprise engaged in the research and development, production and sales of cellulose ether. It is a high-quality enterprise with an annual capacity of 6,000 tons. During the production of cellulose ether, a kind of high-salt wastewater will be produced. Now This method is used to treat the high-salt and high-COD sewage produced by the enterprise's research and development and production of cellulose ether, thereby reducing the difficulty and cost of treatment.

[0048] The actual COD of the wastewater discharged from the production of the enterprise is measured, which is 18000mg / L, and the water volume is about 3000m 3 / d, the salt content in water is high, 7-10%, mainly sodium chloride, the biodegradability of water is poor, the water quality is dark, and the composition of COD is mainly soluble cellulose ether and small molecular organic matter discharged during the production process ,mid product.

[004...

Embodiment 3

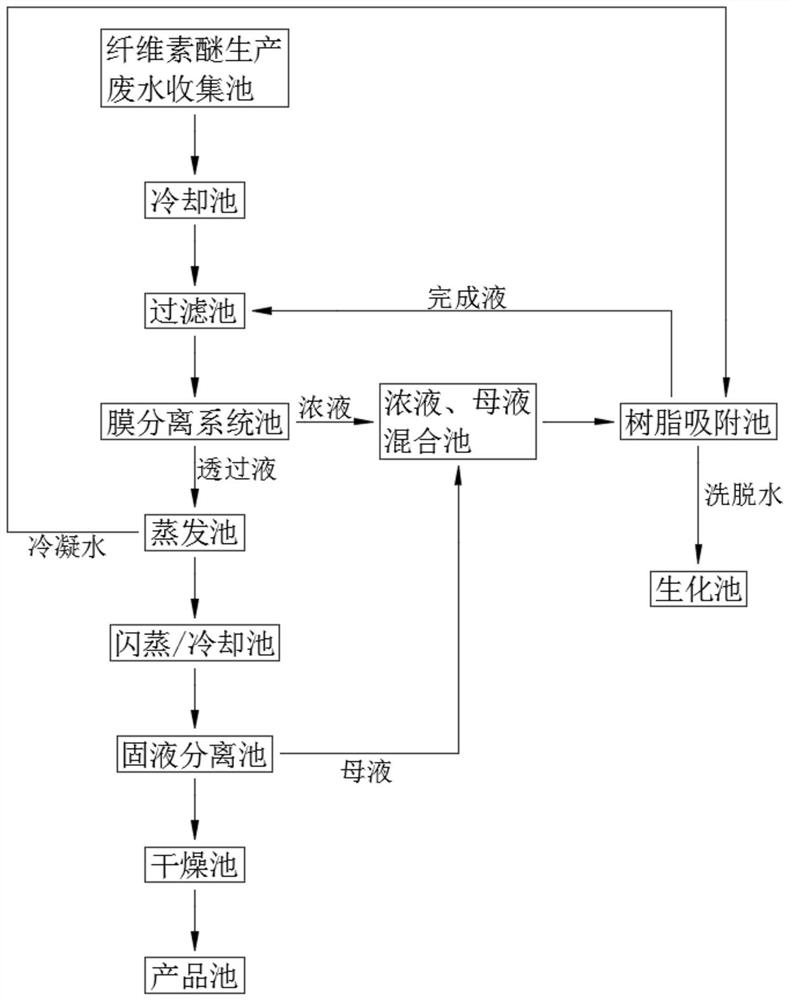

[0054] refer to figure 2 Shown process flow chart, its process description is as follows:

[0055] The cellulose ether production wastewater collection pool, which is set up in the wastewater discharge link, prevents the production wastewater from being discharged into the positive water system, collects the cellulose ether production wastewater in a centralized manner, and temporarily stores it;

[0056] Cooling pool, the cooling pool is a process for preliminary treatment of cellulose ether production wastewater, so that the wastewater will settle after cooling down;

[0057] Filter pool, the filter pool is a process for filtering waste water, filtering the settled particles produced after cooling and cooling, and mixing with the finished liquid;

[0058] Membrane separation system pool, the membrane separation system pool performs membrane separation on the filtered wastewater, separates the concentrate and permeate, and treats them separately;

[0059] The evaporation poo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com