Plant-mixed heat regeneration equipment with cold adding function and production method thereof

A thermal regeneration and functional technology, applied in the direction of roads, road repairs, roads, etc., can solve problems such as asphalt is easy to adhere to the drying drum and other parts, the asphalt on the surface of fine materials is seriously aging, and the equipment cannot operate normally, etc., to achieve structural Compactness, reduced heat loss, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details.

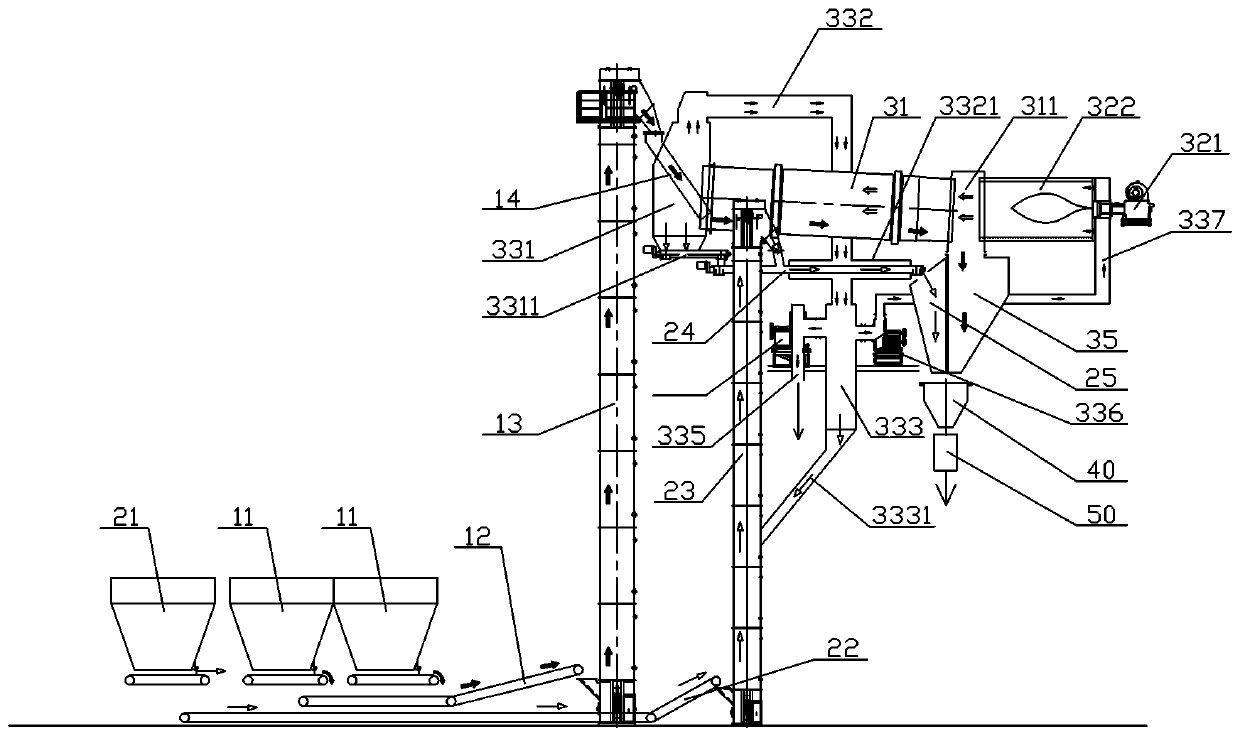

[0027] A plant-mixed hot regeneration equipment with cold addition function, refer to figure 1 , including a coarse aggregate conveying system, a fine aggregate conveying system, a coarse aggregate drying heating system, a weighing scale 40 and a recycled material conveying device 50. The coarse aggregate conveying system comprises a coarse aggregate silo 11, a coarse aggregate belt conveyor 12 and a coarse aggregate hoist 13, and the feed end of the coarse aggregate belt conveyor 12 is located below the coarse aggregate silo 11, the coarse aggregate The discharge end of the collection belt conveyor 12 is docked with the feed end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com