High-reference plant-mixed heat regeneration equipment

A thermal regeneration, high-parameter technology, applied in buildings, roads, dispersed particle separation, etc., can solve the problems of crisis operator safety, small space of screw conveying device, easy blockage of negative pressure pipes, etc., to reduce external emissions and improve the level of Matching accuracy and ensuring the effect of grading requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

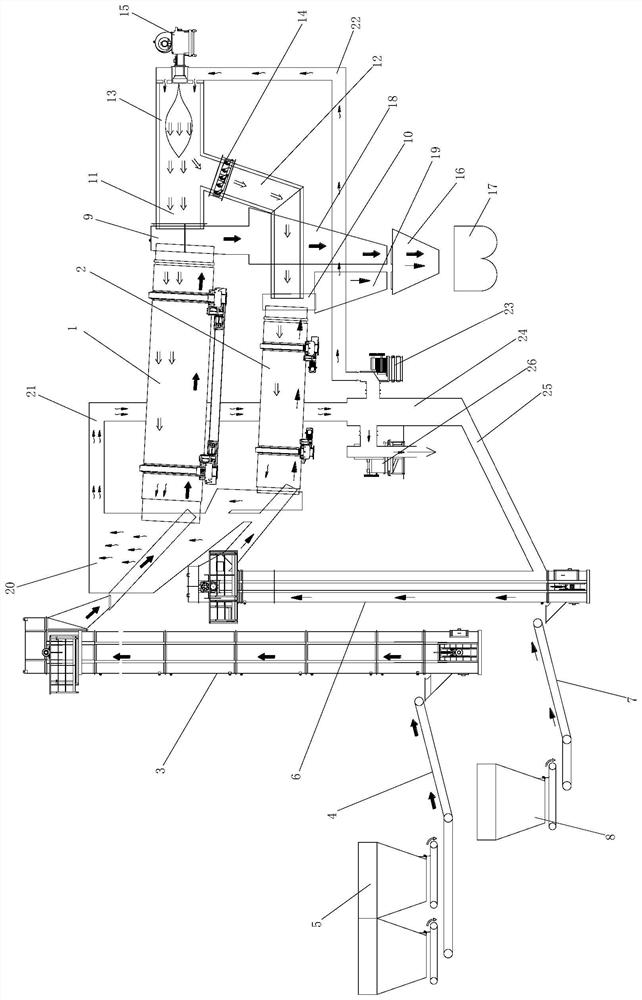

[0022] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0023] A high reference plant mixed heat regeneration equipment, such as figure 1 As shown, it includes a first regenerative drying drum 1 and a second regenerative drying drum 2 arranged at intervals, and the feed end of the first regenerative drying drum 1 is connected to the discharge end of the regenerated coarse aggregate hoist 3 pass; the feed end of the regenerated coarse aggregate hoist 3 is connected with the discharge end of the regenerated coarse aggregate belt conveyor 4; the feed end of the regenerated coarse aggregate belt conveyor 4 is connected to the regenerated coarse aggregate belt conveyor 4 The feed bin 5 is matched; the feed end of the second regenerated drying drum 2 is connected with the discharge end of the regenerated fine aggregate ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com