Gas-solid reaction device realizing synergistic adsorption of two heavy metals based on solid states

A gas-solid reaction and adsorption reaction technology, which is applied in gas treatment, separation methods, dispersed particle separation, etc., can solve the problems such as the device is not easy to disassemble, cannot be taken out immediately, and the adsorption efficiency is wrong, so as to avoid heavy metal spilling and mutual Influence and reduce the effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

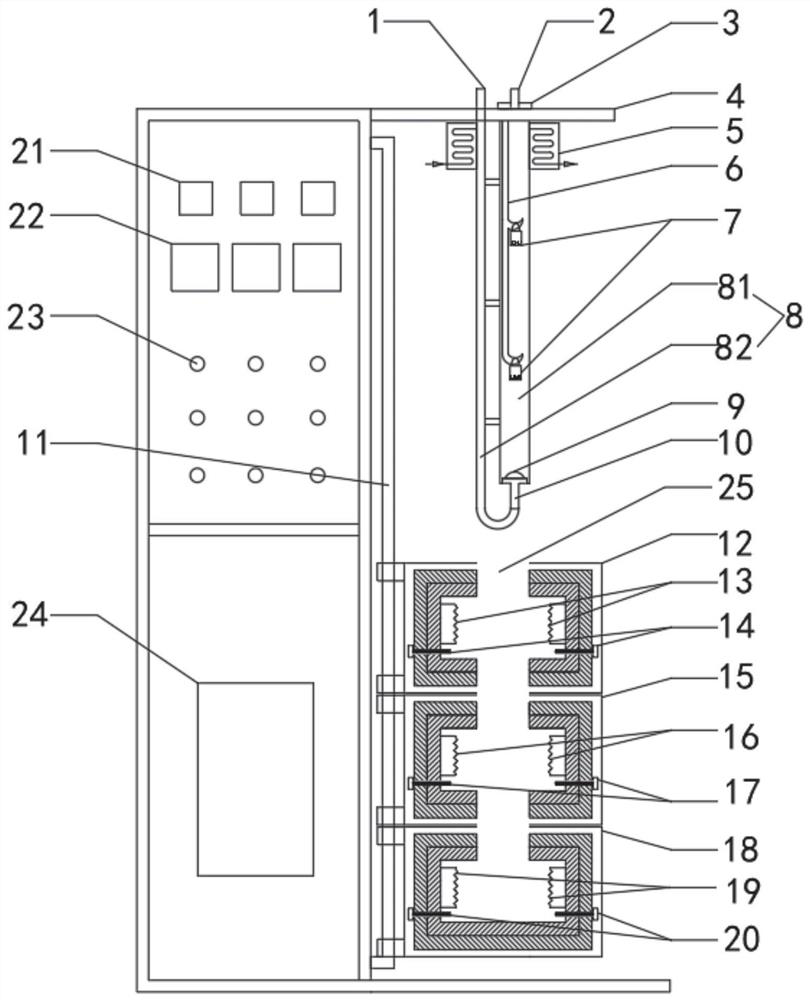

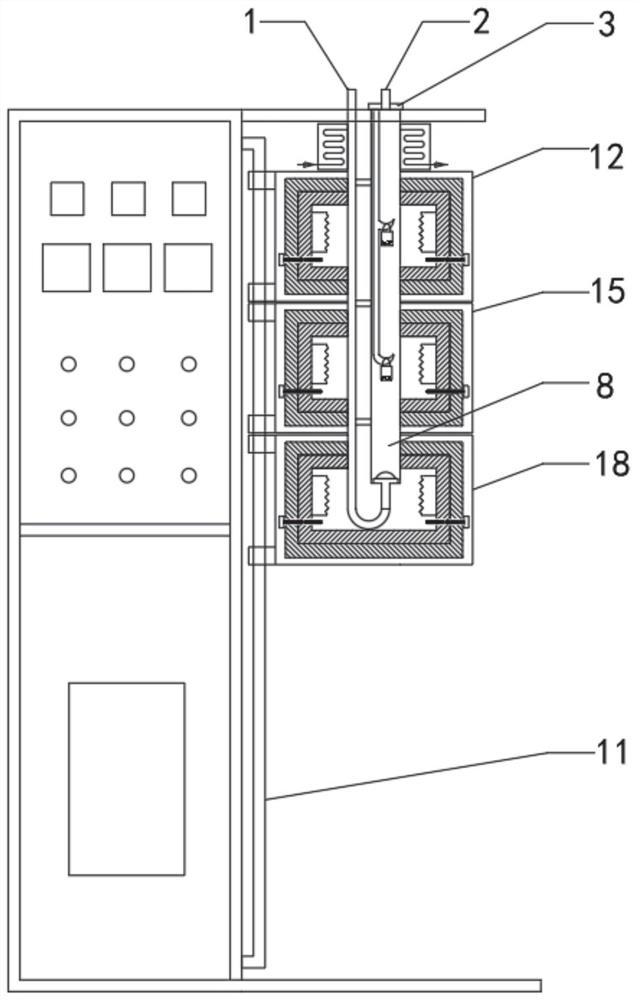

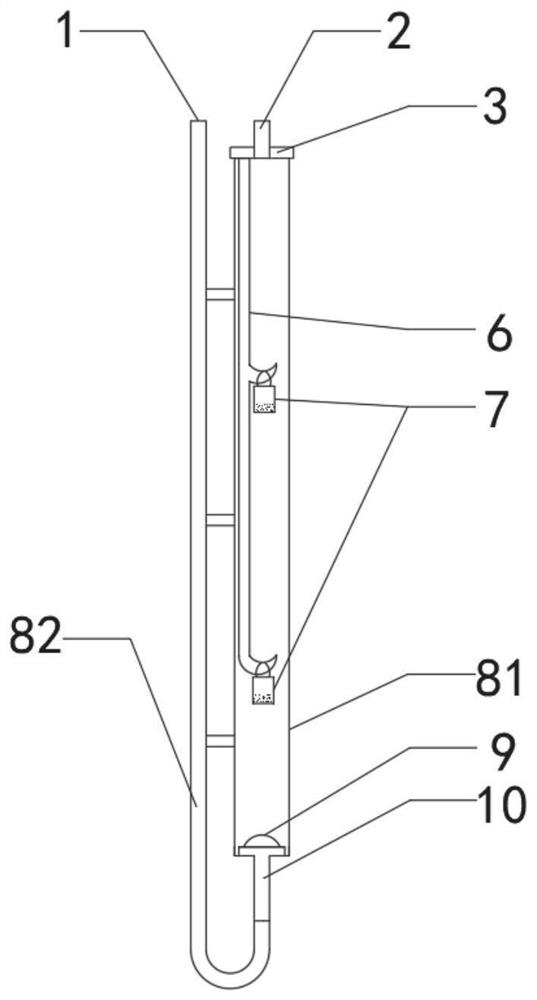

[0029] A gas-solid reaction device based on solid-state generation and collaborative adsorption of two heavy metals in this embodiment, such as figure 1 As shown, it comprises a U-shaped reaction tube 8, and its two sides are respectively an inlet section 81 and an air outlet section 82, and at least two metal evaporation zones and an adsorption reaction zone are sequentially formed in the inlet section 81; the U-shaped reaction tube 8. One side is provided with a guide rod 11 along the vertical direction. The guide rod 11 is provided with at least three heating furnaces sliding along it. The at least three heating furnaces are used to heat at least two metal evaporation regions and adsorption reaction regions respectively. The top and bottom surfaces of the heating furnace are provided with openings 25 aligned up and down, and the openings 25 are u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com