Rubber vulcanizing waste gas treatment process

A technology for waste gas treatment and rubber vulcanization, which is applied in the direction of gas treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of energy and resource waste, without considering energy recovery and utilization in the vulcanization process, comprehensive utilization and treatment process, etc., to achieve The effect of reducing use, saving boiler operating costs, and reducing overall energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

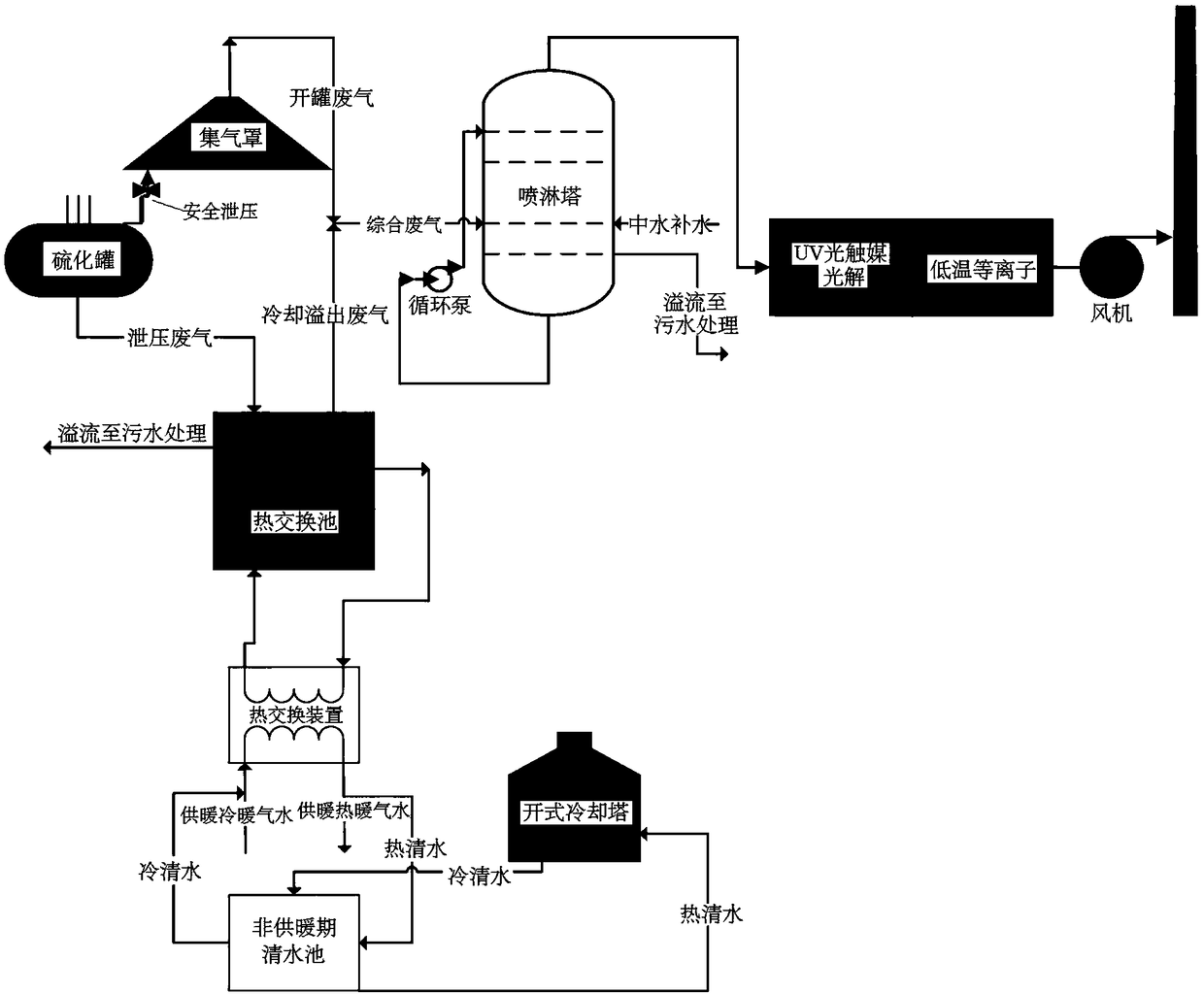

[0018] A rubber vulcanization waste gas treatment process, the specific steps are as follows:

[0019] Step 1: Use a gas collecting hood to collect the waste gas generated by opening the tank, wash and spray dry, and then perform triple ultraviolet catalytic oxidation to crack and oxidize high-molecular pollutants into low-molecular harmless substances to obtain the first product;

[0020] Step 2: The first product is subjected to low-temperature plasma treatment, and the ion generator in the equipment emits high-energy positive and negative ions, which can contact with organic volatile gas molecules (VOCs) in the air, open the chemical bonds of VOCs molecules, and decompose into carbon dioxide and Water, then undergo low-temperature high-energy plasma treatment. The ion generator emits high-energy positive and negative ions, which can contact with organic volatile gas molecules (VOCs) in the air, open the chemical bonds of VOCs molecules, and decompose them into carbon dioxide...

Embodiment 2

[0023] A rubber vulcanization waste gas treatment process, the specific steps are as follows:

[0024] Step 1: washing, spraying and drying the waste gas generated by opening the tank, and then carrying out triple ultraviolet catalytic oxidation to decompose and oxidize the polymer pollutants. get the first product;

[0025] Step 2: The first product is subjected to low-temperature plasma treatment, and the ion generator in the equipment emits high-energy positive and negative ions, which can contact with organic volatile gas molecules (VOCs) in the air, open the chemical bonds of VOCs molecules, and decompose into carbon dioxide and water , and then low-temperature high-energy plasma treatment, the ion generator emits high-energy positive and negative ions, which can contact with organic volatile gas molecules (VOCs) in the air, open the chemical bonds of VOCs molecules, decompose into carbon dioxide and water, and then use the activated carbon adsorption device Activated ca...

Embodiment 3

[0028] A rubber vulcanization waste gas treatment process, the specific steps are as follows:

[0029] Step 1: Use a gas collecting hood to collect the waste gas generated by opening the tank and wash it with water, spray and dry it, and then perform triple ultraviolet catalytic oxidation to decompose and oxidize polymer pollutants. Molecular harmless substances, the first product is obtained;

[0030] Step 2: The first product is subjected to low-temperature plasma treatment, and the ion generator in the equipment emits high-energy positive and negative ions, which can contact with organic volatile gas molecules (VOCs) in the air, open the chemical bonds of VOCs molecules, and decompose into carbon dioxide and Water, then undergo low-temperature high-energy plasma treatment. The ion generator emits high-energy positive and negative ions, which can contact with organic volatile gas molecules (VOCs) in the air, open the chemical bonds of VOCs molecules, and decompose them into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com