Thermal recovery circulating system of air compressor

A technology of air compressors and circulation systems, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve problems such as huge equipment installation costs, fuel and electricity costs, and environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

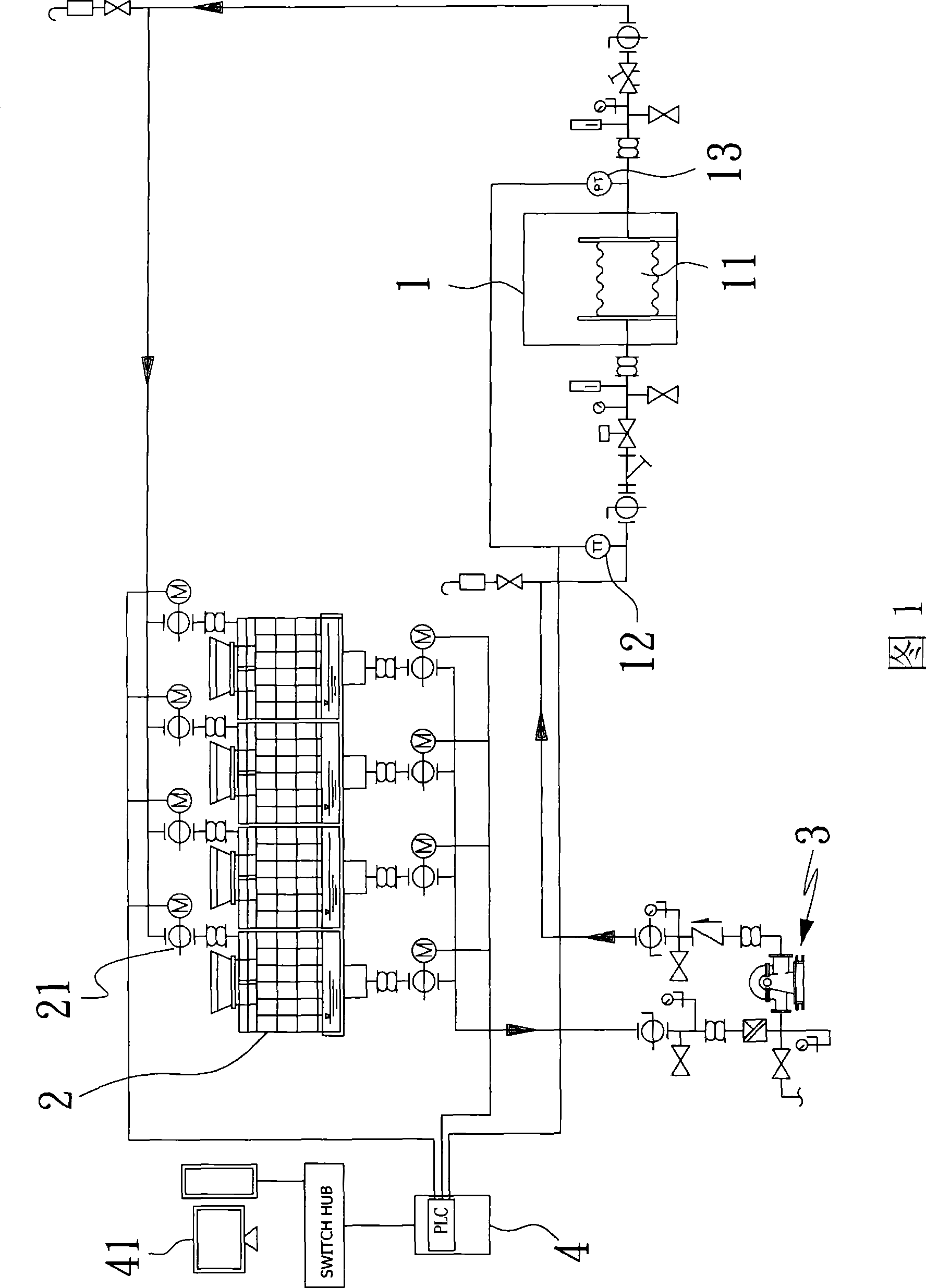

[0015] As shown in FIG. 1 , the air compressor and related cooling device in the prior art, its main components and its missing, have been described above, and will not be repeated here.

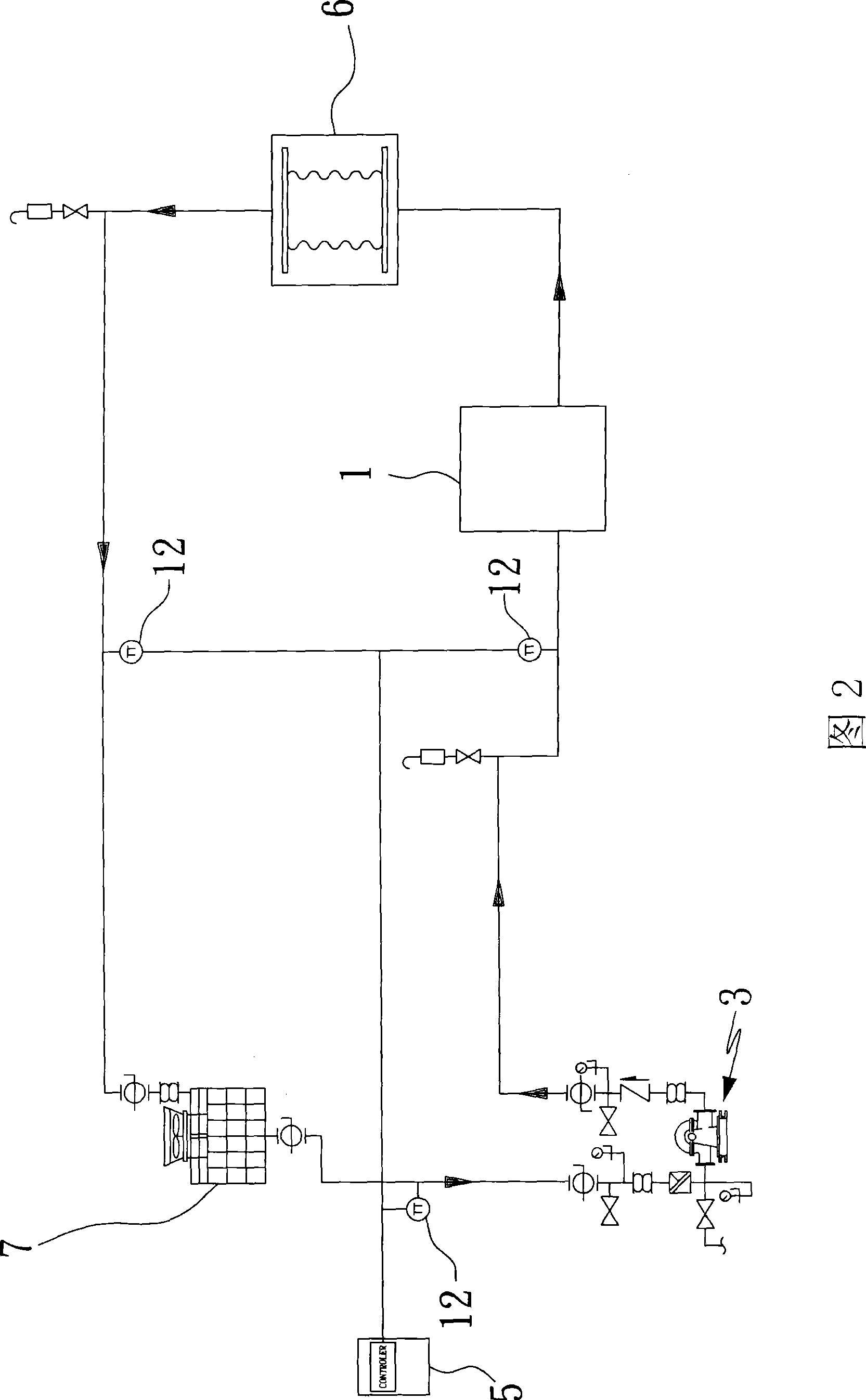

[0016] Fig. 2 is a structural schematic view of an embodiment of the present invention, from which it can be clearly seen that the structure of the embodiment of the present invention mainly includes: an air compressor 1, a cooler 7, a pump 3, a controller 5, and a heat transfer device 6 and other parts, wherein the pump 3 can inject cooling water into the air compressor 1 so as to absorb the heat generated by the air compressor 1 during operation, and then the hotter cooling water passes through the heat transfer device 6 to make the heat transfer device 6 absorb The heat in the cooling water is used to obtain an available heat source and reduce the temperature of the cooling water appropriately. After passing through the heat transfer device 6, the lower temperature cooling water is monitor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com