Patents

Literature

45 results about "Acceleration deceleration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

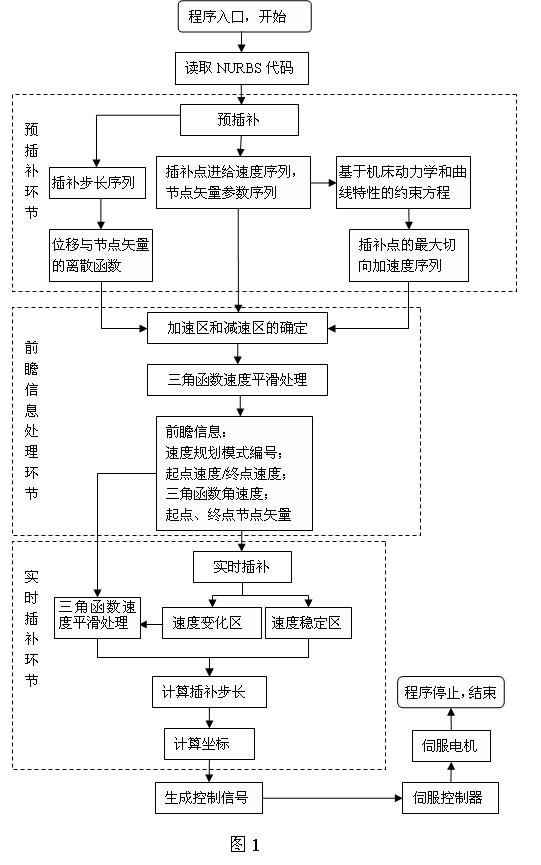

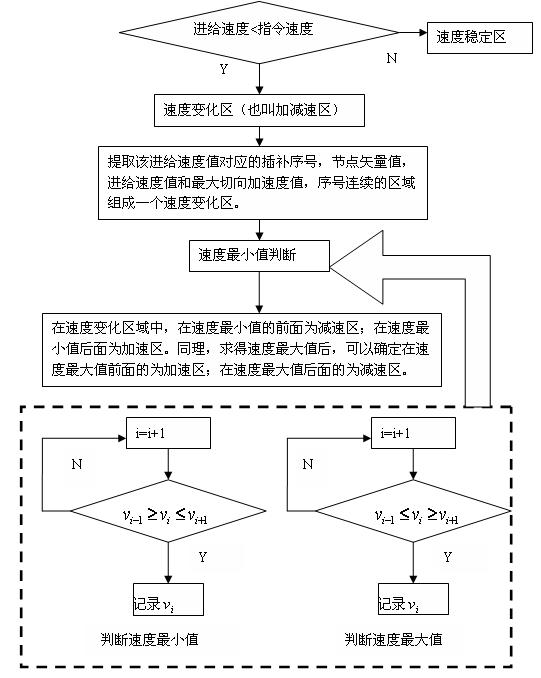

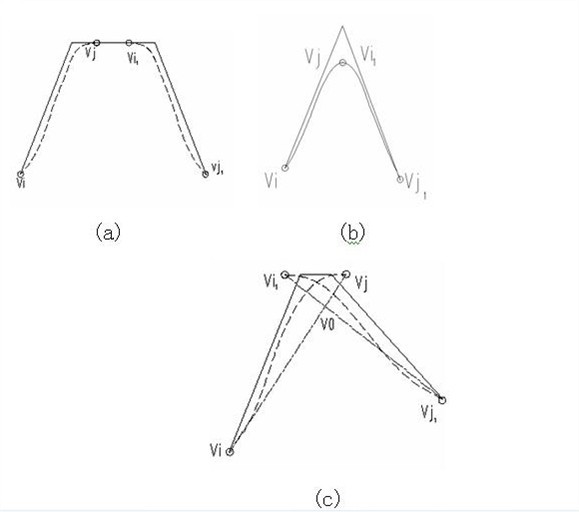

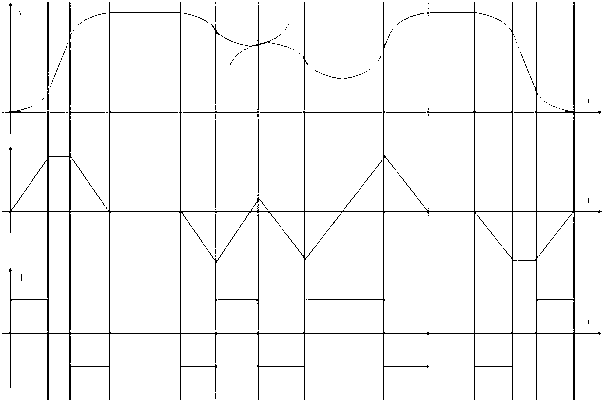

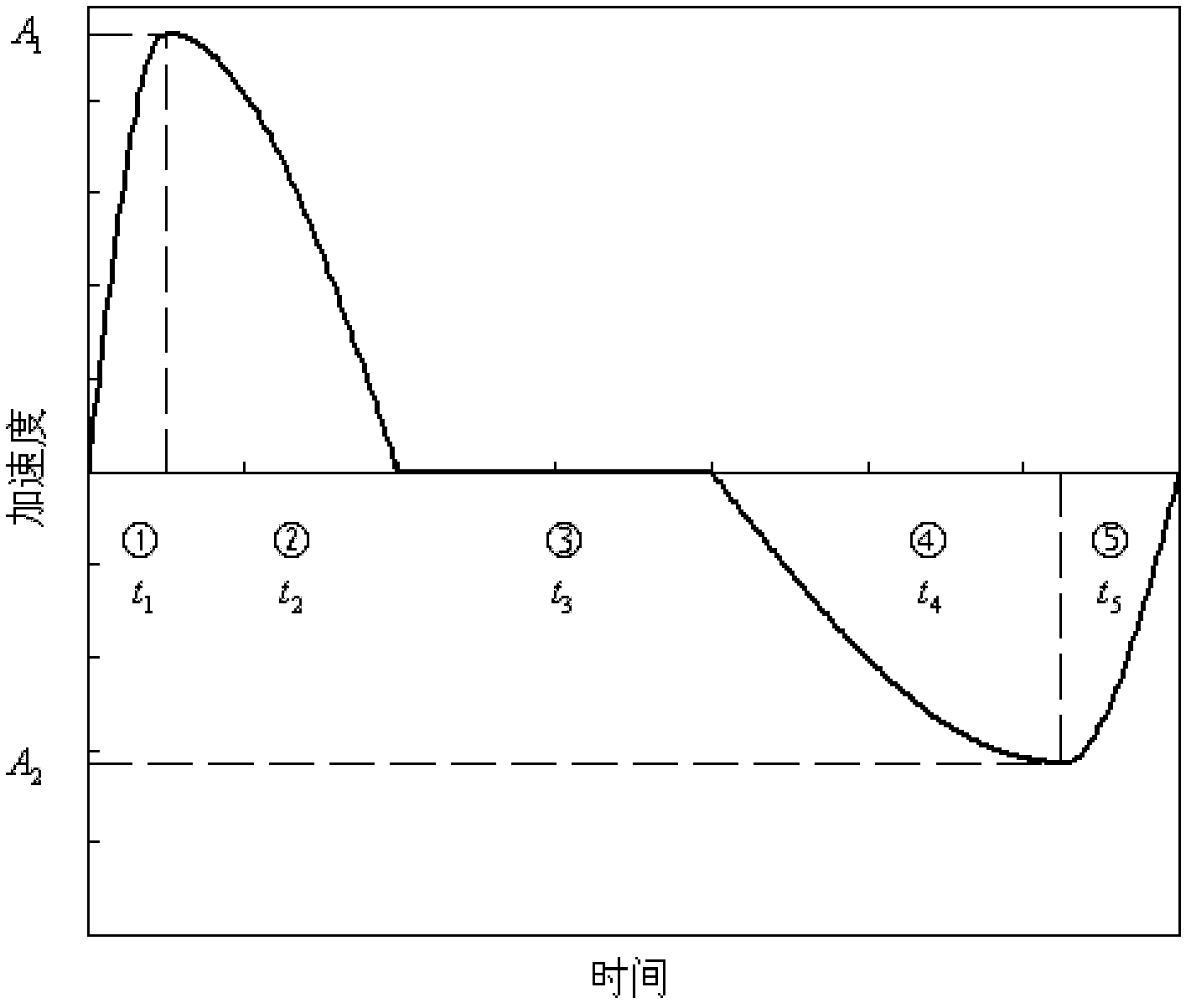

NURBS (Non-Uniform Rational B-Spline) interpolation method based on machine tool dynamics and curve characteristics

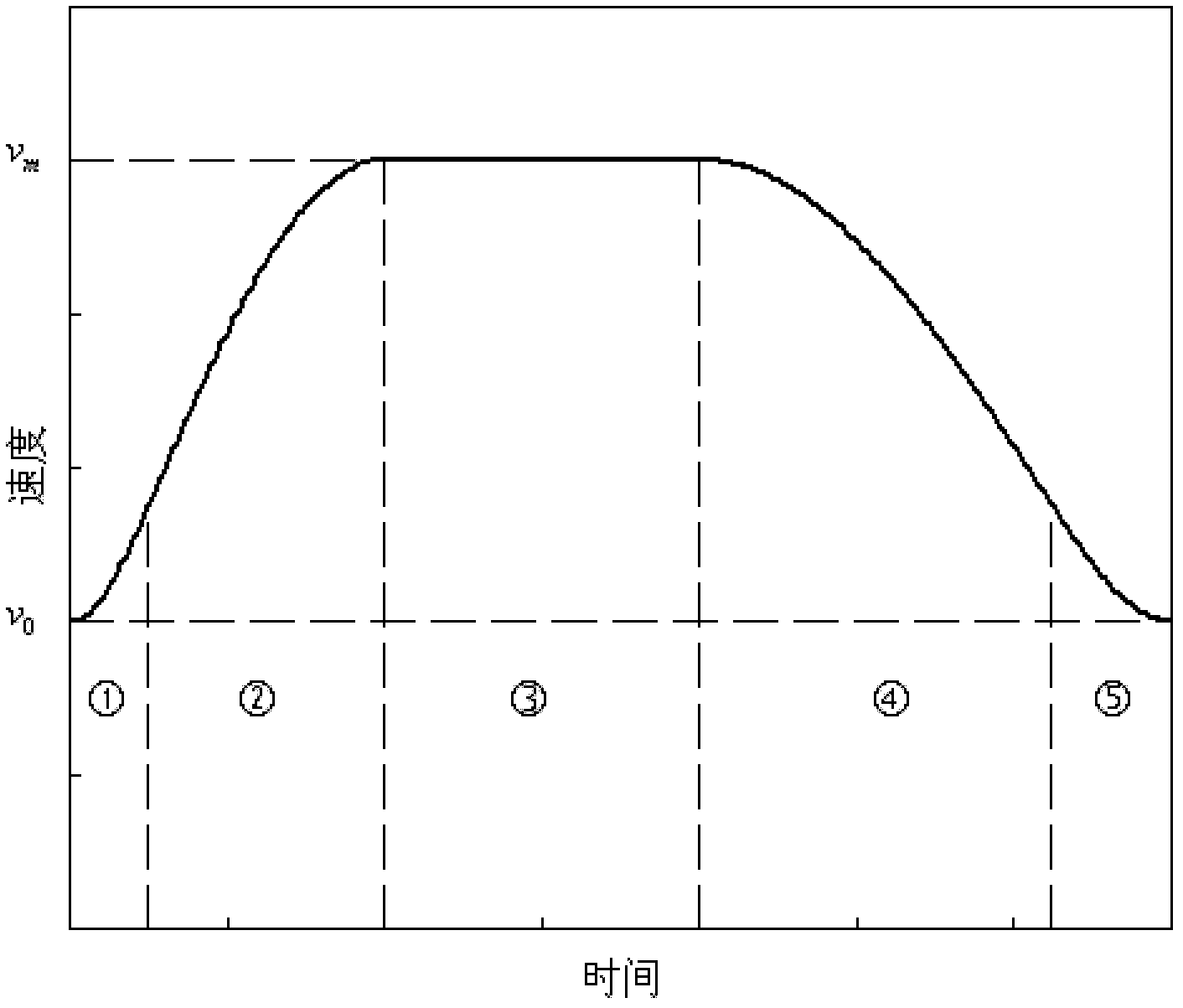

ActiveCN101976060AThe interpolation movement process is smooth and stableContinuous speedNumerical controlInformation processingAcceleration deceleration

The invention discloses an NURBS (Non-Uniform Rational B-Spline) interpolation method based on machine tool dynamics and curve characteristics, which adopts a constraint equation ZHYS considering integrative factors of machine tooling for controlling the feeding speed and the acceleration of the interpolation algorithm. The method consists of three links: pre-interpolation, prospective information processing and real-time interpolation, and comprises the following steps of: carrying out trigonometric function speed smoothing processing according to the corresponding speed mode; storing corresponding data after the trigonometric function speed smoothing processing; adopting the trigonometric function speed smoothing processing according to prospective information if entering an acceleration-deceleration region; and adopting a speed self-adapting method for calculation if not entering the acceleration-deceleration region, thus finally obtaining the coordinates and the feeding speed of interpolation points. The method of the invention has the advantages that the interpolation is always in the safe range of a machine tool, the whole interpolation movement process is smooth and stable through the trigonometric function speed smoothing processing, in addition, the tangential acceleration and the continuity of the tangential acceleration in the speed change region can be ensured, and the NURBS interpolation method has the important significance on the development of a high-speed and high-precision numerical control system.

Owner:成都天佑创软科技有限公司

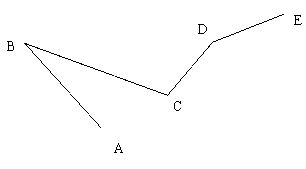

Method for planning velocity of S-shaped acceleration and deceleration control for control system of numerical control equipment

The invention discloses a method for planning the velocity of S-shaped acceleration and deceleration control for a control system of numerical control equipment. A 'collimation line' concept is introduced in the method and the method comprises the following steps: setting the parameters of a vectorial line segment are set; calculating the allowed velocity Vc of a collimation line according to theinput vectorial line segment; judging whether the collimation line conditions are reached or not, if so, producing one collimation line, and adding the produced collimation line into a collimation line linked list in sequence; after the collimation line linked list is fixed, respectively calculating the maximum velocity of each collimation line according to a traversal algorithm; and completing the collimation line interpolation task through a field programmable gate array (FPGA) program, distributing the pulses of the collimation lines to all the practical movement axes of an electronic gear, and converting digital information into electrical information for controlling the movement of a motor. The method has the beneficial effects that the method is applied to S-shaped acceleration deceleration control, so that shacking and collision which are generated because a machine is very heavy can be well avoided, the operation stability of the machine is improved, and the processing efficiency is increased. The solution idea of the collimation line is introduced. The data processing amount is effectively reduced, and the data processing capability is improved.

Owner:成都乐创自动化技术股份有限公司

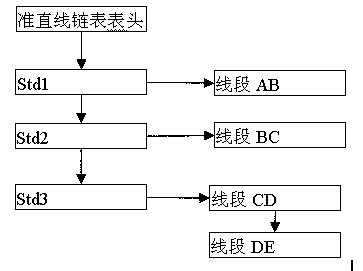

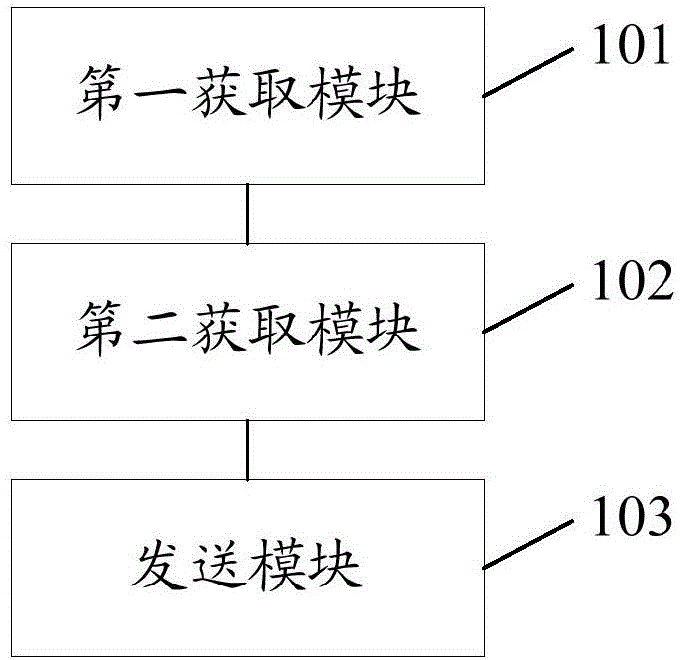

Method for controlling vehicle machine application operating authorization, vehicle-mounted device and terminal

InactiveCN105799612AEnsure driving safetyTransmissionElectric/fluid circuitSteering wheelAcceleration deceleration

The invention provides a method for controlling vehicle machine application operating authorization, a vehicle-mounted device and a terminal. The vehicle-mounted device comprises a first acquisition module, a second acquisition module and a sending module. The first acquisition module is used for acquiring the running states of the vehicle, and the running states comprise a vibration state, a turning state and an acceleration-deceleration state; the second acquisition module is used for acquiring the control data of the vehicle, and the control data comprises the speed, the engine rotating speed, the steering wheel turning direction, and the accelerator / brake pedal state; and the sending module is used for sending the running states and the control data to a terminal, and the terminal automatically adjust the operating authorization of the vehicle machine application on the terminal according to the running states and the control data; and the terminal is connected with the vehicle-mounted device in a communication manner. According to the above scheme, the operating authorization of the vehicle machine application is controlled and adjusted according to the monitored running state and the running data of the vehicle, and therefore when a driver needs to pay attention to driving the vehicle, the driver cannot carry out some operations of the vehicle machine application, and the driving safety of the driver is guaranteed.

Owner:CHINA MOBILE COMM GRP CO LTD

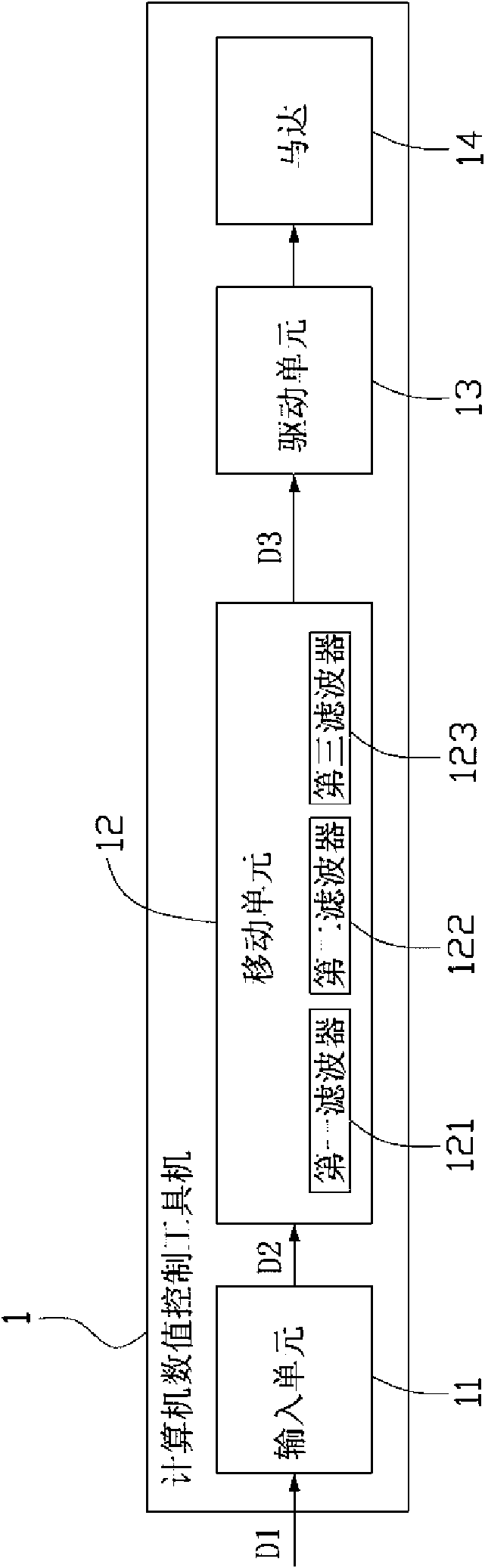

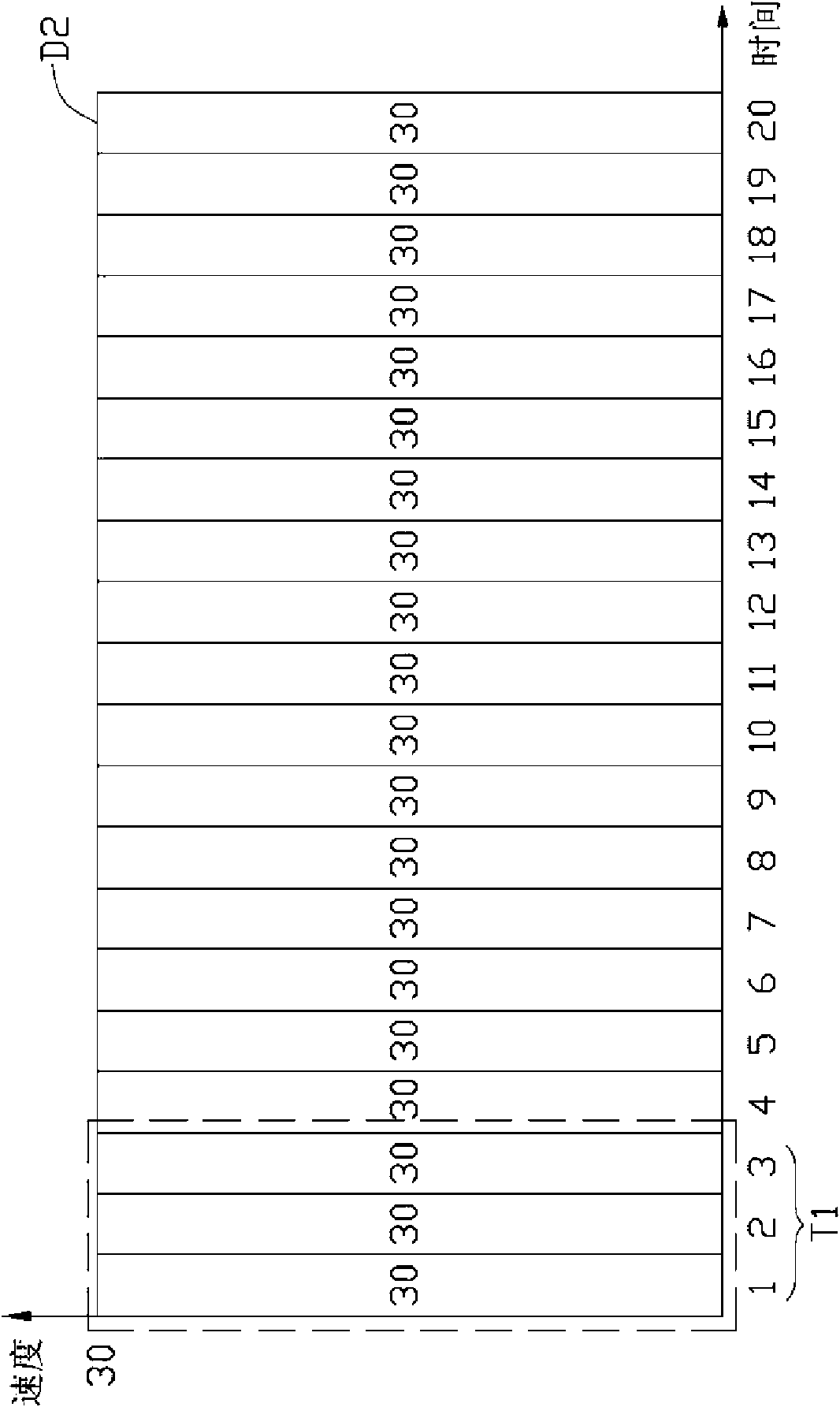

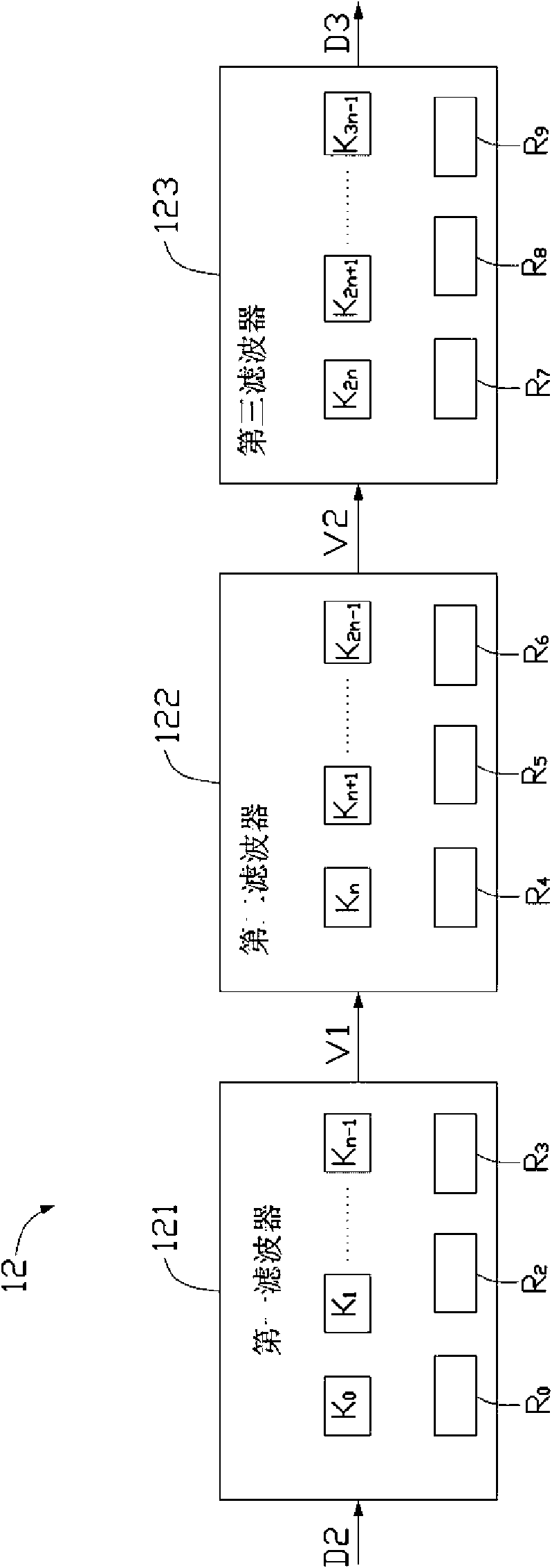

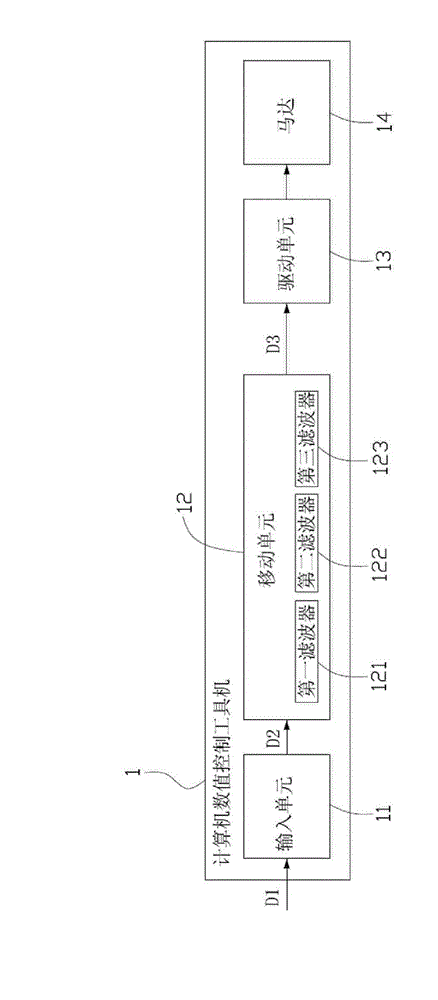

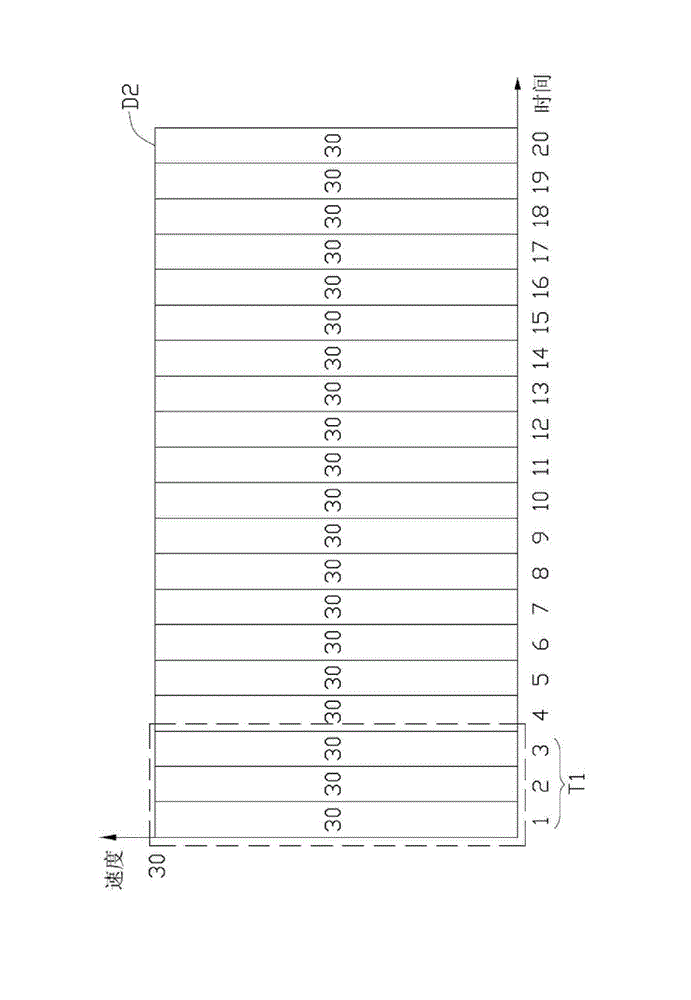

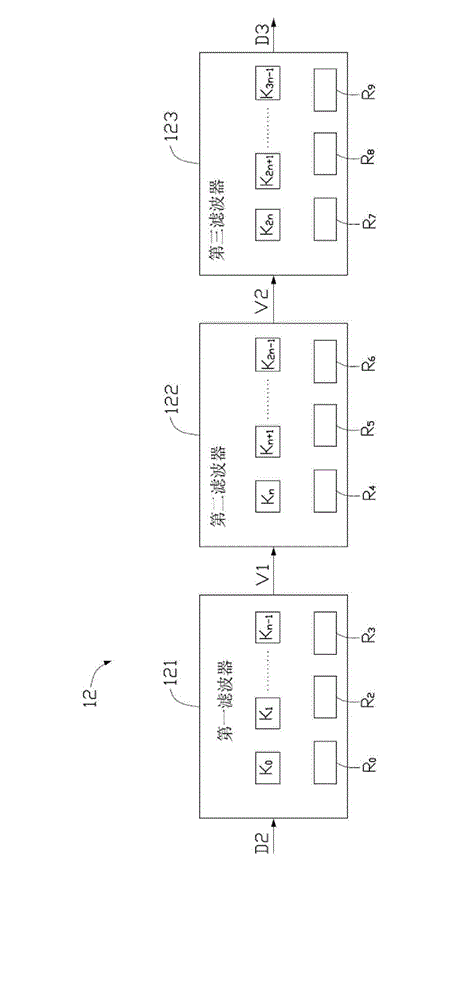

Computerized numerical control machine tool and acceleration-deceleration method thereof

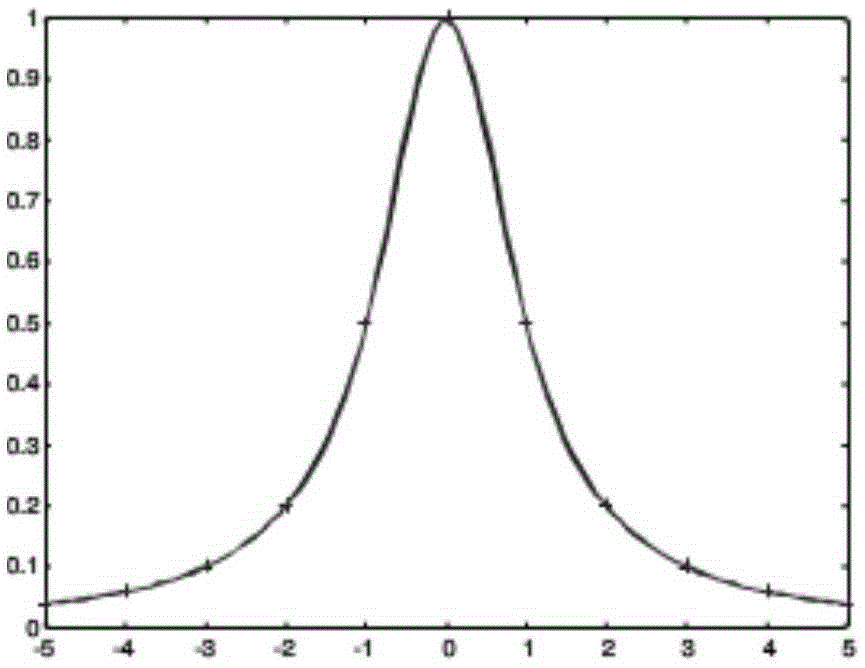

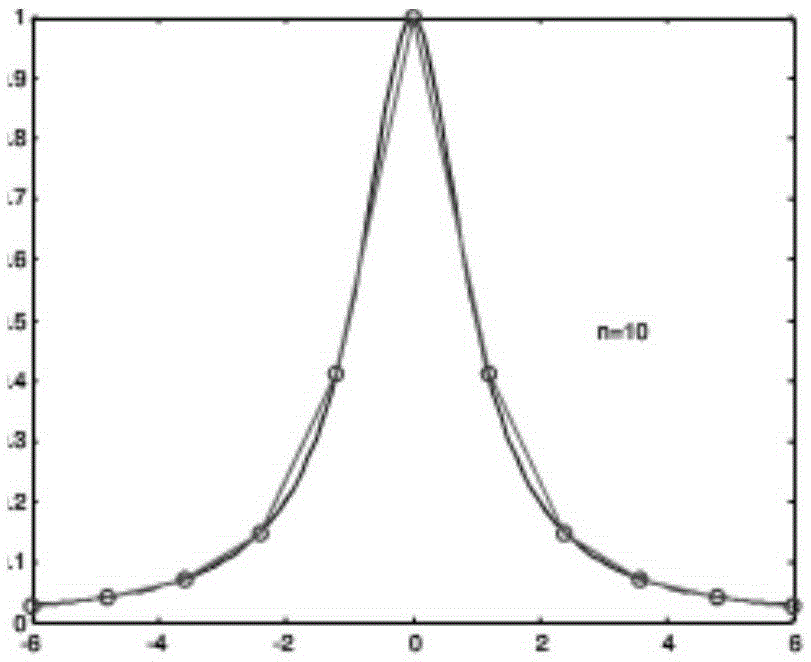

ActiveCN101581927AControl acceleration and deceleration timeJerk controlNumerical controlNumerical controlMoving average

The invention relates to an acceleration-deceleration method for a computerized numerical control machine tool, which comprises the following steps: recieving an acceleration-deceleration time signal and a speed signal; obtaining dissimilar first weight value and second weight value by the acceleration-deceleration time signal through a first function and a second function; judging whether a speed variation of the speed signal is zero, a positive value or a negative value; outputting the speed signal when the speed variation is zero; obtaining an acceleration signal by the product of the speed signal and the first weight value when the speed variation is the positive value; obtaining an deceleration signal by the product of the speed signal and the second weight value when the speed variation is the negative value; and converting the speed signal, the acceleration signal and the deceleration signal into a first driving signal, a second driving signal and a third driving signal respectively. The acceleration-deceleration method for the computerized numerical control machine tool of the invention can achieve the effect of a thrice moving average method only by once acceleration-deceleration plan, effectively control the jerk and the acceleration-deceleration time signal, and improve the product quality.

Owner:HONG QI MECHATRONICS ANHUI CO LTD +1

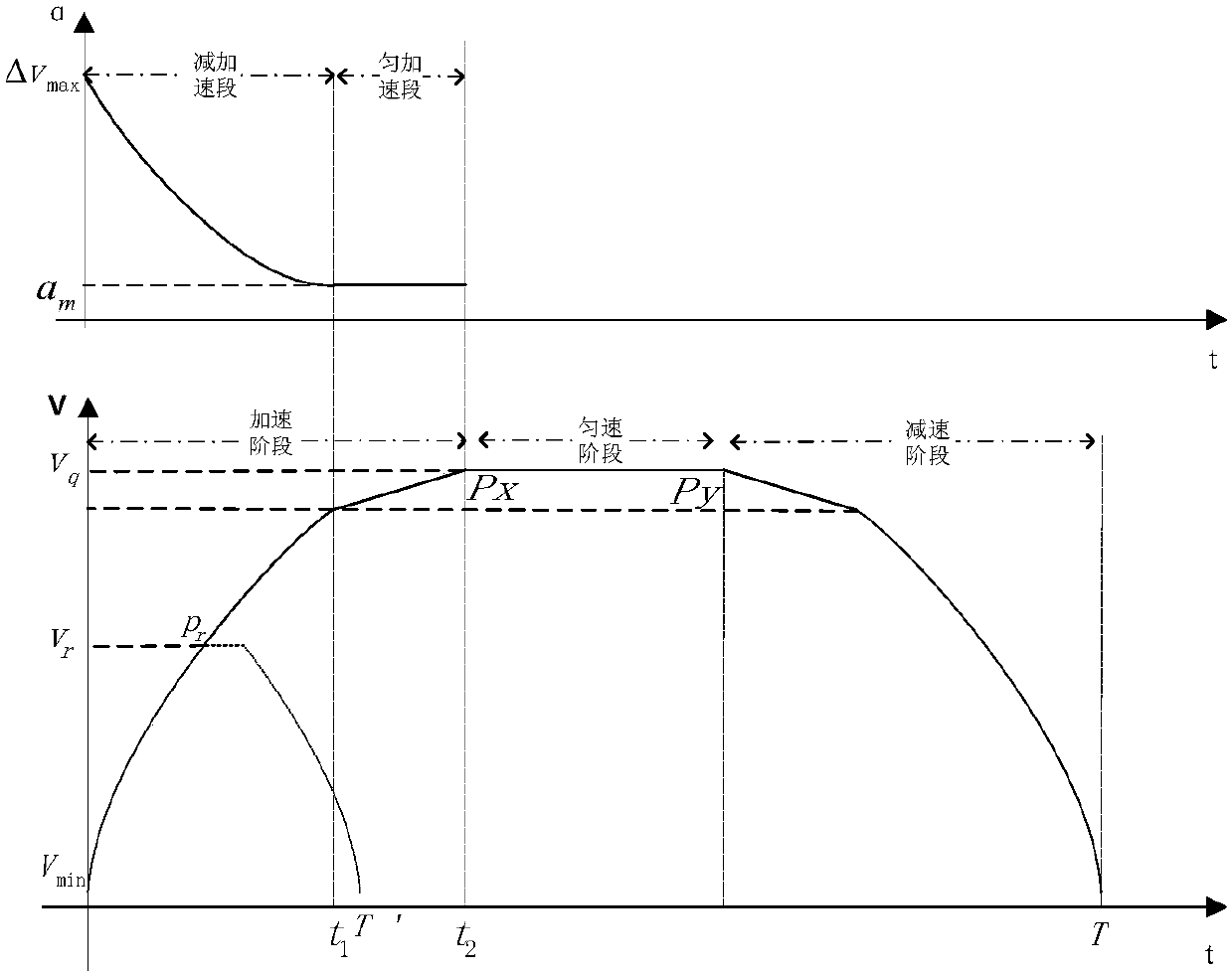

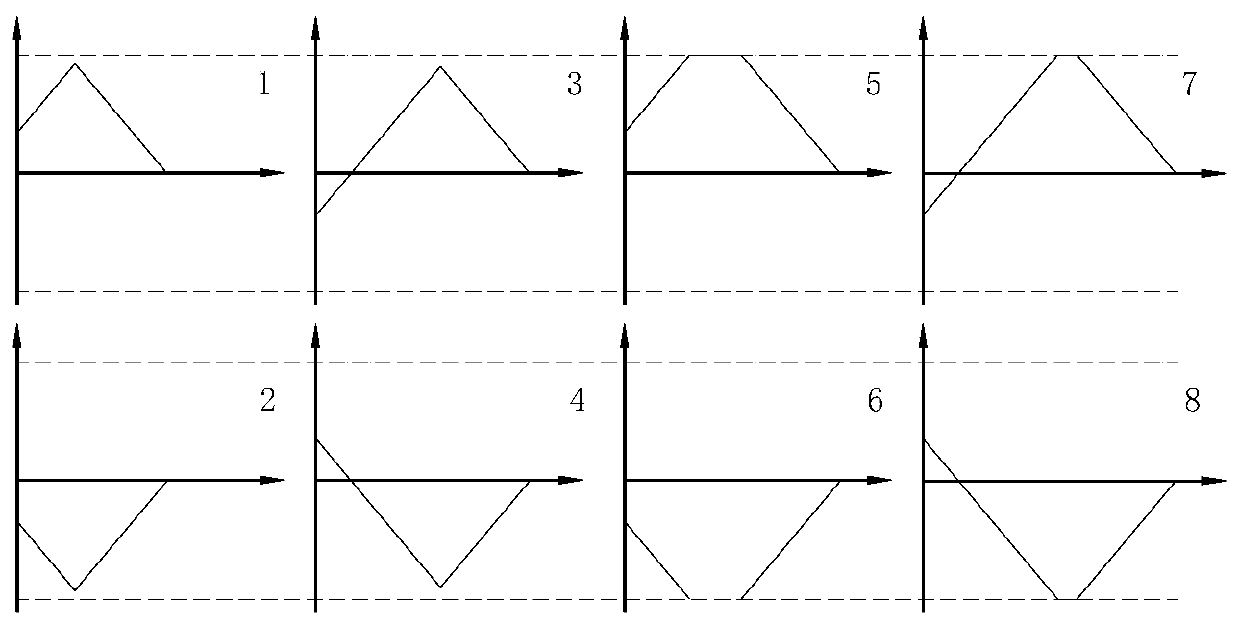

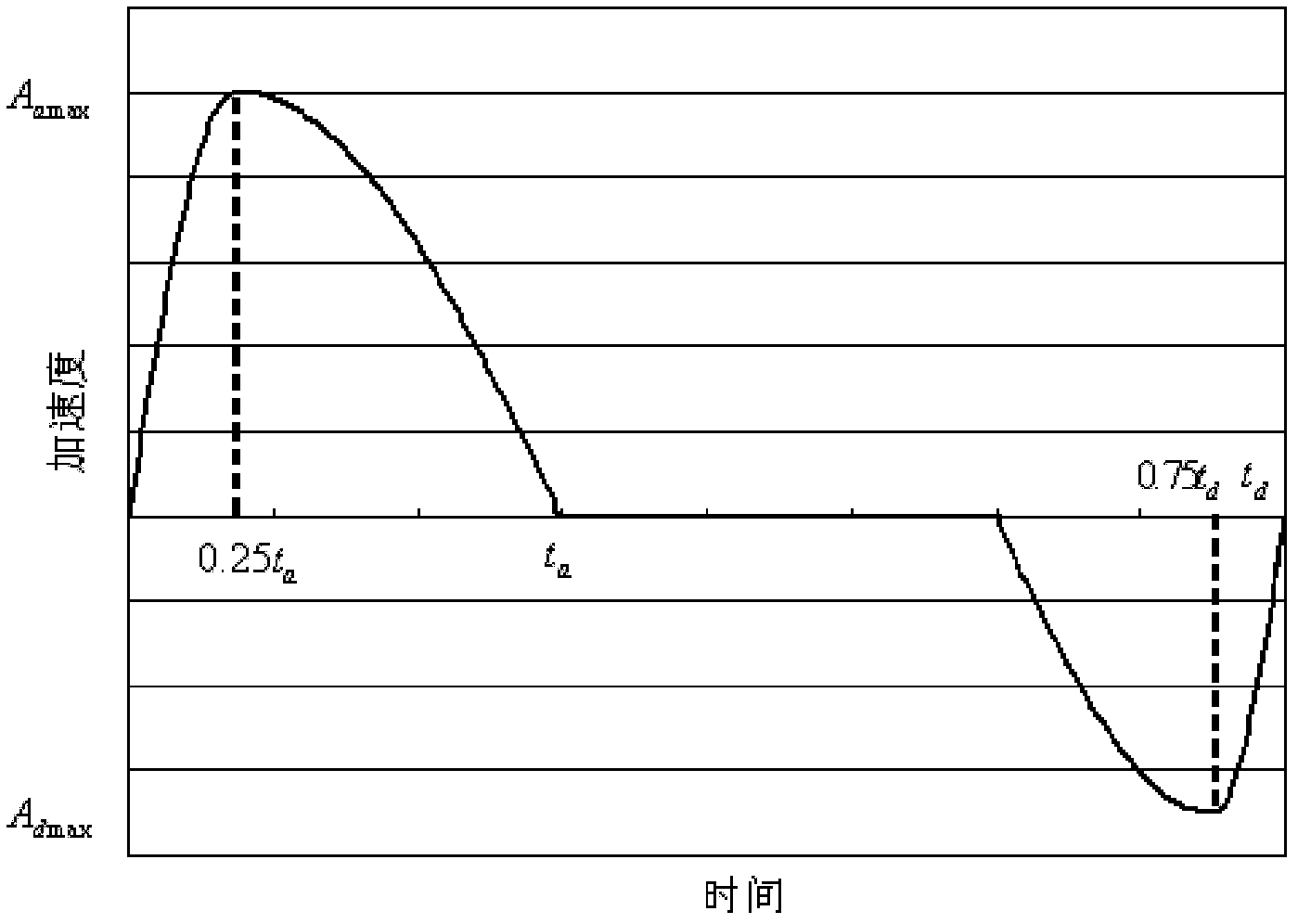

Servo-motor acceleration-deceleration control method for servo pressure machine

ActiveCN102522944AContinuous changeAvoid Flex ShockElectronic commutation motor controlElectric motor controlTriangular functionAcceleration deceleration

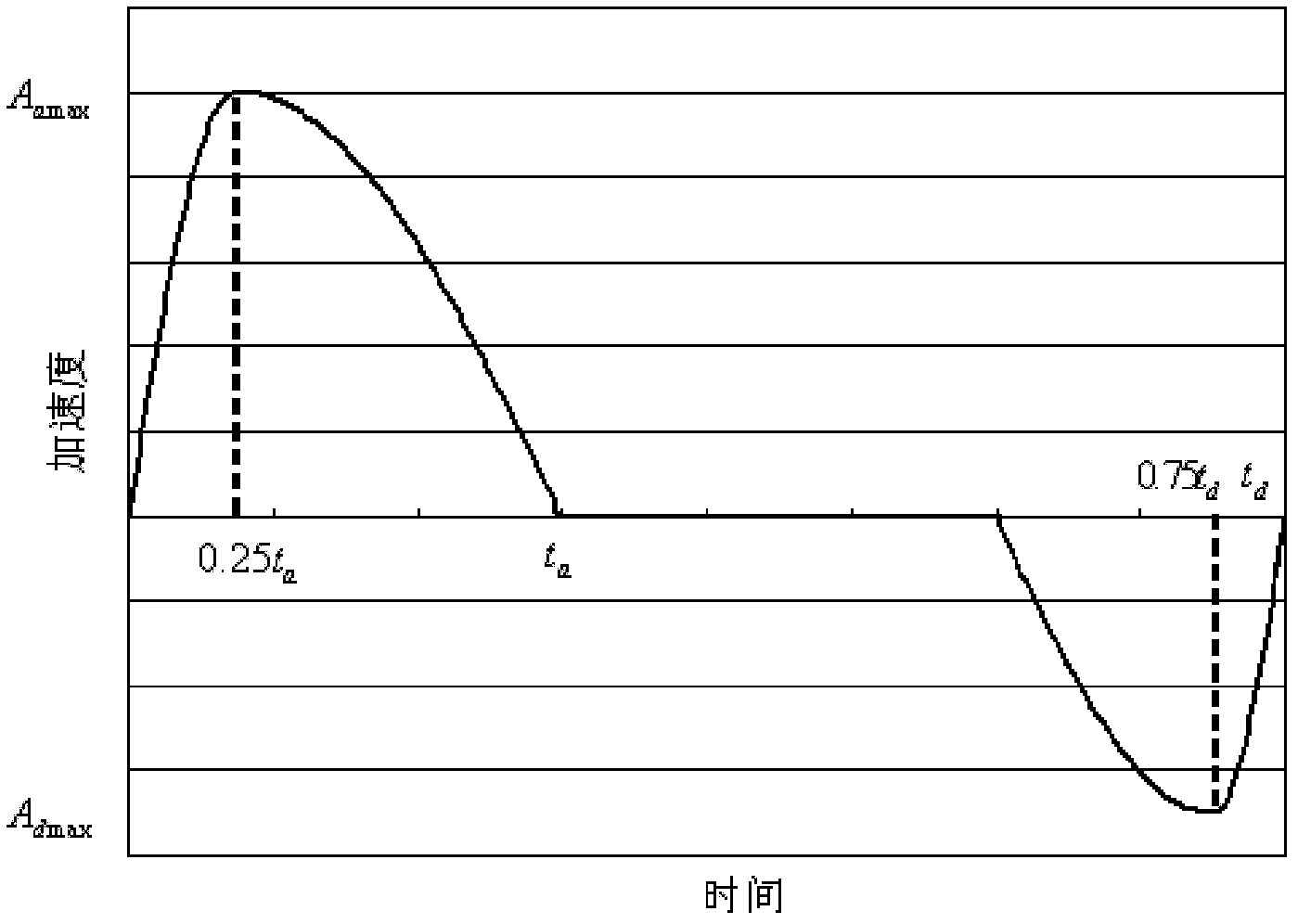

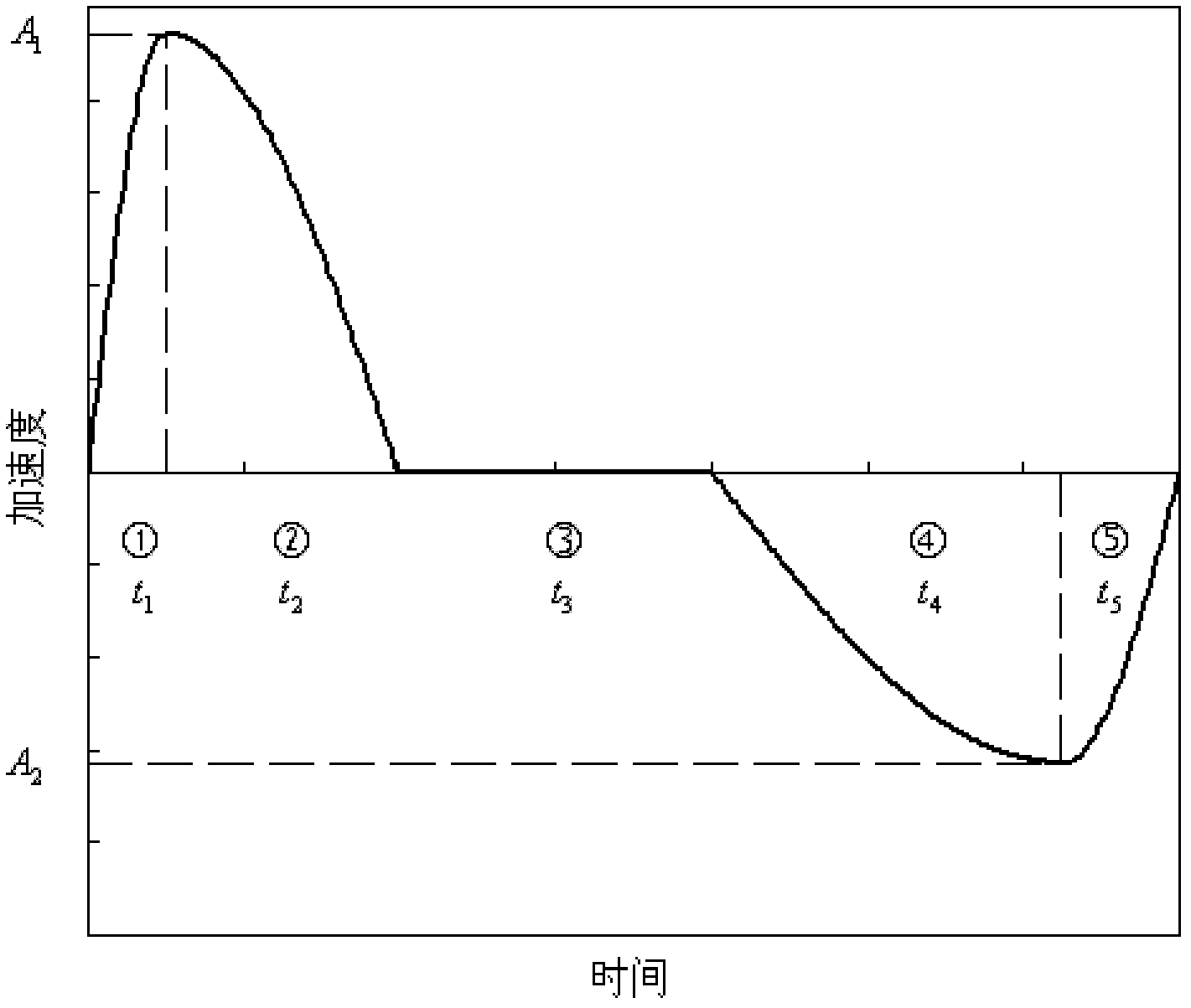

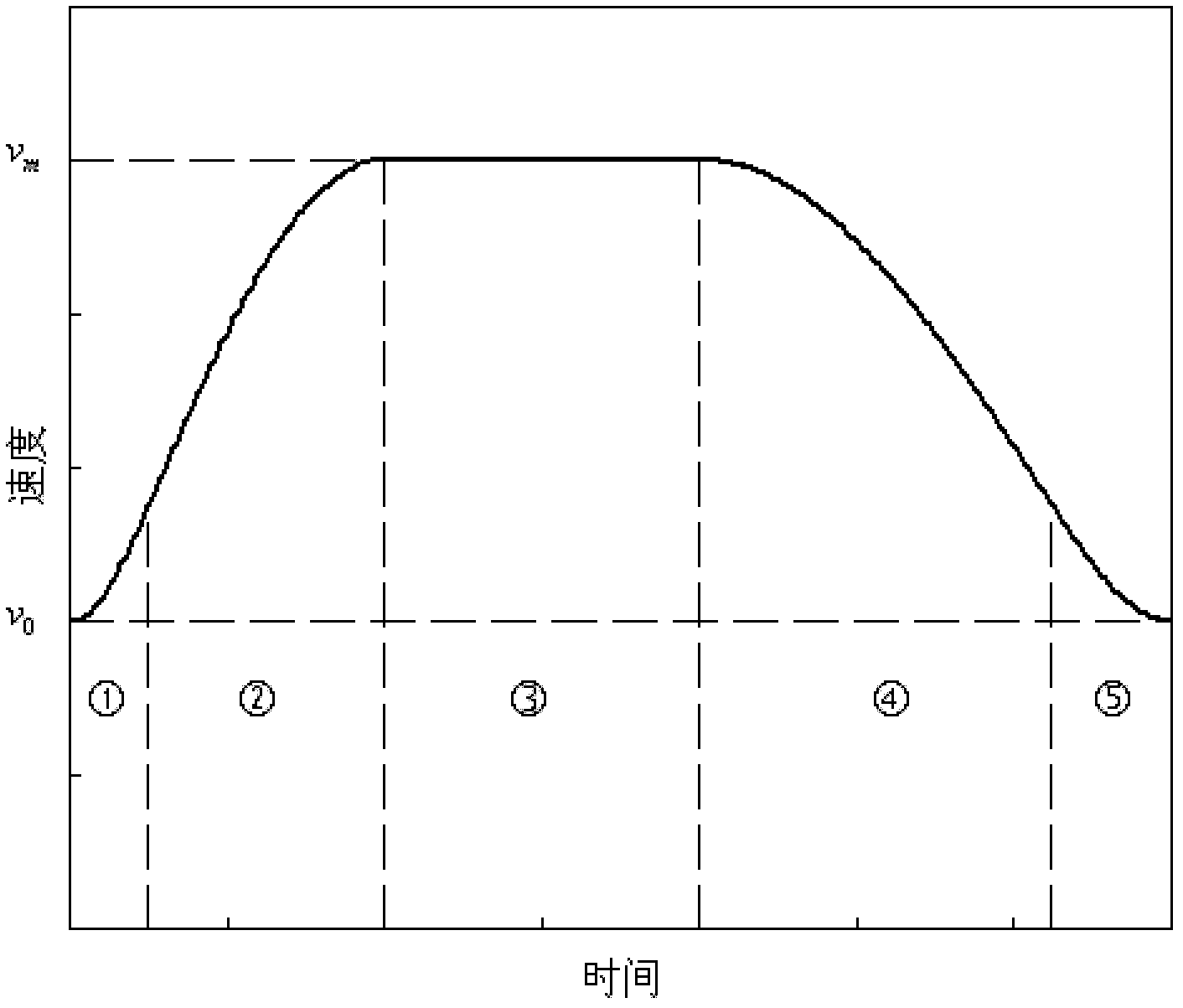

The invention discloses a servo-motor acceleration-deceleration control method for a servo pressure machine, comprising the following steps of: constructing an acceleration function of a servo motor at an acceleration stage; establishing a speed expression of the servo motor at the acceleration stage; establishing a rotary displacement expression of the servo motor at the acceleration stage; constructing an acceleration function of the servo motor at a deceleration stage; establishing a speed expression of the servo motor at the deceleration stage; establishing a rotary displacement expression of the servo motor at the deceleration stage; and determining total acceleration time and total deceleration time. According to the servo-motor acceleration-deceleration control method, two triangular functions with different periods are adopted as acceleration-deceleration constructed functions of the servo motor, so that the change of the speed, the acceleration and the accelerated acceleration is continuous, the soft shock of the acceleration-deceleration process on the machine body is avoided, the operation stability of the pressure machine is improved and the softness of acceleration-deceleration control of the pressure machine is higher; and by full utilization of the constant and maximum output torque of the server motor under the rated rotating speed, the operation period of the servo pressure machine can be shortened and the takt time of stamping production is improved.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

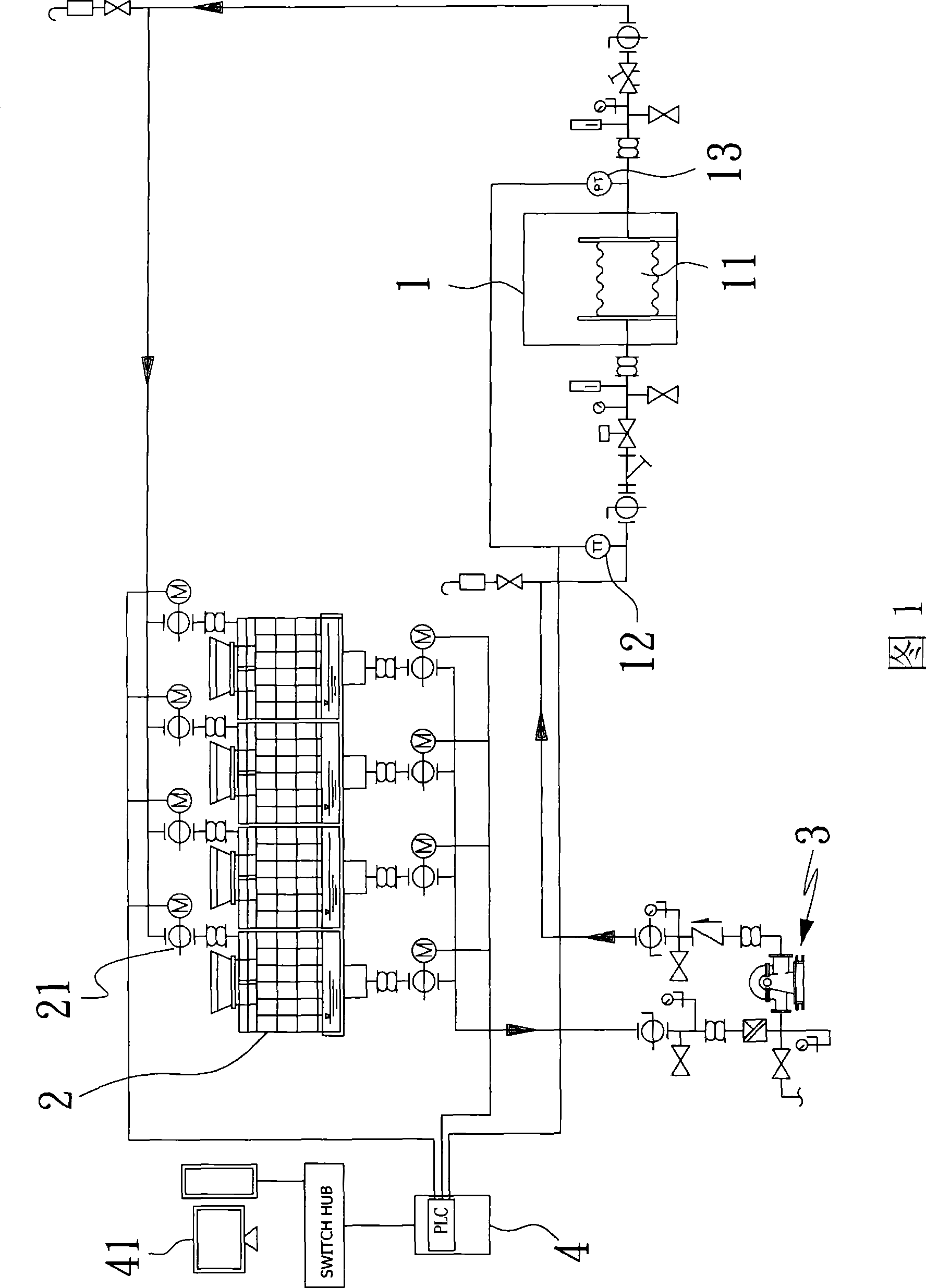

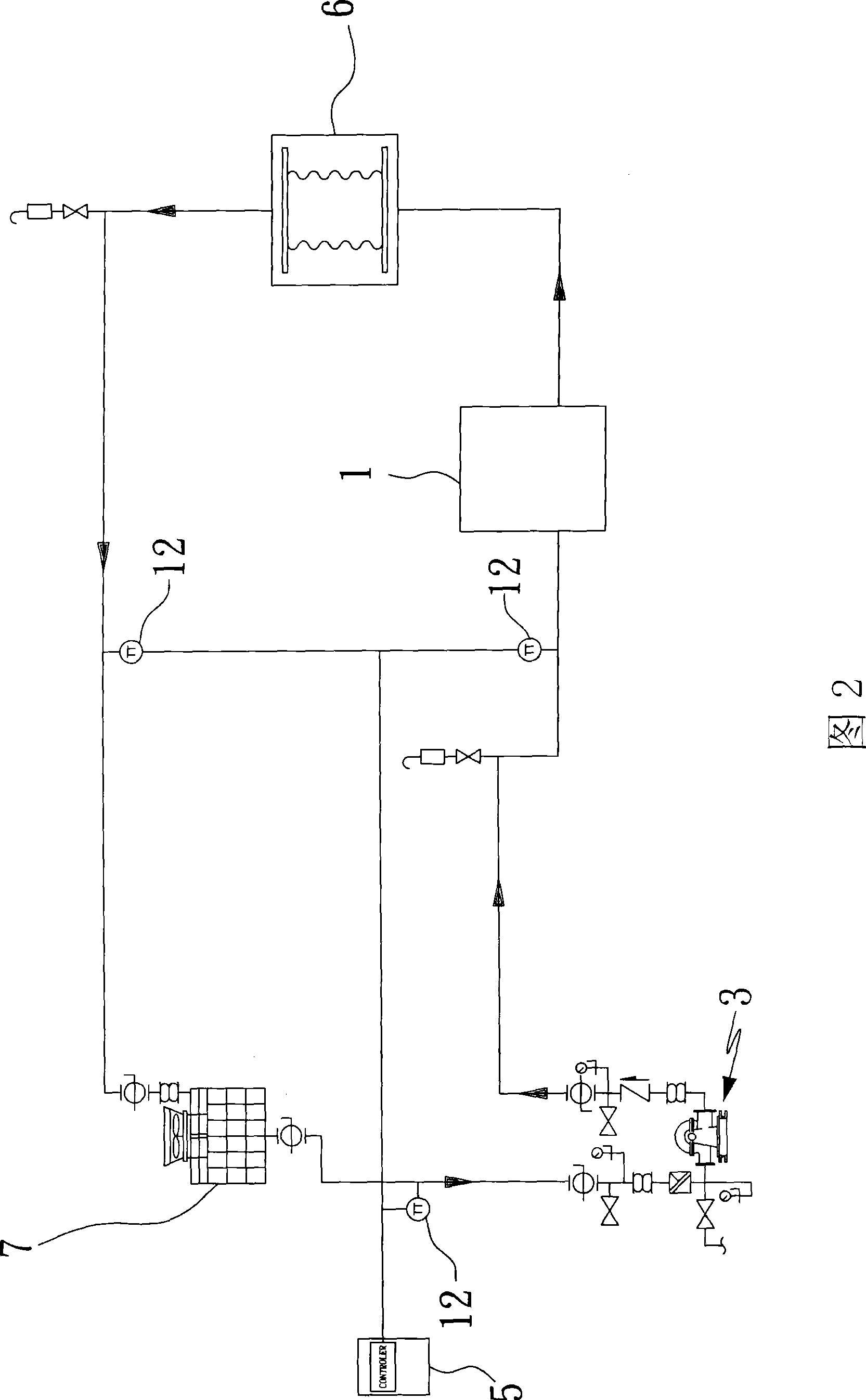

Thermal recovery circulating system of air compressor

InactiveCN101435420AReduce consumptionAvoid damagePositive displacement pump componentsPositive-displacement liquid enginesThermal energyControl signal

The invention provides a heat recovery and circulating system of an air compressor. Typically, a heat-transferring device is arranged between the air compressor and a cooler. The system can recycle the heat energy produced by the air compressor effectively, and converts the heat into heat resources for other purposes, uses a pump to pressurize cooling water to make the cooling water to pass through the air compressor, the heat transferring device and the cooler respectively, uses a controller to monitor the temperature of the cooling water flowing through the air compressor and the cooler, and then outputs a control signal after calculation according to the preset condition so as to control the acceleration-deceleration or operation stop of the cooler so that the cooling water can flow back to the pump via the cooler after passing through the air compressor and the heat transferring device to form the heat recovery and circulating system. With control of the temperature of the cooling water at control positions, the heat recovery and circulating system can achieve the optimum recovery and heat dissipating efficiency.

Owner:曾德勋

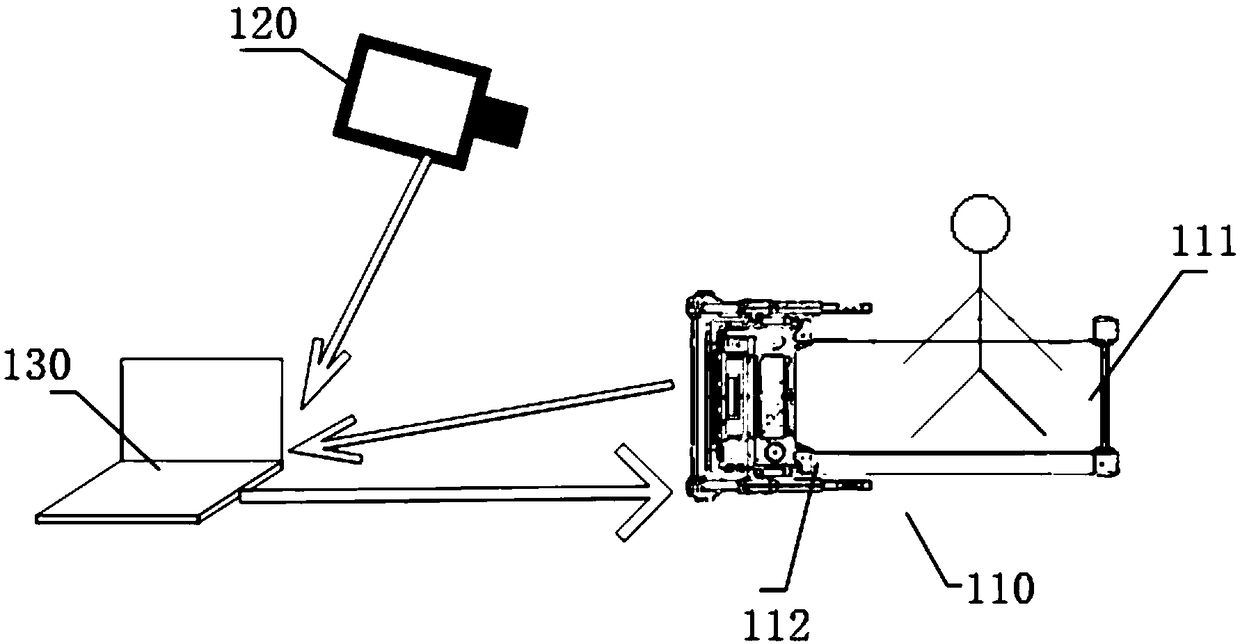

Treadmill adaptive system based on 3D depth camera and flexible pressure-sensitive sensor

ActiveCN108114405ASpeed adjustmentReal-time dynamic speed adjustmentMovement coordination devicesCardiovascular exercising devicesCurrent velocityComputer module

The invention discloses a treadmill adaptive system based on 3D depth camera and flexible pressure-sensitive sensor, comprising a treadmill body. The treadmill body comprises a running belt driven bya motor; a flexible pressure-sensitive sensor is arranged below the running belt; the treadmill body is provided with a 3D depth camera; the flexible pressure-sensitive sensor is used for acquiring sole pressure distribution information of a user and uploading to an upper computer; the 3D depth camera is used for acquiring running attitude information of the user and uploading to the upper computer; the upper computer can adjust the speed of a motor according to current subjective acceleration-deceleration intention and current speed and acceleration information. The treadmill adaptive systemallows the speed of the running belt to be well adaptively adjusted.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

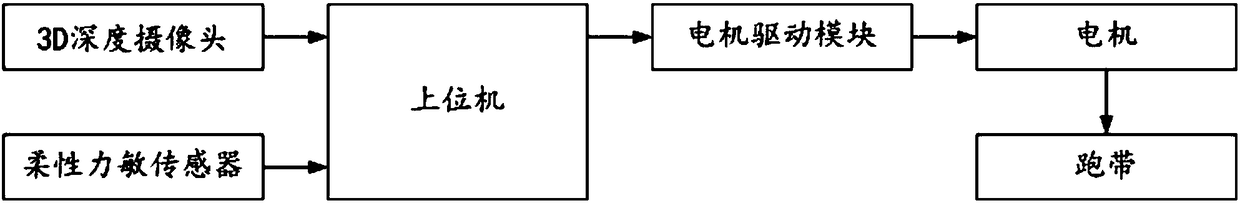

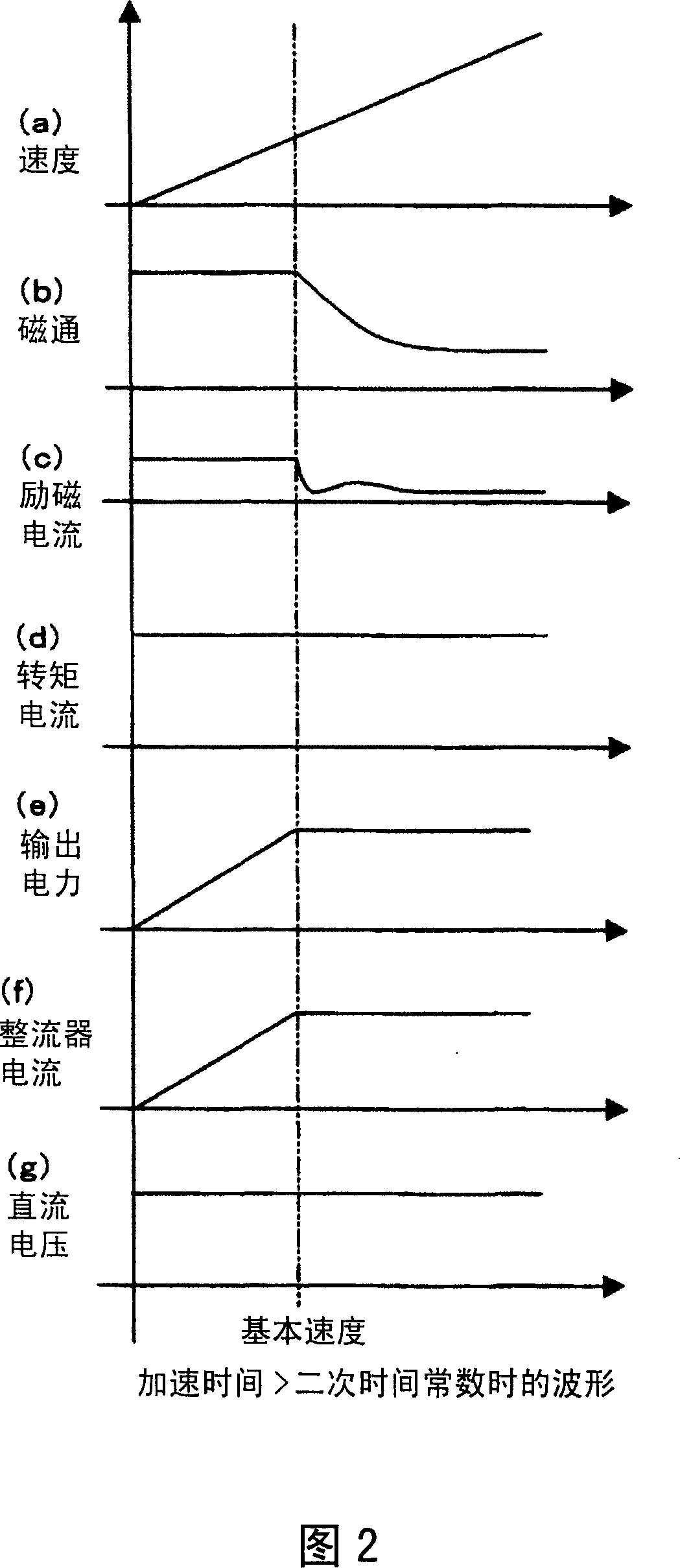

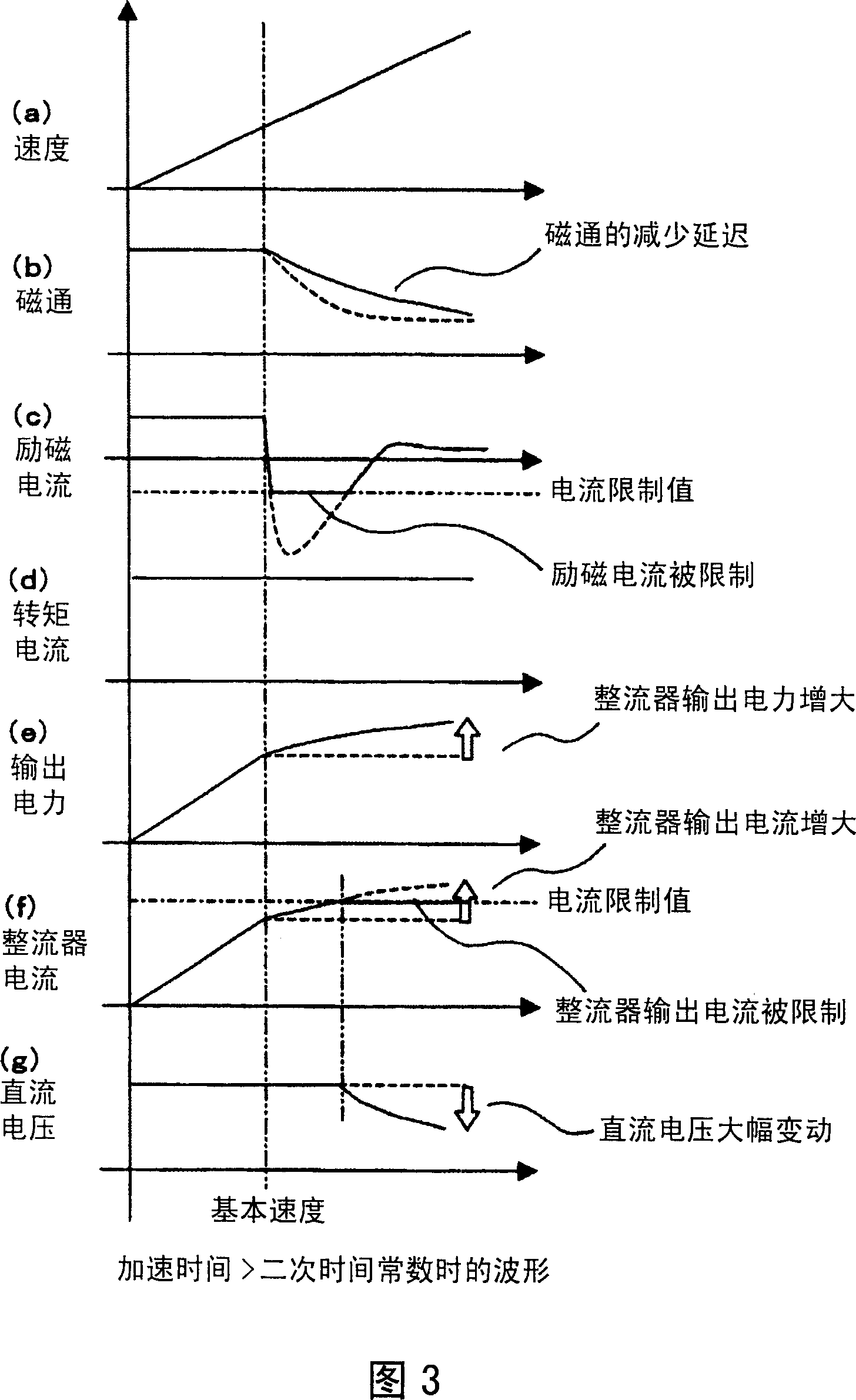

Ac motor system and method for controlling same, and related power conversion device

ActiveCN101022261ALarge capacitySmooth movementAC motor controlCurrent limitingAcceleration deceleration

The objective of the invention is to provide a power conversion device for reliably restrain the switching of the dc voltage, even if in the harsh operation such as rapid acceleration-deceleration. In order to restrain the excessive inverter output power generated by flux control delay due to urgent acceleration-deceleration at the inverter side to the value corresponding to the rectifier. The processing comprises: setting the inverter output power maximum depended on the rectifier control capacity at power limiting set device, inputting the setting value of the power limiting set device, current detecting value detecting by the inverter output current detector and voltage detecting value detected by inverter output voltage detector to the power limiting calculator, calculating the torque current limiting value calculated by current detecting value and voltage detecting value, not exceeding the setting value, inputting the limiting value after calculation to the torque current order limiter, restraining the torque current order value based on the input limiting value in the torque current order limiter.

Owner:HITACHI LTD

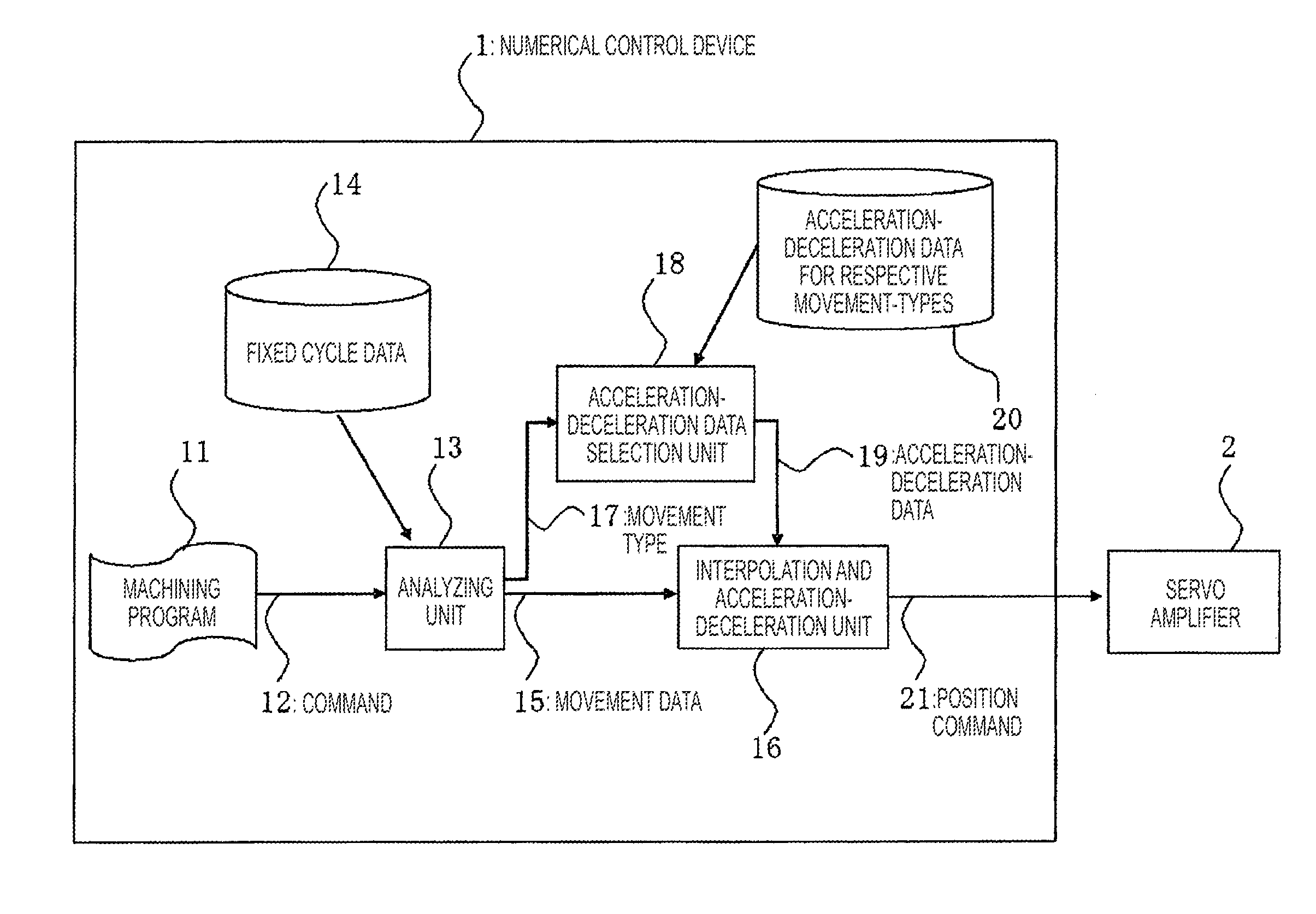

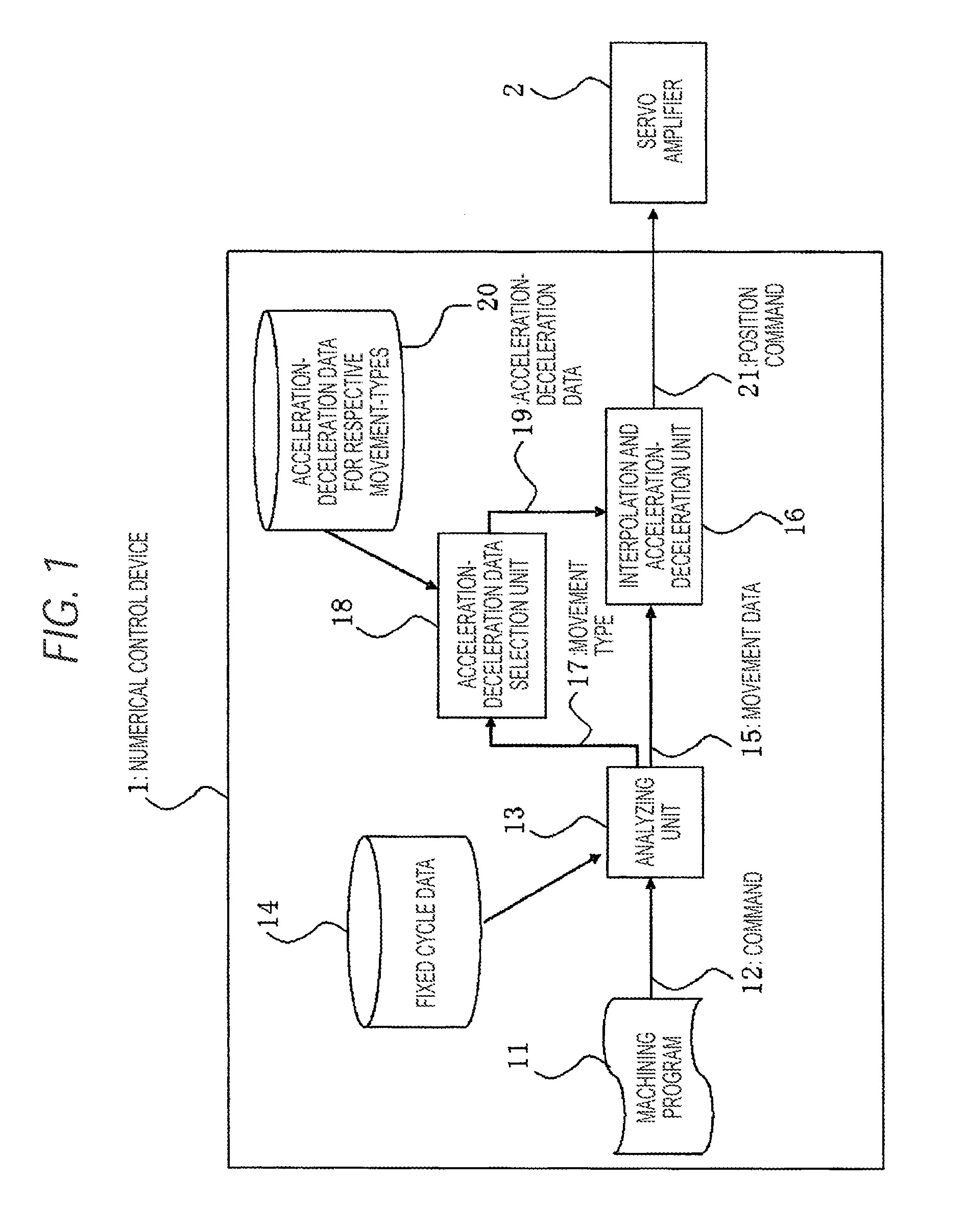

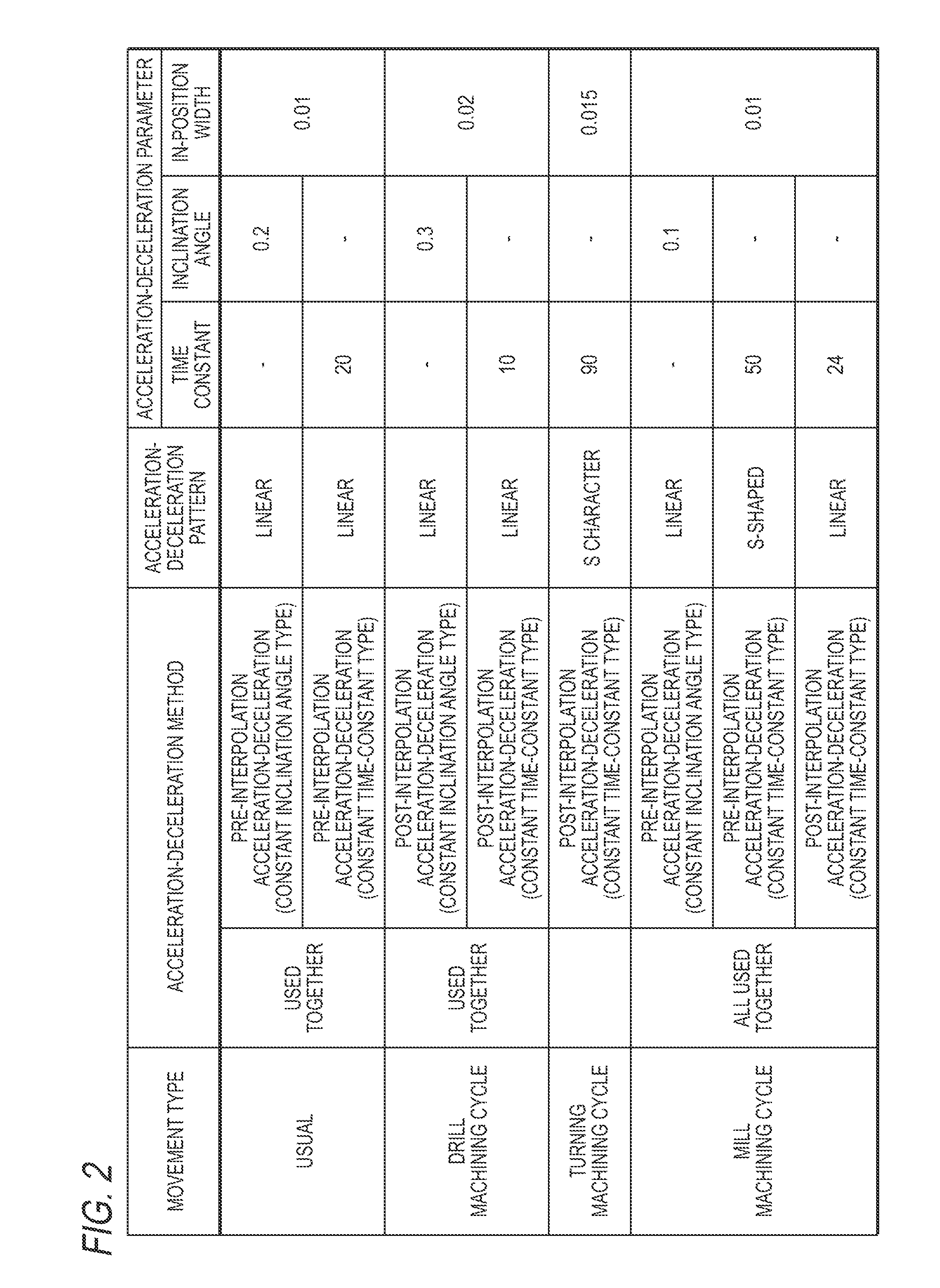

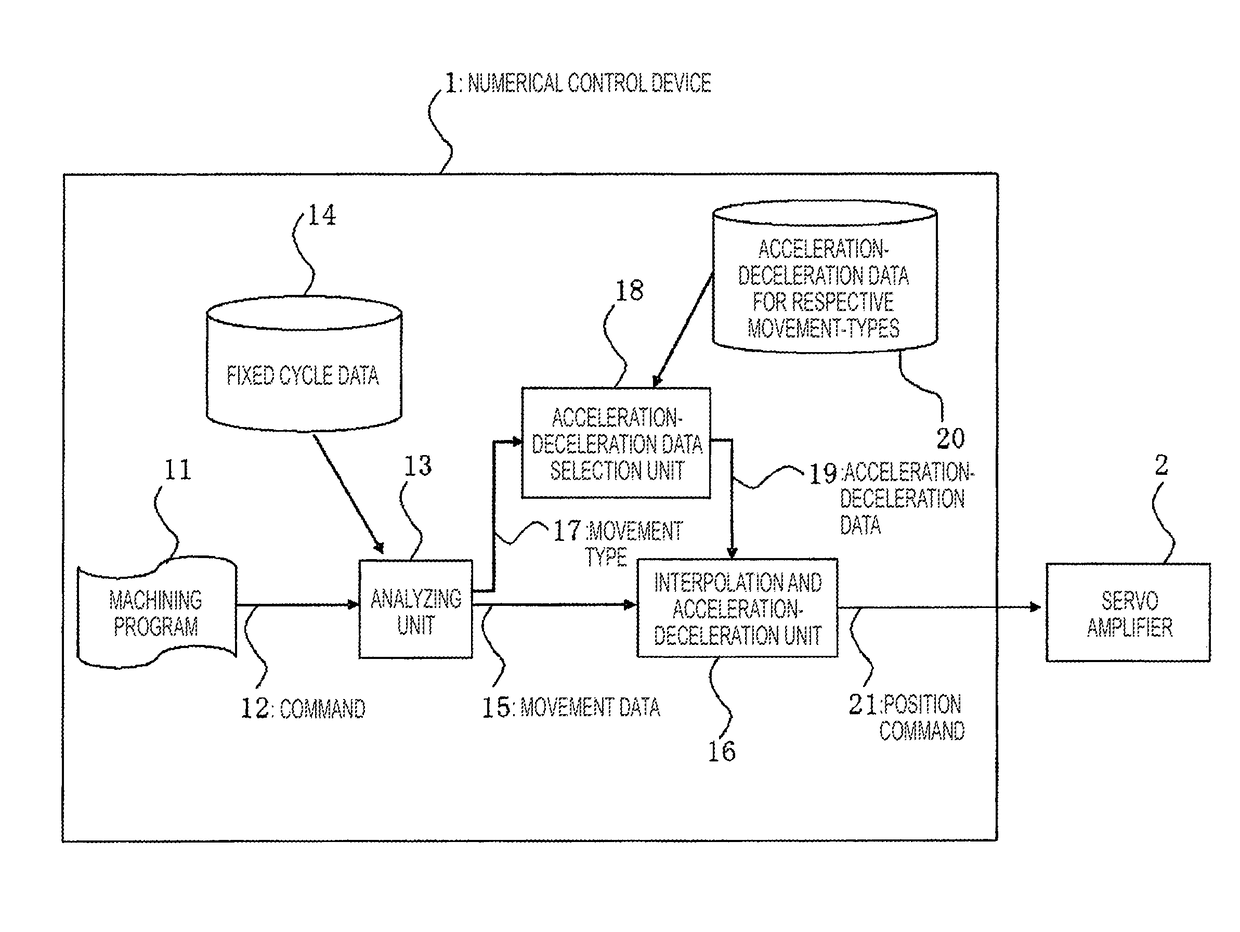

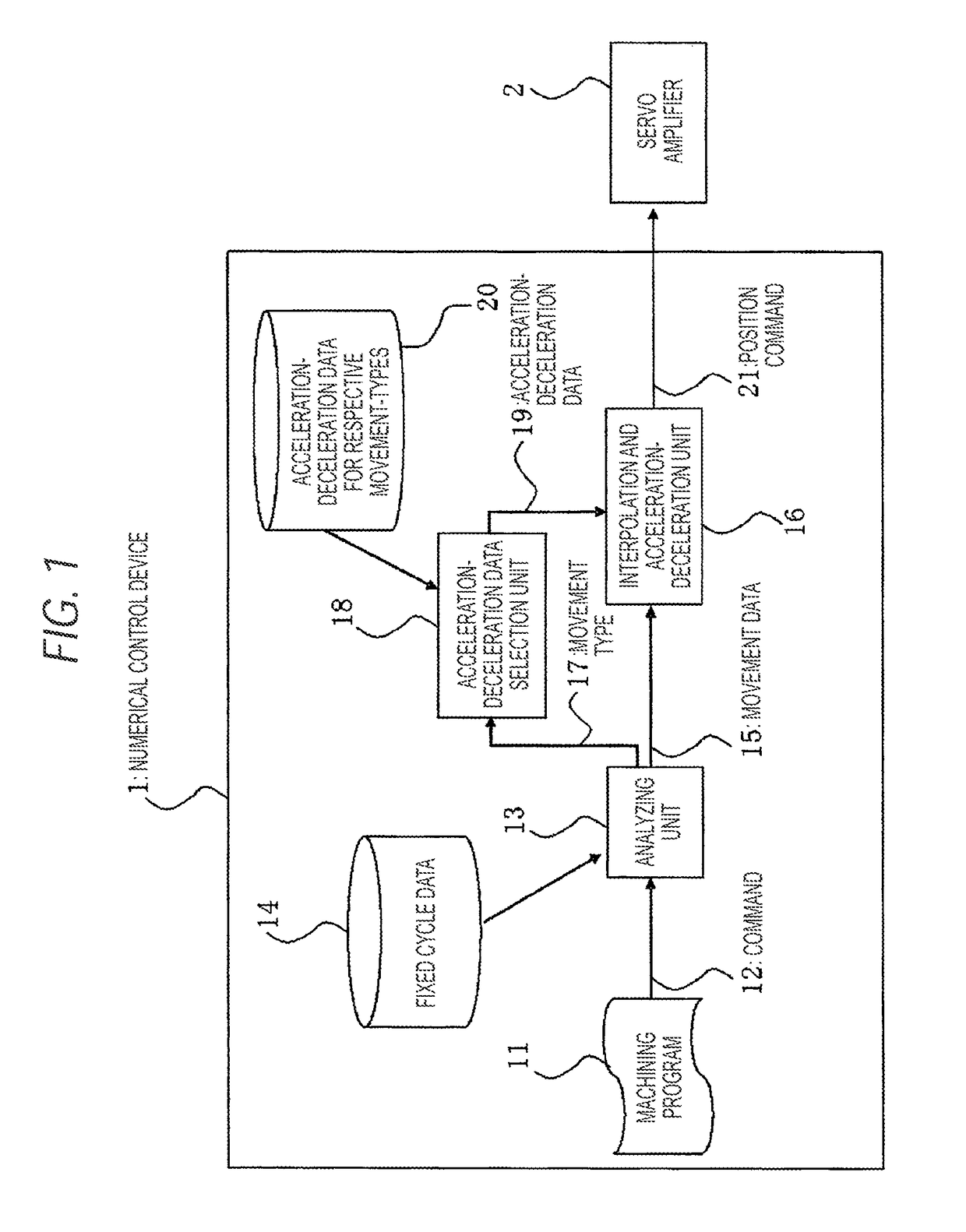

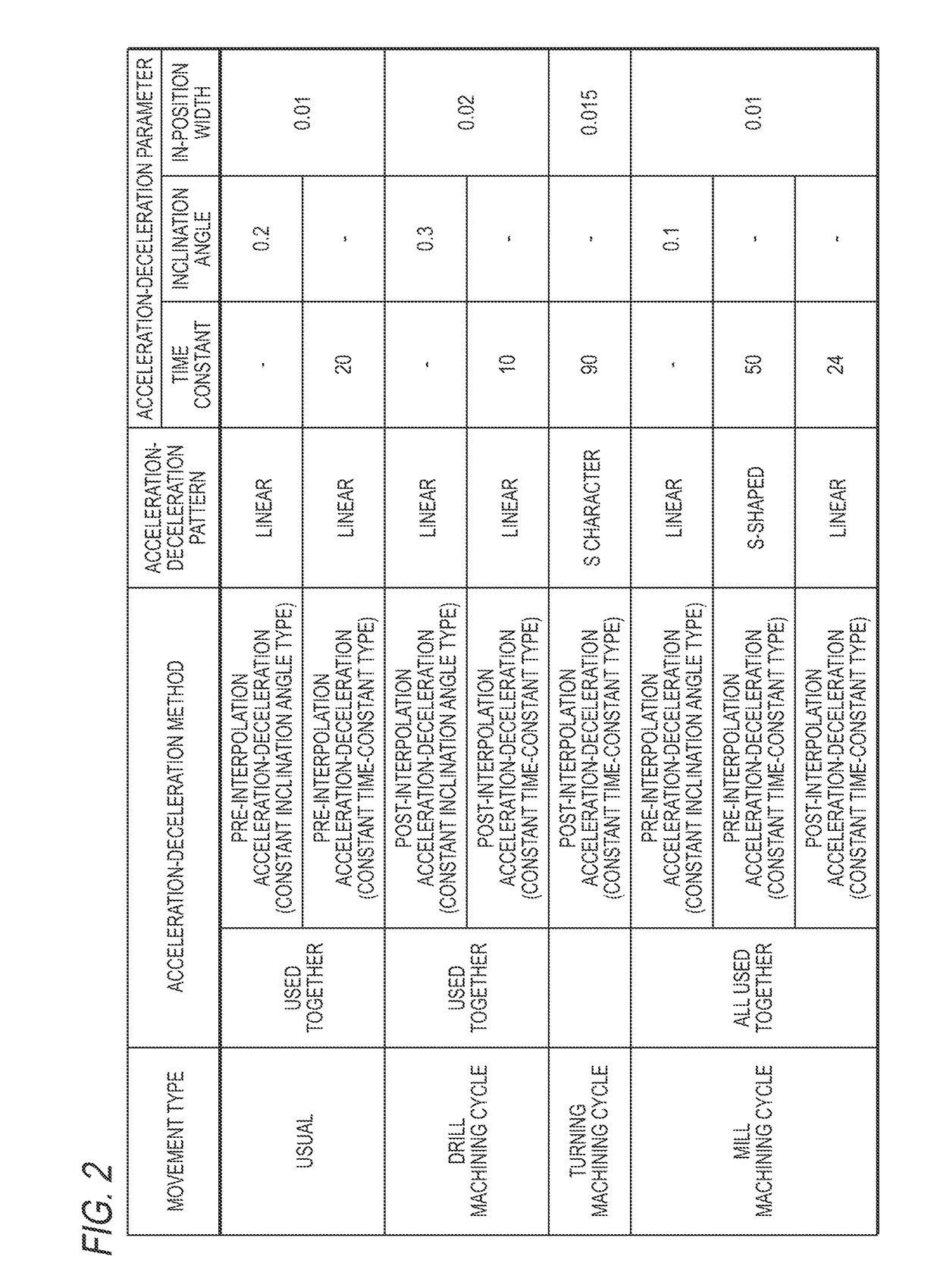

Numerical control device

ActiveUS20160091886A1Improve accuracyReduce processing timeSpecial data processing applicationsNumerical controlNumerical controlData selection

In a numerical control device 1 which controls positions of respective axes of a machine tool according to a machining program 11, a command 12 instructed to the machining program 11 is analyzed by an analyzing unit 13, thereby obtaining movement data 15 and a movement type 17, an acceleration-deceleration data selection unit 18 selects acceleration-deceleration data 19 according to the movement type 17, and an interpolation and acceleration-deceleration unit 16 generates a position command 21 by performing an interpolation on a movement route, which is instructed to the movement data 15, according to a command speed and performing acceleration-deceleration according to the acceleration-deceleration data 19.

Owner:MITSUBISHI ELECTRIC CORP

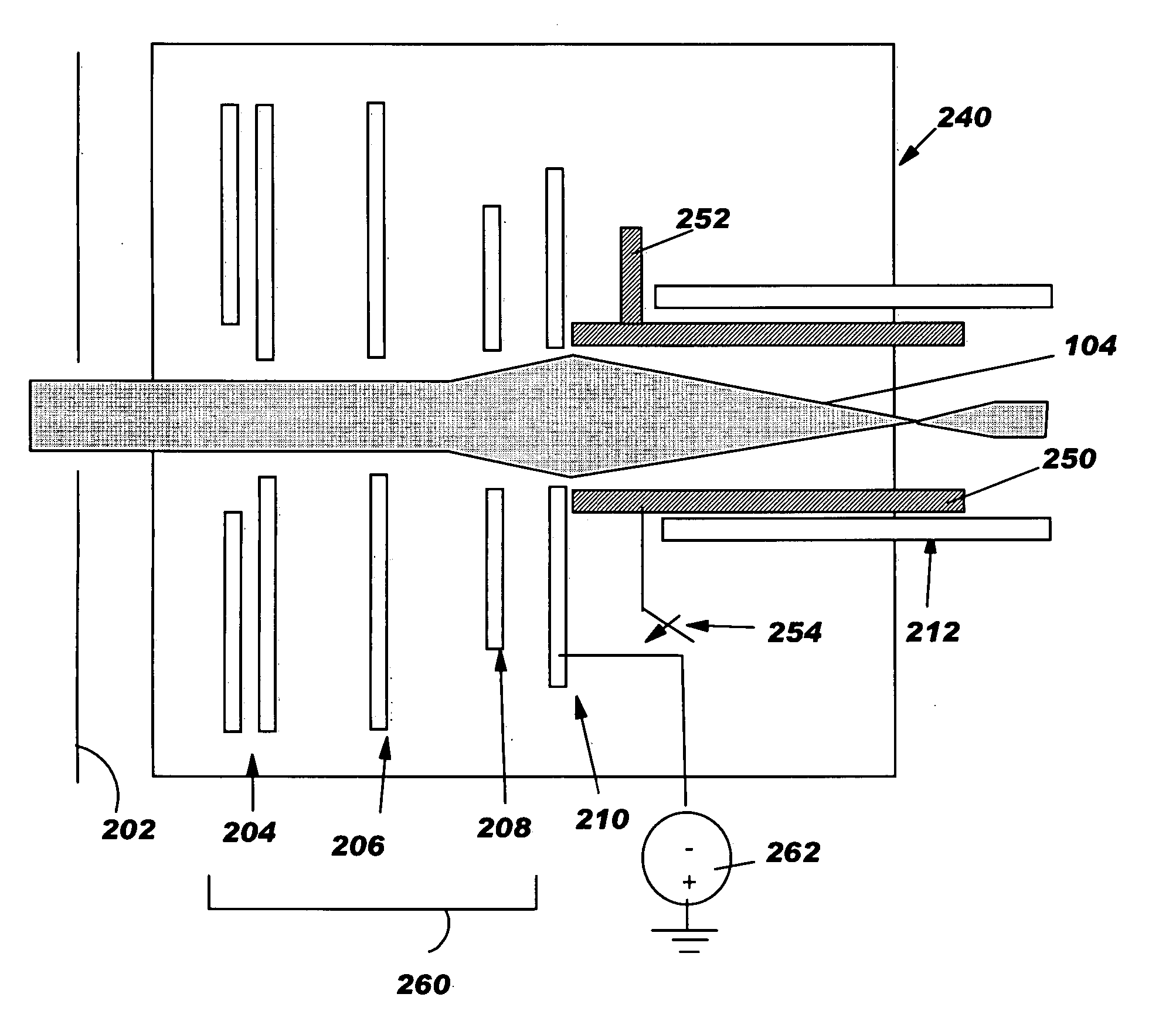

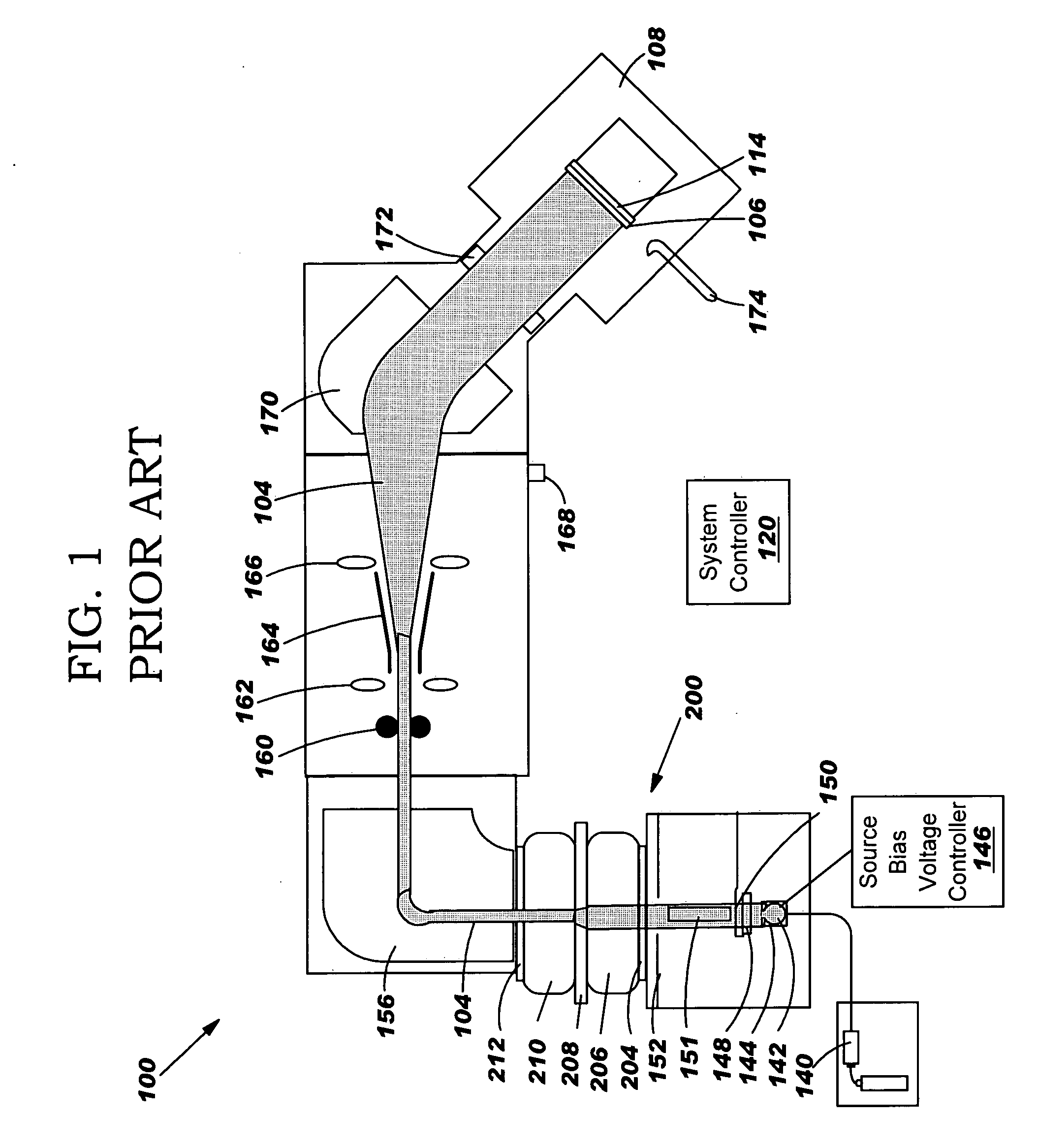

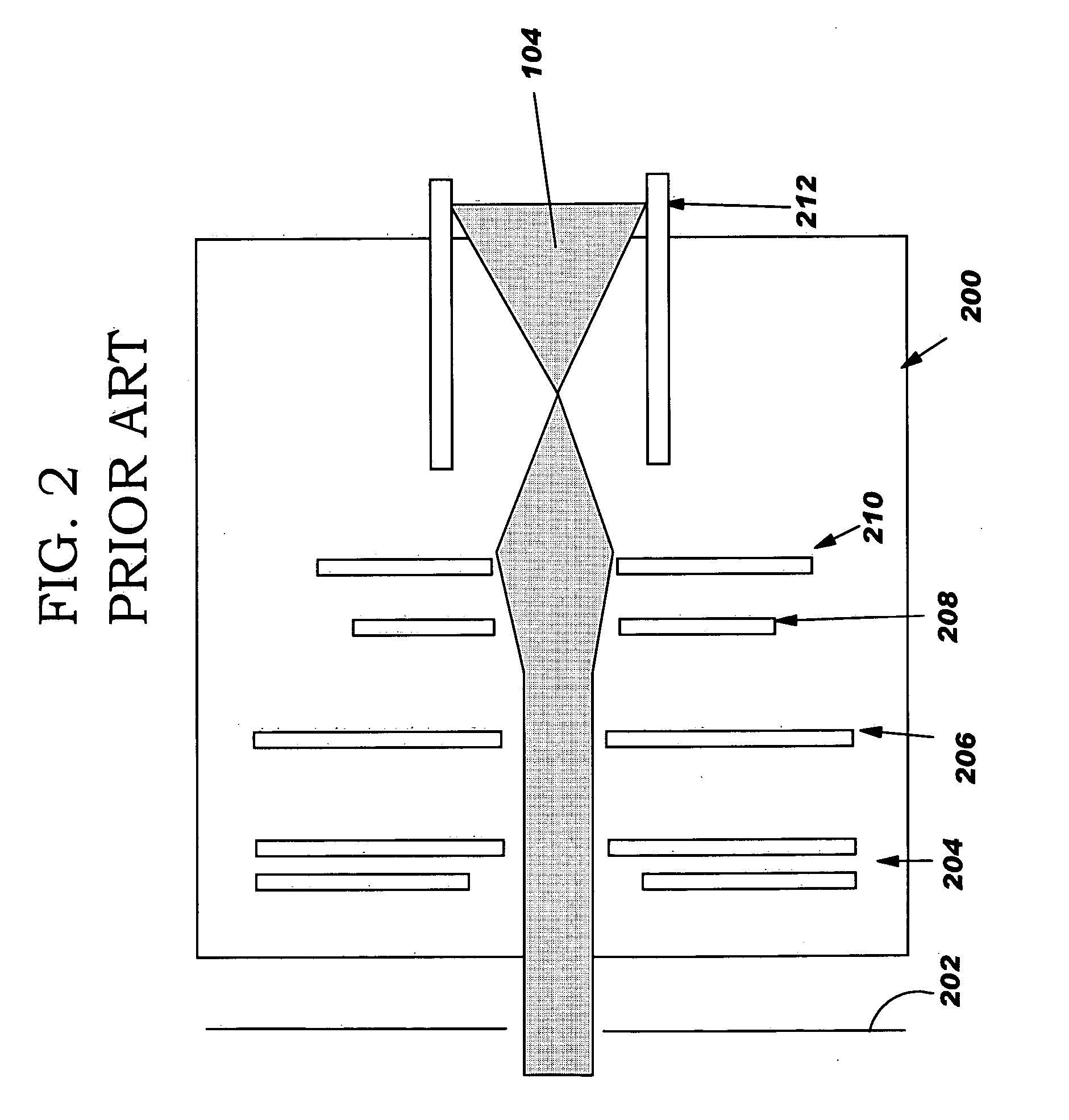

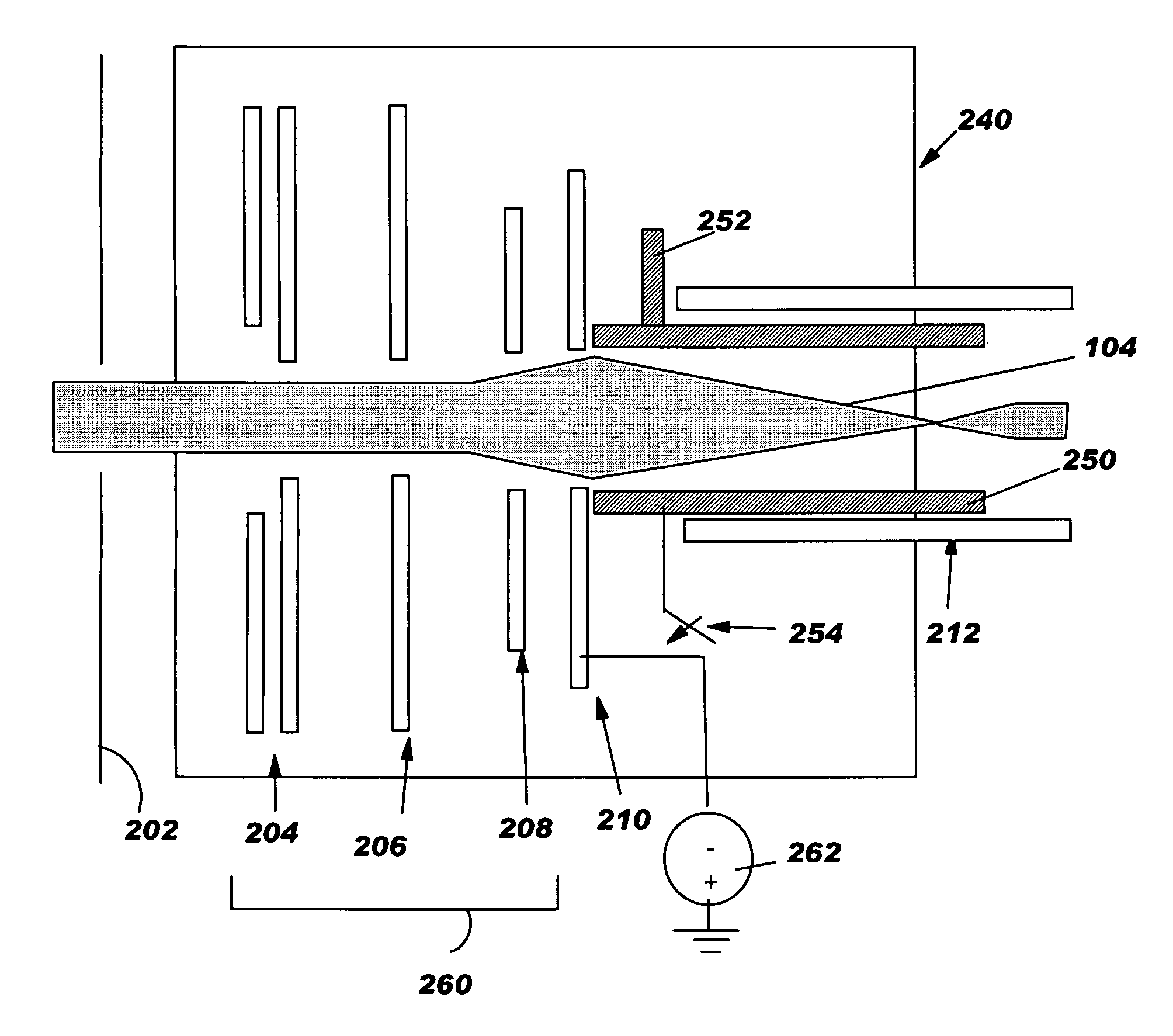

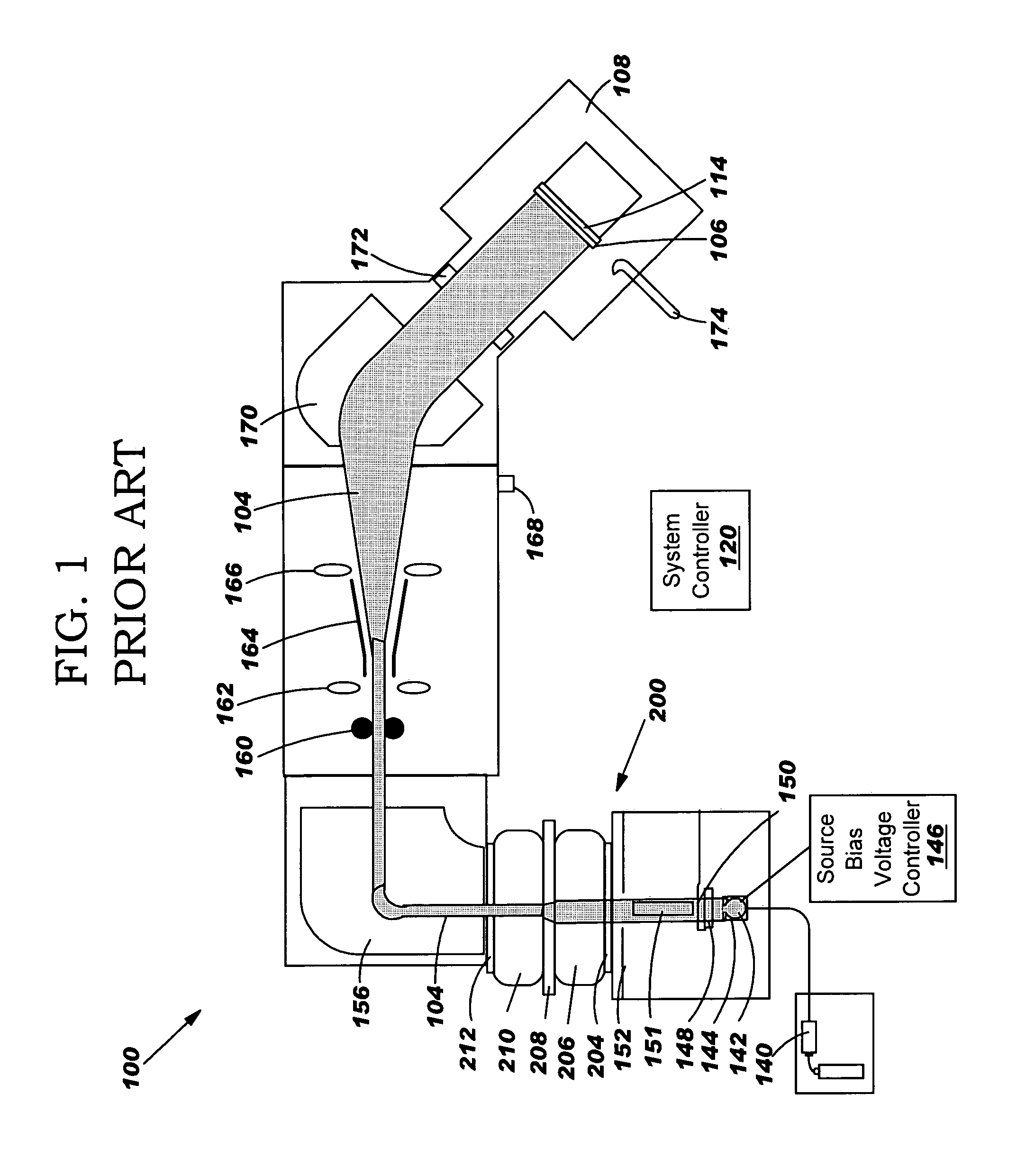

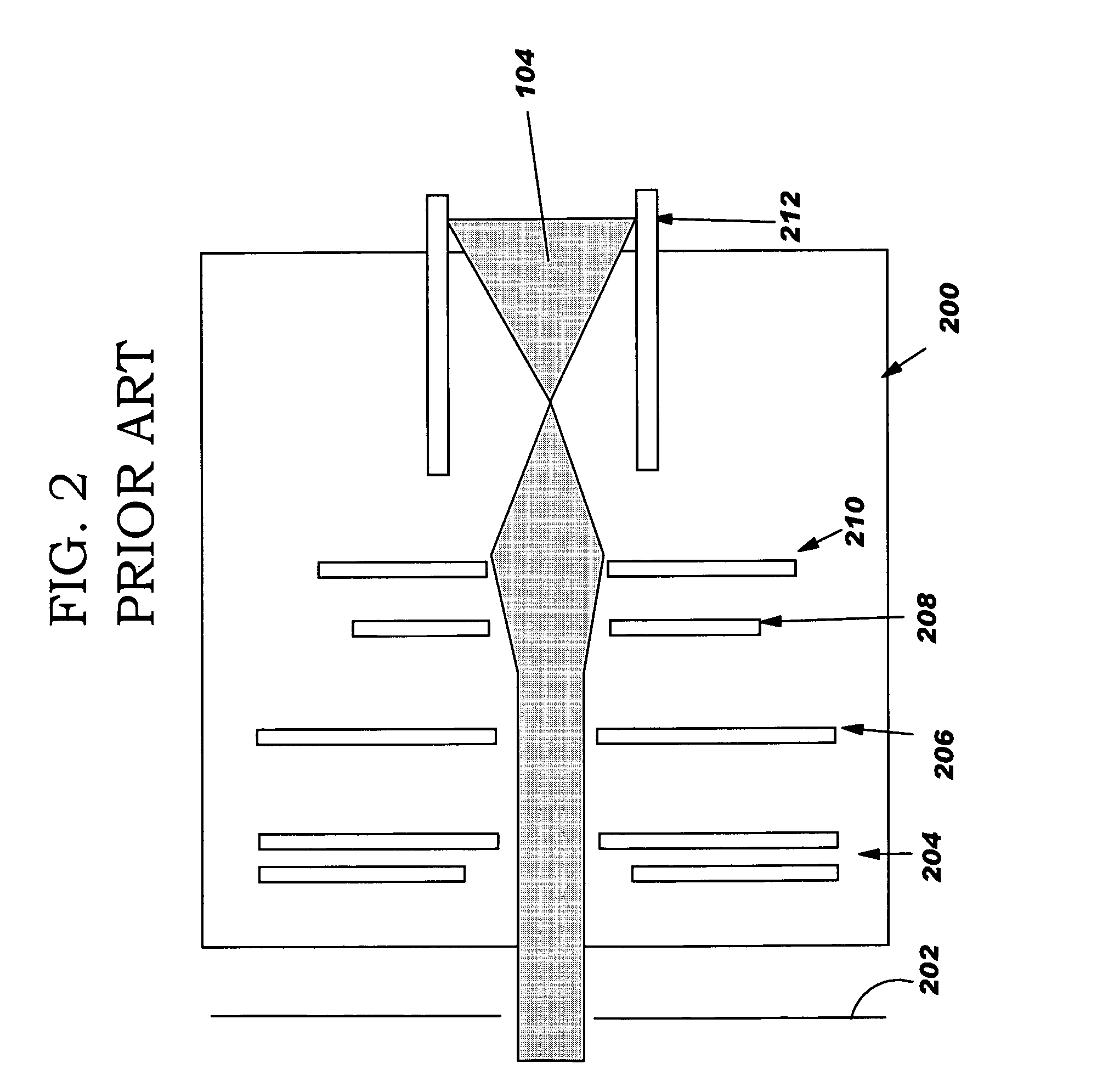

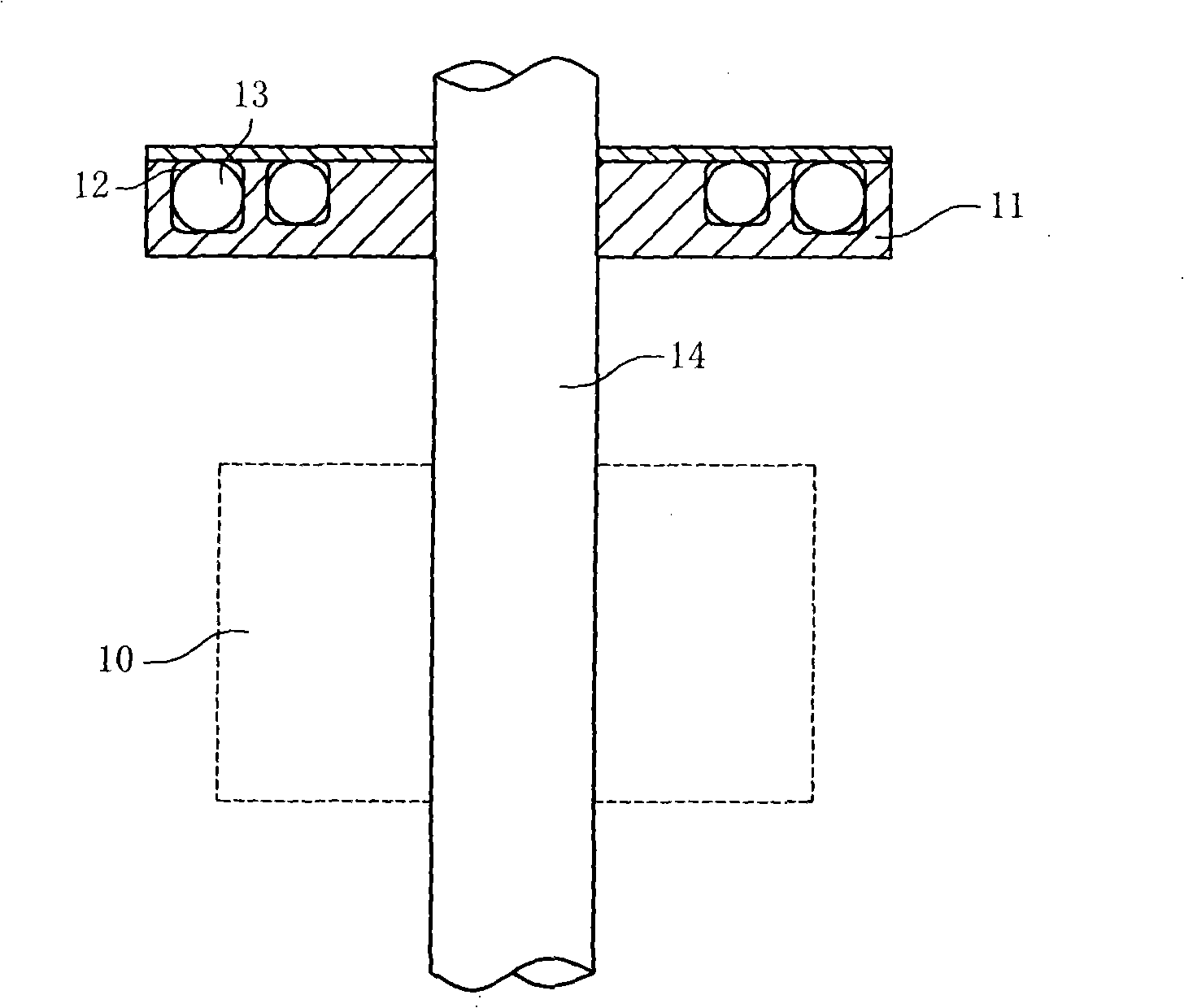

Weakening focusing effect of acceleration-deceleration column of ion implanter

ActiveUS20060108543A1Good effectReduce decreaseParticle separator tubesIsotope separationIon beamAcceleration deceleration

A method and apparatus for weakening a strong focus effect of an acceleration-deceleration column of an ion implanter during a deceleration mode are disclosed. The apparatus includes a tube lens surrounding the ion beam adjacent to a deceleration lens of the acceleration-deceleration column. The tube lens causes a defocusing of the ion beam at the entrance of the tube lens, which reduces the ion dispersion problem generated by the column. The invention also includes an accel-decel column and ion implanter incorporating the tube lens. An additional deceleration-suppression electrode may also be added subsequent to the tube lens for confining electrons within the tube lens.

Owner:VARIAN SEMICONUTOR EQUP

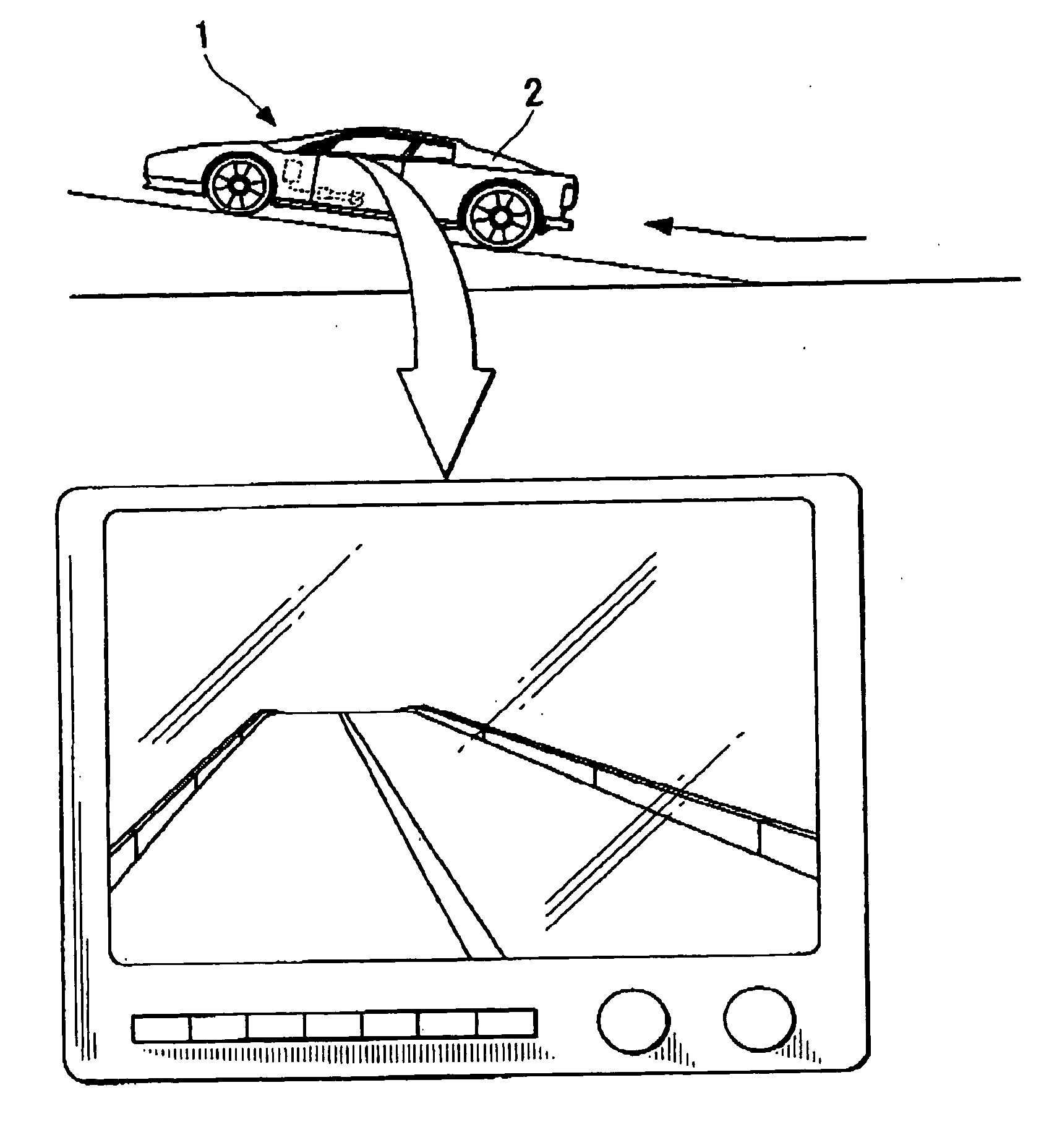

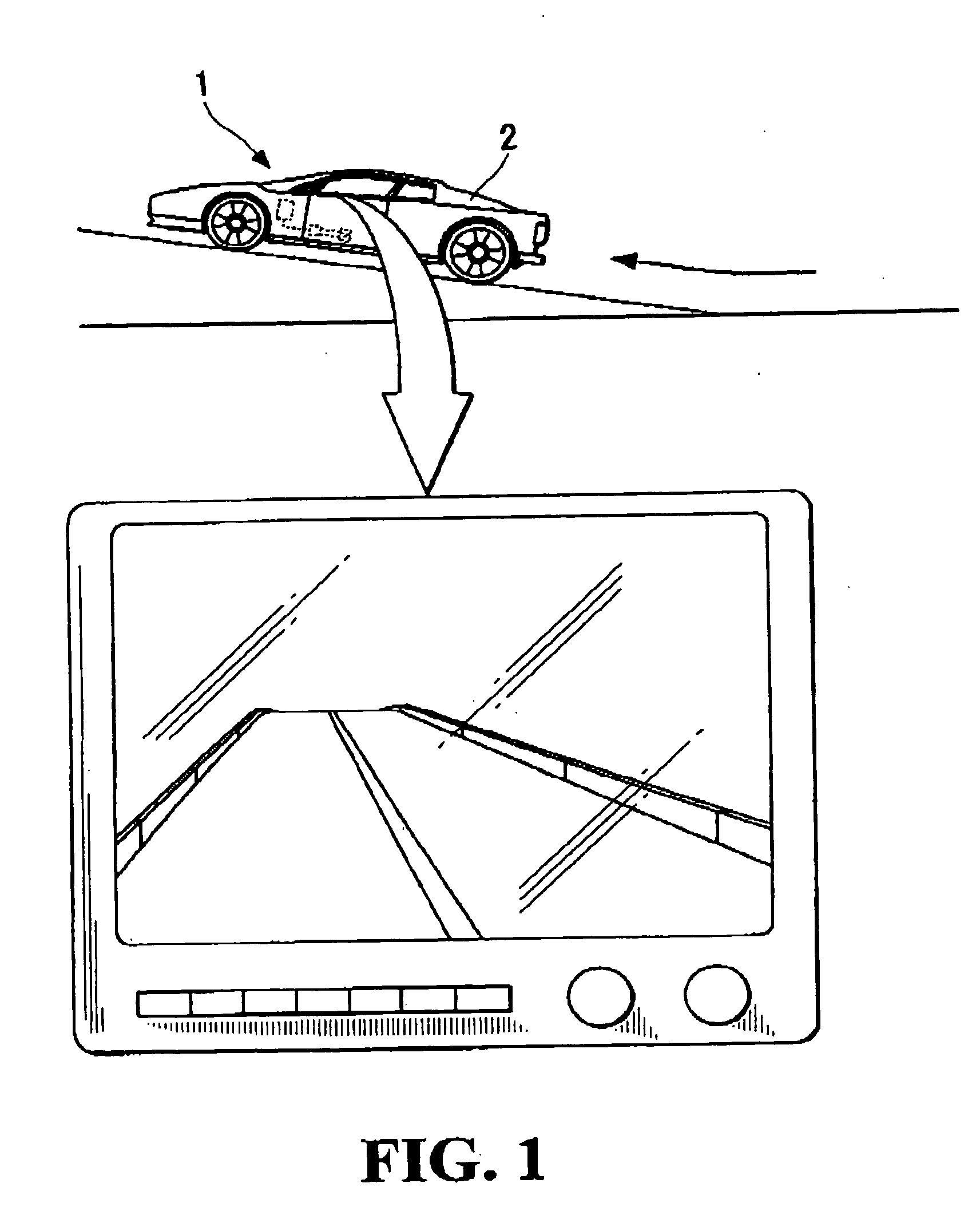

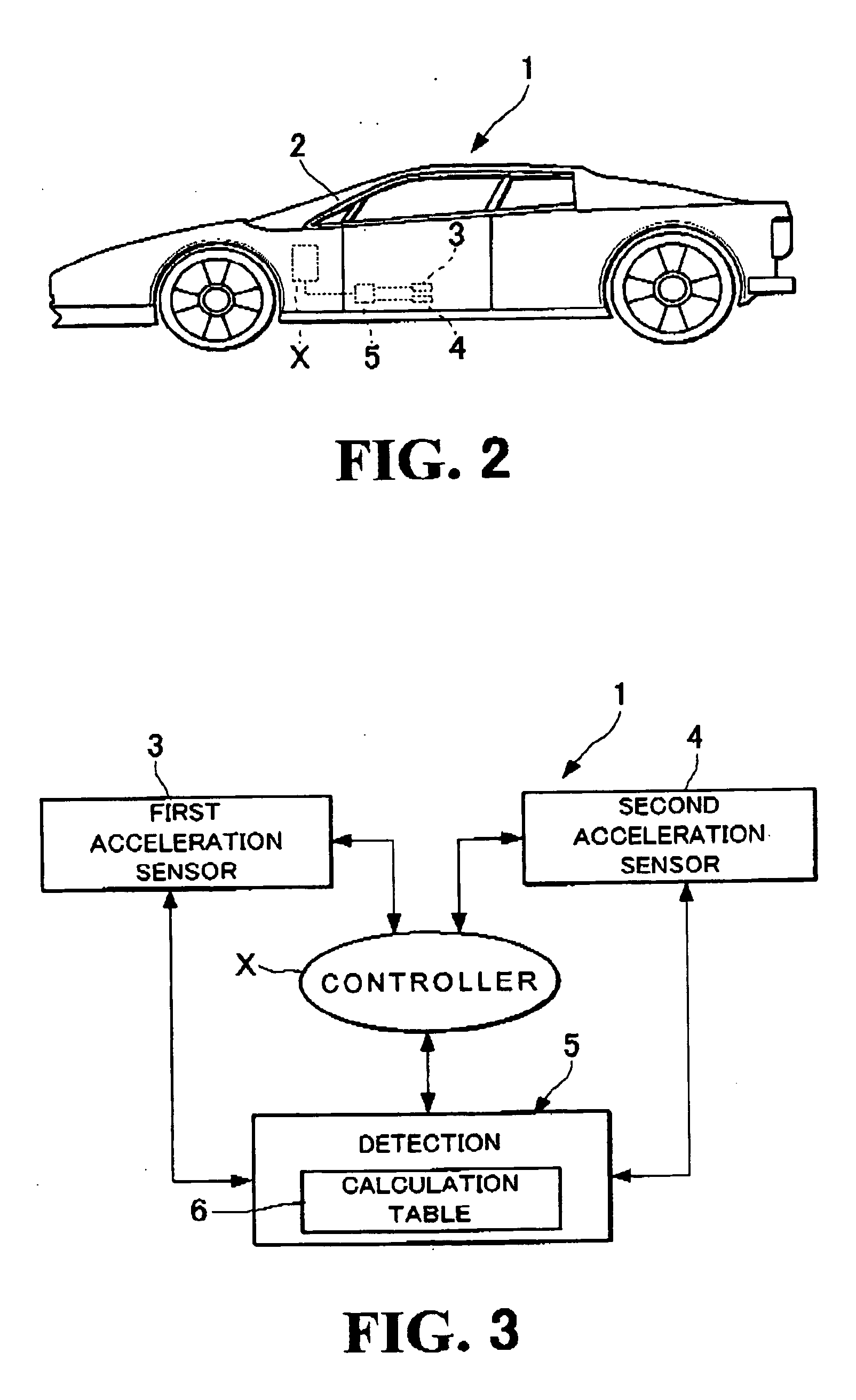

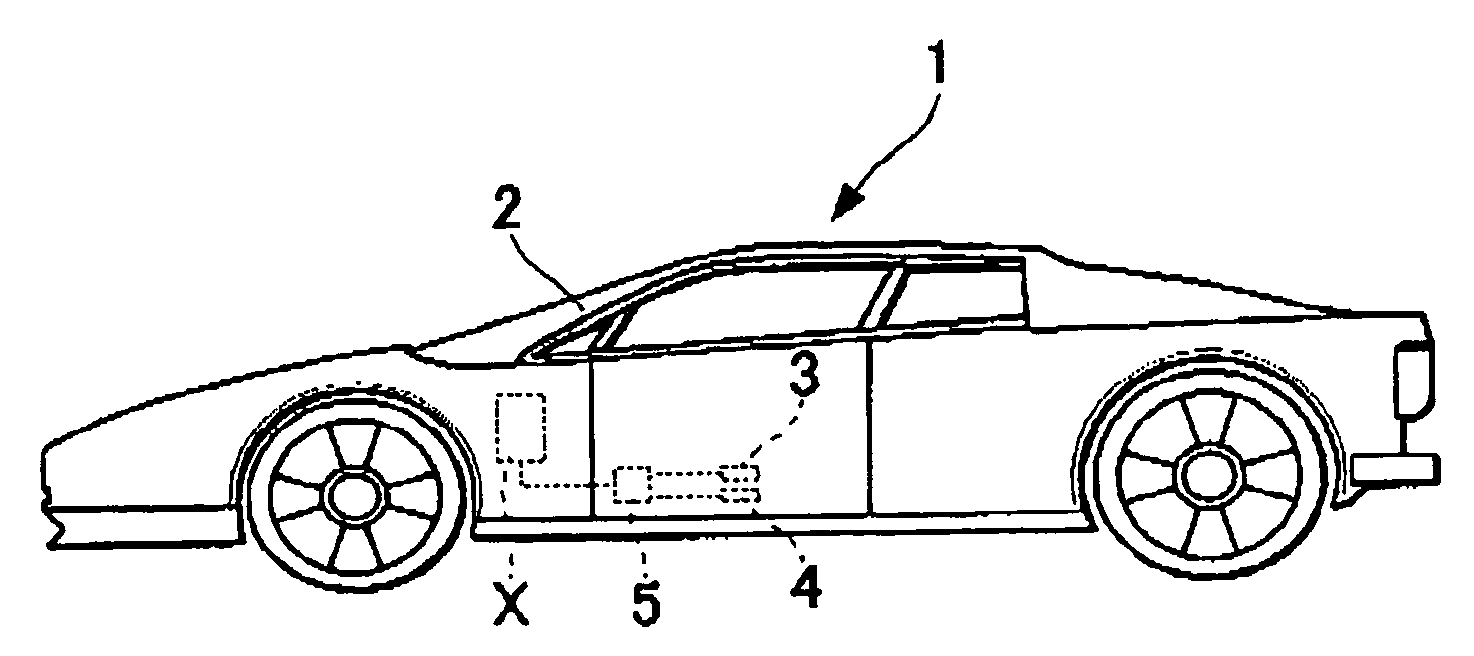

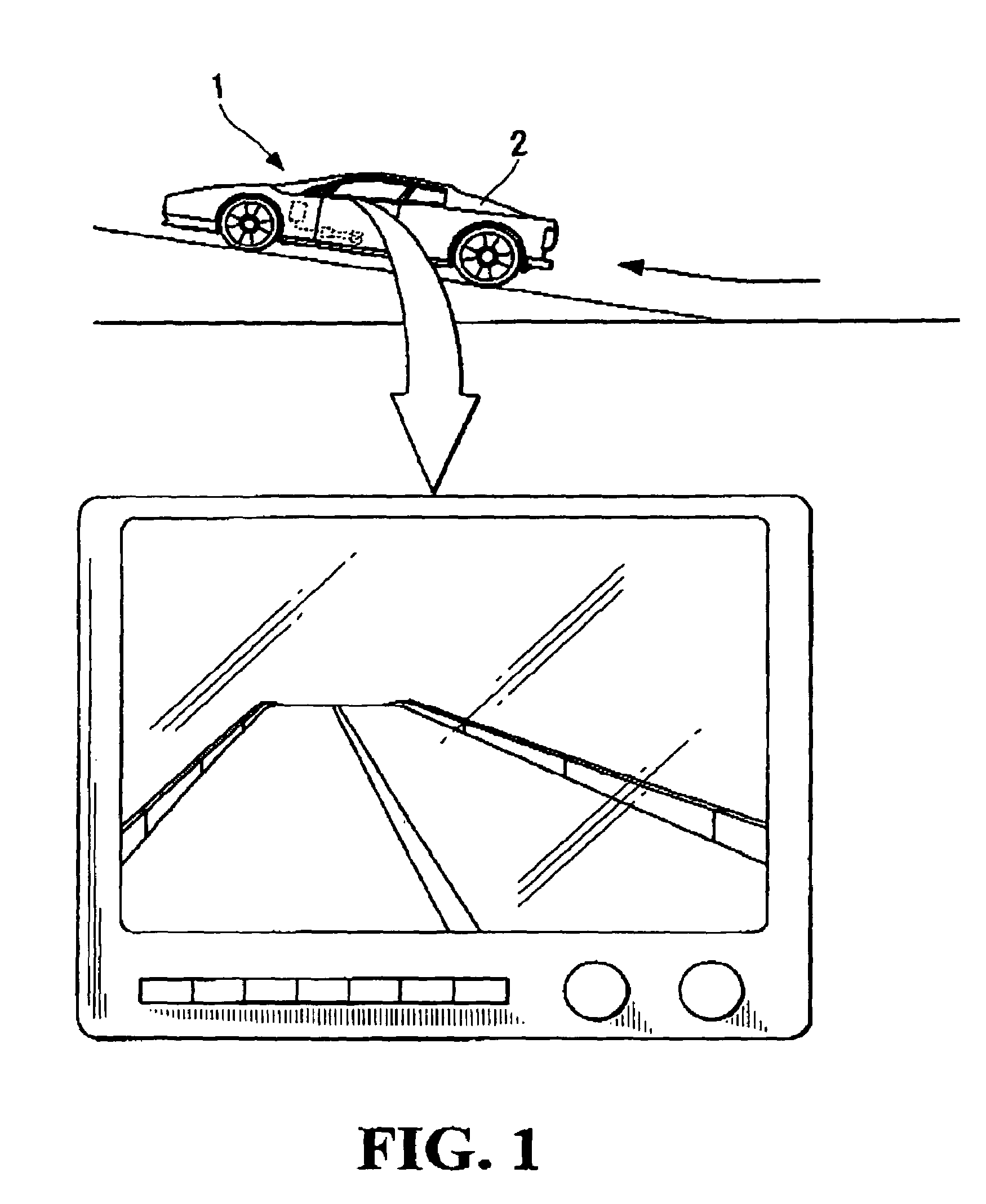

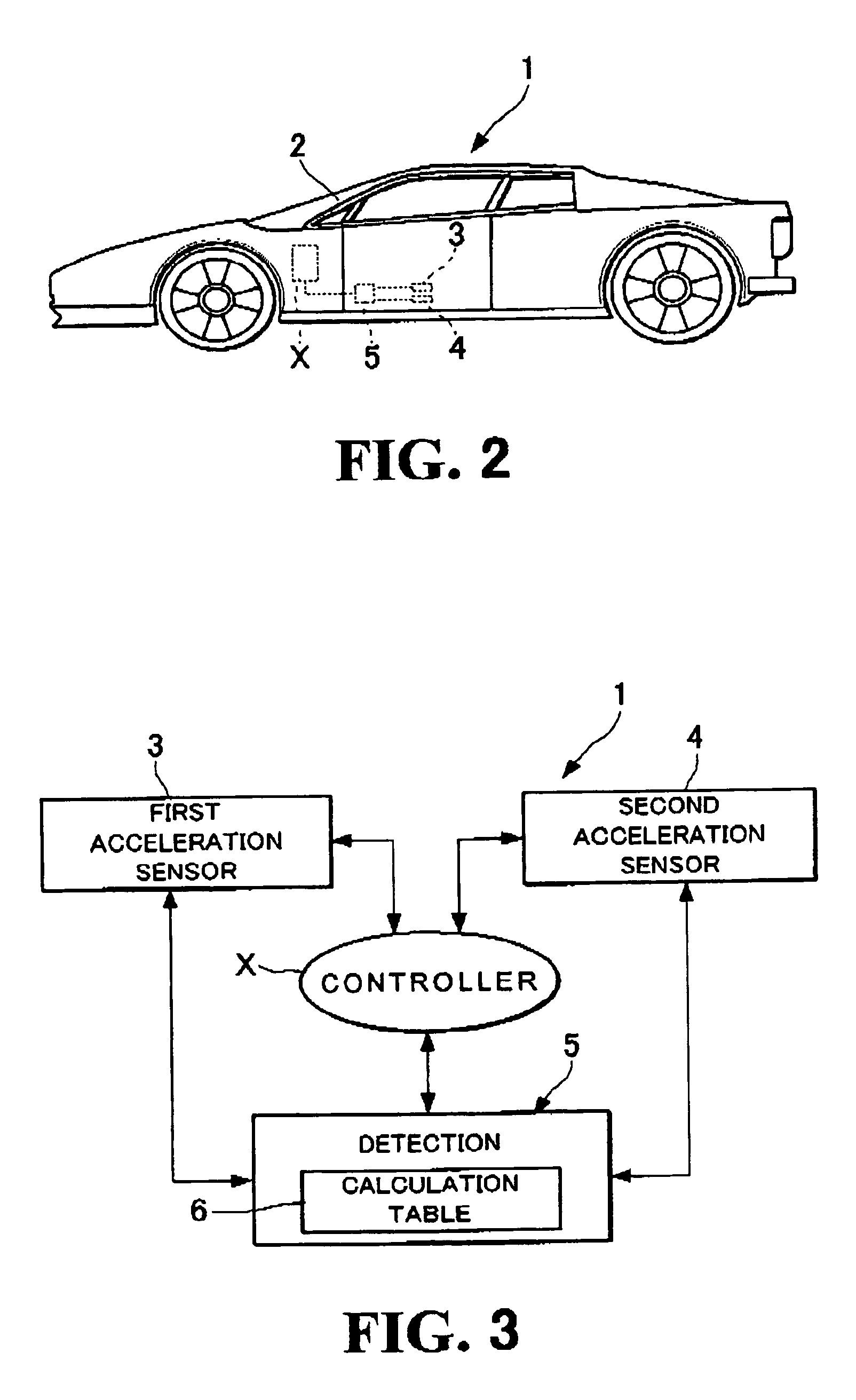

Device for detecting slope of vehicle or the like

InactiveUS20050078000A1Digital data processing detailsAnimal undercarriagesAcceleration decelerationGravitation

The slope detecting device includes means for detecting a horizontal acceleration of the vehicle; means for detecting perpendicular acceleration to the running direction of the horizontal detecting means; and means for detecting, attaching relatively to the horizontal detecting means and perpendicular detecting means, detecting the acceleration-deceleration the moving object by whether the sum of squares respectively which the acceleration detected by the horizontal detecting means and the acceleration detected by the perpendicular detecting means is equal to the second power of gravity acceleration, and calculating the slope of the vehicle in acceleration-deceleration so that it can detect the slope of vehicle in acceleration-deceleration as well as during running the vehicles at a constant speed.

Owner:MACNICA

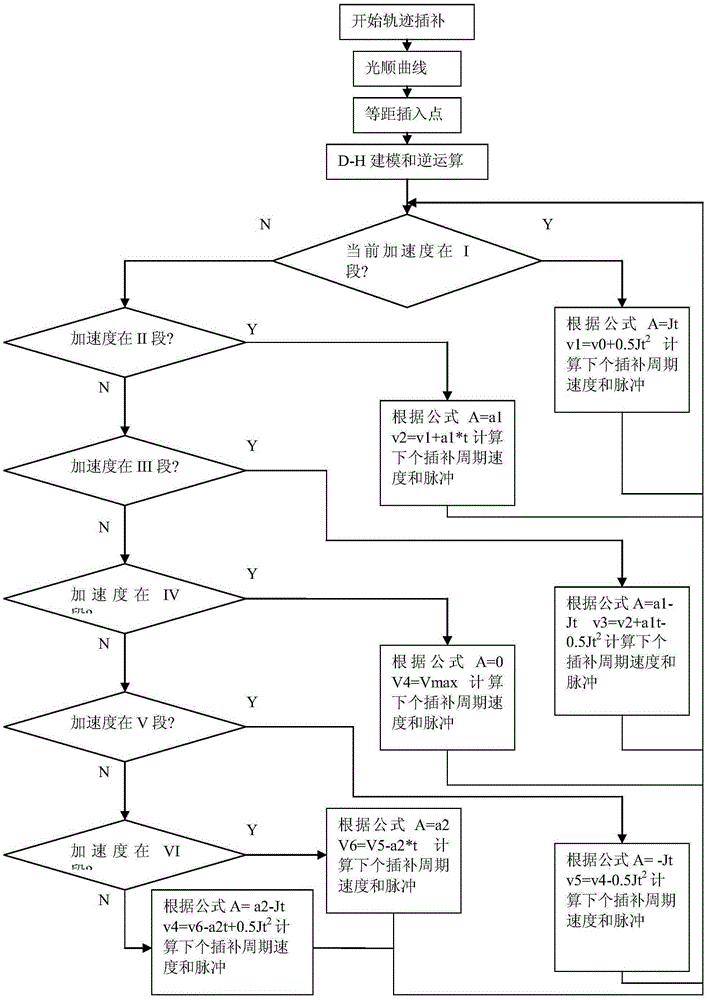

Acceleration-deceleration interpolation algorithm for robot control system trajectory

InactiveCN105278462AAcceleration changes continuouslyAcceleration time is shortProgramme controlComputer controlAcceleration decelerationInverse operation

The invention relates to an acceleration-deceleration interpolation algorithm for a robot control system trajectory. The acceleration-deceleration interpolation algorithm comprises the following steps: S1, smoothing curves: for interpolation trajectories, using cubic spline interpolation to smooth curves and calculating a function value at each node and derivative information at two boundaries; S2, inserting isometric points in a cubic spline curve calculated in the S1 and calculating the moving distance of each rotation axis through motion inverse operation after D-H modeling. According to the robot motion control method, S-shaped and linear acceleration and deceleration are adopted for accelerating and decelerating. The acceleration changes continuously, the time of acceleration is short, high motion precision and good speed smoothness are achieved. For interpolation trajectories, multiple spline interpolations are adopted as rough interpolations. Then digital integral method and equal time interpolations are adopted to perform fine interpolations for the interpolation trajectories. Due to the high V speed, the interpolation precision will not get poor.

Owner:CHONGQING LINGLONG AUTOMATION EQUIP CO LTD

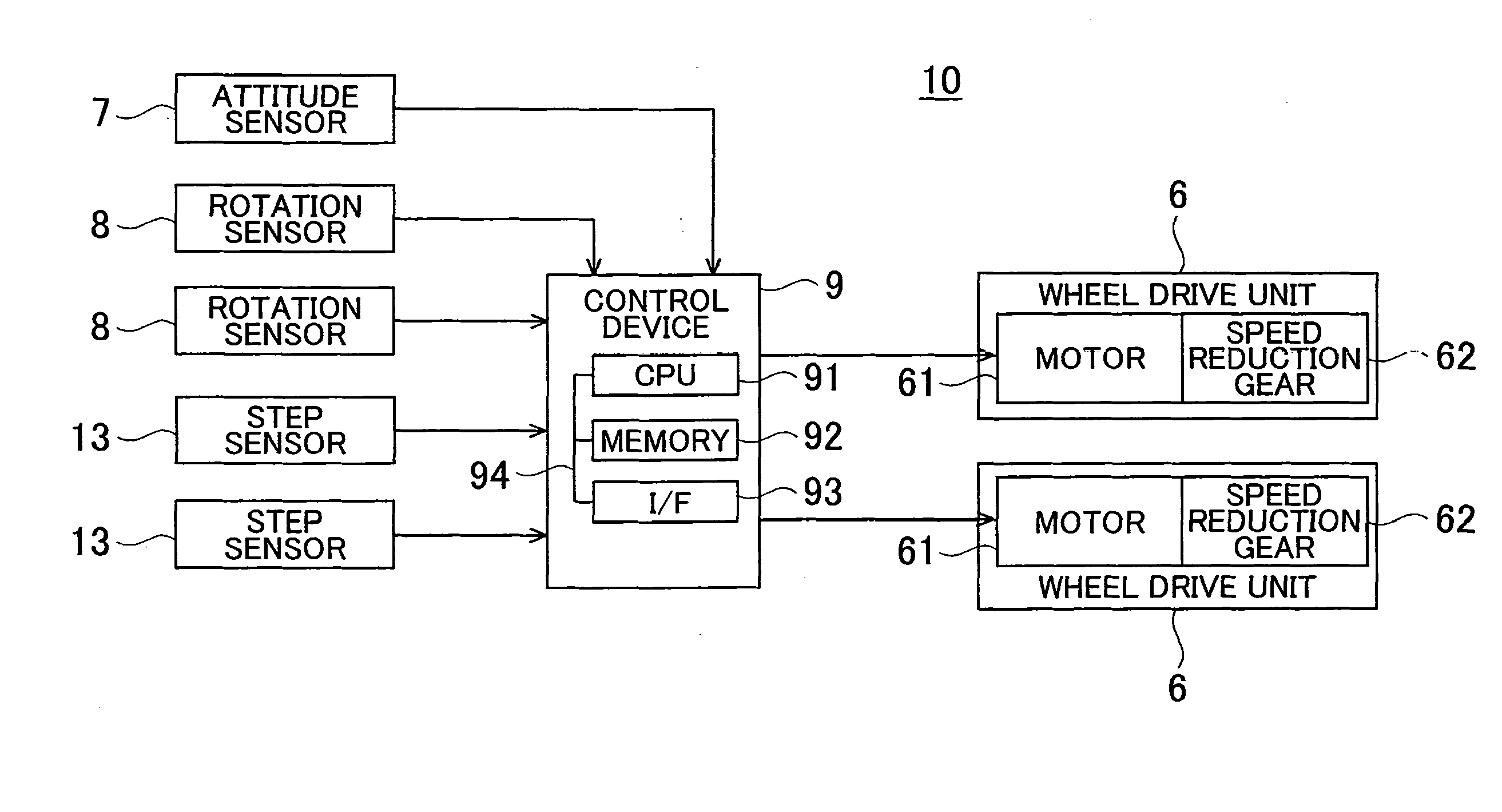

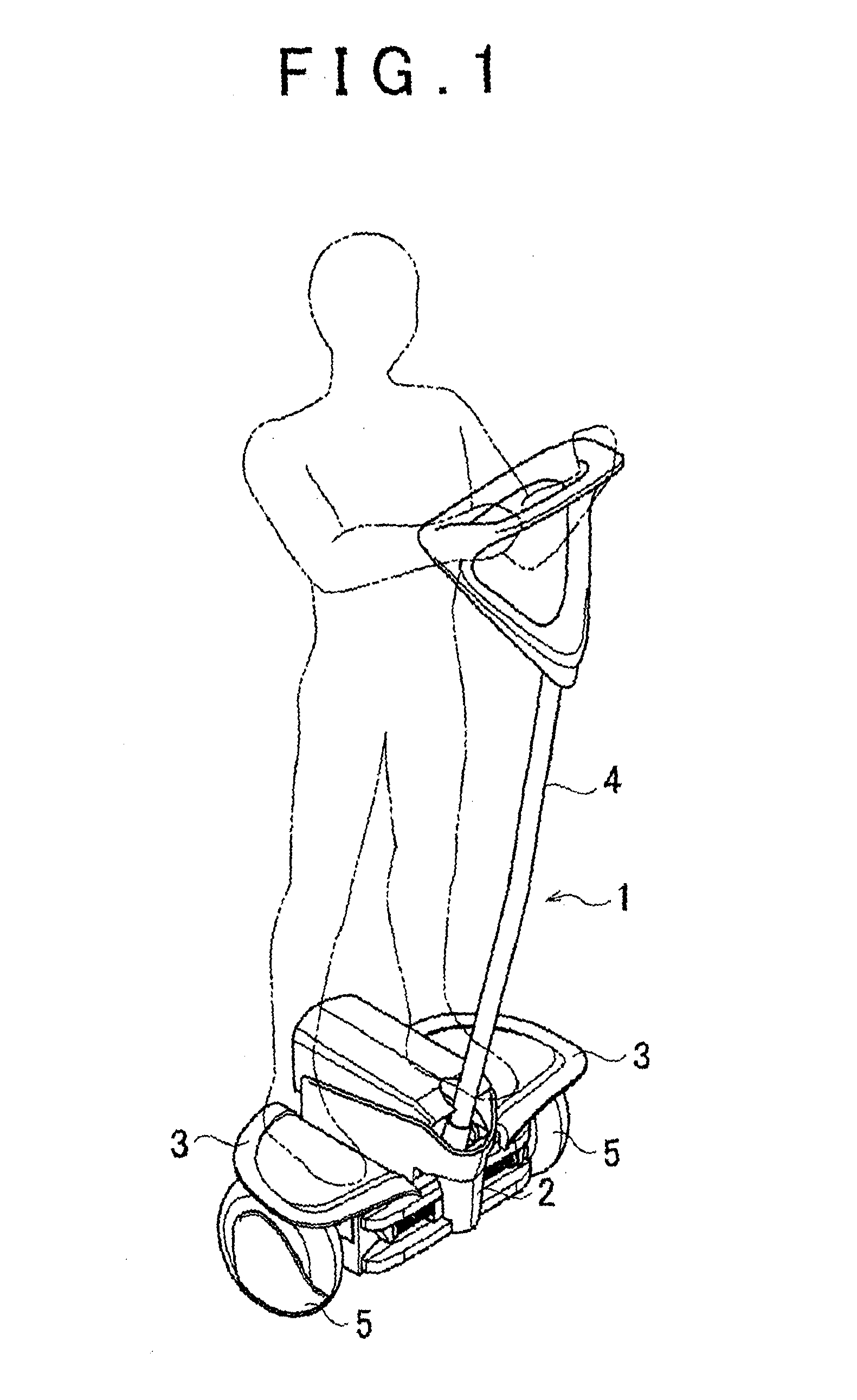

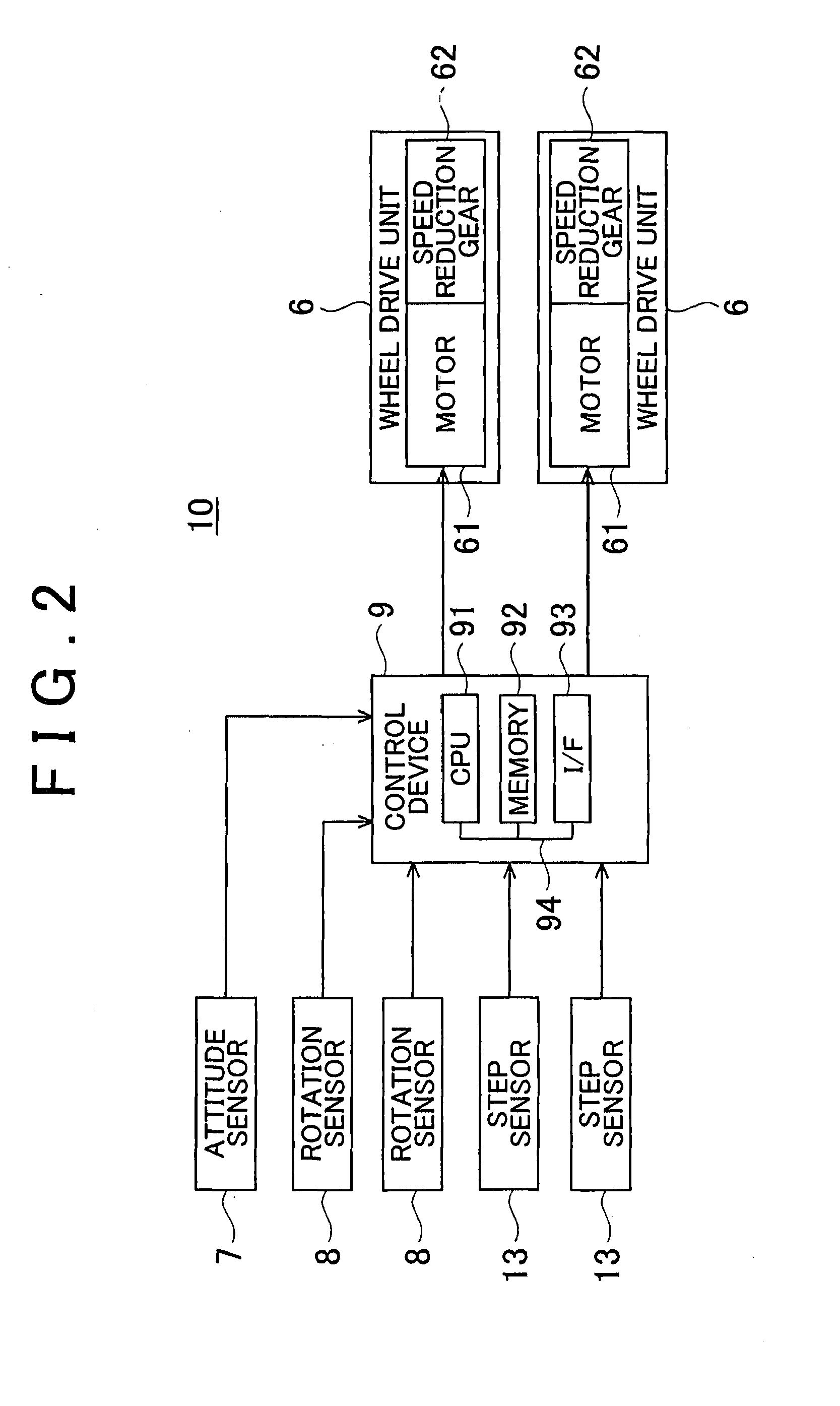

Moving body control device, moving body control method, and control program

ActiveUS20160059860A1Analogue computers for trafficComputations using stochastic pulse trainsAcceleration decelerationControl theory

A moving body control device includes an attitude angle detection section configured to detect ah attitude angle of an inverted moving body, a command value generation section configured to generate an attitude angular speed command value of the inverted moving body according to the attitude angle detected by the attitude angle detection section, a control section configured to control drive of the inverted moving body according to the attitude angular speed command value generated by the command value generation section, a determination section configured to make a determination whether or not the inverted moving body travels in a constant direction for a prescribed time or longer, and an acceleration-deceleration command section configured to increase or decrease the attitude angular speed command value generated by the command value generation section when the determination section makes a determination that travel is performed in the constant direction for the prescribed time or longer.

Owner:TOYOTA JIDOSHA KK

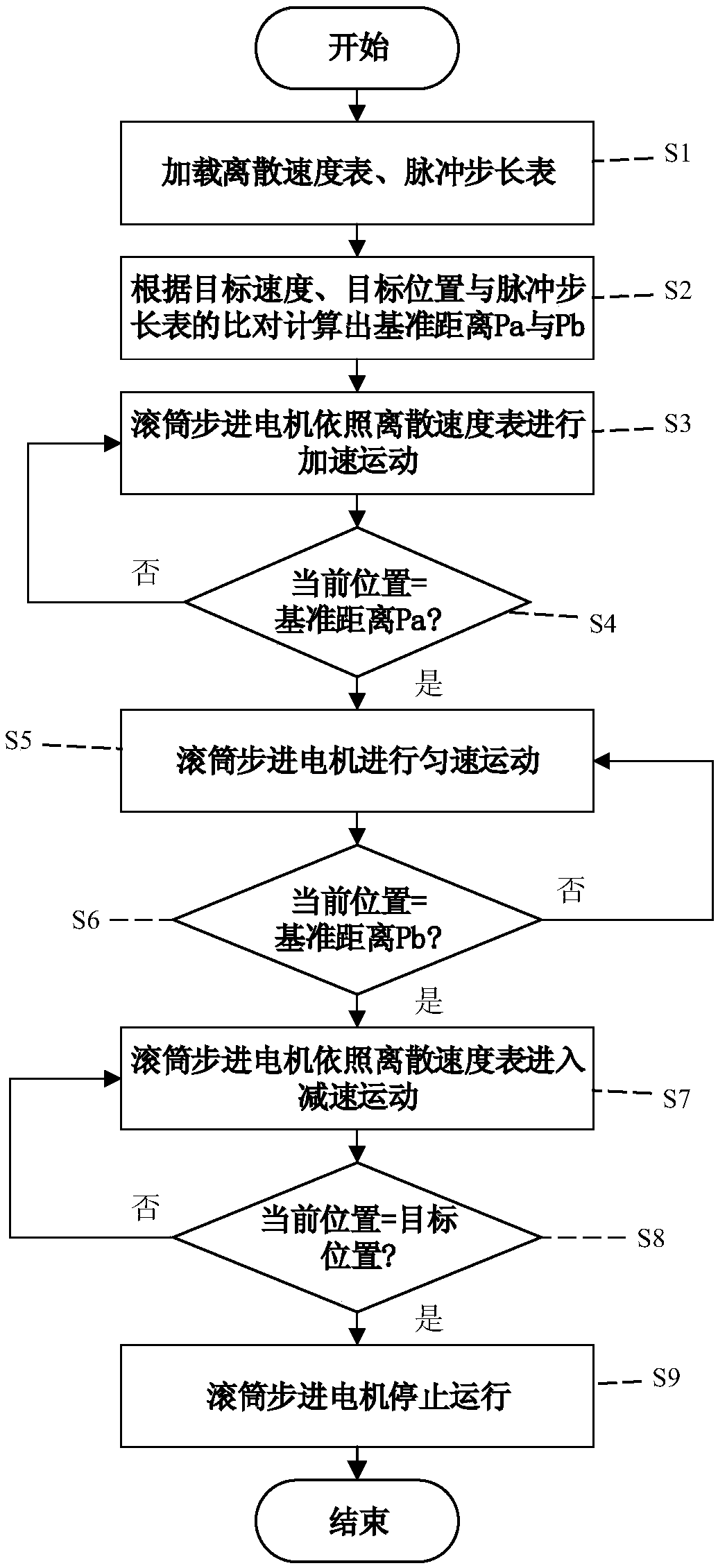

Method of controlling needle selection discrete speed for cylinder of intelligent glove machine

ActiveCN108396451AImprove real-time performanceShorten the timeWeft knittingAcceleration decelerationEngineering

A method of controlling needle selection discrete speed for a cylinder of an intelligent glove machine comprises the steps of 1) determining maximum sudden change velocity Delta vmax and minimum sudden change velocity Delta vmin that a step motor allows when the cylinder selects needles, according to the mechanical structure of the cylinder of the glove machine, type attribute of the step motor and a field test; 2) when acceleration is less than the maximum sudden change velocity Delta vmax, acquiring an acceleration table (a1, a2 to an) according to an acceleration-deceleration control algorithm; 3) setting startup velocity Vmin, planning period Delta t for the motor, and sequentially establishing a discrete velocity table (v1, v2 to v<n+1>) and a pulse step length table (p1, p2 to p<n+1>) in conjunction with the acceleration table (p1, p2 to p<n+1>); 4) comparing motion target distance l and target velocity Vp of the cylinder to the values in the discrete velocity table and the pulsestep length table, adjusting maximum velocity that the motor can reach actually, and planning an acceleration-deceleration curve of the step motor. The problem can be effectively solved that a cylinder step motor of an intelligent glove machine has low needle selection speed and easily experiences overload and step-out in case of high-speed motion and frequent acceleration and deceleration.

Owner:ZHEJIANG UNIV OF TECH

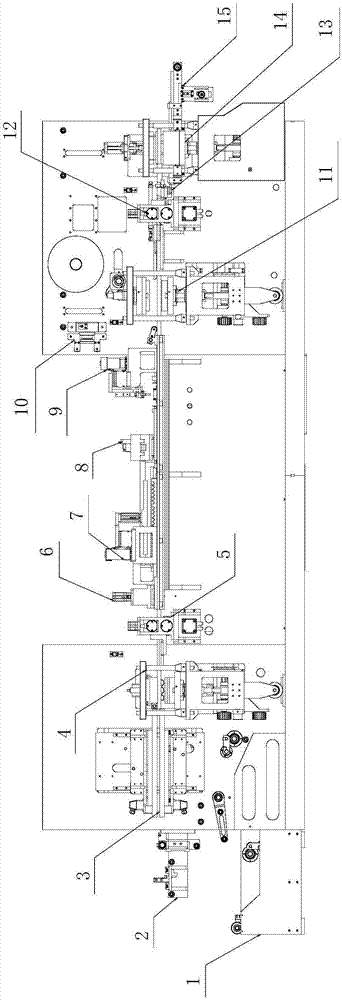

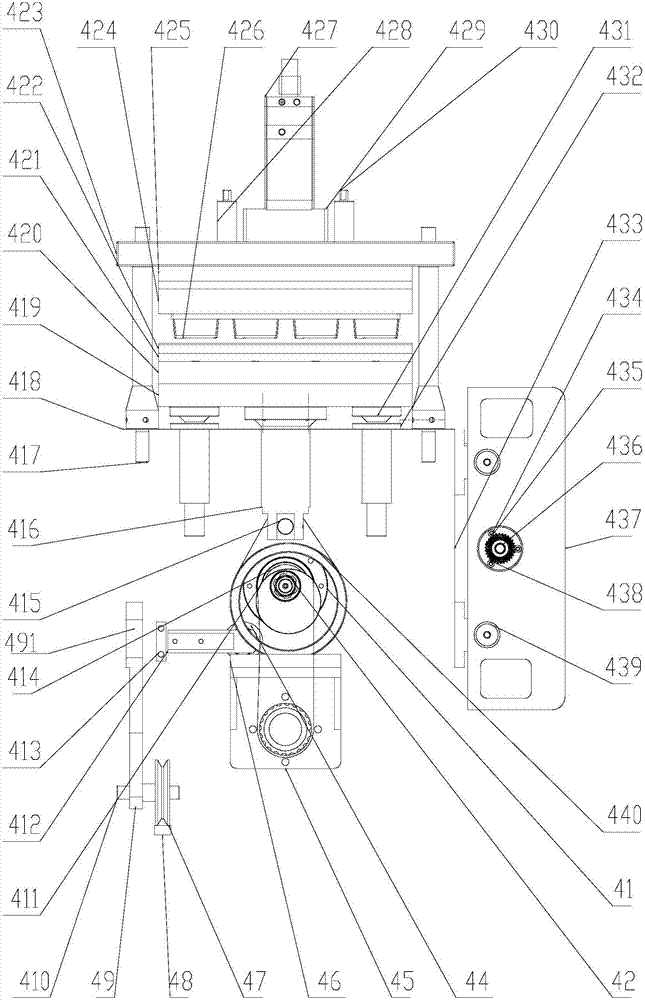

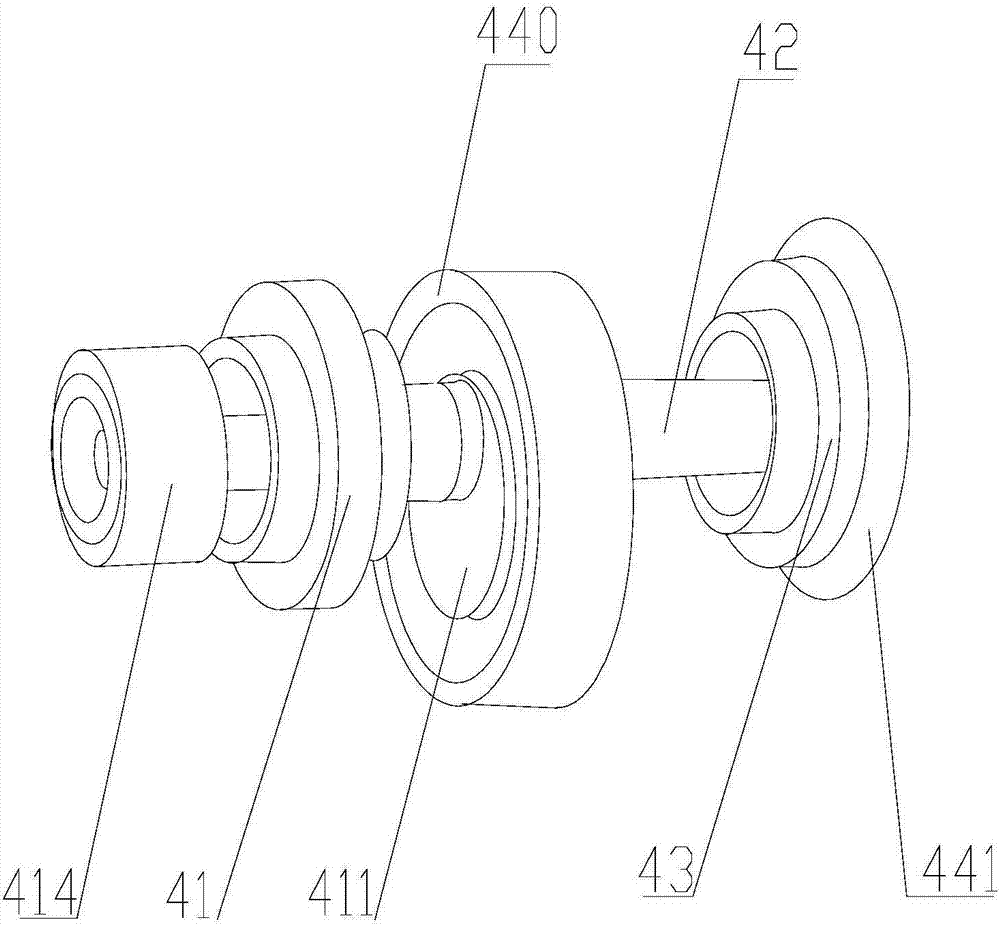

High-speed aluminum-plastic bubble cap machine

ActiveCN107458645AAdjustable strokeEasy to packWrapping material feeding apparatusWrappingAcceleration decelerationElectric machinery

The invention belongs to the technical field of packaging, and particularly relates to a high-speed aluminum-plastic bubble cap machine. According to the high-speed aluminum-plastic bubble cap machine, tablets, capsules, ampoule bottle and other similar materials can be packaged in a plurality of specifications, and good packaging effect is effectively guaranteed; forming cam mechanism serves as a transmission mechanism through a servo motor and a precise cam mechanism, a pure mechanical cam mechanism is replaced, the constraint of mechanical transmission is avoided, the forming speed and stability are increased, automatic compression and automatic forming of the packaging material can be realized, wherein both the compression force and the forming depth can be adjusted, and the problem that the packaging material cannot reach the standard and the raw materials are wasted due to inaccurate positioning between the upper mold and the lower mold is solved; and the vibration-proof acceleration deceleration blanking mechanism is provided with a rotating-sequence suction head mechanism which can effectively prevent section blocks from being clamped in concave molds, the normal operation of the whole machine is guaranteed, pressure plate air pipes enable the section blocks to be slowly descended, the situation that the section blocks due to the gravity of bottles at the moment when being punched fall on a conveying belt of an outlet is avoided, the anti-vibration and anti-inclination effects can be achieved, the damage can be reduced, and the production cost can be saved.

Owner:江苏特富丹机械有限公司

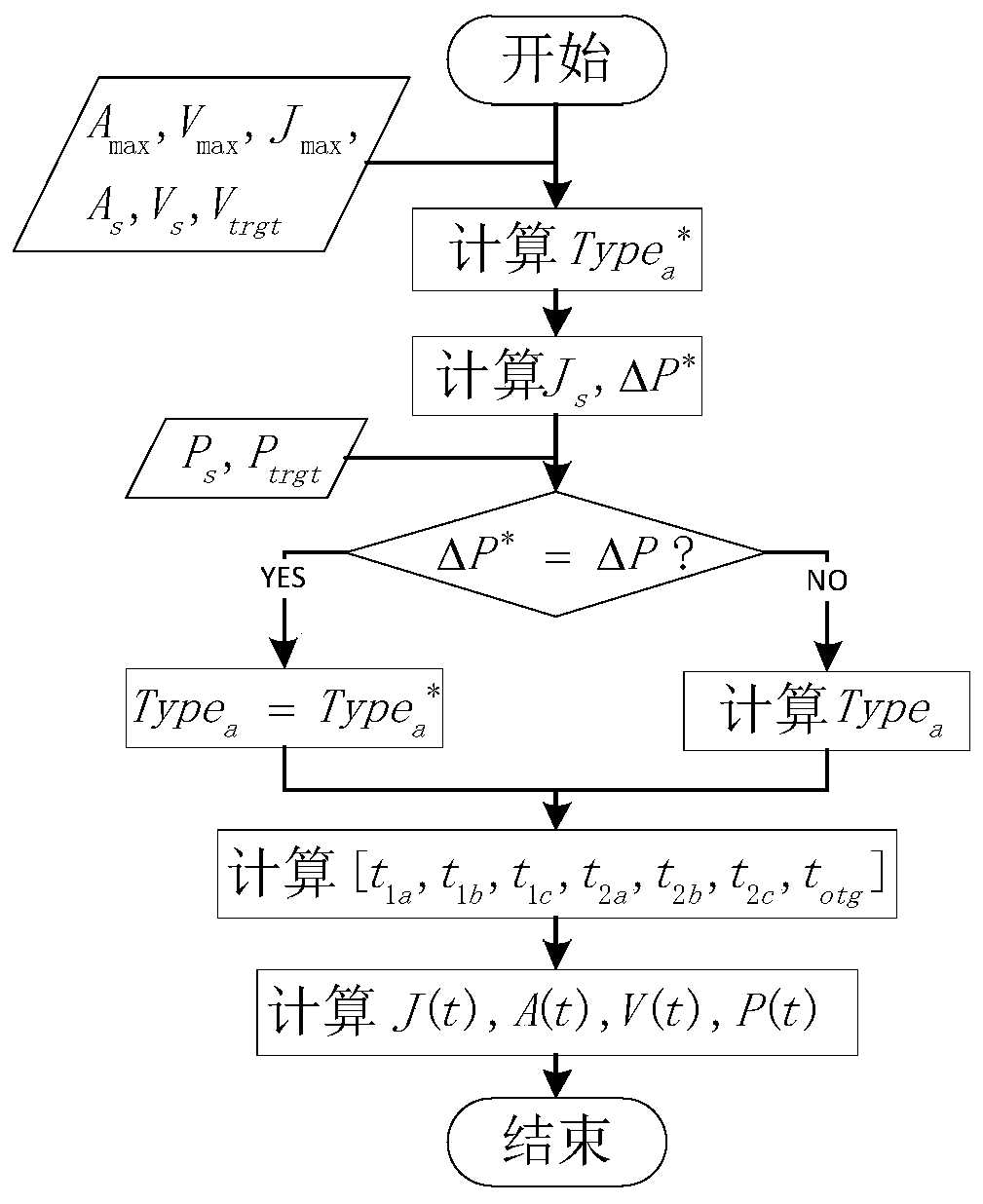

Online S-type acceleration-deceleration planning method with optimal time

ActiveCN109991934AProductive timeThe solution algorithm is simpleNumerical controlAcceleration decelerationComputation process

The invention discloses an online S-type acceleration-deceleration planning method with optimal time. The method has a feature of realizing online real-time computation, and can plan out an interpolation trajectory satisfying a movement constraint condition according to any initial movement state and an ending state that the acceleration is equal to zero; an offline computation process is simplified, and the movement trajectory can be automatically planned in real time according to a signal returned by a sensor under an unknown environment.

Owner:TIANJIN UNIV

Non-uniform rational B-spline (NURBS) interpolation feed speed planning method aiming at embedded system

ActiveCN102981456AImprove computing efficiencySimplify complexityNumerical controlAcceleration decelerationPlanning method

The invention discloses a non-uniform rational B-spline (NURBS) interpolation feed speed planning method aiming at an embedded system. The prior method cannot satisfy requirements of the embedded system. The method disclosed by the invention comprises the steps that firstly, simulation values of the interpolation feed speed are stipulated; and afterwards, the feed speed is planned in a segmented manner according to turning points of a NURBS curve. The method disclosed by the invention has the advantages that the minimum acceleration-deceleration contour curves of feed shafts in respective integral intervals are computed from a global view, so that the computing efficiency is effectively improved; and through screening effective feature switching points and correcting the minimum contours of the acceleration-deceleration curves of the feed shafts at the feature switching points, the complexity of a planning algorithm is greatly simplified.

Owner:HANGZHOU DIANZI UNIV

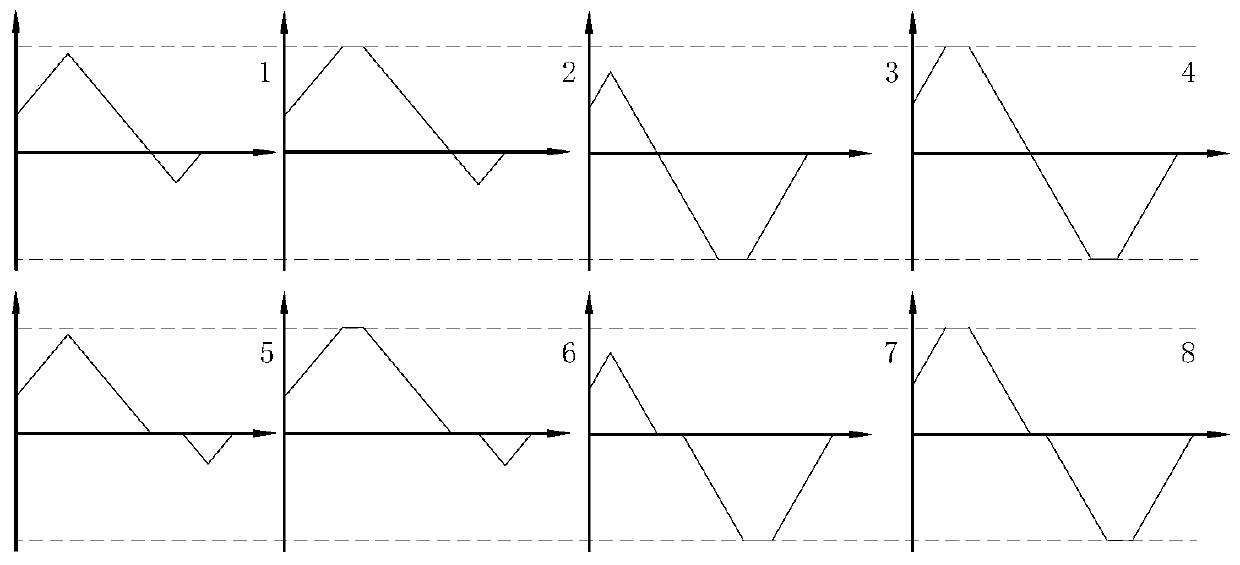

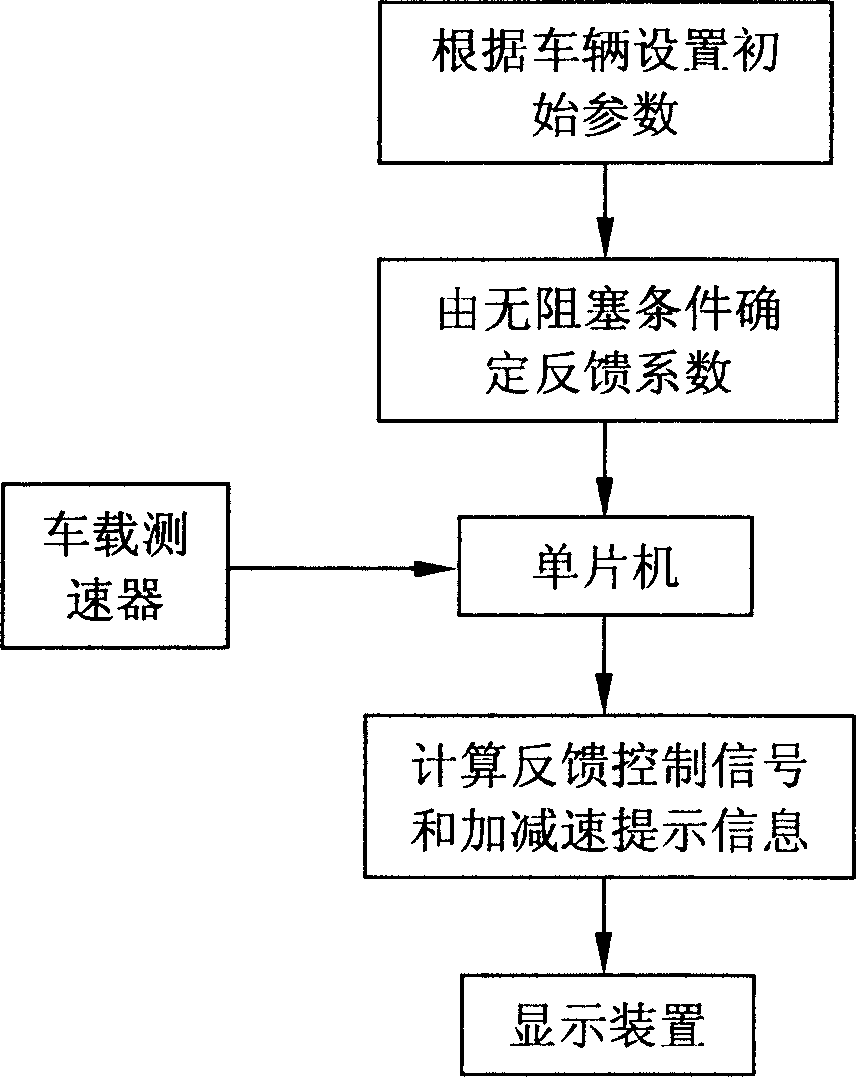

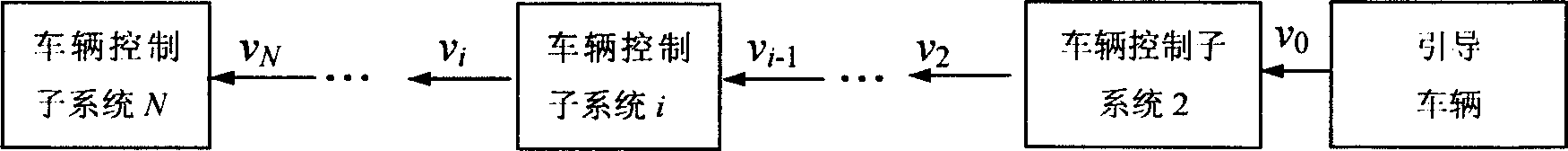

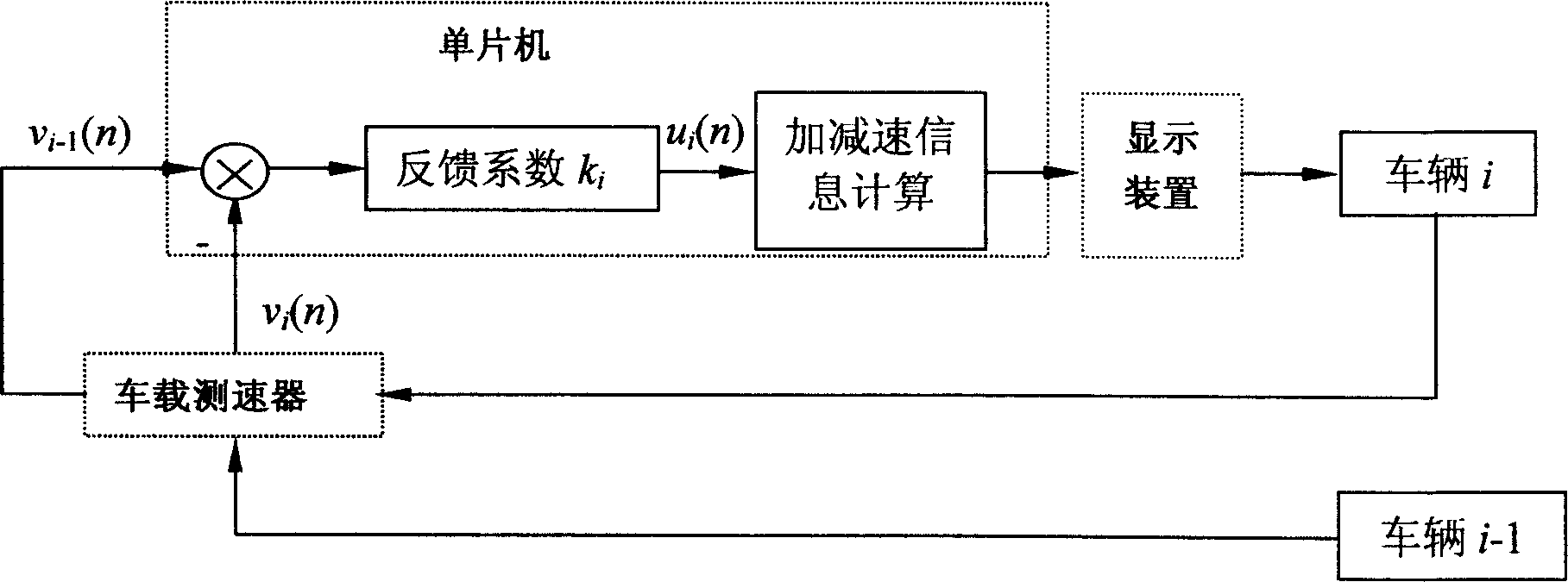

Blocking inhibiting method for city road traffic system

InactiveCN1825380AWell formedSmall amount of calculationArrangements for variable traffic instructionsMicrocontrollerAcceleration deceleration

The invention discloses a jam prohibiting method for a city road traffic system, advancing a jam signal control technique, transmitting front vehicle speed signal and local vehicle speed signal measured by a vehicle-carried speed measurer to a MCU, determining feedback coefficients by the MCU according to the designed feedback control signal and jam-free conditions, calculating acceleration deceleration prompting information and displaying the prompting information on a display unit, and as seeing the prompting information, a driver will properly adjust the vehicle speed, thus improving responding sensitivity of the driver so as to avoid the traffic jam. And the control technique has characters of simple structure, low cost and easy to implement, able to improve driving safety and comfortableness and making full use of road traffic capacity.

Owner:BEIJING JIAOTONG UNIV

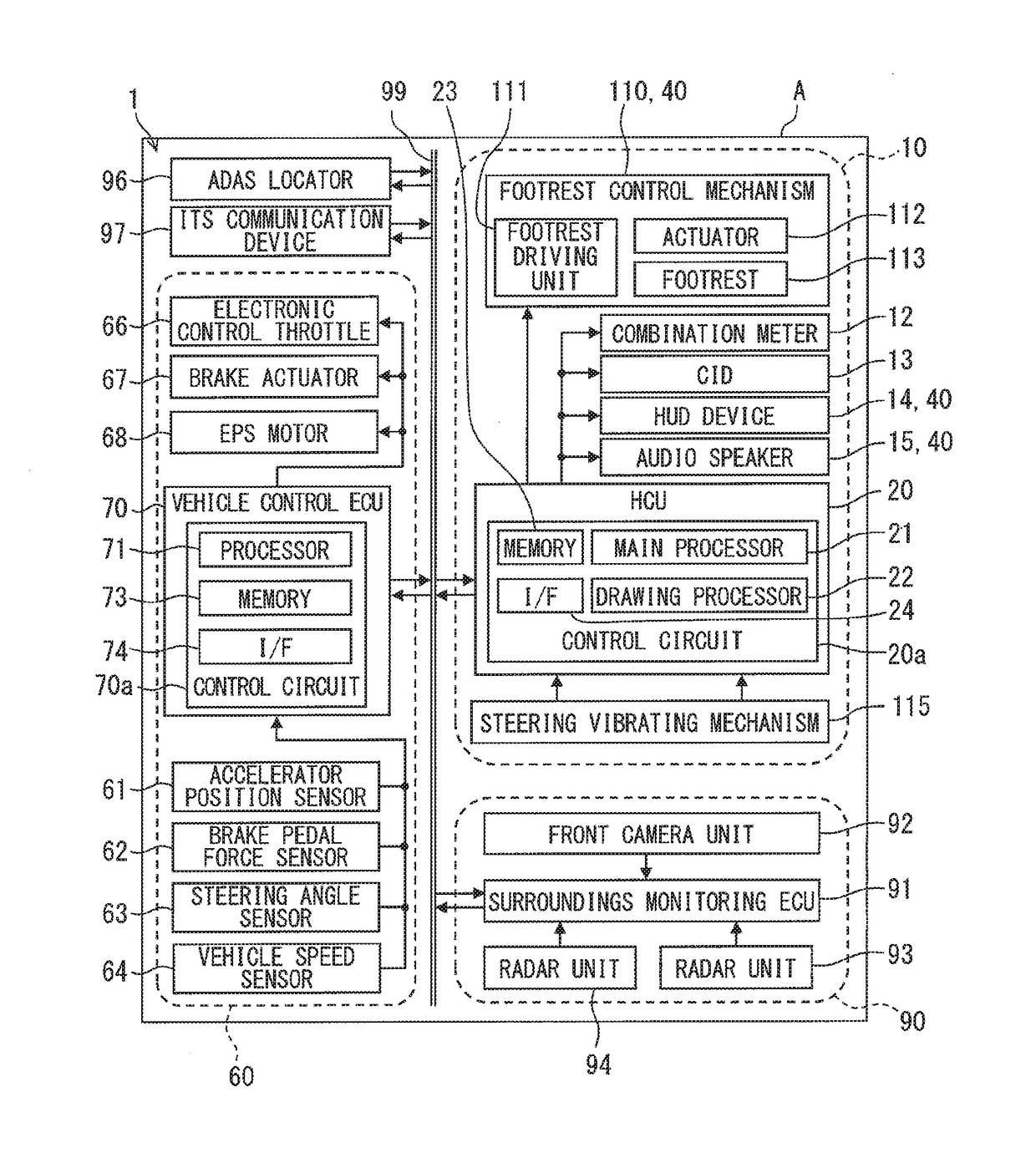

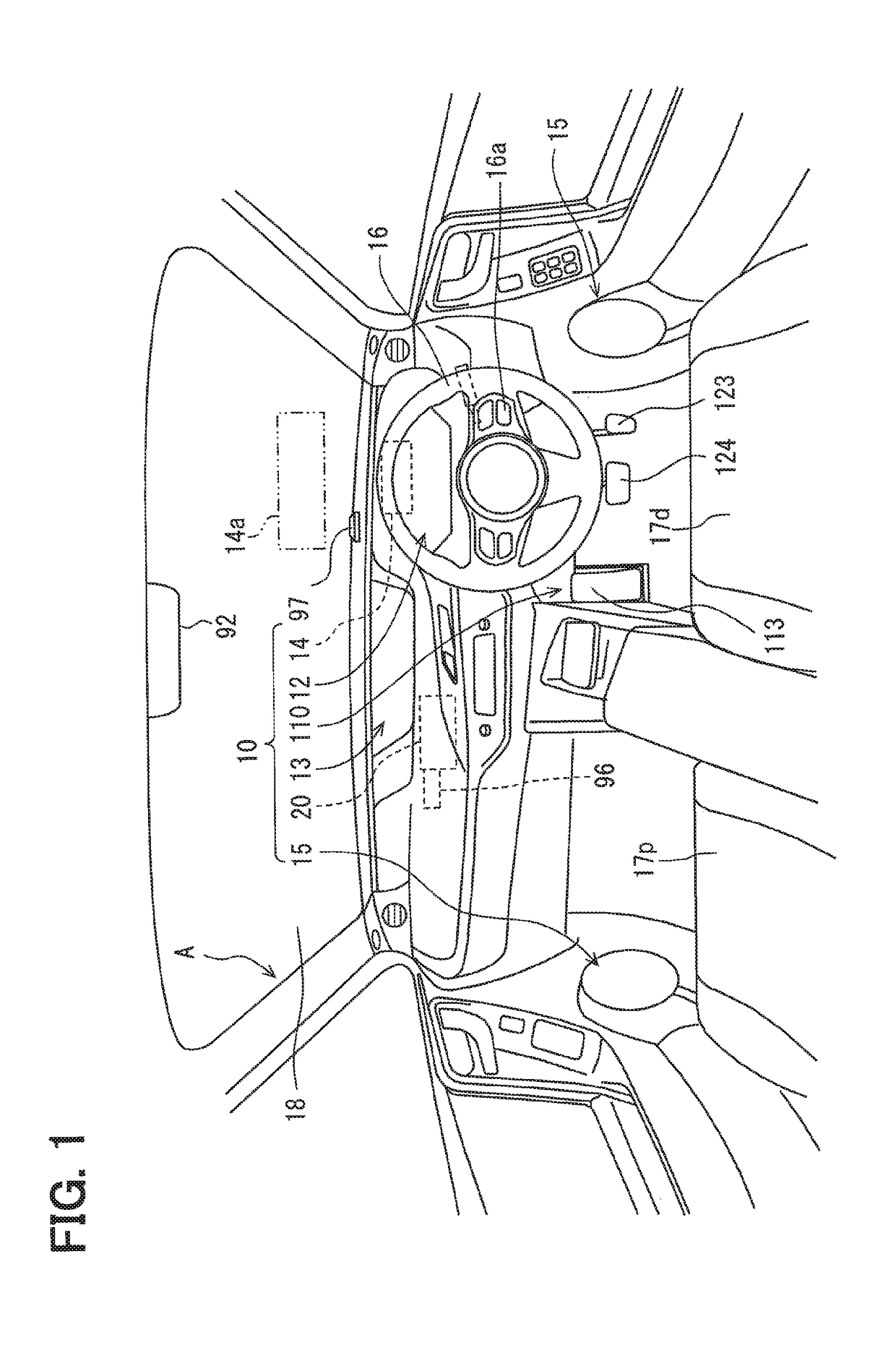

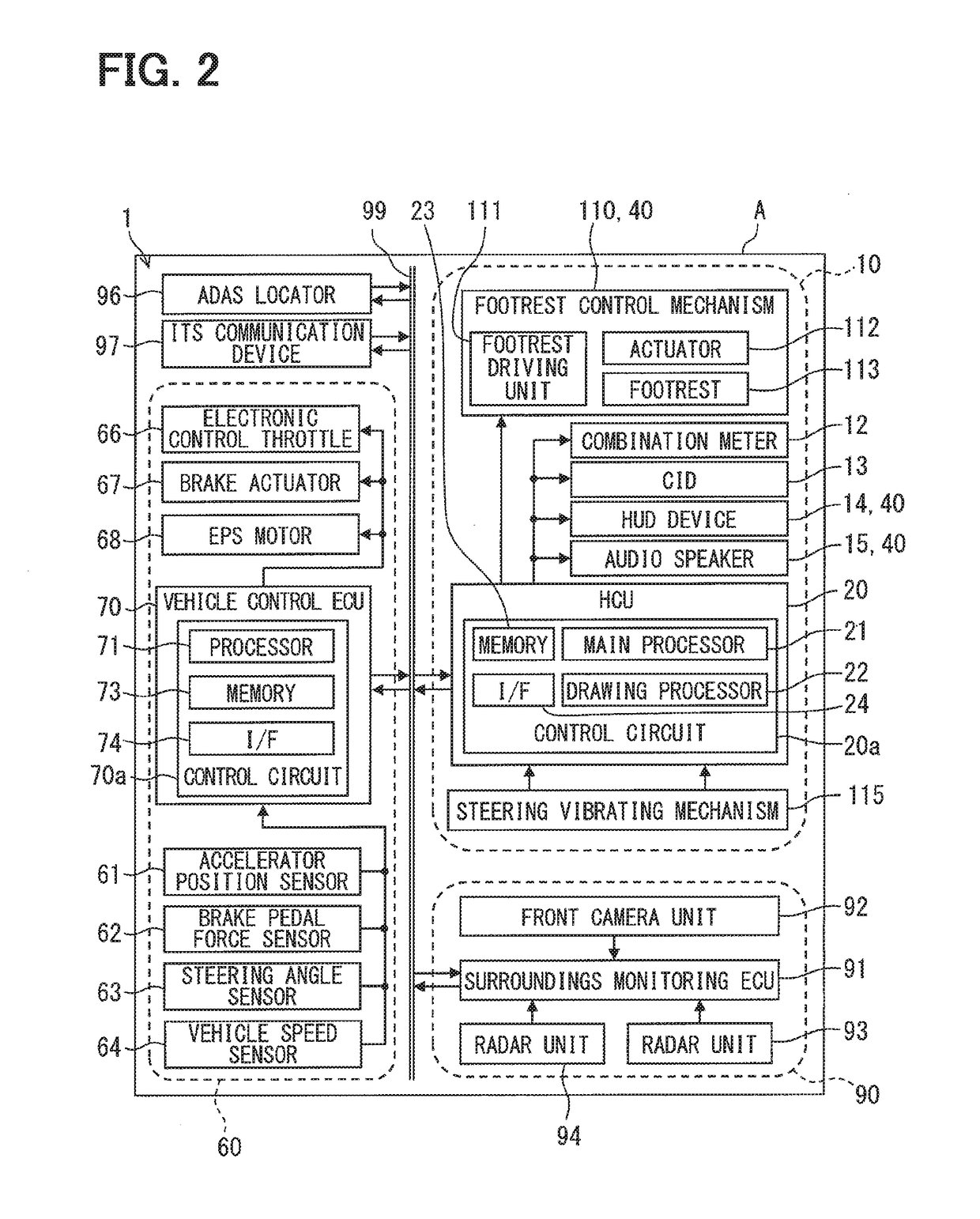

Presentation control device and presentation control method

ActiveUS20180326996A1Reduce anxietySignificant changeRoad vehicles traffic controlVehicle position/course/altitude controlProgram planningControl objective

A presentation control device controlling an information presentation device in a vehicle equipped with a vehicle control device for controlling an acceleration-deceleration function or a steering function, includes: a plan acquisition section that acquires a travel plan indicating a control content of the vehicle; a behavior change determination section that determines whether a control target value relating to a magnitude of a behavior change included in the travel plan is larger than an advance threshold; and a presentation execution section that presents the control content to the occupant using the information presentation device in accordance with the behavior change occurring in the vehicle when the control target value is smaller than the advance threshold, and presents the control content temporarily in advance of an actual behavior change when the control target value is larger than the advance threshold.

Owner:DENSO CORP

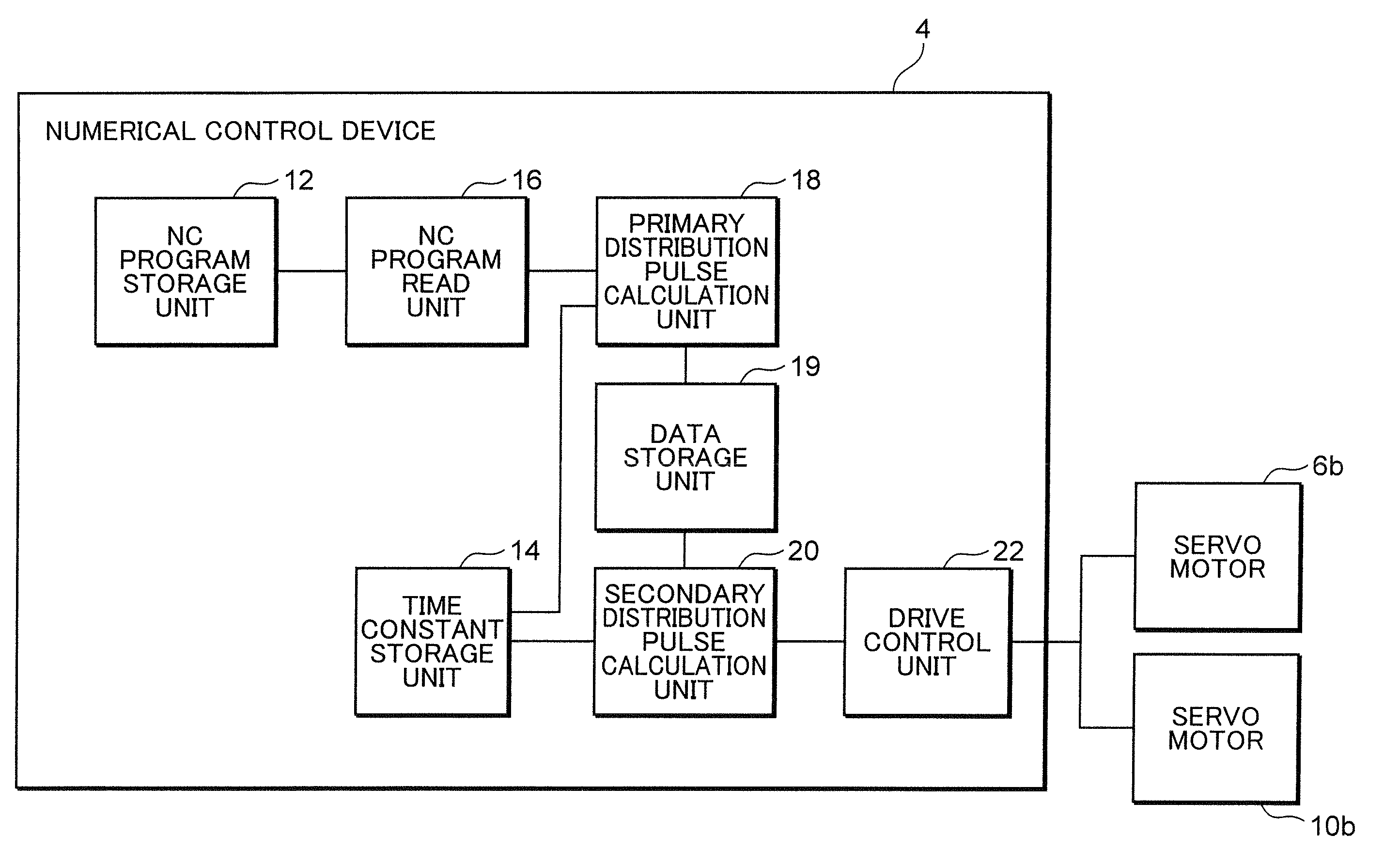

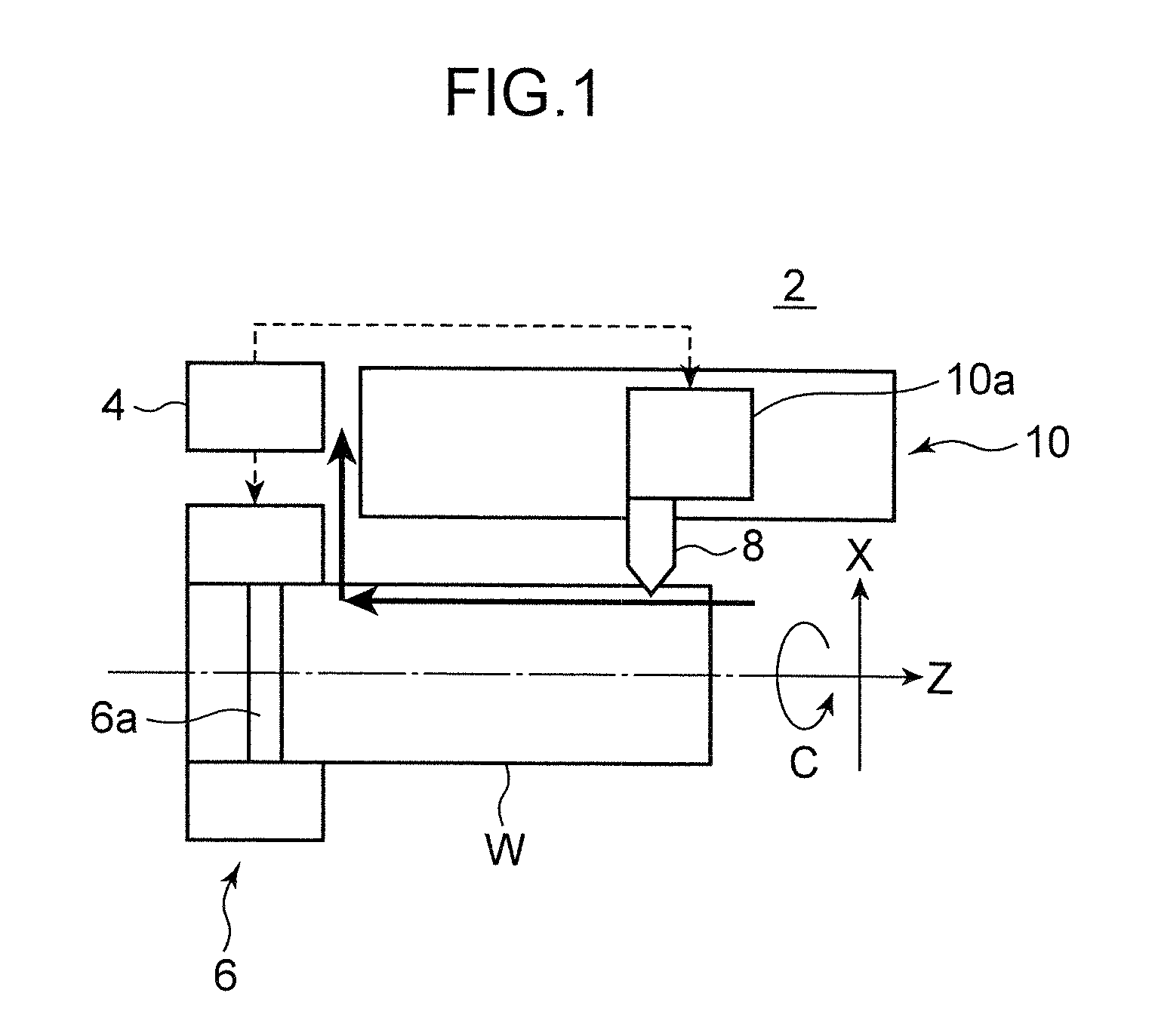

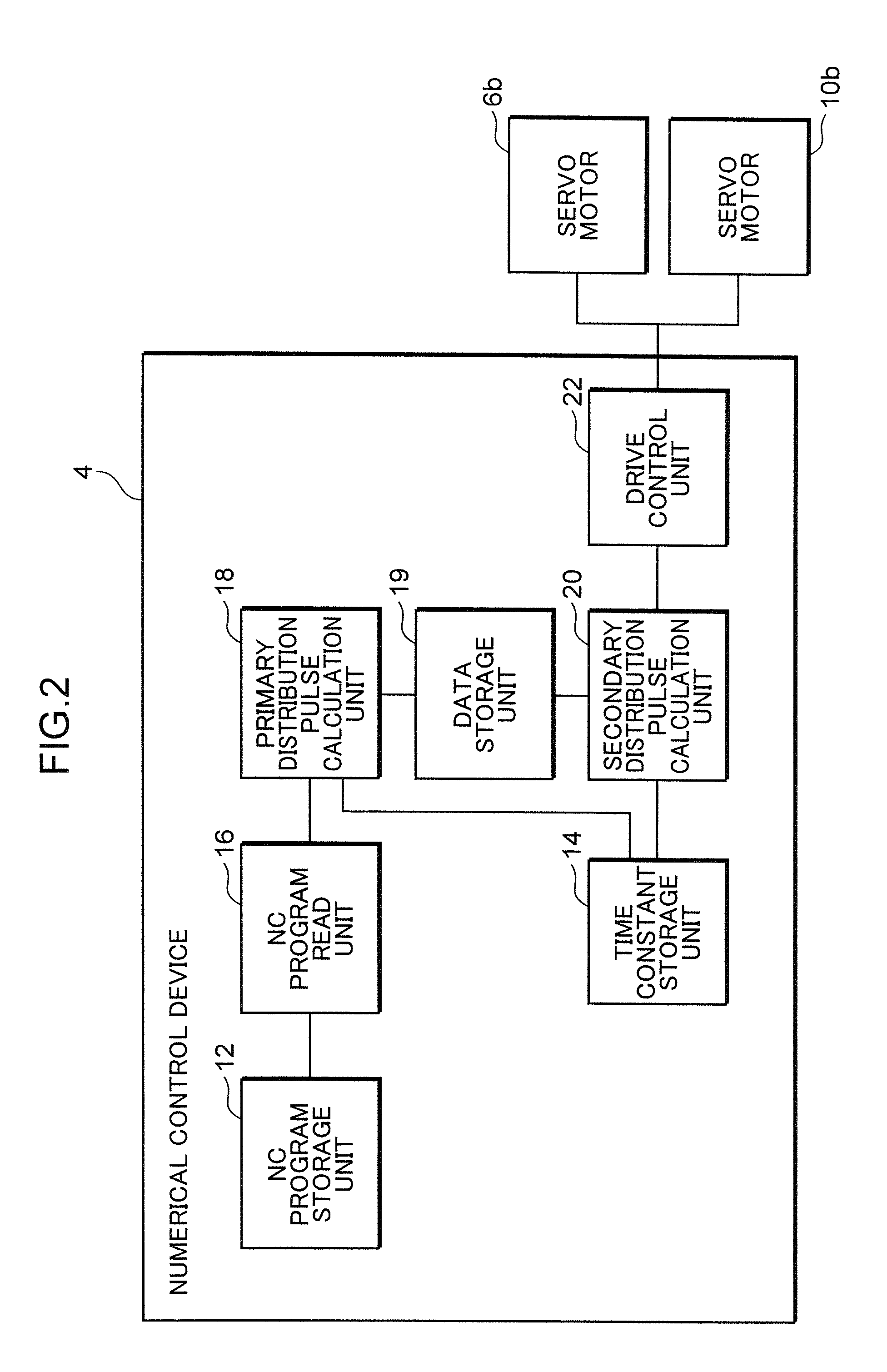

Numerical control device for tool machine

InactiveUS8478439B2Improve machining accuracyComputer controlSimulator controlNumerical controlAcceleration deceleration

A numerical control device includes a primary distribution pulse calculator that calculates primary distribution pulses obtained by distributing movement amounts in first and second directions included in a movement command of a work or a tool for each of predetermined calculation cycles. A secondary distribution pulse calculator calculates, for each movement direction, secondary distribution pulses obtained by distributing the primary distribution pulses of each calculation cycle calculated by the primary distribution pulse calculator, before and after corresponding calculation cycles within ranges of distribution sections across the corresponding calculation cycles and having an acceleration-deceleration time constant of the corresponding movement direction as a section width, and then accumulating the primary distribution pulses for each calculation cycle. A drive controller drives at least one of a tool moving device and a work moving device on the basis of the secondary distribution pulses calculated by the secondary distribution pulse calculator unit.

Owner:SHINNIPPON KOKI

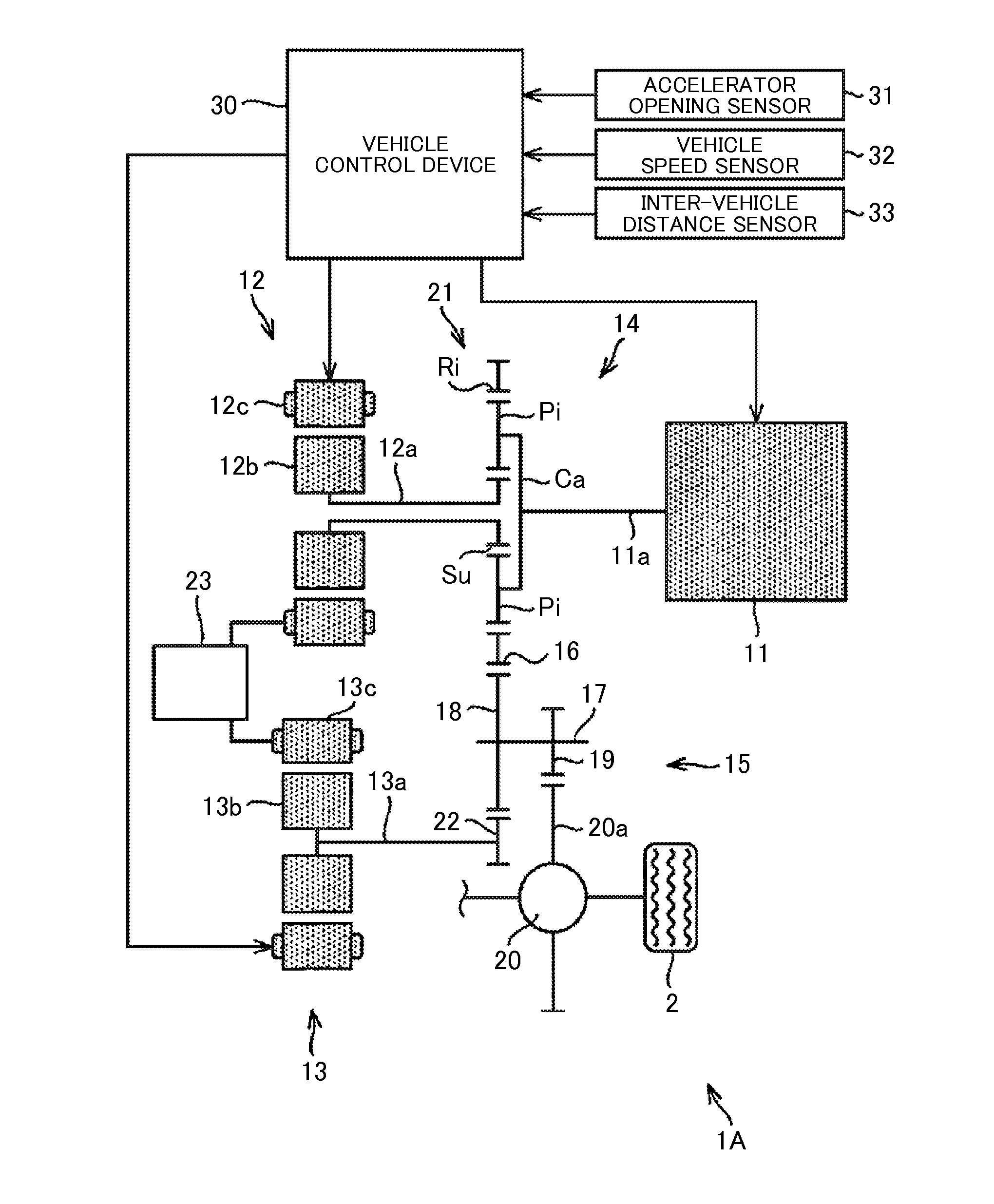

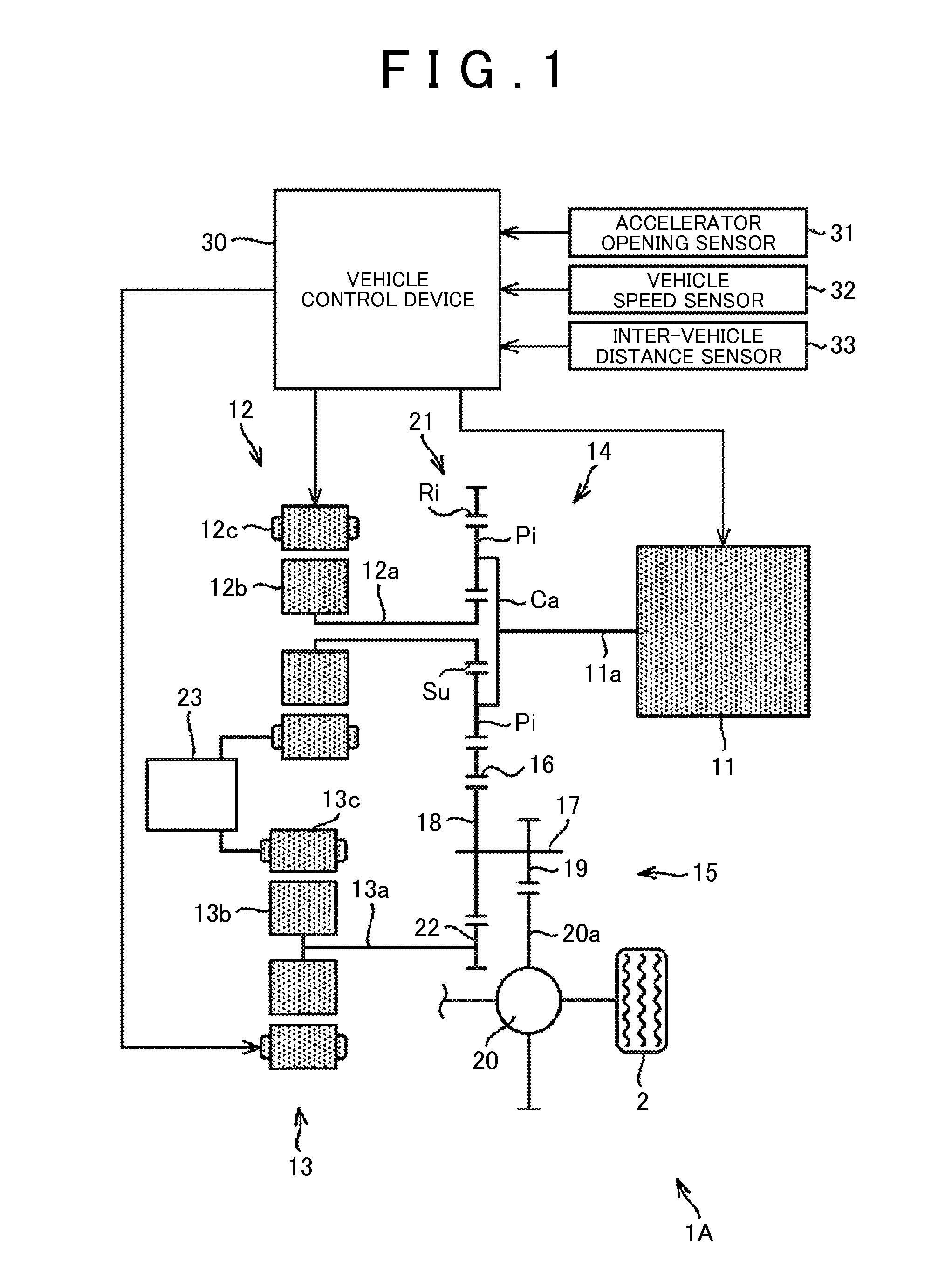

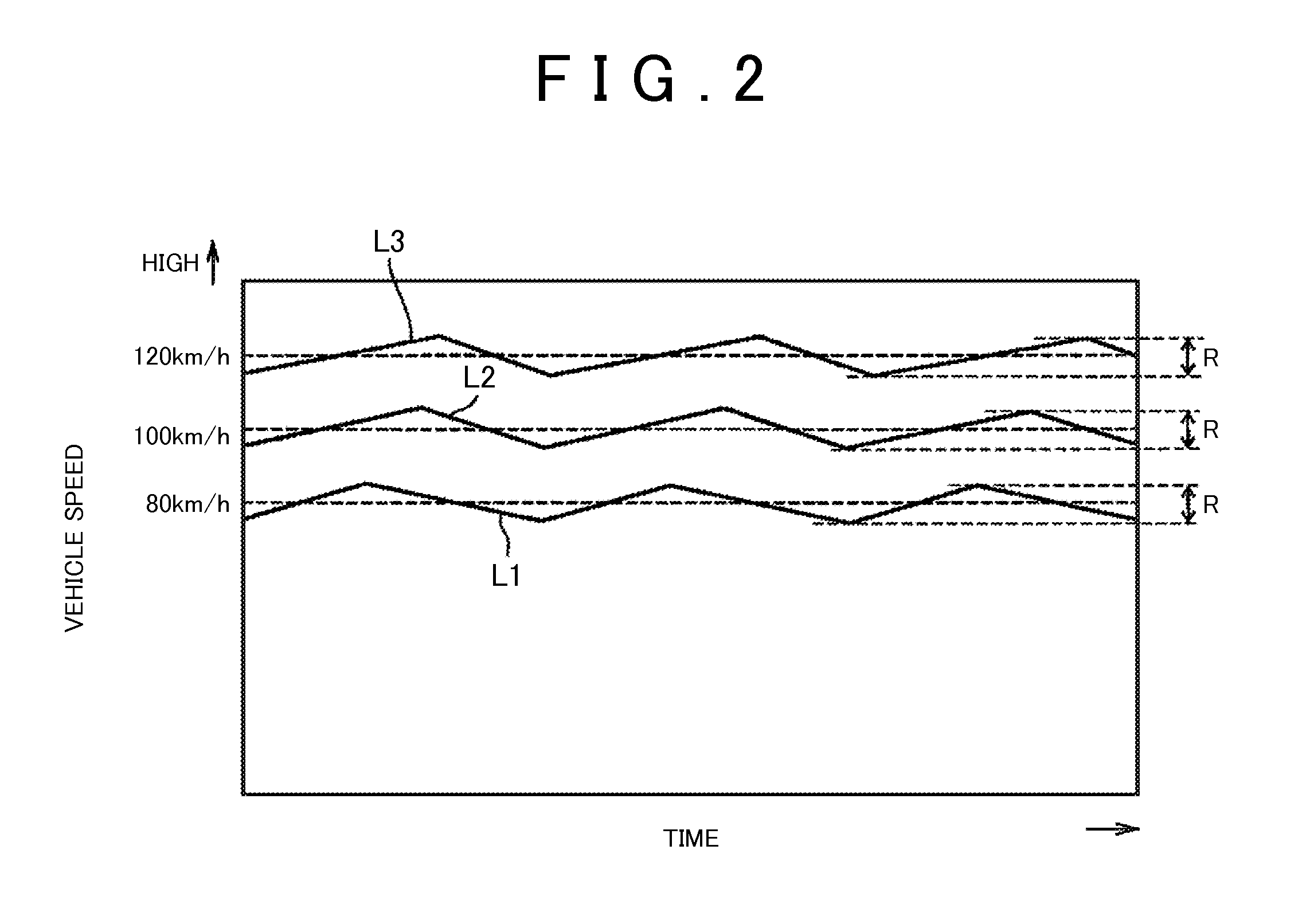

Travel control device of hybrid vehicle

ActiveUS20150367833A1InhibitionReduce transmission efficiencyHybrid vehiclesInternal combustion piston enginesTravel modeExternal combustion engine

A travel control device is applied to a hybrid vehicle which includes a planetary gear mechanism capable of distributing power of an internal combustion engine to a first MG and an output part, and a second MG capable of outputting power to the output part. The travel control device allows the vehicle to travel in an acceleration-deceleration travel mode in which, when a high-speed steady travel condition is established during travel of the vehicle, acceleration travel for accelerating the vehicle with power output from the internal combustion engine and coasting travel for allowing the vehicle to coast with the internal combustion engine in a stop state are alternately repeated within a target vehicle speed range. In the travel control device, given power is output from the internal combustion engine at the time of acceleration travel, and the internal combustion engine is controlled such that the vehicle is accelerated at an acceleration such that the rotation speed of the first MG becomes zero.

Owner:TOYOTA JIDOSHA KK

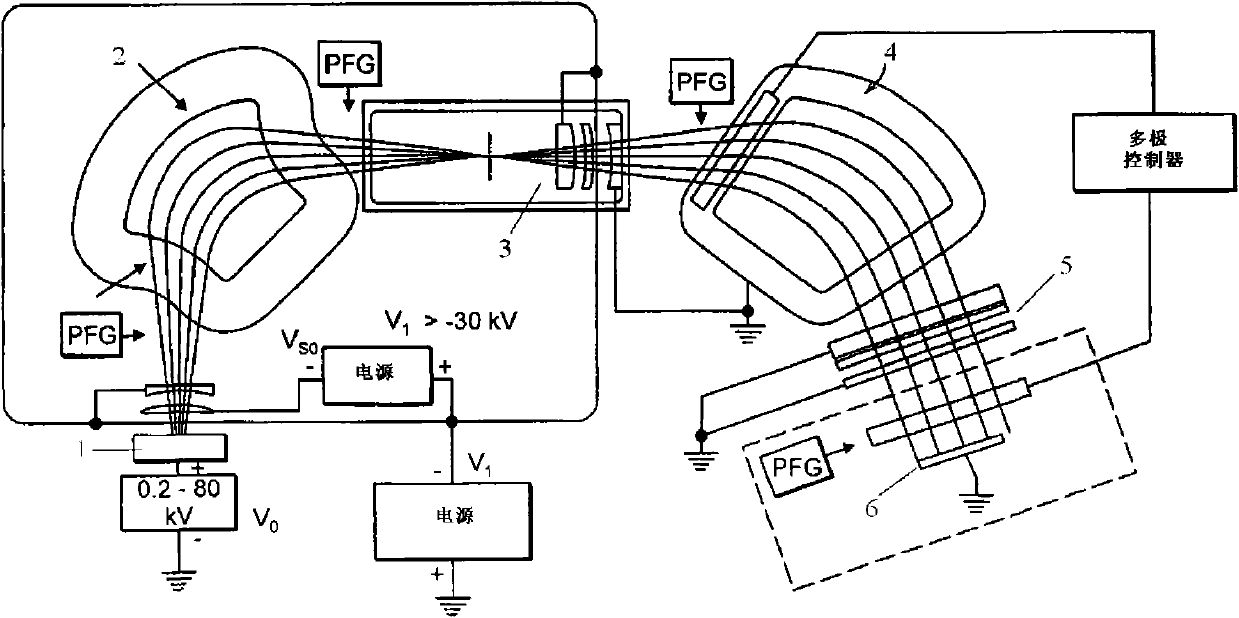

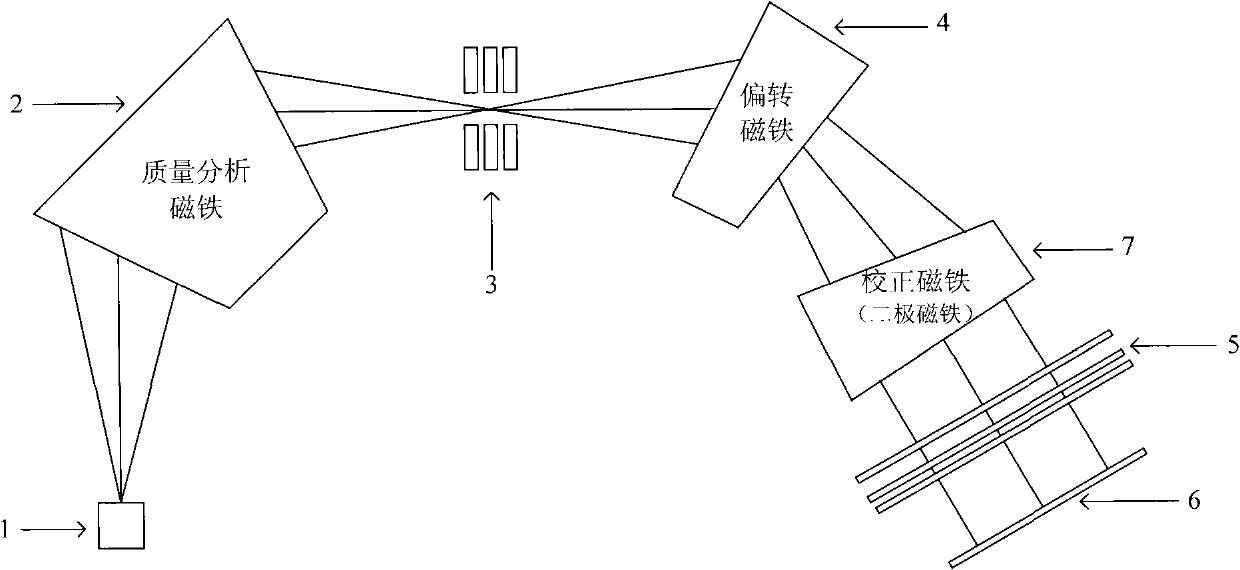

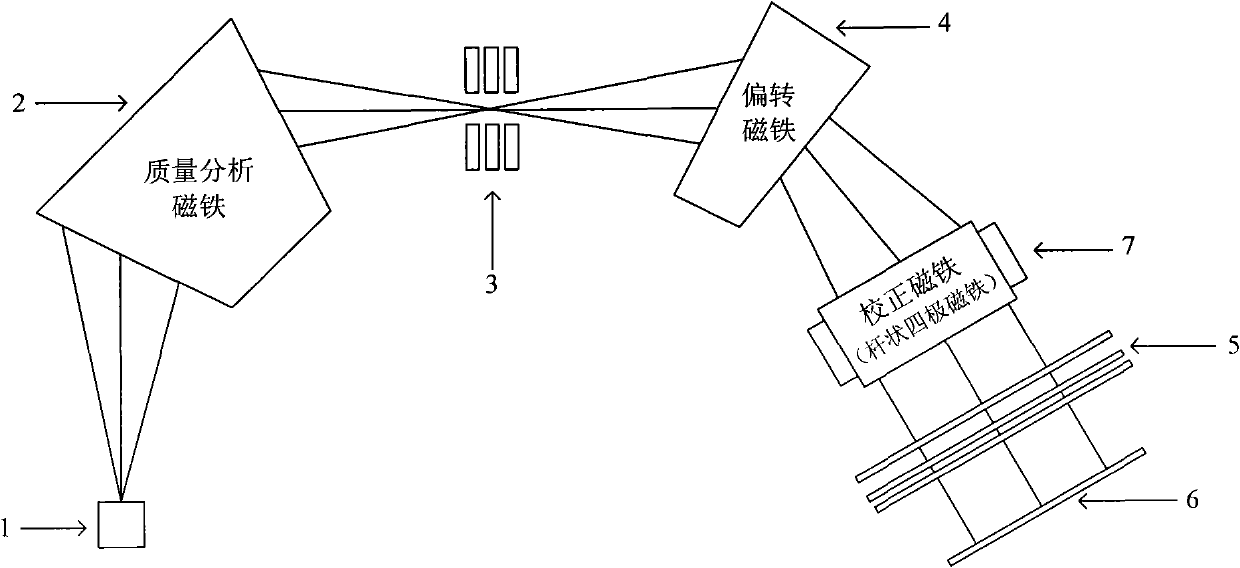

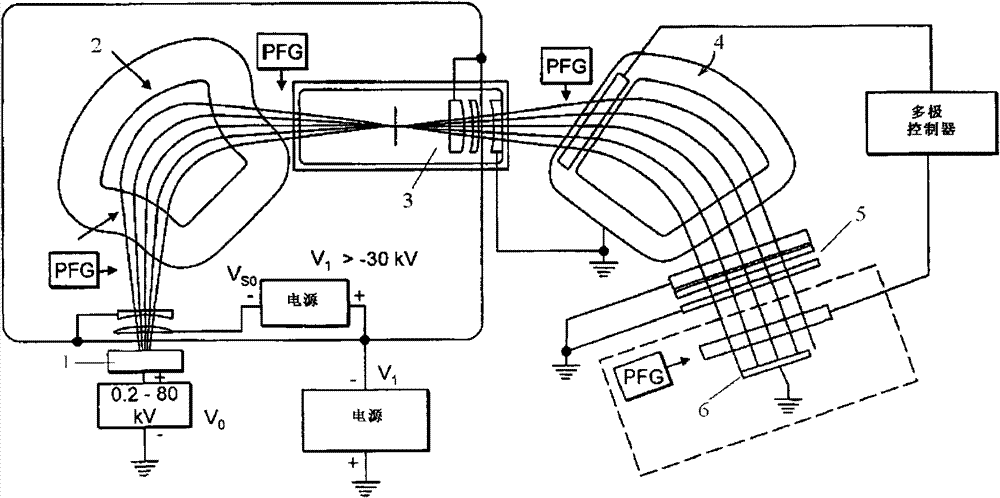

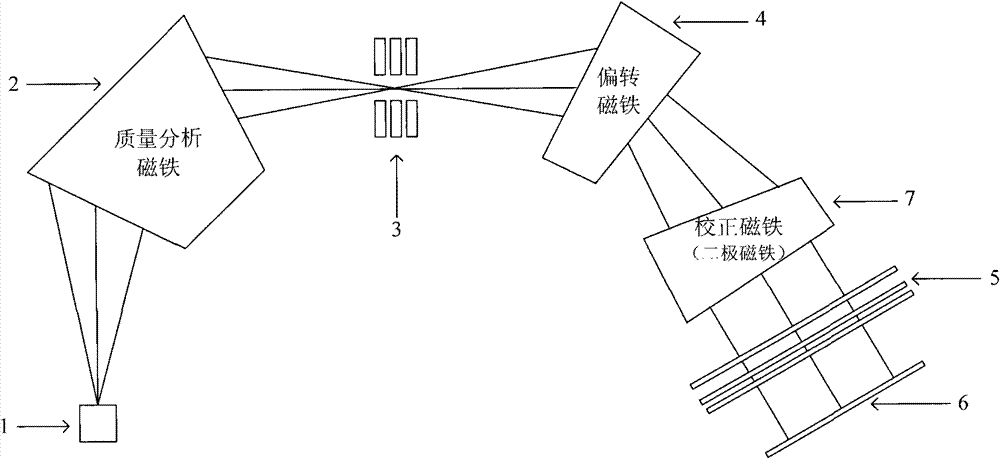

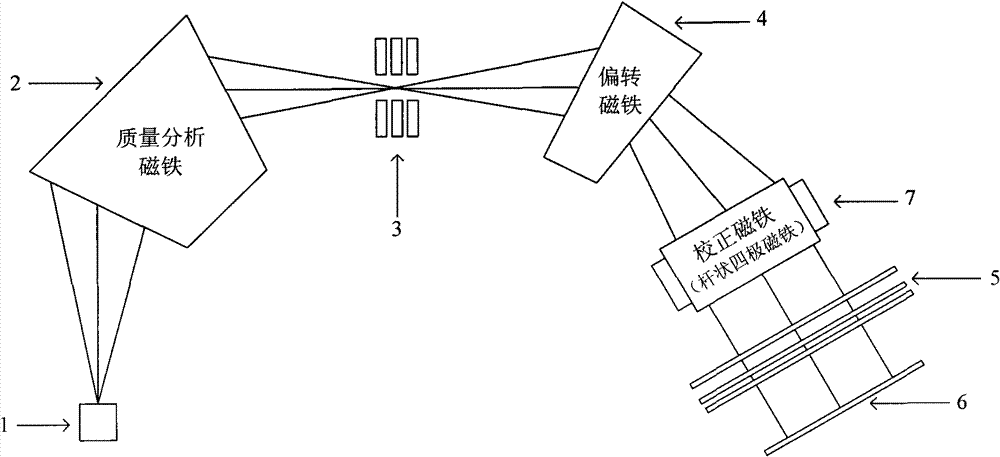

Ion implantation system and method

The invention discloses an ion implantation system comprising an ion source and an extractor, a quality analysis magnet, a first acceleration-deceleration device, a deflecting magnet, a second acceleration-deceleration device and a work piece scanner. The deflecting magnet makes ion beams within a preset charge-to-mass ratio range divergent; the system further comprises a correction magnet arranged between the deflecting magnet and the second acceleration-deceleration device, and the correction magnet is used for correcting the ion beam deflected and diverged by the deflecting magnet within the preset charge-to-mass ratio range to be a preset implantation angle. The invention further discloses an ion implantation method realized by utilizing the ion implantation system. Through the ion implantation system and method, disclosed by the invention, the evenness of dosage of ions implanted into a large wafer work piece can be improved, thus the production efficiency is improved, and the cost consumed due to the comprehensive update of the whole ion implantation system can be largely saved.

Owner:KINGSTONE SEMICONDUCTOR LIMITED COMPANY

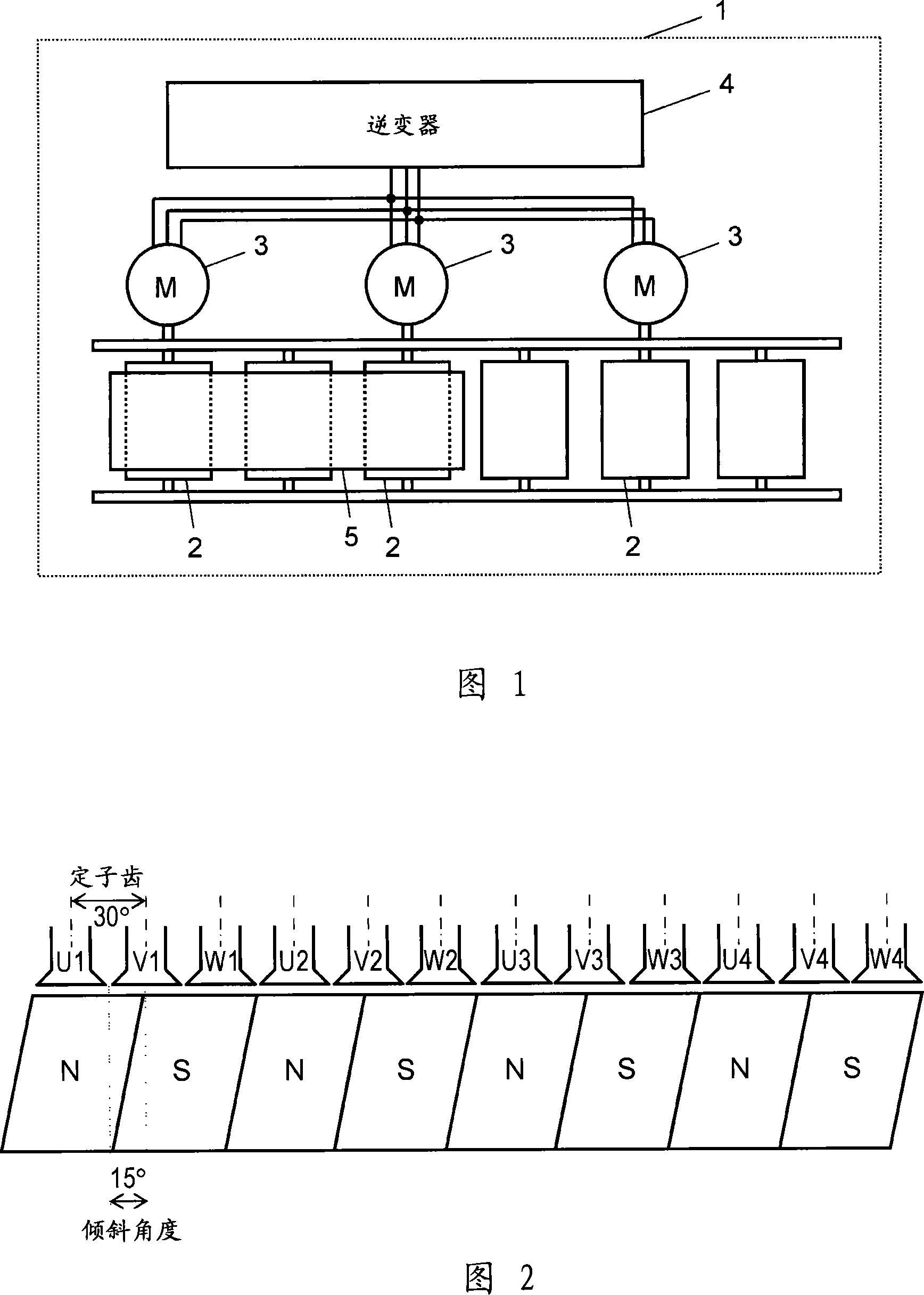

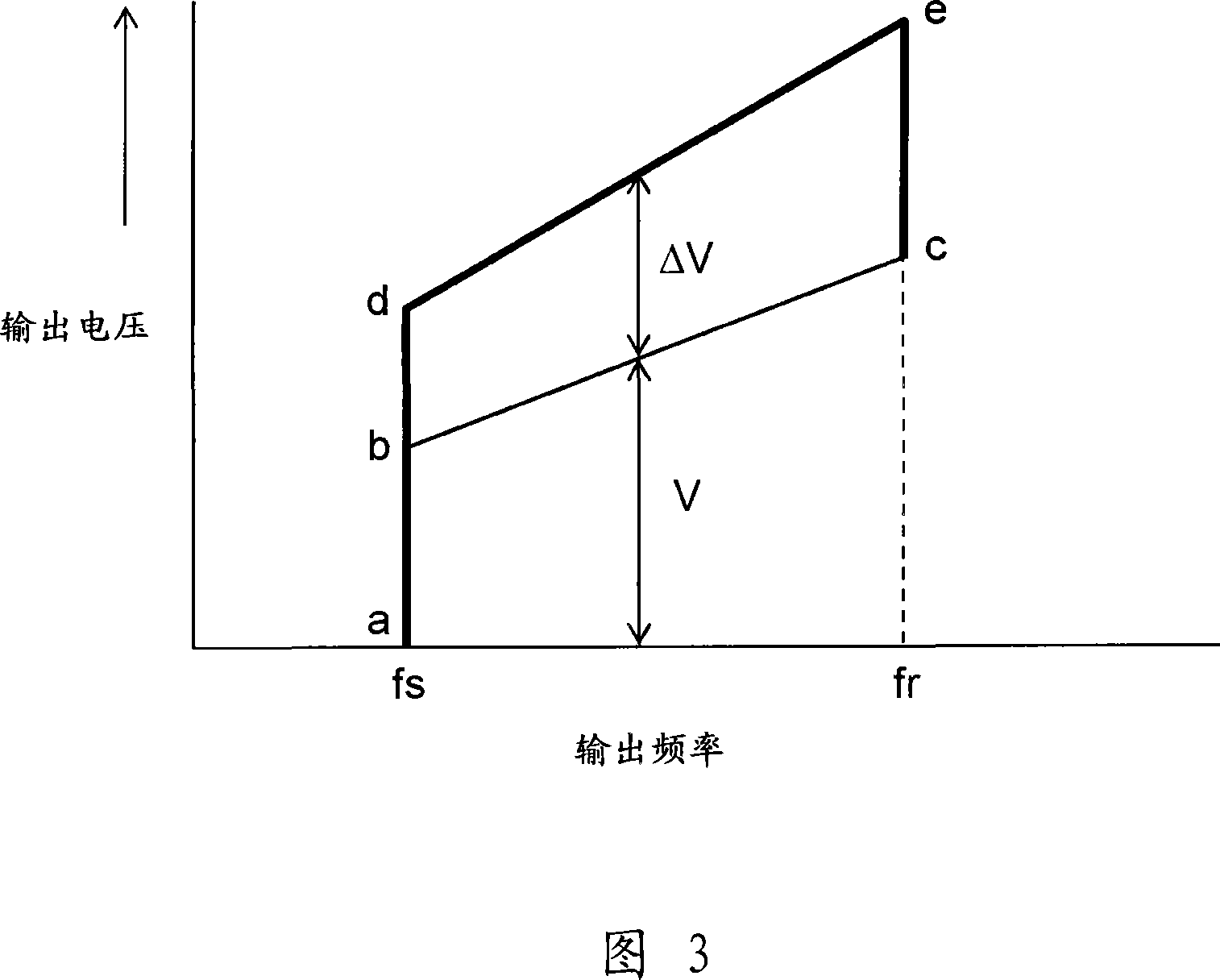

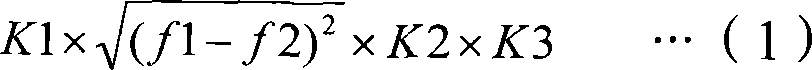

Synchromous machine drive system

InactiveCN101106346AElectronic commutation motor controlAC motor controlMotor driveAutomatic control

An inverter of in a synchronal motor drive system synchronally drives a plurality of synchronal motors containing the inclined magnet rotor after the magnetization. The inverter does a feedforward operation based on the inertia and the value of the acceleration-deceleration so as to automatically control the output voltage when the inverter drives the output frequency to change and operate in the acceleration-deceleration state.

Owner:PANASONIC CORP

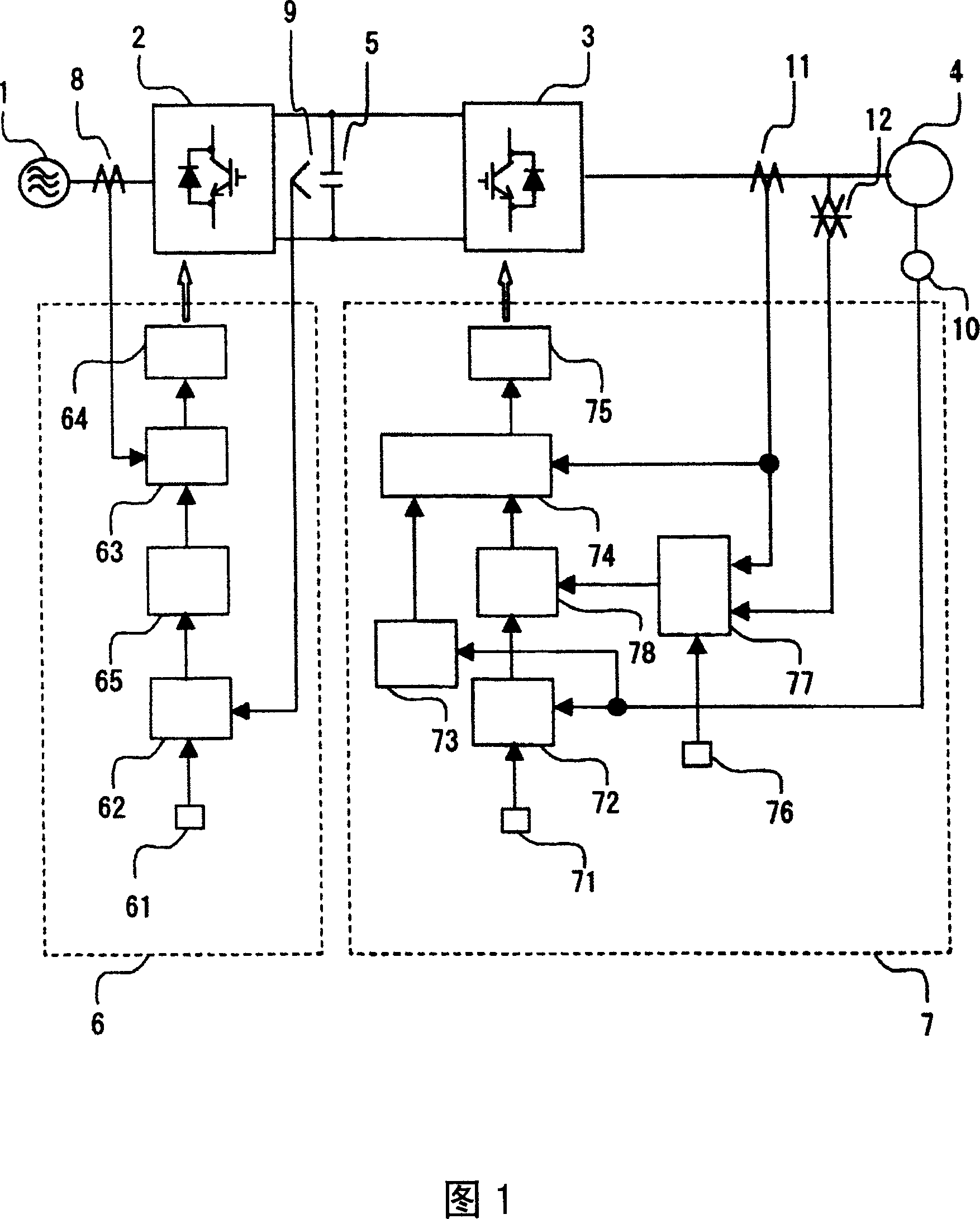

Numerical control device

ActiveUS9851709B2Improve accuracyReduce processing timeNumerical controlNumerical controlData selection

In a numerical control device 1 which controls positions of respective axes of a machine tool according to a machining program 11, a command 12 instructed to the machining program 11 is analyzed by an analyzing unit 13, thereby obtaining movement data 15 and a movement type 17, an acceleration-deceleration data selection unit 18 selects acceleration-deceleration data 19 according to the movement type 17, and an interpolation and acceleration-deceleration unit 16 generates a position command 21 by performing an interpolation on a movement route, which is instructed to the movement data 15, according to a command speed and performing acceleration-deceleration according to the acceleration-deceleration data 19.

Owner:MITSUBISHI ELECTRIC CORP

Servo-motor acceleration-deceleration control method for servo pressure machine

ActiveCN102522944BContinuous changeAvoid Flex ShockElectronic commutation motor controlElectric motor controlTriangular functionAcceleration deceleration

The invention discloses a servo-motor acceleration-deceleration control method for a servo pressure machine, comprising the following steps of: constructing an acceleration function of a servo motor at an acceleration stage; establishing a speed expression of the servo motor at the acceleration stage; establishing a rotary displacement expression of the servo motor at the acceleration stage; constructing an acceleration function of the servo motor at a deceleration stage; establishing a speed expression of the servo motor at the deceleration stage; establishing a rotary displacement expression of the servo motor at the deceleration stage; and determining total acceleration time and total deceleration time. According to the servo-motor acceleration-deceleration control method, two triangular functions with different periods are adopted as acceleration-deceleration constructed functions of the servo motor, so that the change of the speed, the acceleration and the accelerated acceleration is continuous, the soft shock of the acceleration-deceleration process on the machine body is avoided, the operation stability of the pressure machine is improved and the softness of acceleration-deceleration control of the pressure machine is higher; and by full utilization of the constant and maximum output torque of the server motor under the rated rotating speed, the operation period of the servo pressure machine can be shortened and the takt time of stamping production is improved.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

Weakening focusing effect of acceleration-deceleration column of ion implanter

ActiveUS7045799B1Good effectReduce decreaseParticle separator tubesIsotope separationAcceleration decelerationIon beam

A method and apparatus for weakening a strong focus effect of an acceleration-deceleration column of an ion implanter during a deceleration mode are disclosed. The apparatus includes a tube lens surrounding the ion beam adjacent to a deceleration lens of the acceleration-deceleration column. The tube lens causes a defocusing of the ion beam at the entrance of the tube lens, which reduces the ion dispersion problem generated by the column. The invention also includes an accel-decel column and ion implanter incorporating the tube lens. An additional deceleration-suppression electrode may also be added subsequent to the tube lens for confining electrons within the tube lens.

Owner:VARIAN SEMICONUTOR EQUP

Device for detecting slope of vehicle or the like

InactiveUS7019627B2Digital data processing detailsAnimal undercarriagesAcceleration decelerationVertical acceleration

The slope detecting device includes means for detecting a horizontal acceleration of the vehicle; means for detecting perpendicular acceleration to the running direction of the horizontal detecting means; and means for detecting, relatively to the horizontal detecting means and perpendicular detecting means, the acceleration-deceleration of the moving object by whether the sum of squares respectively which the acceleration detected by the horizontal detecting means and the acceleration detected by the perpendicular detecting means is equal to the second power of gravity acceleration, and calculating the slope of the vehicle in acceleration-deceleration so that it can detect the slope of vehicle in acceleration-deceleration as well as during running the vehicles at a constant speed.

Owner:MACNICA

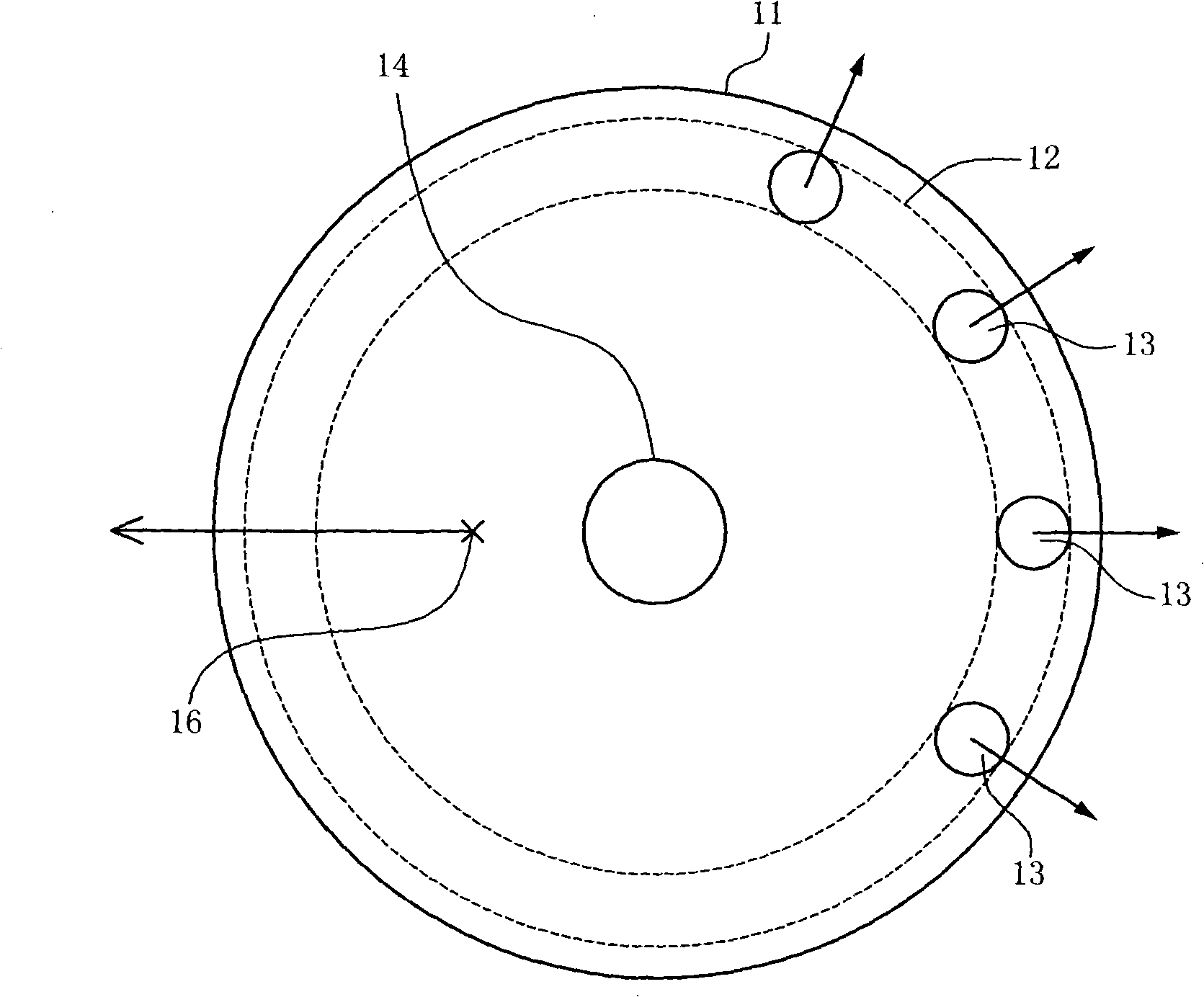

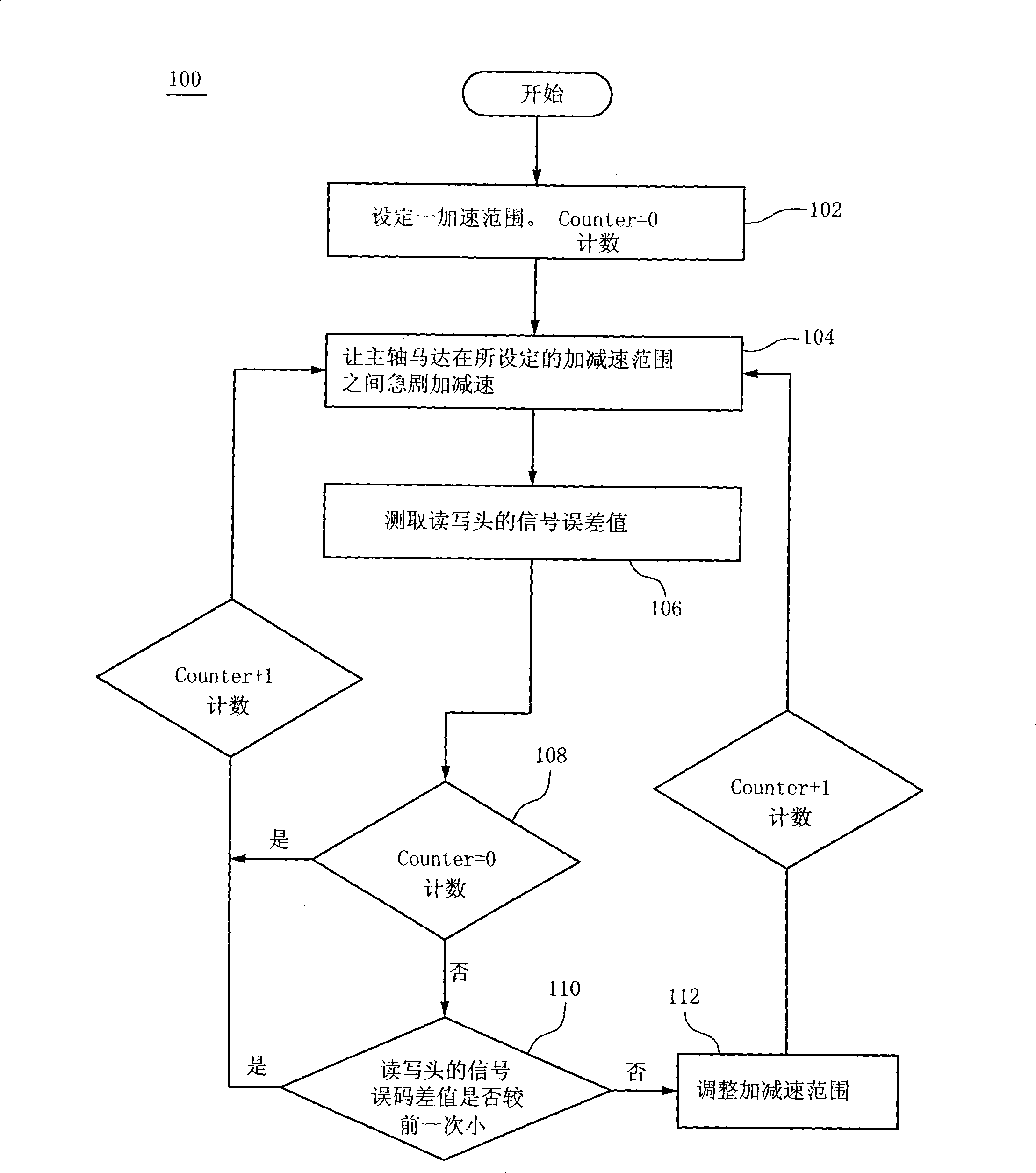

CD ROM ball automatic balance system control method

ActiveCN101286337ABest damping positionRotating vibration suppressionUndesired vibrations/sounds insulation/absorptionMotor driveAcceleration deceleration

The invention discloses a control method used for a CD-ROM roller automatic balancing system. The method provides a rotary body which is fixed on the rotary shaft of the CD-ROM to lead the rotary body to revolve with the rotary shaft synchronously. Rollers are provided in a round rail in the rotary body to move smoothly. A revolution speed scope is arranged, and a main shaft motor drives the rotary shaft to accelerate-decelerate by at least two times within the revolution speed scope. During the multiple acceleration-deceleration of the main shaft motor, if a measured signal difference value is greater than the signal difference value measured previously, the acceleration-deceleration scope is adjusted. The roller balancing method of the roller-type automatic balancing system of the invention drives the rotary shaft to repeat the acceleration-deceleration within the revolution speed scope to further balance the rollers to the best vibration-reducing position in the round rail. Additionally, when the automatic balancing system generates a bigger difference caused by manufacturing tolerance, the acceleration-deceleration scope is adjusted again to be applied to all the CD-ROM automatic balancing systems.

Owner:ASUSTEK COMPUTER INC

Computerized numerical control machine tool and acceleration-deceleration method thereof

ActiveCN101581927BControl acceleration and deceleration timeJerk controlNumerical controlNumerical controlMoving average

The invention relates to an acceleration-deceleration method for a computerized numerical control machine tool, which comprises the following steps: recieving an acceleration-deceleration time signal and a speed signal; obtaining dissimilar first weight value and second weight value by the acceleration-deceleration time signal through a first function and a second function; judging whether a speedvariation of the speed signal is zero, a positive value or a negative value; outputting the speed signal when the speed variation is zero; obtaining an acceleration signal by the product of the speedsignal and the first weight value when the speed variation is the positive value; obtaining an deceleration signal by the product of the speed signal and the second weight value when the speed variation is the negative value; and converting the speed signal, the acceleration signal and the deceleration signal into a first driving signal, a second driving signal and a third driving signal respectively. The acceleration-deceleration method for the computerized numerical control machine tool of the invention can achieve the effect of a thrice moving average method only by once acceleration-deceleration plan, effectively control the jerk and the acceleration-deceleration time signal, and improve the product quality.

Owner:HONG QI MECHATRONICS ANHUI CO LTD +1

Ion implantation system and method

Owner:KINGSTONE SEMICONDUCTOR LIMITED COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com