High-speed aluminum-plastic bubble cap machine

An aluminum-plastic, cover machine technology, applied in packaging/bundling items, external support, packaging, etc., can solve the problems of unstable sealing effect, insufficient film pulling, process dispersion, etc., to achieve simple structure and increase molding speed. and stability, ensuring the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

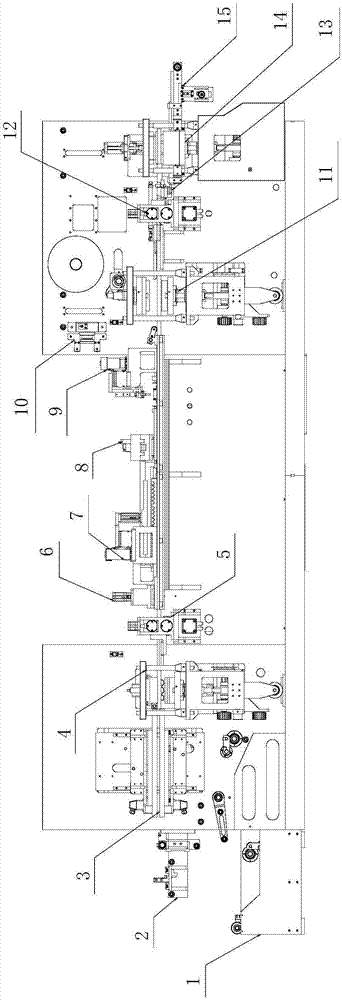

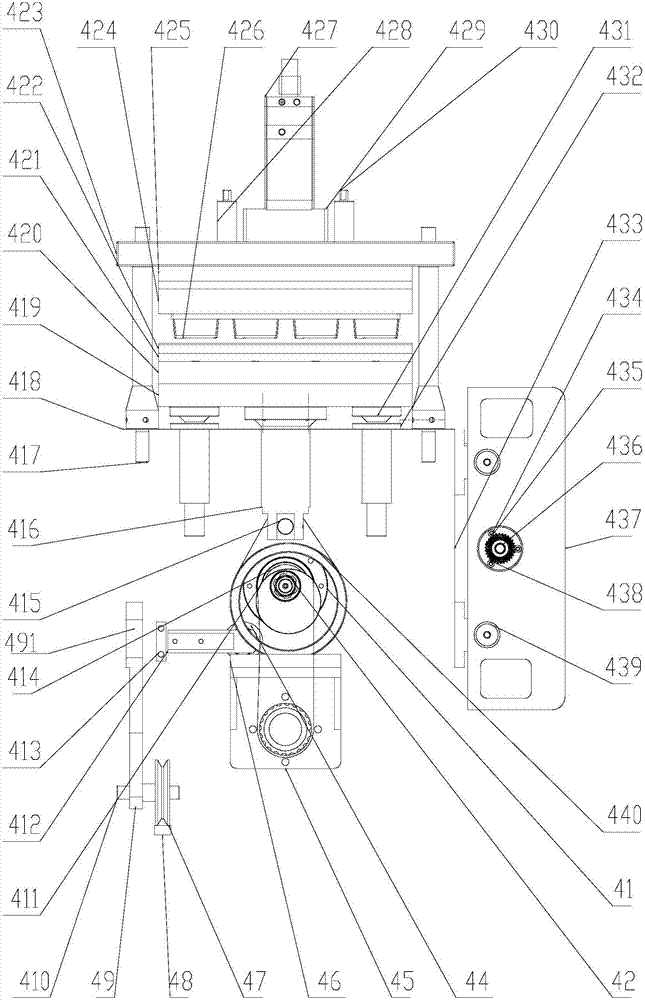

[0030] Such as figure 1 A high-speed aluminum-plastic blister machine shown includes a PVC unwinding mechanism 1 for placing blister film coils, a heating plate mechanism 3 connected downstream of the PVC unwinding mechanism 1, and a PVC unwinding mechanism 1 and a heating plate mechanism 3. A material cutting platform mechanism 2 is arranged at the junction, and the downstream of the heating plate mechanism 3 is connected with a rapid prototyping cam mechanism 4, and the downstream of the rapid cam mechanism 4 is installed with a poor forming detection mechanism 6, and the rapid cam mechanism 4 is connected to the hot plate through the first pulling mechanism 5 The upstream of the sealing mechanism 11 and the heat sealing mechanism 11 are also provided with a feeding mechanism 7, a single straw automatic feeding machine 9 and a serpentine deviation correction mechanism 10. The heat sealing mechanism 11 is connected to the anti-vibration acceleration and deceleration punching t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com