a lift system

A lift and lift unit technology, applied in the field of lift systems, can solve the problems of insufficient transmission accuracy, fixed stroke, insufficient precision, etc., and achieve the effect of adjustable stroke, solving the problem of transmission synchronization, and solving high-speed and high-precision docking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

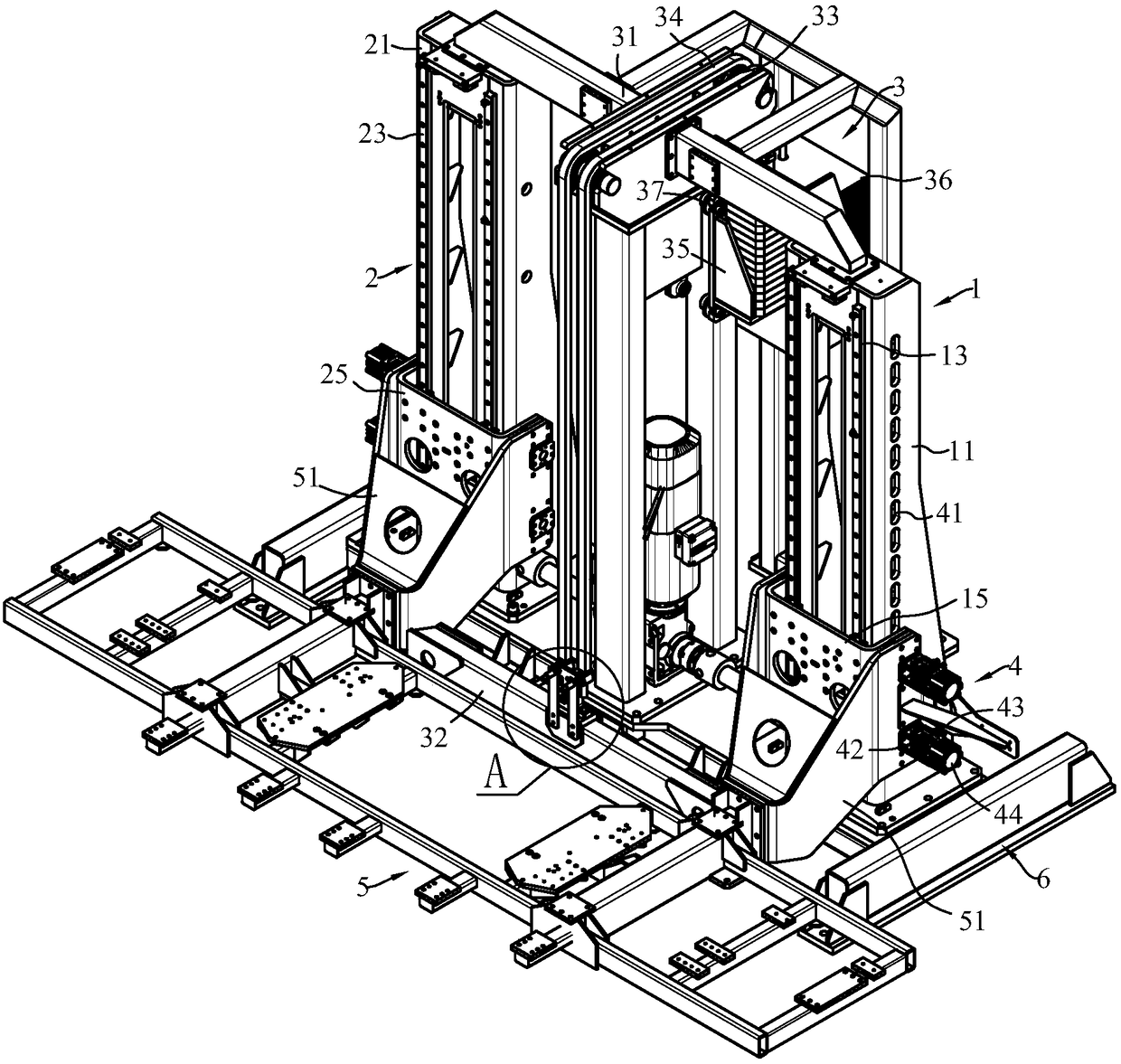

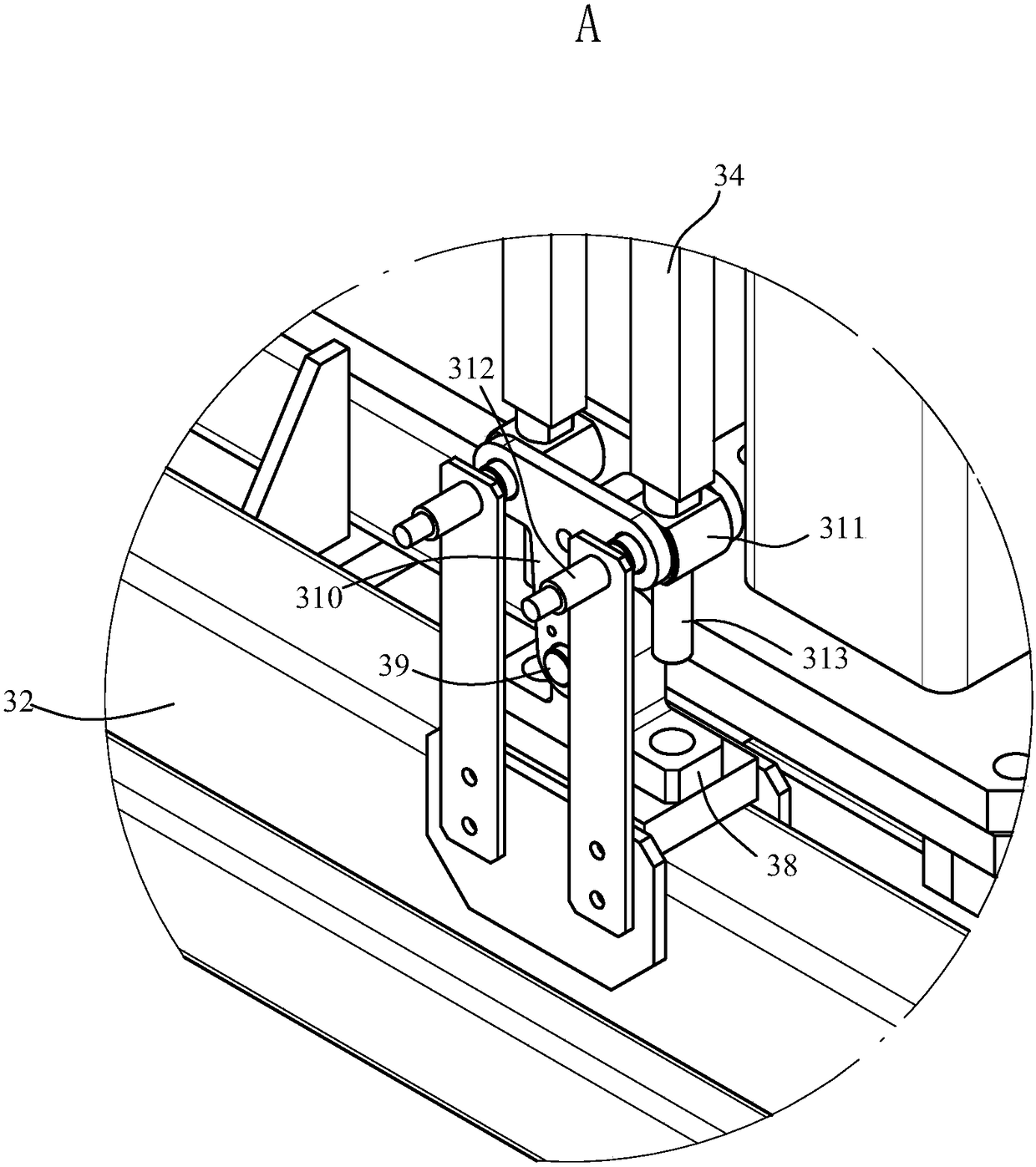

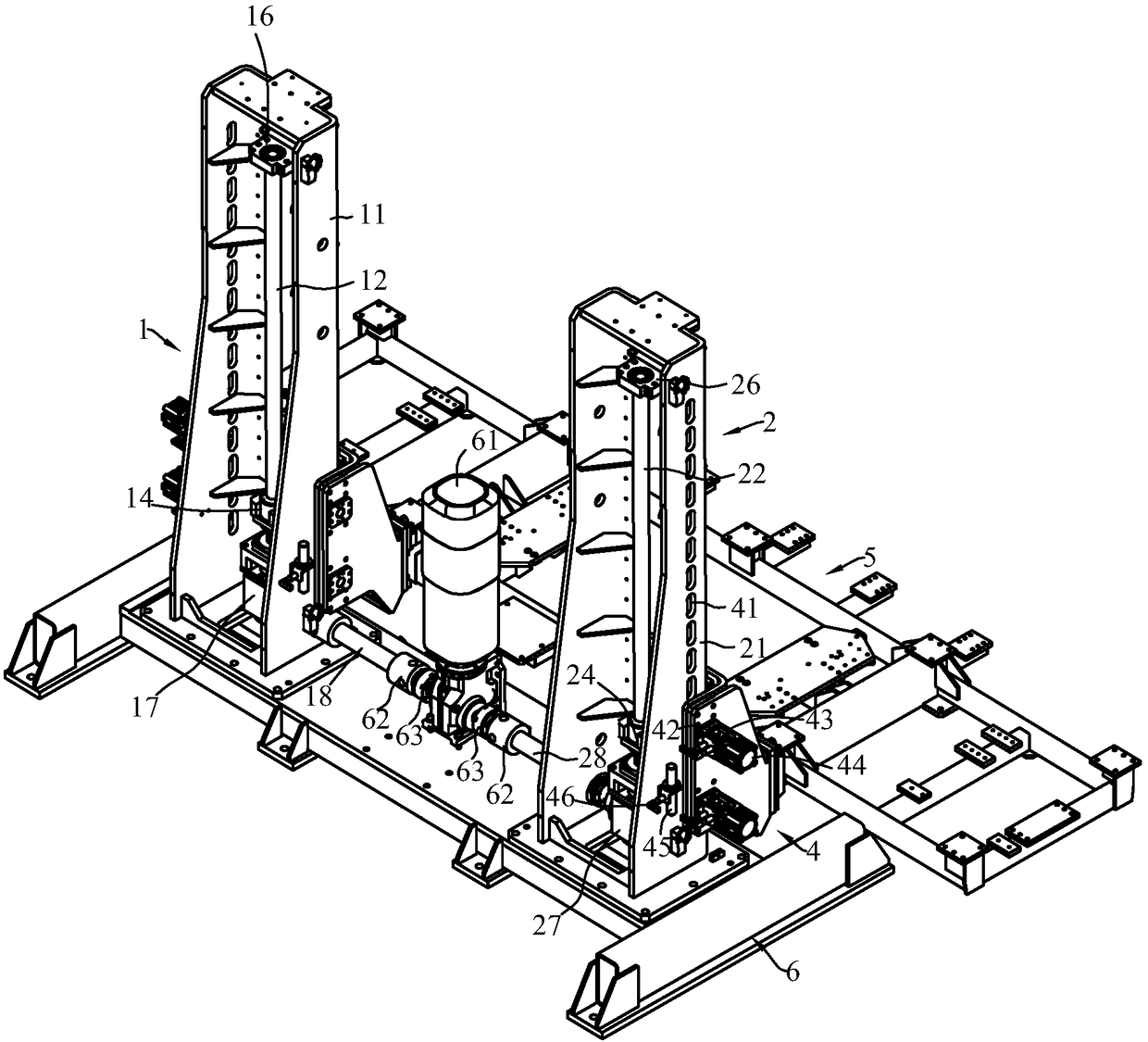

[0019] refer to Figure 1 to Figure 3 , which shows the specific structure of the preferred embodiment of the present invention. The structural features of each element of the present invention will be described in detail below, and if there is a description of the direction (up, down, left, right, front and back), it is based on image 3 The shown structure is a reference description, but the actual use direction of the present invention is not limited thereto.

[0020] The invention provides an elevator system. The elevator system is mainly used to switch the conveying load between the upper station and the lower station, so as to satisfy the cyclic conveyance of the conveying load. The elevator system mainly includes a left lifting unit 1 and a right lifting unit 2, a counterweight unit 3 and a fall prevention mechanism 4.

[0021] Specifically, it includes a tray 5, a base 6, and a left lifting unit 1 and a right lifting unit 2 arranged on the base 6. The left lifting un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com