Positioning and clamping device for LNG gas bottle production line

A production line and clamping device technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems that cannot meet the requirements, affect the production efficiency of the assembly line, and cannot clamp the gas cylinder, so as to prevent movement and improve reliability , reducing the effect of adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

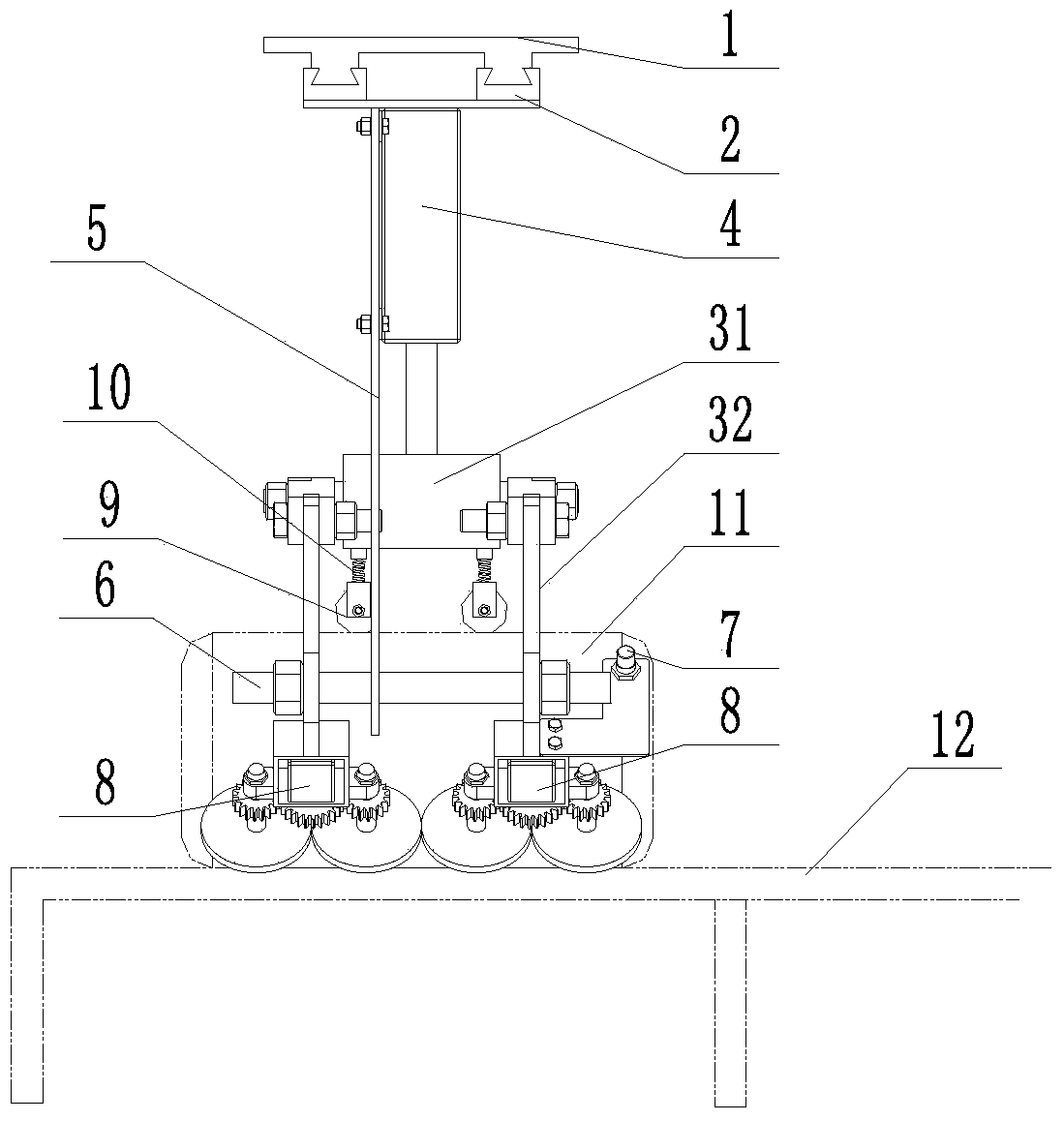

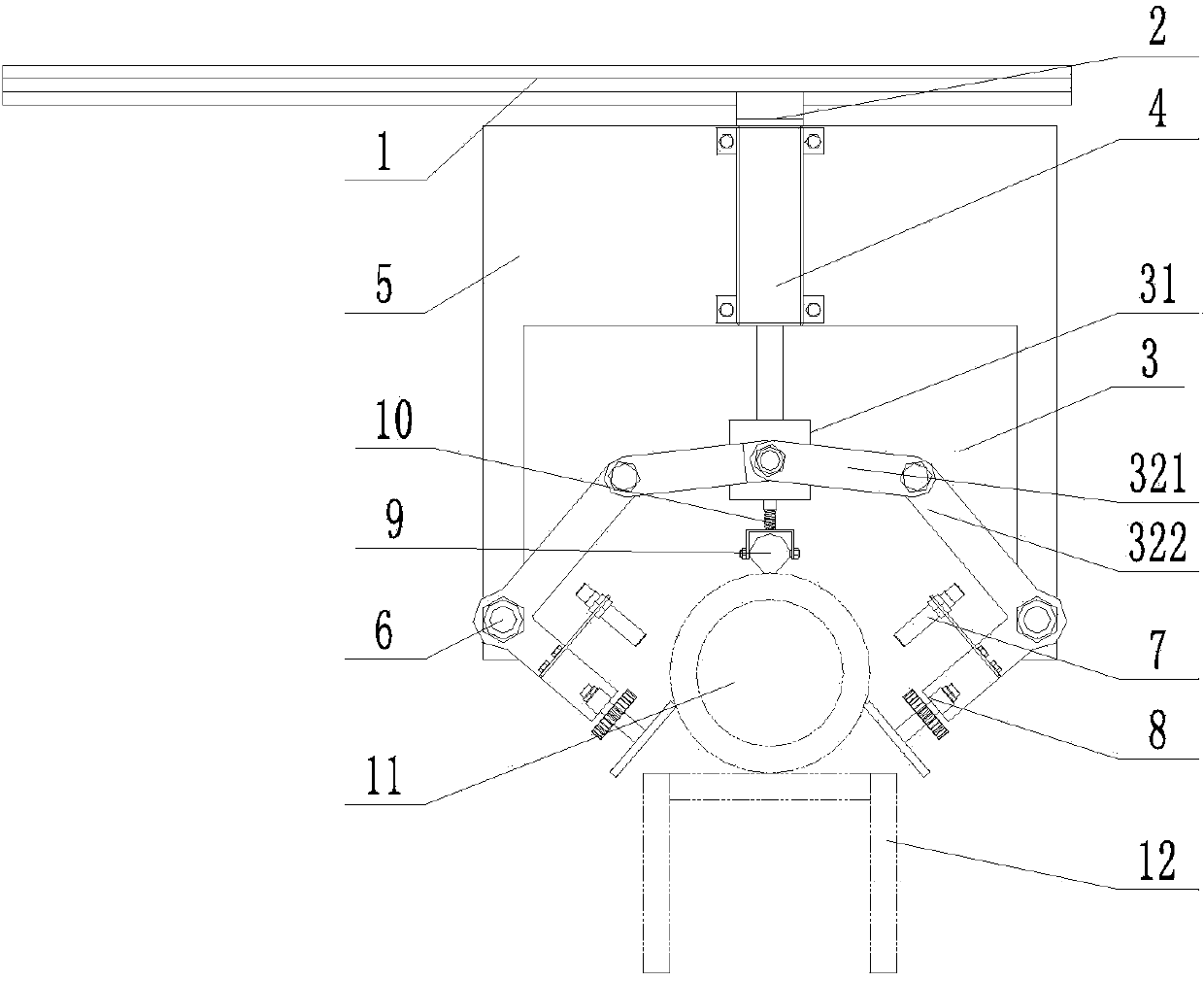

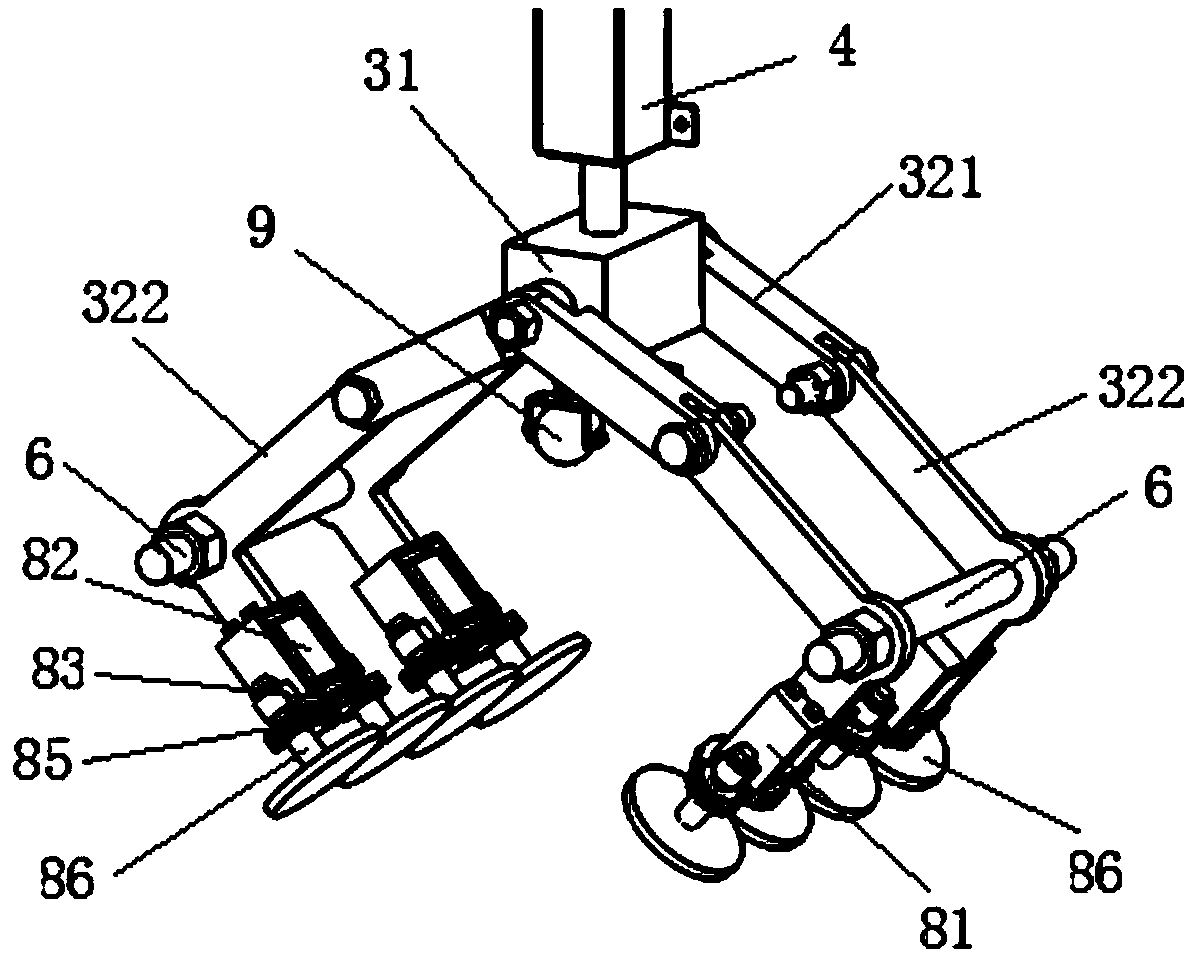

[0022] Such as Figure 1-3 As shown, a positioning and clamping device for LNG gas cylinder 11 production line 12 includes a sliding track 1, a moving base 2 is arranged on the sliding track 1, and a radial clamping gas cylinder is arranged on the moving base 2 11 bottle clamp mechanism 3 and the cylinder 4 with adjustable stroke that drives the bottle clamp mechanism 3 to open and close. The bottle clamping mechanism 3 includes a connecting seat 31 arranged at the end of the piston rod of the cylinder 4. The connecting seat 31 is provided with two pairs of oppositely arranged clamping connecting rods 32 arranged side by side. 31 on the drive rod 321, the end of the drive rod 321 is hinged with an inwardly bent L-shaped rocker 322, the mobile base 2 is provided with a mounting frame 5, and the mounting frame 5 is provided with two fixed shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com