Multi-cascaded double-cylinder linear compressor

A linear compressor, double-cylinder technology, applied in multi-stage pumps, liquid displacement machinery, mechanical equipment, etc., can solve the problems of low energy utilization rate of high-pressure compressors, poor system stability, large volume, etc., to achieve regulation The effect of wide range, adjustable displacement and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

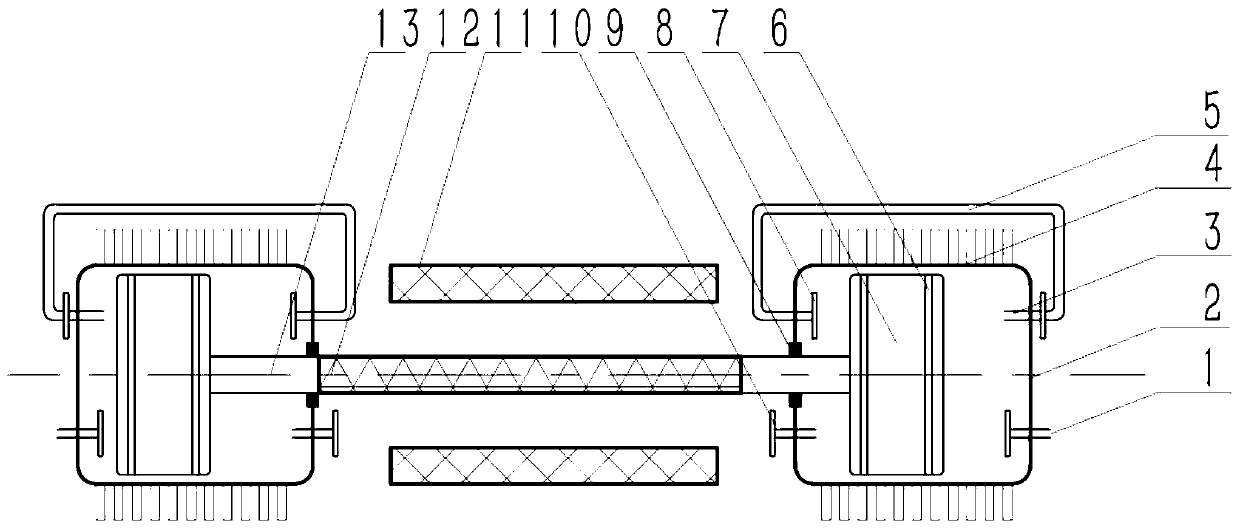

[0030] Such as figure 1 As shown, the multi-cascade twin-cylinder linear compressor of this embodiment is the basic structure.

[0031] The connection relationship is: the motor stator 11 is a hollow structure, the motor mover 12 is inserted into it, and the motor mover 12 makes a reciprocating linear motion; the double-chamber compression cylinder is located on both sides of the linear motor, the cylinder body 4 is a hollow structure, and both ends pass through the cylinder head 2 Realize the sealing of the cylinder; the double-sided piston 7 is inserted into the cylinder body 4, and the cylinder is divided into a primary compression cavity and a secondary compression cavity (it is stipulated that the compression cavity close to the linear motor side is a secondary compression cavity, and the opposite side is a primary compression cavity); The cylinder head 2 forming the primary compression chamber is provided with a primary intake valve 1 and the primary exhaust valve 3, and...

Embodiment 2

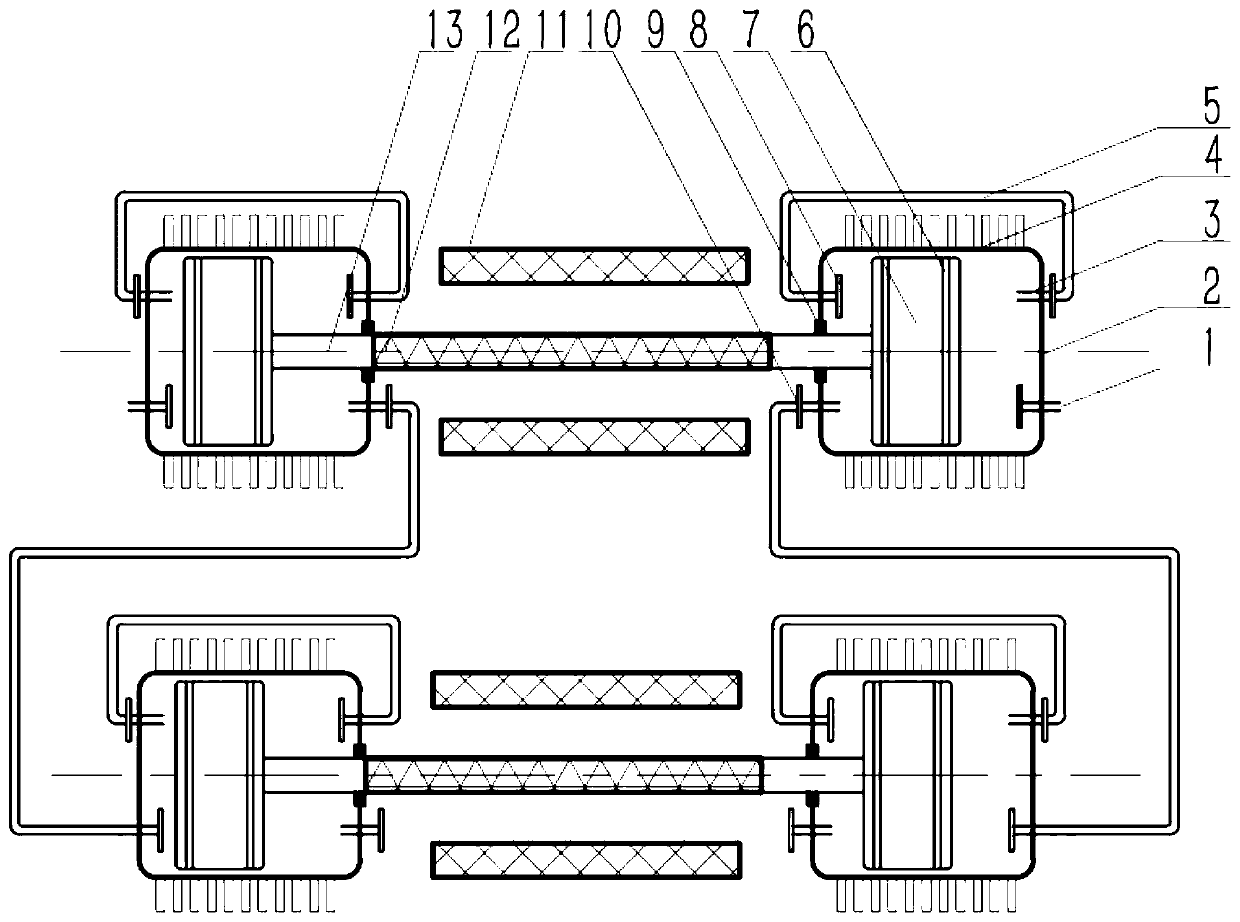

[0036] Such as figure 2 As shown, the parallel type of the multi-cascade two-cylinder linear compressor of this embodiment. It consists of two multi-cascade double-cylinder linear compressors connected in parallel (the upper multi-cascade double-cylinder linear compressor is called the previous multi-cascade double-cylinder linear compressor, and the lower multi-cascade double-cylinder linear compressor The compressor becomes the latter multi-cascade twin-cylinder linear compressor).

[0037]The connection relationship is: connect all the two-stage exhaust valves 10 of the previous multi-cascade two-cylinder linear compressor to the first-stage intake valves 3 on the same side of the latter multi-cascade two-cylinder linear compressor through the interstage connection Tube 5 is connected. The connection relationship of other components is the same as that in Embodiment 1.

[0038] work process:

[0039] The linear motor drives the double-sided piston 7 to perform reciproc...

Embodiment 3

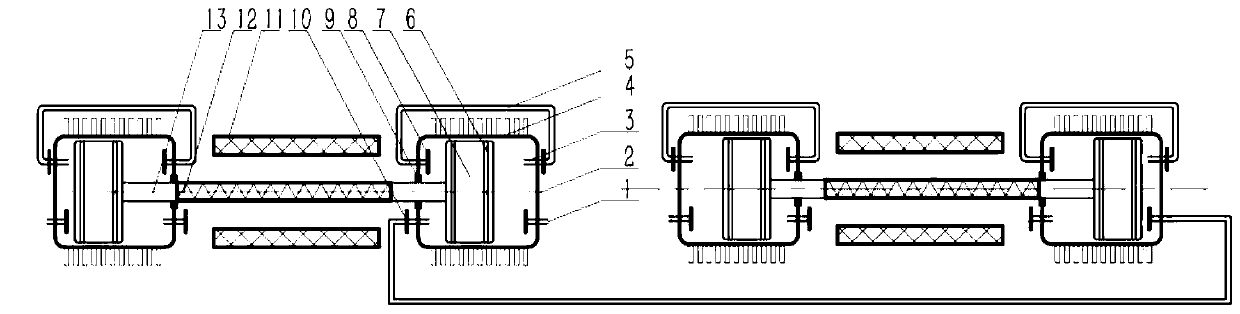

[0043] Such as image 3 As shown, the series type of the multi-cascade two-cylinder linear compressor of this embodiment. It consists of two multi-cascade twin-cylinder linear compressors connected in series.

[0044] The connection relationship is: connect the secondary exhaust valve 10 of the left double-cavity compression cylinder of the left multi-cascade double-cylinder linear compressor to the first stage of the right double-cavity compression cylinder of the right multi-cascade double-cylinder linear compressor. The intake valves 3 are connected through an interstage connecting pipe 5 . The connection relationship of other components is the same as that in Embodiment 1.

[0045] work process:

[0046] The linear motor drives the double-sided piston 7 to perform reciprocating linear motion, and the gas working fluids in the eight compression chambers complete the suction-compression-exhaust-expansion process in turn.

[0047] When the multi-cascade double-cylinder li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com